- Submissions

Full Text

Annals of Chemical Science Research

Assessment of Cooling Condensation and Adsorption Methods for Atmospheric Water Harvesting from Energy Point of View

Mahmoud Parvazinia*

Iran Polymer and Petrochemical Institute, Iran

*Corresponding author:Mahmoud Parvazinia, Iran Polymer and Petrochemical Institute, Iran

Submission: October 10, 2023;Published: December 11, 2023

Volume4 Issue3December , 2023

Abstract

Different methods are developed to harvest water from the atmosphere. The most developed method for atmospheric water harvesting is cooling condensation method which is commercially available. There are also a number of research works on harvesting by using desiccant materials with some works at prototype and pilot scale. The energy consumption per collected water is of essential impotence for water harvesting from the air. Here an assessment is made by simple calculations to analysis and compare these two methods.

Introduction

Water scarcity is becoming a severe issue in different parts of the world. Although desalination is an effective way for water shortage, but the main problem is difficulty to supply remote regions far away from water resources. Atmospheric water harvesting (AWH) is an alternative solution for local water supply [1]. Different techniques are developed for AWH. Among them cooling condensation is most developed and commercially available technique. There is a lot of works on adsorption AWH in which vapor can be concentrated by using desiccants that adsorb the vapor from the air and can later be recovered in a thermaldriven step [2].

In cooling condensation technique to have one cubic meter of water at 4 °C, about 698KWh energy is theoretically required [3]. Lower relative humidity of the air makes lower dew point temperature that increase energy consumption as significant amount of energy is spent for cooling of the air. From 500 to 7000KWh/m3 energy consumption is reported depending on the air humidity, temperature and the atmospheric water generator (AWG) design [4].

The problem is harvesting atmospheric water in an energy efficient way. Since harvesting air humidity by direct cooling may wastes a large portion of the energy on cooling the air [5], concentrating the water vapor can reduce this sensible heat load [6]. Kim et al. [7] analysis indicates that the adsorption-based approach is superior to refrigeration systems. Adsorption-based AWH performs better than traditional, refrigeration-based dewing systems particularly in arid, low humidity climates [8].

It is state that the cooling condensation works well at humid regions [9]. The purpose of the present work is assessing the energy consumption in cooling condensation and adsorption methods for atmospheric water harvesting by simple calculations based on the sensible heat and enthalpy to indicate the energy efficient regions for each method.

Results and Discussions

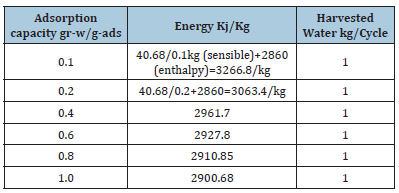

Heat capacities of air and average heat capacity of common adsorbents are known and so sensible heat can be easily calculated. Here the average heat capacity on common MOFs is used for calculations. Cpair=1.006 KJ/Kg.k (at 0 °C-25 °C) and CpMOFs Average= 0.904Kj/Kg.k [10]. Average enthalpy of adsorption for common MOFs is 2860Kj/kg Kj/Kgwater [11] and enthalpy of water evaporation is equal to 2261Kj/Kgwater. The air temperature is assumed to be 25 °C and desorption temperature is assumed 70 °C. For both methods the sensible heat changes at different conditions but the enthalpy of evaporation or adsorption is fixed. The basis of calculations is 1kg harvested water. Total energy is the sum of sensible heat and the heat of adsorption. For adsorption method from 10wt% to 100wt% adsorption is considered from low humidity to higher humidity. The results for adsorption AWH are presented in Table 1.

Table 1:Adsorption AWH. Sensible heat of adsorption=mMOF*CpMOF*(70 °C-25 °C).

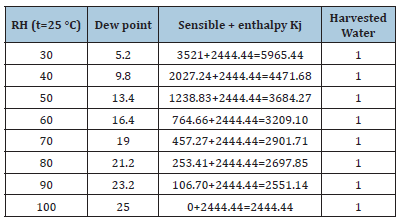

For cooling condensation from 30%RH to 100%RH is considered and shown in Table 2. Total energy is the sum of sensible heat and the heat of evaporation. At 20% relative humidity (RH), the dew point at 25 °C is -1.2 °C and the cooling condensation cannot work.

Table 2:Cooling condensation AWH. Sensible heat= mair*Cpair*(25 °C-dew °C).

As it can be seen in comparison with Table 1, for RH higher than 70% the energy consumption of cooling condensation is lower than adsorption AWG. But in region below 50% down to 30% the consumption increases dramatically. And below 30% the cooling condensation cannot work because of under zero dew point and the problem of freezing. Therefore, at dry region below 30% the cooling condensation essentially is unable to work and adsorption AWG can perform well. As RH decreases the sensible heat for cooling condensation AWH is considerably increased while this sensible heat is much lower for adsorption AWH.

