- Submissions

Full Text

Annals of Chemical Science Research

A Study of the Anisotropic Mechanical Behavior of Nine Photocopy Papers

Katerina Chryssou* and Eugenia Lampi

General Chemical State Laboratory, B’ Chemical Division of Athens, Department A’ Tsocha 16, Greece

*Corresponding author:Katerina Chryssou, General Chemical State Laboratory, B’ Chemical Division of Athens, Department A’ Tsocha 16, 11521 Athens, Greece

Submission: June 26, 2024;Published: July 12, 2024

Volume4 Issue5July 12, 2024

Abstract

The in-plane tensile properties, tensile stress in MPa, strain in %, elongation in mm, of machine-made copy papers were determined using a testing machine equipped with extensometer. Nine different kinds of copy paper were tested. The moisture content in % w/w of each copy paper was determined also with the oven method at 105 °C. Non-linear stress-strain curves were obtained as well as stresselongation non-linear curves and stress–moisture content non-linear curves, in both directions MD and CD for the nine copy papers. Polynomial functions were used to curve-fitting stress-strain relationship. The anisotropic behaviors of the nine copy papers including tensile strength and moisture content were experimentally measured. Graphs of the MD and CD strain in % versus MD/CD tensile strength ratio were also obtained.

Keywords:Machine direction; Cross direction; Tensile strength; Moisture content; Orientation dependence; Anisotropy

Introduction

Paper is a common sheet material in pulp and paper and packing industry. The paper generally exhibits anisotropic and non-linear mechanical behavior, affected by the temperature and moisture of the paper [1]. Systems like paper that are directionally dependent are called anisotropic [2]. The increasing diversity of end-use applications of paper and paperboard requires accurate assessment of their mechanical properties in various aspects [3]. Tensile strength values are higher in the direction of the fibre orientation and can be increased by higher orientation. Tensile strength is reduced perpendicular to the direction of fibre orientation. Not many studies exist that try to relate composite materials anisotropy caused by the anisotropic paper directly to paper properties [4]. The objective of the present work is to characterize the tensile stress-strain behavior of nine types of commercial copy paper related to temperature and moisture content.

Materials and Methods

Instruments and materials

The study of the anisotropic behavior of the nine copy paper samples was performed on the basis of three research methods, i.e. tensile force, elongation, and moisture. The tensile testing machine Zwick Roell Z2.5 BT1-FR 2.5th D14/2008, S.N.181435/2008, was used for measuring the tensile strength of the nine copy paper samples. The machine extended the test pieces at 20mm/min constant rate of elongation and measured the tensile force and the elongation produced [5]. The strength force of the machine was 2.5KN. Two clamps holded the test pieces of 15mm width and grab them along a straight line across the full width of the paper test pieces. The clamping force was adjusted pneumatically. A guillotine IDEAL 1043 GS made in Germany cut the test pieces to dimensions of 15mmx210mm. The paper test pieces were pre-conditioned at 23° ± 2 °C and 30%±5%r.h. for 24 hours and then they were conditioned at 23 °C ±1 °C and 50%r.h.±2%r.h. for 16 hours, according to the ISO 187 standard [6], in a conditioning chamber. The moisture content of the nine copy paper samples was determined according to the ISO 287 standard [7] and the ISO 638 standard [8], in an oven Memmert GmbH UNE 400, at 105 °C ± 2 °C, for 16 hours. Glass containers with glass lids and a glass desiccator were used, as well as an electronic balance Sartorius Basic AGGöttingen Germany BP 221S, with maximum capacity 220g, precision of four decimal places and accuracy to 0.1mg. Excel spreadsheet as well as IBM SPSS data analysis software were used in this study.

Results and Discussion

The degree of anisotropy of the nine copy papers was mainly evaluated by their tensile properties. The method for determination of the tensile properties of the nine copy paper samples tested was specified in ISO 1924-2 [5], whereas the constant rate of elongation applied was 20mm/min. Ten replicates were measured in each direction (machine direction MD and cross direction CD) for each of the nine copy paper samples (Table 1).

