- Submissions

Full Text

Advancements in Civil Engineering & Technology

Recent Sustainable Advanced High Strength Steel for Civil Infrastructure Applications

Nicky Kisku*

Department of Metallurgical and Materials Engineering, National Institute of Technology, India

*Corresponding author:Nicky Kisku, Department of Metallurgical and Materials Engineering, National Institute of Technology, India

Submission: April 07, 2025;Published: April 16, 2025

ISSN: 2639-0574 Volume6 Issue 5

Introduction

As the civil infrastructure system expands globally, the demand for construction materials which are both high performance and durable, have never been high [1-9]. The long -standing high power steels (AHS) in the motor vehicle sector have been rapidly discovered for their capacity in civil infrastructure. The developed composition and processing of AHS not only enhances mechanical properties, but also reduces the environmental footprint of structures [9-11]. This opinion piece discusses recent progress in permanent AHSS and their purpose in the civil engineering domain. Additionally, the availability of various grades, including dual stages, complex-phase and martensitic steels, allows for flexibility in design in bridges, buildings and transport networks [11-18]. With innovations supporting better corrosion resistance and better weldability, AHSS could address several limitations that previously prohibited their civil use [15-20]. This opinion piece discusses recent progress in permanent AHSS and their purpose in the civil engineering domain.

Material efficiency and structural performance

One of the most compelling arguments to integrate AHSS into a citizen infrastructure lies in their excellent power-to-world ratio [21]. These steels demonstrate tensile strength of more than 800MPa, maintaining sufficient flexibility, allowing mild structural designs without compromising safety. Recent developments in dual stages (DP), change-inspired plasticity (travel), and mitigation and division (Q&P) steels have opened new avenues for earthquakeresistant structures, bridges and their use in high-growing buildings [18-22].

Weight reduction potential and embodied carbon savings

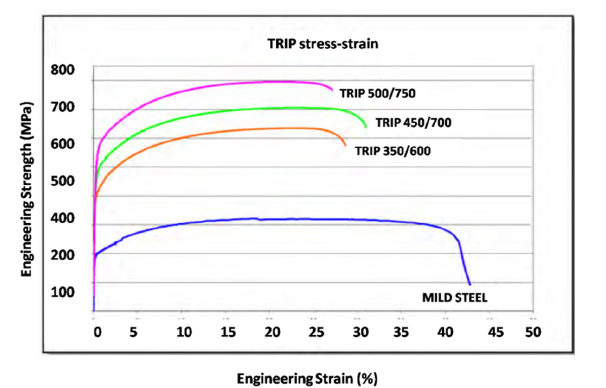

One of the most compelling arguments to integrate AHSS into a citizen infrastructure lies in their excellent power-to-world ratio. These steels demonstrate tensile strength of more than 800MPa while maintaining sufficient flexibility, allowing mild structural designs (as shown in Figure 1) [6]. By optimizing the section thickness, engineers can manufacture efficient loadbearing framework that maintain high security margin, while significantly reduces structural mass. Reducing overall material uses directly translates into lower embodied carbon [23]. AHSS enables designs that achieve uniform structural integrity with low raw materials that contribute to stability benchmarks and life cycle carbon cut strategies in modern construction.

Enhanced mechanical properties, fatigue and post-yield behavior

AHSS grades such as dual stages (DPs), change-inspired plasticity (travel), and mitigation and division (Q&P) Steels have shown significant promise in improving structural flexibility. Their better energy absorption and cruelty makes them suitable for earthquake-resistant construction, bridge decks and high-growing frames [24-26]. The AHSS components display excellent fatigue resistance and subsequent behavior of yields, which are important to ensure long-term reliability in infrastructure subject to dynamic and cyclic loads. These characteristics help to increase the service life of structures, reduce the needs of maintenance and repair. Trip steels are well suited to civil infrastructure due to their excellent combination of strength and flexibility (Figure 1), which increases energy absorption during dynamic loads [9-11]. Their better deformation ability makes them ideal for seismic resistant designs and long-lasting structural applications.

Figure 1:Stress-strain plots for series of grades of TRIP steel [6].

Sustainability and Lifecycle Benefit

Stability is no longer optional, but an essential in material selection. AHSS provides a dual benefit: using low raw materials and long -term service life. AHSS supports the principles of permanent construction, by reducing the amount of steel required per structure and reducing maintenance due to better corrosion resistance and fatigue properties [24-28]. Additionally, several new generations of AHSS grade are designed with better recurrence, which enables offloop material use, which align with circular economy targets.

