- Submissions

Full Text

Academic Journal of Engineering Studies

Changes in a Forty-Year-Old Concrete: Some Chemical and Physical Observations in Itaipu Dam

Cláudio Neumann Junior1,2*, Ana Carolina P Santos1 and Étore F de Faria2

1Itaipu Binacional, Brazil

2UNILA, Universidade Federal da Integração Latino Americana, Brazil

*Corresponding author: Avenida Tancredo Neves, Itaipu Binacional, UNILA, Universidade Federal da Integração Latino Americana 6731 Foz do Iguaçu, Brazil

Submission: December 18, 2018;Published: January 30, 2019

.jpg)

ISSN:2694-4421 Volume1 Issue1

Abstract

The long-term behavior of concrete can be influenced by its composition and environment exposure. Leaching is a chemical process of degradation caused by water, leading to dissolution of cement components, increasing the permeability and reducing mechanical properties. Backfill concrete with fly ash was used in Itaipu dam, in a region subjected to water flow. Chemical analyses have been done since the 1980’s and concrete samples were recently extracted to perform laboratory tests, showing increase in resistance, despite partial loss of calcium caused by leaching, by what it is understood as a localized small change, with no implications to the dam safety.

Basic Concepts of Leaching and Concrete

Concrete is porous material, being calcium the main chemical element of the cement paste [1]. As a consequence of long-term contact with water, structures such as dams, bridges and tunnels can be damaged [2-5], although this process is relatively slow [6]. This is called leaching, whereby there is mass transport from a solid to a liquid [7], depending on the differences in composition and concentration between the water in contact with concrete and the internal solution of their pores.

The most vulnerable components to dissolution are calcium hydroxide (Ca(OH)2) and calcium carbonate (CaCO3) [10]. There is an increase in porosity of the cement paste over time [1-11]. As the microstructure changes, the permeability increases and the mass density decreases [2-5,10]. New increases in porosity will result in a higher diffusion coefficient, which will further accelerate the leaching process, in a progressive effect [3,9].

There is also mention of the beneficial effects of fine particles of pozzolanic silica on leaching and consequent deterioration [10], whereas for the results of the analysis of samples with incorporation of appropriate amount of slag or fly ash showed low rate of microstructural deterioration and good resistance to leaching, when compared to samples without these fine particles [2,4].

General Data of Itaipu Power Plant

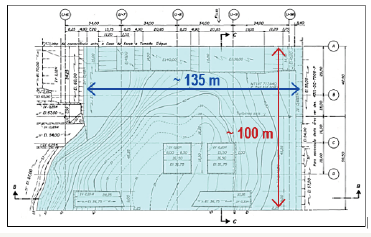

Itaipu Hydroelectric is located at Paraná River, on the border between Brazil and Paraguay and was built between 1975 and 1982. The dam is 7,370m long and has a maximum height of 196m, been composed by different kinds of dams: rockfill, earth and concrete for the hollow gravity, gravity dam and buttresses. For the powerhouse construction, some partial excavations in the river basin were necessary between the generating units U6 and U10, replacing an approximate volume of 150,000m3 with a 10MPa concrete from Elevation 35 to 54, called “backfill concrete” [12]. Figure 1 shows a partial plan of excavations for the powerhouse and the backfill concrete highlighted in blue.

Figure 1:Main dam and powerhouse excavation plan.

Treatments for the Foundation and Backfill Concrete

At the end of 1970’s, while drilling for the downstream injection curtain, it was observed that drilling water was lost. Tests were carried out in this region, showing permeability higher than 10- 3cm/s in some cases, similar to sand. Some zones of lower porosity interspersed with other more permeable ones were identified. It was concluded that these differences in concrete quality resulted from insufficient vibration in overlap zones between neighboring concrete discharges, as a consequence of the adopted constructive process.

This problem, and also considering the impossibility of determining the real extent of the affected regions, has raised concerns about the possibility of deformations which could affect the stability of civil structures and consequently the positioning of electromechanical equipment; subpressions increase due to more percolation that would overload the drainage system; and concrete durability decrease caused by leaching, due to water percolations from downstream river, whose surface is around El. 100 (this equals to about 50 meter water pressure acting on the foundations).

Providences done included:

A. Drainage curtains in the backfill concrete perimeter;

B. Improvements in the downstream curtain at El. 60, with a triple injection front;

C. Installation of two extensometers in the backfill concrete and

D. Qualitative and quantitative analysis of percolation water, to evaluate the leaching process.

Upon completion of the downstream curtains, a reduction in the concrete’s permeability was observed, with permeability coefficients up to 10-7cm/s. It was also observed a tendency of uniformity of the permeability of the concrete, through the water tests.

Water infiltrations and respective chemical analysis began in August 1982, during the partial filling of the reservoir when downstream cofferdams were removed and are carried out to date.