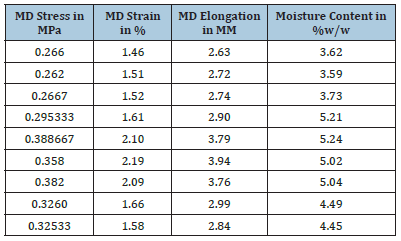

Table 1:MD stress values in MPa and the corresponding values of MD strain in %, in mm, and the moisture content in %w/w, of nine different copy paper samples.

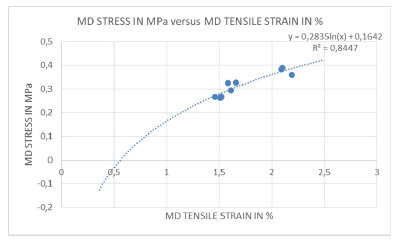

Figure 1:Logarithmic in plane tensile stress-strain curve in the MD direction for nine different kinds of copy paper (Table 1).

The curve in Figure 1 agreed reasonably well with the nonlinear stress-strain curves up to 0.5% strain. Beyond this strain value, a straight line could be well fitted. The stress-strain curve continued to develop after yielding and plastic deformation of the paper material, until reaching maximum stress before decreasing to eventual fracture. The ultimate strength was the highest point on the stress-strain curve and was the strength that the structure of the paper could sustain in tension [9]. The non-linear stress-strain curves clearly depicted the anisotropic elastic, strain hardening behavior. That was explained by the fact that machine-made paper had more fibers aligned in the machine direction (MD).

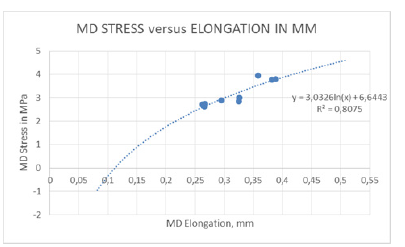

The curve in Figure 2 agreed reasonably well with the nonlinear stress-strain curves up to 0.1% strain. Beyond this strain value, a straight line could be well fitted.

Figure 2:Logarithmic in plane tensile stress-elongation at break curve in the MD direction for nine different kinds of copy paper (Table 1).

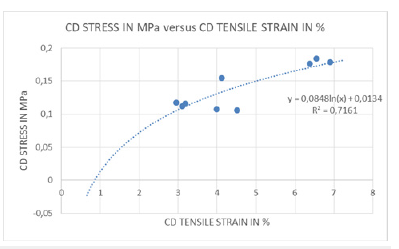

The curve in Figure 3 agreed reasonably well with the nonlinear stress-strain curves up to 1% strain. Beyond this strain value, a straight line could be well fitted (Table 2).

Figure 3:Logarithmic in plane tensile stress-strain curve in the CD direction for nine different kinds of copy paper (Table 2).

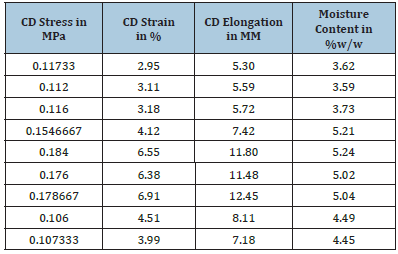

Table 2:CD stress values in MPa and the corresponding values of CD strain in %, in mm, and moisture content in %w/w, of nine different copy paper samples.

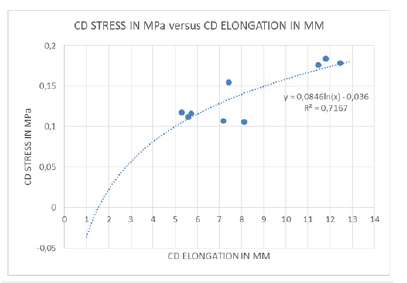

The curve in Figure 4 agreed reasonably well with the nonlinear stress-strain curves up to 1.5% strain. Beyond this strain value, a straight line could be well fitted.

Figure 4:Logarithmic in plane tensile stress-elongation at break curve in the CD direction for nine different kinds of copy paper (Table 2).

