- Submissions

Full Text

Advancements in Civil Engineering & Technology

Evaluation of Structural Elements in Fire

Julio Cesar Molina1* and Carlito Calil Junior2

1 University of São Paulo State, Brazil

2 Laboratory of Wood and Timber Structures, University of São Paulo, Brazil

*Corresponding author: Julio Cesar Molina, College of Timber Industrial Engineering, University of São Paulo State, Brazil

Submission: June 09, 2018;Published: August 24, 2018

ISSN 2639-0574Volume2 Issue1

Abstract

The evaluation of structural elements in fire is done through standardized tests in furnaces, which are built specifically for this purpose. The specifications for the tests in this case present some drawbacks such as the consideration of a single test specimen to obtain the response of structural elements. In addition, consider a limited amount of data collected during the tests, and this fact difficult in many cases to evaluation of the element’s resistance at high temperatures. Some drawbacks about the main normative specifications used to perform fire resistance tests of structural elements are presented in this review as well as some comments on the improvements needed to make the standardized fire resistance tests more effective.

Keywords:Fire resistance; Standard fire test; Structural fire performance; Testing specification

Introduction

Nowadays, in Brazil, it is of great importance the definition of the guidelines for the analysis of structural elements in fire. In this context, the need for the development of research aimed at the analysis of structural elements in fire in a theoretical, numerical and mainly experimental character is evident. Simulation of fire conditions more realistically is an important requirement in the analysis of building design. In North Ameri-can and European countries with a tradition in the study of Safety of Structures in Fire, the specifications for obtaining the response of structural elements subjected to fire are given by different standards [1,2]. Furthermore, most standards with fire resistance requirements use calculation methods that are based on the individual response of structural elements in furnaces without considering the interaction between different structural elements during the fire. This has led, in general, to uneconomic and inflexible projects. According [3] in a prescriptive approach, the temperature of the material composing the structural element is limited to a value corresponding to the socalled critical temperature, that is, the collapse temperature of the element when exposed to high temperatures during the test. This approach assumes that, for temperatures higher than the value established for the “critical temperature” the element analyzed is not safe.

Based on this procedure, the temperature of the material is taken as the ultimate limit state of the analyzed element, in which case the particular circumstances in which the structure is subjected during the actual fire (such as the type of fire, the consequences of exposure to fire and the interaction between the various structural elements) are not considered. For example, according to [4], for steel elements, in a prescriptive approach, it is com-mon to assume that when the steel reaches a temperature of approximately 540 °C it has about 50% of its temperature resistance environment and in this case, the failure is imminent. On the other hand, in an approach based on structural performance, all factors are weighted, and the temperature of the material is one of the many variables involved in problem analysis. Although this second approach consists of a more costly procedure, it is possible to obtain, for the analyzed structure under high temperatures, a more representative response when compared to the actual fire situations. It can be said then that the fire resistance determined on the basis of only standardized tests of structural elements is excessively conservative. In addition, another limitation that always appears in the standardized testing of structural elements in fire refers to the quantity and quality of response data collected during the tests. In the case of the analysis of a structure exposed to fire based on the performance of the structural element there is a need to obtain a greater number of response data, especially when the initial objective is the calibration of the test system. The technological advances achieved in the last years have allowed the data of test response in structural elements to be registered very efficiently from external data acquisition systems.

However [1] recommends that the temperature of the element be read at time intervals not exceeding 5 minutes during the first 2 hours and after the initial 2 hours the reading intervals should not exceed 10 minutes. The data recorded every 5 minutes may not be sufficient for the calibration of computational numerical models. It is therefore recommended that data be recorded at intervals of no more than 1 minute in standard recommendations. On the other hand, preparation (fabrication and instrumentation) of the structural element may take several days, in addition to the additional time (on average 28 days) required for the test specimen to reach the test conditions (concrete curing). However, the main normative specifications require only the test of a single test specimen to determine the resistance of the element to the fire. It is thus observed that this approach compromises the reliability of the test results, since they can not be established by testing a single test specimen mainly in the case of such severe test conditions as in the case of tests in high temperatures. The basic provisions for standardized fire resistance tests were developed early in the 20th century [3].

In some normative prescriptions minor revisions occurred, but the test methods remain practically unchanged until today. In North America there are four different standards [1,5-8] very similar to each other for the evaluation of the resistance of structural elements in fire. Most European and Asian countries adopt [2]. Countries like New Zealand, Australia and Japan have their own policy recommendations. According to [9], a single test can cost up to 30,000 in same cases.

Equipment of tests

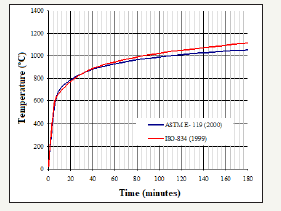

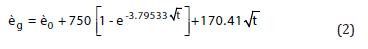

Furnaces for the testing of structural elements are equipment constructed with specific dimensions for each type of structural element to be analysed. Thus, horizontal furnaces are used for the test of slabs and beams and vertical furnaces are used for the testing of walls and collumns. Both the horizontal and vertical furnaces follow standardized curves [1,2] that relate the internal temperature of the furnace to the test duration. These curves were defined by consensus between technical and scientific means and did not represent a real heating curve. Moreover, is important to clarify that the test of structural elements in furnaces is not intended to represent a real fire, but rather to standardize the resistance of the element for specific times of exposure to fire. Figure 1 illustrates standard fire curves [1,2] which are based on the eqs. (1) and (2), respectively.

figure 1:Standard fire curves. Source [8].

where: θg = temperature of the flaming environment gases; θ0 = temperature of gases at time t=0 (usually 20 °C) and t=time.