Innovations in alloy design and processing

Recent innovations have focused on lean alloy design using elements such as Mn, Si and Al to reduce dependence on expensive or environmentally effective elements [29]. Thermomechanical controlled processing (TMCP) and quick cooling techniques have further enhanced microstic control, enabling the stitching of properties to specific structural applications. Research in Ti-, Nb-, and V-Micro alloyed AHSS has exhibited capacity in optimization of weldability and improvement [25,30-31].

Challenges and implementation strategies

Despite their advantages, the widespread adoption of AHSS in civil infrastructure faces challenges [32]. These include higher initial material costs, limited familiarity among civil engineers, and fabrication constraints [33-34]. To overcome these, interdisciplinary collaboration between materials scientists and civil engineers is essential. Design codes must evolve to incorporate AHSS, and practical demonstrations through pilot projects are needed to build confidence in the material’s performance.

Conclusion

Advanced High Strength Steels present a transformative

opportunity for sustainable civil infrastructure and it is summarized

below:

A. Advanced high-power steels (AHS) provide exceptional

power-to-knowledge ratio, which enable light, more efficient

structural design without compromising safety.

B. By reducing embroidered carbon and improving recycling,

the AHS contribute significantly to stability goals and circular

economy practices in the construction sector.

C. Mechanical properties such as fatigue resistance and

post-film behavior have increased, which is ideal for dynamic

and long-life citizens of infrastructure applications.

D. Cross-disciplinary collaboration, pilot projects and

updated engineering code will increase cost and design

standard obstacles through AHSS adoption in civil engineering.

References

- Rocha Da, Aglaé BT, Maximilian E, Jayakrishna K, Otavio O, et al. (2024) Advancing sustainability in the steel industry: The key role of the triple helix sectors. Environmental Science and Pollution Research 31: 43591-43615.

- Yang C, Jiang X, Zhang W (2023) Prediction of surface microstructure, grain size, martensite content and microhardness of 316L austenitic stainless steel in surface mechanical grinding treatment process. Journal of Materials Engineering and Performance 32: 450.

- Hollaway LC (2003) The evolution of and the way forward for advanced polymer composites in the civil infrastructure. Construction and Building Materials 17(6-7): 365-378.

- Plevris V, Almutairi A, Rios AJ (2024) Advancing sustainability through structural optimization: Innovations in material efficiency and environmental impact reduction. In The International Conference on Net-Zero Civil Infrastructures: Innovations in Materials, Structures and Management Practices Springer Nature Switzerland (NTZR), pp.1611-1623.

- Srikanth M, Khan WS, Asmatulu R (2025) Nanotechnology safety in construction and infrastructure industries. In Nanotechnology Safety 135-156.

- YI HL (2014) Review on δ-transformation-induced plasticity (TRIP) steels with low density: The concept and current progress. JOM 66: 1759-1769.

- Wu X (2006) Advanced civil infrastructure materials: Science, mechanics and applications. Woodhead Publishing.

- Shen YF, Qiu CH, Wang L, Sun X, Zhao XM, et al. (2013) Effects of cold rolling on microstructure and mechanical properties of Fe-30Mn-3Si-4Al-0.093C TWIP steel. Materials Science and Engineering: A 561: 329-337.

- Fraley, George J (2013) Principles of trip steel optimization for passive damping applications. Diss Northwestern University.

- Badiola DJ, Mendia AI, Gutiérrez I (2077) Evaluation of intragranular misorientation parameters measured by EBSD in a hot worked austenitic stainless steel. J Microsc 228: 373-383.

- Olson, Gregory B, Azrin M (2012) Transformation behavior of TRIP steels. Metallurgical Transactions A 9: 713-721.

- Kanno, Ryoichi (2012) Steels, steel products and steel structures sustaining growth of society (infrastructure field). Nippon Steel Technical Report 101: 57-67.

- Vercammen S, Blanpain B, De Cooman BC, Wollants P (2004) Cold rolling behaviour of an austenitic Fe-30Mn-3Al-3Si TWIP-steel: The importance of deformation twinning Acta Mater 52: 2005-2012.

