- Submissions

Full Text

Academic Journal of Engineering Studies

Application of Double-Crystal X-Ray Difractometry Methods and Topography for Characterization of Isotopically Modified CVD Diamond Films

Romanov DA* and Kosushkin VG

Bauman Moscow State Technical University Kaluga Branch, Russia

*Corresponding author: Romanov DA, Bauman Moscow State Technical University Kaluga Branch, Russia

Submission: March 08, 2021 Published: March 25, 2021

.jpg)

ISSN:2694-4421 Volume1 Issue5

Abstract

technology for their growth has been demonstrated. The main structural defects (dislocations, stacking faults, second-phase inclusions, etc.) that occur in synthetic diamond crystals during their preparation have been identified.

Keywords: Double-crystal x-ray diffractometry; X-ray topography; Defects in the crystal structure; Epitaxial films; Isotopically modified films

Abbreviations: XRD: X-Ray Diffractometry; MDs: Misfit Dislocations; ES: epitaxial structures

Introduction

Crystals are the basis of numerous instruments and devices of modern technology. All

real crystals contain a variety of structural imperfections that strongly, sometimes cardinally

change the properties of crystals and have a direct impact on the operational characteristics

of devices made on their basis. To study the laws of formation and control of the real structure

of crystals a wide range of physical research methods are currently used. Double-crystal X-Ray

Diffractometry (XRD) and topography methods are widely used in laboratory practice as the

most accessible and relatively simple from a technical point of view. The use of these methods

in the study of epitaxial structures makes it possible to determine: structural perfection of

the substrate and film; the mismatch in the interplanar spacings of the crystal lattices of the

substrate and the film and their mutual misorientation; thickness of the epitaxial film over

the period of the intensity oscillation (Pendellösung); lattice mating coherence; the curvature

of the plate and, accordingly, the level of elastic stresses in the system, and also the change in

the thickness composition and the structure of the interphase boundary when processing the

swing curve using mathematical modeling methods.

In this research the capabilities of the XRD and topography methods are analyzed by the

example of the study of isotopically modified CVD diamond films, which, due to their unique

properties: high hardness, chemical and radiation resistance, low coefficient of thermal

expansion and high thermal conductivity, are increasingly used in various fields of science and

techniques [1,2]. The main structural defects (dislocations, stacking faults, micro segregation

growth bands, second phase inclusions, etc.) arising in crystals during their preparation were

identified. The formation of dislocation beams originating at the film-substrate interface was

discovered due to possible near-surface disturbances of the substrate and relaxation of elastic

macrostresses, which arise due to the mismatch between the periods of the crystal lattices

of the substrate and the film. In isotopically modified diamond films 13C(99.96%) grown on

diamond Ib substrates, the XRD method revealed a significant decrease in the crystal lattice

period (Δа/а)relax~ (1.1/1.2)·10-4. Data on the features of relaxation processes in epitaxial

CVD films of diamond and its crystallographic analogue of germanium are presented. Special

characteristics of plastic deformation in these materials due to specific distribution of elastic

stresses are revealed. The process of relaxation of elastic stresses in germanium structures at film thicknesses exceeding critical is accompanied by formation

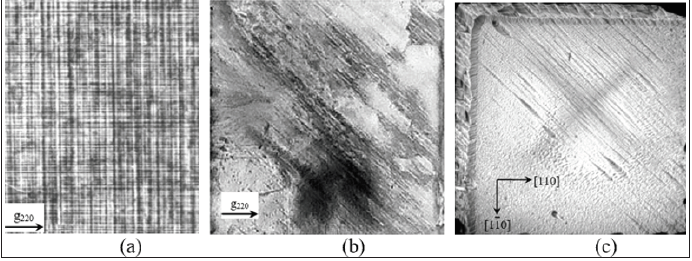

of 60-degree Misfit Dislocations (MDs) at the interphase boundary

(Figure 1a); [3]. Traces of plastic deformation with the formation

of MDs in Epitaxial Structures (ES) 13C/natC (001) with a film

thickness of ~ 80μm, almost two orders of magnitude greater than

the critical value tc~1.1μm [4], on the x-ray topogram (Figure 1b)

are not visible. Only traces of mechanical processing on the reverse

side of the substrate are detected, along the direction [100], which

is the direction of the light polishing of diamond [5]; (Figure 1c).

This seems to be connected with the low epitaxy temperature (950

°С). Compared to the melting temperature of diamond, dislocations

are inactive, and the effective plastic deformation observed in ES

germanium does not occur in the diamond film.

Figure 1:(a) X-ray topograms of ES Ge(B)/Ge(001)

(b) 13C/natC(001)

(c) and micrograph of ES diamond 13C/natC(001)

References

- Wandersande JW (1994) Properties and growth of diamond. L. The Inst Electric Eng p. 33.

- Ralchenko VG, Bolshakov AP (2017) Carbon photonics. In: Konov VI (Ed.), Nauka, Moscow, Russia, p. 9.

- Prokhorov IA, Voloshin AE, Romanov DA (2017) Crystallogr Rep 64(3): 369.

- Prokhorov IA, Voloshin AE, Ralchenko (2020) Crystallogr Rep 61(6): 945.

- Yurov V, Bushuev E, Bolshakov A (2017) Phys Status Solidi A 2017, 00, 1700177.

© 2021 Romanov DA. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)