Figure 2 shows the details of a furnace of tests built in Brazil for tests of horizontal structural elements.

figure 2:Detail of the furnace of test for for horizontal structural elements, built at EESC/USP, Brazil

Finally, the resistance of the structural element in fire is significantly influenced by the magnitude of the load applied during the test. The criterion used by [1], which indicates that the load value acting on the structural element during fire exposure in a controlled environment, must be equal to the maximum value of the load of service. The maximum load value used in this case varies according to the type of material used in the structural element. It is recommended in terms of standardized tests that the load to be applied to the structural elements at high temperatures is estimated in a manner similar to that proposed by [10], ie (1.2 permanent load + 0.5 variable load) equivalent to level of charge between 40 and 50% of the ultimate capacity of the element obtained at room temperature. The main experimental and numerical studies [11-12] related to the analysis of structural elements at high temperatures have made this consideration.

Case study

A horizontal furnace (Figure 2) was built to perform tests in structural elements in high temperatures. The furnace consider the curve [2] showed in Figure 1 and a data acquisition system. The test in the furnace was performed in a timber-concrete composite beam, with section T, distance between suports of 5.10 meters, and loaded of 40% of the ultimate capacity of the element obtained at room temperature. From the tests was possible the evaluation of the response of the furnace and the temperature in the section T. In the evaluation of the internal temperature of the furnace with relationship the theorical curve [2] a total of nine thermocouples in different points were used. The test on the composite beam had 20 minutes of duration.

Results

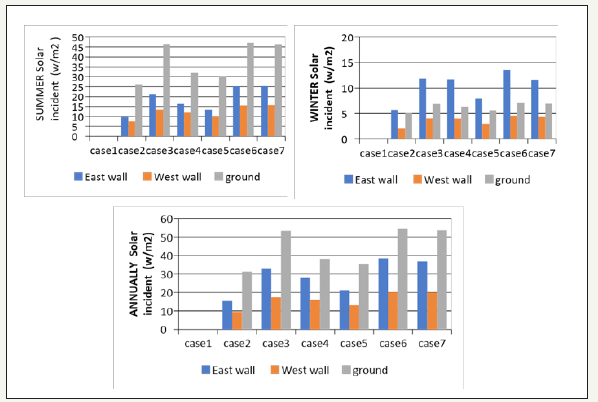

Figure 3 and 4 show the responses of the test furnace and test element. From the obtained results it was observed the homogenization of the internal temperature of the furnace in relation to the curve [2] and the temperature of point 4 of the crosssection T (about 100 ºC in 20 minutes of fire).

figure 3:Response of the furnace (Figure 2) considering nine diferent points of the evaluation.

figure 4:Response of point 4 of the wood-concrete composite beam.

Conclusion

The recommendations for the high temperature tests presented in this manuscript were pertinent in the test performed on a timber-concrete composite beam. Data collected from this fire test can be used to calibrate finite element-based computer models, thus demonstrating the effectiveness of collecting test data.

References

- ASTM (2007) Standard methods of fire test of building construction and materials. Fire and Flammability Standards, ASTM, West Conshohocken, USA.

- International Organization for Standardization (1999) Fire resistance tests-elements of buildings construction. Geneva, Switzerland.

- Vila Real P (2003) Incêndio em Estruturas Metálicas-Cálculo Estrutural. Edições Orion, Mafra, Portugal.

- Eurocode ENV (2005) General rules-structural fire design. European Committee for Standardization, Brussels, Belgium.

- National Fire Protection Association (2006) Standard methods of test of fire resistance of building construction and materials. NFPA, Batterymarch Park, Quincy, Massachusetts, USA.

- Underwriters Laboratory (2003) Fire tests of building construction and materials. UL, North-brook, Illinois, USA.

- Underwriters Laboratory of Canada (2007) Standard methods of fire endurance tests of building construction and materials. ULC, Northbrook, Illinois, USA.

- Costa CN, Silva VP (2002) Estruturas de concreto armado em situação de incêndio. Jornadas Sul-Americanas de Engenharia Estrutural, Universidade de Brasília, Brasil.

- Kodur VKR, Fike R (2009) Guidelines for improving the standard fire resistance test specifications. Journal of ASTM International 6(7).

- American Society of Civil Engineers (2005) Minimum design loads for buildings and other structures. ASCE, Reston, Virginia, USA.

- Michael K, Joachim S (2017) Design of cross-laminated timber in fire. Structural Engineering Inter-national 27(2): 224-230.

- Thi VD, Khefila M, Oudjene M, Ganaoui M EI, Regaume Y (2017) Finite element analysis of heat transfer through timber elements exposed to fire. Engineering Structures 143: 11-21.

© 2018 Julio Cesar Molina. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)