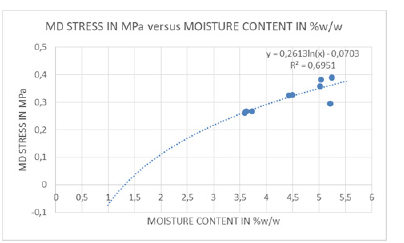

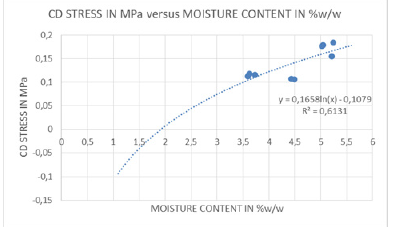

Figures 1 to 6 showed the effect of test direction on tensile stress-strain curves and stress-moisture content %w/w curves, for the nine different copy papers. All the above tensile tests were performed at 23 °C temperature and 50% relative humidity.

Figure 5:Logarithmic in plane tensile stress-moisture content %w/w curve in the MD direction for nine different kinds of copy paper (Table 1).

Figure 6:Logarithmic in plane tensile stress-moisture content %w/w curve in the CD direction for nine different kinds of copy paper (Table 2).

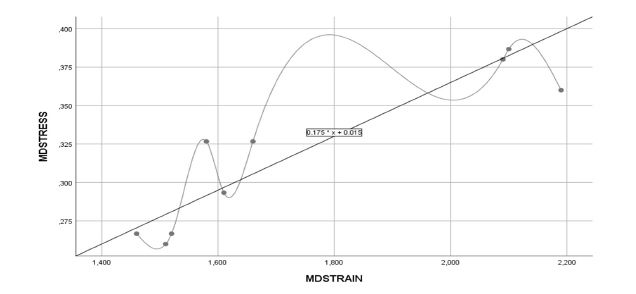

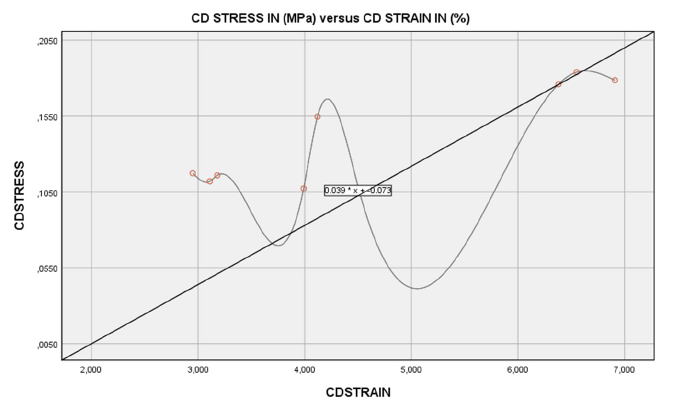

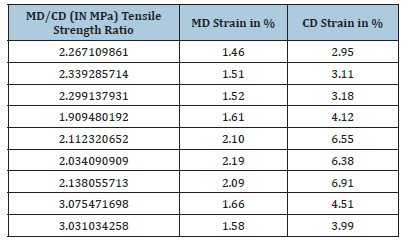

The Figures 7 and 8 showed curve fitting using polynomial functions to model stress-strain mean-difference relationships [10]. Also, the values of the MD/CD tensile strength in MPa ratios were shown in Table 3. The MD/CD ratio ranged from 1.909 to 3.0755 [4,11].

Figure 7:Graph in SPSS of the MD stress in (MPa) versus MD strain in (%) for nine different kinds of copy paper (Table 1).

Figure 8:Graph in SPSS of the CD stress in (MPa) versus CD strain in (%) for nine different kinds of copy paper (Table 2).

