- Submissions

Full Text

Academic Journal of Engineering Studies

Additives for the Construction Developed for Concretes, Mortars and Gypsum Terminations

Raúl Andrés Montejo1 and Abel Castañeda2*

1Faculty of Chemical Engineering, Cuba

2Material Protection Group, Cuba

*Corresponding author:Abel Castañeda, Material Protection Group, Cuba

Submission: December 13, 2019;Published: January 17, 2020

.jpg)

ISSN:2694-4421 Volume1 Issue2

Abstract

The development of construction additives based mainly on by-products or wastes of the Cuban industry has been one of the research lines in the Materials and Corrosion Engineering Group in the Faculty of Chemical Engineering. Technological University of Havana. The proposed objective is showing an overview of the main results obtained in the study of these substances and the enormous perspectives offered by the Cuban industry in the development and production of additives for construction. The by-products of the sugar industry and other industries that use these by-products, together with some waste, constitute a source for the production of different substances to be used in the industry in general, including the construction industry. The work shows the additives developed for concretes, mortars and gypsum terminations. Between the first two are, water reducers, plasticizers, retarders and anti-corrosion agents. The development, production and use of these additives would allow the substitution of imports, the use of by-products and eliminate polluting residues from the environment of the national industry.

Keywords: Reducers; Plasticizers; Retarders

Introduction

The development of construction additives based mainly on by-products or wastes from Cuban industry has been one of the research lines in the Materials and Corrosion Engineering Group in the Faculty of Chemical Engineering of the Techno-logical University of Havana. The studies have allowed the evaluation of substances with plasticizing characteristics, set-ting retarders, water reducers for concrete, from the production of sulfonated lignin’s obtained of highly polluting waste produced by the cane bagasse paper industry. Additives for the manufacture of long-lived mortars using nitrified bentonite of national production, for the precast industry, demolding solutions and for the temporary protection against corrosion of equipment in general using the sugar cane wax were obtained [1-3].

Finally, a system of additives is shown for the mechanical projection of the gypsum that allows the delay, the adherence in the support and its subsequent smoothing to obtain an excellent finish in the walls. All these products would allow the pro-duction of effective additives for use in concrete, mortar and gypsum terminations, which would allow the country to partially or totally replace imports, bringing two important results, as a considerable economic saving and secondly find products, by-products and waste of practical utility avoiding the contamination of the environment. The proposed objective is to show an overview of the main results obtained in the study of these substances and the enormous perspectives offered by the Cuban industry in the development and production of additives for construction.

Developed

The by-products of the sugar industry and other industries that use these by-products, together with some waste, constitute a source to produce different substances to be used in the industry in general, including the construction industry. For the latter, different additives or additive systems can be developed to be used in the manufacture of concrete with different features, in the prefabricated industry, etc.

Plasticizer, water reducer and setting retarder

This additive was developed from the sulfonation of the lignin contained in the wastewater from the production of sugar-cane bagasse paper, adding other substances. This preparation was called VIGRALIK. The formulation with the different substances was first studied. A proportion of the different components of the additive were reached. A reduction of water of almost 15% was obtained, as well as achieving a set time of 6 h as stipulated time for the safe transportation of the concrete from the plants up to work. Additive dose is 1.5% by weight while the settlement is the same in all cases. A commercial superplasticizer was used to compare the results.

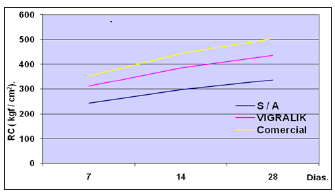

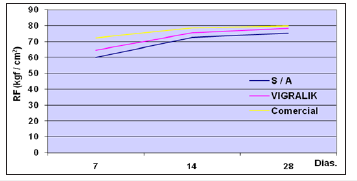

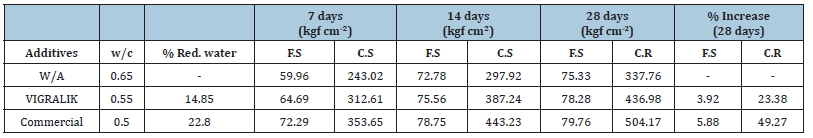

As can be seen in Table 1 and Figures 1 & 2 VIGRALIK is inferior to the commercial superplasticizer, so it can be considered as a good plasticizer due to mechanical resistance by flexion and compression increased in 4% and 23.4% at the ages analyzed and are intermediate to the percentages of increase of the commercial. This VIGRALIK additive is studied to see its effectiveness as an inhibitor of corrosion because all products derived from the sugar industry and waste from other industries such as alcohol and paper are good inhibitors of corrosion in different media. The results of these studies will be presented at upcoming events. Figure 2 Flexion strength (F.S).