The real conditions

The above calculations include the sensible heat and heat of adsorption but there is heat and mass transfer inside the bed and porous adsorbent which make more energy consumption and need optimum design to reduce the total energy consumption. For the cooling condensation there is also heat transfer inside the mass of the passing air through condenser and also some design considerations are necessary to increase the performance of the system to condense maximum possible water from the air. In addition, there is pump and compressor with less than 100% efficiency that increase the energy consumption.

Beside these general problems about 628KWh/m3 is just needed for condensation of water but the reports by manufacturers show even lower consumption while prototype experimental data shows much higher consumptions [4]. The lower consumption reported by manufacturers has a few reasons. First the condenser for cooling the refrigeration fluid is air cooled and uses no external energy for cooling. The 2nd is a kind of intelligent control to decide the AWG works or not. When the RH is lower than a specified threshold the system does not work. The system may work at nighttime in humid region where the air is close to its dew point and use less sensible energy to be cool down. It is possible that the temperature at some point equals the dew point and with no consumption the condensation happen in the condenser (evaporator). The reports may be yearly average, and the outcome is consumption less than the enthalpy of evaporation as the minimum consumption. And finally, the optimum design of the AWH unit reduces the energy consumption while a simple experimental prototype has the lack of optimum design and intelligent control system.

We have to notice that in sophisticated design a hydrophobic surface becomes easily wet and nucleation of water vapor occurs and the condensation at 100% humidity and even lower humidity close to saturation can happen and less energy is required for condensation than what is calculated at Table 2 for 100%RH or close to it.

Conclusion

The results clearly show that at high humidity the cooling condensation is favorable. At RH more than 70% the energy consumption of cooling condensation begins to be lower than that of adsorption AWH. Less than 50%RH, adsorption AWH shows to be more energy efficient and less that 30%RH because of under zero dew point the cooling condensation is unable to work while the adsorption AWH performs well. For adsorption AWH there is difference between single cycle and multicycle regimes. In a single cycle which definitely use direct solar power the adsorption capacity is important as daily harvested water is equal to wateruptake/ cycle. But in a multicycle system the sensible heat is less than 20% of total energy consumption (Table 1) and adsorption capacity is less effective (minor parameter) in the energy consumption per harvested water. Even at humid regions if it is intended to have solar driven AWH the solution is adsorption AWH as the cooling condensation cannot use the direct solar energy and needed external power.

References

- Tu Y, Wang R, Zhang Y, Wang J (2018) Progress and expectation of atmospheric water harvesting. Joule 2(8): 1452–1475.

- Parvazinia M (2023) Recent advances in atmospheric water harvesting by desiccant materials. Ann Chem Sci Res 3(3): ACSR. 000564.

- Loo SL, Fane AG, Krantz WB, Lim TT (2012) Emergency water supply: A review of potential technologies and selection criteria. Water Res 46(10): 3125–3151.

- Fessehaye M, Abdul-Wahab SA, Savage MJ, Kohler T, Gherezghiher T, et al. (2014) Fog-water collection for community use. Renew Sustain Energy Rev 29: 52-62.

- Kandeal AW, Joseph A, Elsharkawy M, Elkadeem MR, Hamada MA, et al. (2022) Research progress on recent technologies of water harvesting from atmospheric air: A detailed review. Sustain Energy Technol Assess 52 (Part A): 102000.

- Eslami M, Tajeddini F, Etaati N (2018) Thermal analysis and optimization of a system for water harvesting from humid air using thermoelectric coolers. Energy Convers Manag 174: 417-429.

- Sharan G, Roy AK, Royon L, Mongruel A, Beysens D (2017) Dew plant for bottling water. J Clean Prod 155 (Part 1): 83-92.

- Bagheri F (2018) Performance investigation of atmospheric water harvesting systems. Water Resour Ind 20: 23-28.

- Gido B, Friedler E, Broday DM (2016) Assessment of atmospheric moisture harvesting by direct cooling. Atmos Res 182: 156-162.

- Wieme J, Vandenbrande S, Lamaire A, Kapil V, Vanduyfhuys L, et al. (2019) Thermal engineering of metal-organic frameworks for adsorption applications: A molecular simulation perspective. ACS Appl Mater Interfaces 11(42): 38697-38707.

- Zhang B, Zhu Z, Wang X, Liu X, Kapteijn F (2023) Water adsorption in MOFs: Structures and applications. Adv Funct Mater, p. 2304788.

© 2023 Mahmoud Parvazinia. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)