Instrumentation Analysis

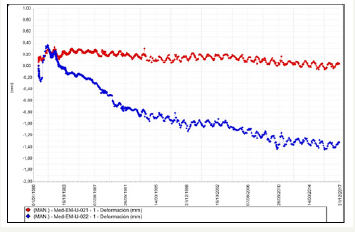

Extensometers have a seasonal behavior, with maximum values in the order of 0.3mm and current oscillation around 0.05mm in EM-U-021; and trend of a small and continuous settlement in EM-U- 022, whose present values are close to 1.4mm, as shown in Figure 2.

Figure 2:Extensometers in the backfill concrete.

It is important to compare these extensometers with others in the same region, which also shows a small tendency of settlement, with current values of 8.2mm in the foundation rock, within the project estimates.

Percolations Through the Backfill Concrete

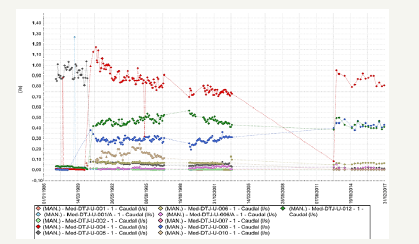

There are eleven drains installed in this region (Figure 3), but only three of them (DTJ-U-004, 008 and 012 - in red, blue and green, respectively, in the graph) are considered for this research as they correspond to 90% of total water infiltrated therein. Current total flows are about 2.0 l/s, acceptable under the design criteria, are very likely to come from downstream (remember here the 50-meter water pressure) due to occasional deficiencies of the injection curtain, or by crossing preferred paths in discontinuities and fractures in foundation rock below the curtain reach, passing through the concrete pores until they are intercepted by the drains.

Figure 3:Infiltrations through the backfill concrete.

Chemical Analyzes of Water

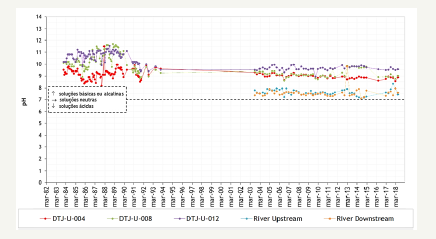

Routine chemical tests are performed with the water collected from each drain, monthly until March 1985 and quarterly since then. It is observed by the pH (Figure 4) that the infiltration waters are more alkaline than those of the reservoir and the river, thus proving that there is still dissolution of concrete components. There is also a higher intensity of the dissolutions between 1984 and 1990, which it is understood as the beginning of the leaching process, right after the reservoir formation and demolition of downstream cofferdams, who allowed the infiltration of water from the river.

Figure 4:pH values.

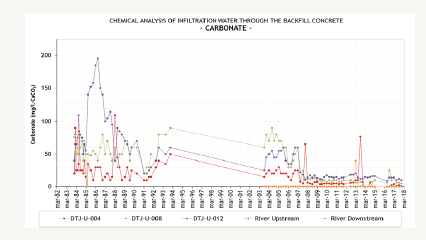

More recently, especially since 2008, there is a stabilization level of carried minerals, some of them with very low concentrations, as exemplified for carbonate contents in Figure 5. Unfortunately, there is no information about chemical tests performed between 1994 and 2003.

Recent Extractions and Physical Tests

In September/2018 some concrete extractions were done in this site, whose samples were taken for axial compression tests, showing high resistances, between 23 and 36 MPA, that is, the double and triple of project specifications, mainly because of fly ash use, as this component cooperate for long-term resistance gains.

Figure 5:Carbonate contents.

Conclusion

Preliminary assessments of the water chemical analyze, carried out since the 1980’s, indicate that the leaching process of the backfill concrete still occurs. However, according to the instrumentation behavior, there are no movements in the structure that could be related to a loss of resistance of the concrete at the moment. Recent compression tests showed samples with triple the resistance specified in original project.

Earlier studies carried out via FEM by a consultants group 12 estimated the approximate time of 140 Years for the admissible loss of 20% of the concrete’s calcium, under certain assumptions, considering the loadings on the structure, among other aspects, representing no risks of structural impairment. In subsequent steps of the present research, it is intended to test extracted samples with X-ray diffraction (XRD) and scanning electron microscopy (SEM) to review these calculations, considering the greater availability of chemical data currently, and re-evaluate the long-term effects of leaching.

References

- André LB, Ziegler Ch (1982) Birth of cuneiform writing and hieroglyphs, Meeting of the National Musses, Paris, p: 383.

- Brion M (1949) The resurrection of the dead cities, Payot, Paris.

- Charles PG (1969) Archeology, discovery of lost civilizations, Larousse, France.

- Einstein A (1934) My worldview, Querido Verlag, Keizersgracht, Amsterdam.

- Dassonville PF (2017) The invention of time and space, springer, New York, USA.

© 2019 Avenida Tancredo Neves. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)