- Submissions

Full Text

Academic Journal of Engineering Studies

Features of Extraction of Valuable Components from Plant Raw Materials

Kasyanov GI*

Kuban state technological University

*Corresponding author: Kasyanov GI, Kuban state technological University

Submission: August 11, 2020 Published: September 11, 2020

.jpg)

ISSN:2694-4421 Volume1 Issue4

Abstract

The article presents the hierarchy of the process of extracting valuable components from spicyaromatic and medicinal raw materials: from essential oils to supercritical extracts. The description of installations for obtaining essential oil, carbon dioxide from flue gases, subcritical CO2-extraction and supercritical fluid extraction is given.

Keywords: Essential oil; Carbon dioxide; Subcritical; Swerczek

Introduction

In practical terms, the extraction of CO2-extractive substances from secondary grain processing resources makes it possible to obtain high-quality products [1]. New ways to intensify the process of extracting valuable components from raw materials are being implemented relatively quickly at the existing extraction plant [2]. The development of modern sub-and supercritical technologies has been recognized not only in the country, but also abroad [3]. The process of obtaining CO2-extracts from grains and nuts can be supplemented with pre-enzymatic and extrusion processing [4]. The prototype for obtaining CO2-extracts has always been essential oils obtained by steam distillation [5]. However, the high temperature of obtaining essential oils leads to the destruction of some of the thermolabile substances. Automation of technological processes plays an important role in increasing the efficiency of extraction production [6,7].

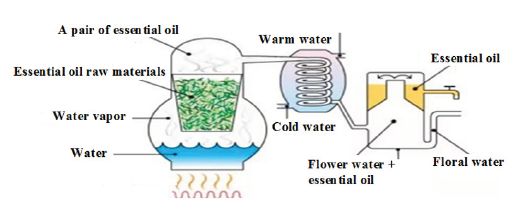

Figure 1: Scheme for obtaining essential oil from vegetable raw materials.

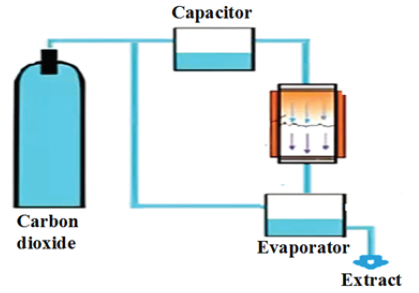

The simplest and most affordable way to process aromatic raw materials is steam distillation (Figure 1). Essential oils are widely used in the perfume and cosmetics industry. The most suitable solvent for essential oils and related substances was liquefied carbon dioxide. Figure 2 shows the line for producing carbon dioxide from flue gases.

The use of liquid carbon dioxide as an extractant has a long history. Scientists and specialists of the scientific and pedagogical school operating at KubSTU made a significant contribution to the development of this technology. Figure 3 shows a diagram of a subcritical CO2-extraction unit operating in the range of temperatures from +10 to +25 oC and pressures from 5 to 6.5MPa. Another option for processing plant raw materials is supercritical fluid extraction, in which the extractant is a dense gas at a temperature of 40 to 60 oC and a pressure of 10 to 60MPa. Thus, the extraction industry has made a transition to high technologies for extracting target components from raw materials with liquefied and compressed carbon dioxide (Figure 4).

Figure 2: line for producing carbon dioxide from flue gases. 1-firebox, 2-heat exchanger, 3-compressor, 4-CO2- production plant, 5-CO2-collector, 6-CO2-tanker.

Figure 3: Scheme of subcritical CO2 extraction plant.

Figure 4: Diagram of a fluid CO2-extraction unit.

References

- Sookwong P, Mahatheeranont S (2017) Supercritical CO2-extraction of rice bran oil-the technology, manufacture, and applications. Journal of Oleo Science 66(6): 557-564.

- Medvedev AM, Inochkina EV (2019) The path from innovative ideas to launching technological lines//Science. Technologies (Polytechnic Bulletin) 3: 296-303.

- Medvedev AM, Magomedov AM (2019) Modern sub-and supercritical CO2-technologies. In the collection of materials of the 24th International Scientific and Practical Conference "Innovation-2019". Tashkent, Uzbekistan, pp. 382-383.

- Medvedev AM, Sakibaev K Sh (2019) Biotechnological features of obtaining CO2-extracts from grain and nut raw materials //University news. Food Technology 5-6: 50-52.

- Puchkova TV, Gurinovich LK, Tarasov VE (2020) Essential oils: chemistry, technology, analysis, application. School of cosmetic chemists, Moscow, Russia, p. 264.

- Silinskaya SM, Malashenko NL (2019) Control over the state of carbon dioxide by means of digitalization. In the collection of materials of the international scientific and practical conference "Exclusive technologies for the production of meat, dairy and fish products". KubSTU, Krasnodar, Russia pp. 190-193.

- Silinskaya SM, Narizhnaya NYu, Tkachenko VV (2017) Methods and means of evaluating the effectiveness of technical equipment for the system of CO2-extraction of plant raw materials. Polythematic network electronic scientific journal of Kuban State Agrarian University, Krasnodar, Russia, 132: 1354-1365.

© 2020 Kasyanov GI. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)