- Tomita, Yoshihiro, Takeshi I (1995) "Constitutive modeling of TRIP steel and its application to the improvement of mechanical properties." International Journal of Mechanical Sciences 37(12): 1295-1305.

- Zaefferer S, Ohlert J, Bleck W (2004) A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel. Acta Materialia 52(9): 2765-2778.

- Kisku N (2024) Evolution of microstructure and mechanical properties attainment in Fe-19Mn-0.6 c-4Si-3Al-0.04Nb steel upon thermo-mechanical processing. Metallography, Microstructure and Analysis 13: 272-295.

- Jun Hu, XuYang Li, QingWang M, LingYu W, YiZhuang L, et al. (2022) Tailoring retained austenite and mechanical property improvement in Al-Si-V containing medium Mn steel via direct intercritical rolling. Materials Science and Engineering: A 855: 143904.

- Wegmann G, Maruyama K (2000) On the microstructural stability of TiAl / Ti3Al polysynthetically twinned crystals under creep conditions. Philos Mag 80(10): 2283-2298.

- Kozłowska A, Stawarczyk P (2023) Microstructure evolution and strain hardening behaviour of thermomechanically processed low-C high-manganese steels: an effect of deformation temperature. Archives of Civil and Mechanical Engineering 23: 373.

- Yi HL, Chen P, Hou ZY, Hong N, Cai HL, et al. (2013) A novel design: Partitioning achieved by quenching and tempering (Q–T & P) in an aluminium-added low-density steel. Scripta Materialia 68: 370-374.

- Ueji R, Tsuchida N, Terada D, Tsuji N, Tanaka Y, et al. (2008) Tensile properties and twinning behavior of high manganese austenitic steel with fine-grained structure. Scr Mater 59: 963-966.

- Knezevic M, Lebensohn RA, Cazacu O, Revil BB, Proust G, et al. (2013) Modeling bending of α-titanium with embedded polycrystal plasticity in implicit finite elements. Mater Sci Eng A 564: 116-126.

- Li GQ, Shen YF, Jia N, Feng XW, Xue WY, et al. (2022) Microstructural evolution and mechanical properties of a micro-alloyed low-density δ-TRIP steel. Materials Science and Engineering: A 848: 143430.

- De Almeida LH, May ILe, Emygdio PRO (1998) Mechanistic modelling of dynamic strain aging in austenitic stainless steels. Mater Charact 41: 137-150.

- Klein T (2017) Mechanical behaviour and related microstructural aspects of a nano-lamellar TiAl alloy at elevated temperatures. Acta Mater 128: 440-450.

- Lecuyer JD, Lesperance G, Akben MG, Bacroix B (1987) Precipitation behavior of a HSLA steel containing molybdenum, aluminium and trace amounts of titanium. Acta Metall 35: 1149-1158.

- Kang S, Jung YS, Jun JH, Lee YK (2010) Effects of recrystallization annealing temperature on carbide precipitation, microstructure and mechanical properties in Fe-18Mn-0.6C-1.5Al TWIP steel. Mater Sci Eng A 527: 745-751.

- Hui Z, Qin Y, Hu T, Wang X, Zhou Y, et al. (2015) On the Faceted and Inclined Twin Boundary of Titanium Carbide Derived from Nanolaminate Ti3AlC2. Journal of the American Ceramic Society 98(5): 1664-67.

- Grässel O, Krüger L, Frommeyern G, Meyer LW (2000) High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development-properties-application. International Journal of Plasticity 16: 1391-1409.

- Slycken V, Joost (2007) Dynamic response of aluminium containing TRIP steel and its constituent phases. Materials Science and Engineering 460(461): 516-524.

- Allain S, Chateau JP (2004) Influence of stacking faults on the plastic behaviour of twinning-induced plasticity steels. Metallurgical and Materials Transactions A 35(9): 2749-2761.

- Raabe D, M Sachtleber (2006) The formation of microstructure and texture in a high-manganese twinning-induced plasticity steel. Acta Materialia 54(8): 2003-2015.

- Doege Eckart, Steffen Kulp, Christina Sunderkötter (2002) Properties and application of TRIP‐steel in sheet metal forming. Steel Research 73(6-7): 303-308.

- Bleck R, Wolfgang, Xiaofei Guo, Yan Ma (2017) The TRIP effect and its application in cold formable sheet steels. Steel Research International 88(10): 1700218.

© 2025 Nicky Kisku. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)