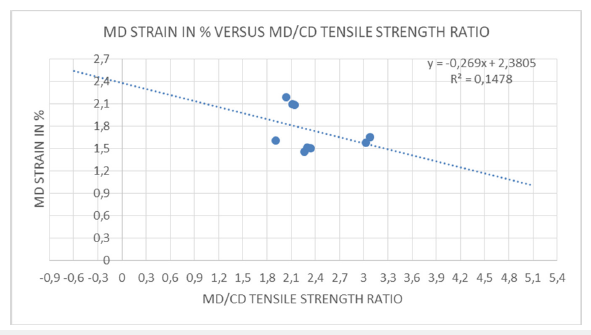

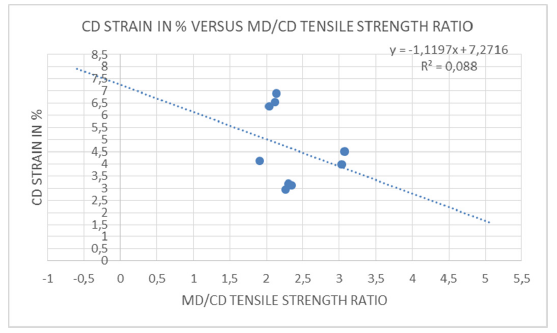

At various MD/CD tensile ratios of 1.909-3.0755 (Figure 9), the MD elongation % obtained from the standard test was 1.46-2.19% with no distinct differences [11]. Also, at various MD/CD tensile ratios of 1.909-3.0755 (Figure 10), the CD elongation % obtained from the standard test was 2.95-6.91 (Table 3).

Figure 9:Graph of the MD Strain in % versus MD/CD tensile strength ratio, for nine different kinds of copy paper (Table 3).

Figure 10:Graph of the CD Strain in % versus MD/CD tensile strength ratio, for nine different kinds of copy paper (Table 3).

Table 3:MD/CD tensile strength ratios, and the corresponding values of MD and CD strain in % of nine different copy paper samples.

Conclusion

The in-plane tensile stress-strain behavior of copy papers has been characterized in a testing machine with extensometer. Tension tests were carried out on the strip-type specimens in the two directions at about 23 °C temperature and relative humidity of 50%. From the experimental results we could draw the following conclusions. The tensile stress-strain characteristics were strongly affected by the test direction, strain rate, temperature, and moisture content. Fibre orientation led to different mechanical properties in machine direction (MD) and in cross direction (CD). That was the anisotropy which would also be affected later by the draws and shrinkage of the paper during drying, inside the printer

References

- Takashi Yokoyama, Kenji Nakai, Tomoya Inagaki (2009) Orientation dependence of in-plane tensile properties of paper: Experiments and theories. Journal of JSEM 9: 86-91.

- Klemen Mozina, Stanislav Pracek, Vili Bukosek (2013) Linear Behaviour of one-side coated paper: Anisotropy. Cellulose Chem Technol 47(5-6): 461-468.

- Yokoyama T, Nakai K, Odamura T (2007) Tensile stress-strain properties of paper and paperboard and their constitutive equations. Journal of JSEM 7: 68-73.

- Kröling H, Endres A, Nubbo N, Fleckenstein J, Miletzky A, et al. (2014) Anisotropy of paper and paper-based composites and the modelling thereof. ECCM16-16th European Conference on Composite Materials, Seville, Spain, 22-26 June 2014, pp. 1-8.

- International Standard ISO 1924-2 (2008) Paper and board-Determination of tensile properties Part 2: Constant rate of elongation method (20mm/min), pp. 1-12.

- ISO 187 (2022) Paper, board and pulps-standard atmosphere for conditioning and testing and procedure for monitoring the atmosphere and conditioning of samples, (3rd edn), pp. 1-7.

- ISO 287 (2017) Paper and board-Determination of moisture content of a lot-Oven drying method, 2009, pp. 1-10.

- ISO 638 (2008) Paper, board and pulps-Determination of dry matter content-Oven drying method, pp. 1-6.

- Yu-Szu Chen (2016) Testing and modeling tensile stress-strain curve for prestressing wires in railroad Ties. Master of Science Kansas State University, Department of Civil Engineering, College of Engineering, Manhattan, Kansas, pp. 1-114.

- Gosling PD, Ben Bridgens (2008) Material testing & computational mechanics-a new philosophy for architectural fabrics. Int J Space Struct. 23(4): 215-232.

- Supattra Panthai, Tongchai Patchiyo, Pratuang Puthson, Phichit Somboon (2016) Analysis of cracking potential and micro-elongation of linerboard. Agric Nat Resour 50(6): 499-504.

© 2024 Katerina Chryssou. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)