Figure 1:Compressive strength (C.S).

Figure 2:Flexion strength (F.S).

Table 1:Compressive strength and flexion strength in time for 30 °C, settlement of 12 and additive percentage of 1.5% by weight.

Abbreviations: W/A: Without Additive; F.S: Flexion Strength; C.S: Compressive Strength; W/C: Water/Cement ratio; %Red: % Reduction

Additive for the preparation of long-life mortars

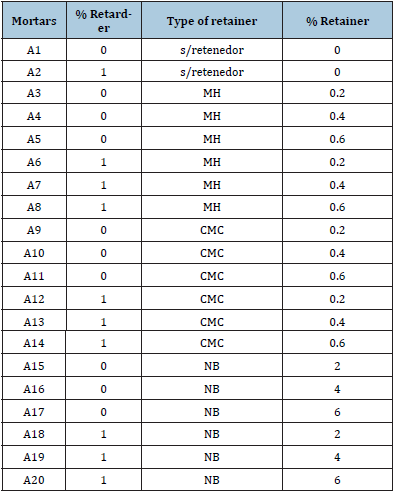

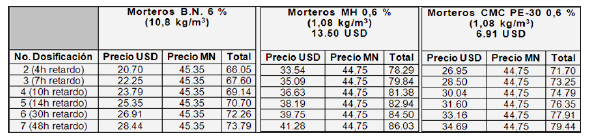

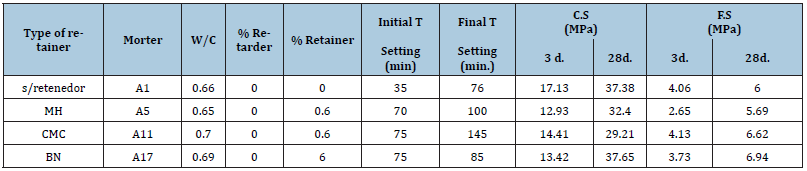

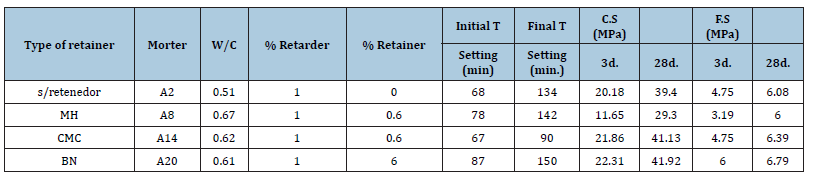

The use of long-life mortars allows to prepare them in concrete plants with an exact dosage, take them to the site in concrete mixer trucks and unload them in silos enabled for this purpose and use them as required on the construction site, speeding up the work of completion and humanizing the work of the operators. The use of additives decreases the consumption of cement, the amount of stone dust bringing savings of these important materials in any construction work are other advantages. For the development of the formulation, hardening retardants, retainers of water of cellulose base and nitrified bentonite of national production were used. An experimental design shown in Table 2 was carried out covering the following additive systems.

Table 2:Composition of mortars.

It should be noted in Table 3 that without setting retarder, the retainers slightly retard the setting, but the mechanical resistance to compression and flexion tends to be less than the system without both additives, only the BN is superior for both after 28 days. In Table 4 of the systems with retarder, the nitrified bentonite is superior to the rest of the retainers in the initial, final setting time. Resistance to compression and flexion is higher than any other age than the rest of the retainers. Although more BN is used, its price in the domestic market is $184/ton while the MH is $12500/ton (68 times higher) and the CMC is $6400/ton (35 times higher) being of import. Although an amount of 10 times greater of bentonite is used, this does not increase costs because of the cheapness of bentonite compared to the other retainers. In Figure 3 the mortar with BN is the most economical for any of the delay ranges requested by the client with a smaller component in National Currency (NC).

Figure 3:Economic analysis of the delayed mortar.

Table 3:Summary of results without retarder.

Table 4:Summary of results with retarder.

Demolding solutions and for the temporary protection of metal structures and equipment

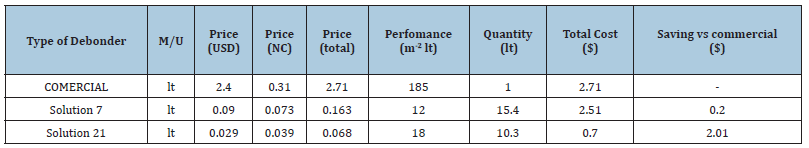

The sugarcane wax extracted from the cachaza is the main raw material of these solutions. To the cane wax, an amidation process is carried out with Dietanola-mina (DEA) to improve its inhibitory properties and subsequently an emulsion is formed with chemically treated wax, water and diesel. Different formulations were tested, some with treated and untreated wax, for a total of 27 of them, the best results based on the stability of the emulsion were numbers 7 and 21.

The number 7 was very viscous and recommended for manual spreading on structures and equipment to protect it against corrosion since the treated wax is known as a corrosion inhibitor and the less viscous could be spread on the surface by means of a nebulizer for its placement in the molds used for the manufacture of prefabricated structures. From the eco-nomic point of view it represents a saving with respect to imported softeners shown in Table 5. To achieve the same performance, it is necessary to use between 10 and 15 times more quantity of the products studied with the other advantage that are protective against corrosion of baking tin.

Table 5:Economic analysis of the products analyzed.

System for the mechanical projection of Cuban gypsum

The gypsum of national production forges after a few minutes of mixing with water. The hardening time is faster if the paste is placed on an absorbent water support, such as: mortar, concrete, blocks, bricks. For these two reasons, the use of gypsum casting machines depends on the use of additives that prevent gypsum hardening and loss of water by absorbing the support. This also eliminates the danger of setting inside the equipment, giving a margin of time that allows the operator to give the final finish. These machines with high productivity, its use depended on the system of additives used, which is imported and extremely expensive, which made its use more expensive, because the square meter of termination far exceeded the price of the manually made.

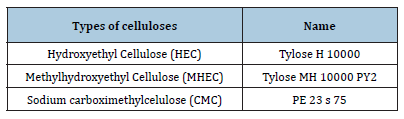

Developing a system of additives that would lower the cost of the square meter required first to determine the function of the three fundamental products of the additive system: Retardant of the gypsum setting, Water retainer and Catalyst to form the gel with the retainer. It was determined that the first (Retardant of the gypsum setting) was a citric acid solution, the retainer was a cellulosic compound with particle surface coating to prevent the formation of lumps and the third was a sodium hydroxide solution with the objective of once dispersed the retainer break the surface coating and form the corresponding gel. Two retardants were tested using grapefruit concentrate juice, but although very good delays were achieved in the setting time similar to that of the commercial one, the cuticles of the citrus fruits obstructed the filter of the projecting machine, although it could be used for manual placement, so it was decided to use citric acid at different dilutions. The tested water retainers are shown in the following Table 6.

Table 6:Types of celluloses used.

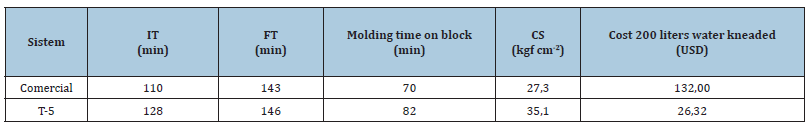

Table 7:Results between the commercial additive system and the T-5.

To obtain the system of additives to replace the commercial system, more than 20 combinations were studied, including the commercial system, the so-called T-5 was chosen, consisting of: citric acid, MHEC and sodium hydroxide solution. The results of this system compared with the commercial system are shown in Table 7. As you can see the proven system is superior to the commercial one in initial and final setting time (IT and FT), mouldable time, Compression Strength (CS) and in cost is 5 times cheaper. A practical test was done with this formulation and almost 200 m2 were projected. According to the operators any difficulty was found. The machine worked without interruption.

General Conclusion

In this brief work we wanted to give an overview of the enormous possibilities of obtaining additives to be used in cement and other materials from substances that are by-products or waste of the industry and that constitute a source to substitute imports or decrease appreciably the costs of similar products. The construction industry of any country should pay attention to the benefits of these products.

References

- Autelitano F, Giuliani F (2018) Influence of chemical additives and wax modifiers on odor emissions of road asphalt. Construction and Building Materials 183: 485-492.

- Yasuyuki M, Seiichi Y (2005) Preparation and evaluation of lignosulfonates as a dispersant for gypsum paste from acid hydrolysis lignin. Bioresour Technol 96(4): 465-470.

- Shainberg I, Sumner ME, Miller WP, Farina MPW, Pavan MA, et al. (1989) Use of gypsum on soils: A Review. Advances in Soil Science book series. Springer, Germany, pp. 1-111.

© 2020 Abel Castañeda. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)