- Submissions

Full Text

COJ Electronics & Communications

Electronics with Plastics, Foils and Fabrics: The Ensuing Flexible and Hybrid Electronics

Choudhary RB*, Kandulna R, Majumder M and Mandal G

Department of Applied Physics, Indian Institute of Technology, India

*Corresponding author: Choudhary RB, Department of Applied Physics, Nanostructured Composite Materials Laboratory, Indian Institute of Technology, Dhanbad, 826004, Jharkhand, India

Submission: July 31, 2018;Published: August 31, 2018

ISSN 2640-9739 Volume1 Issue1

Abstract

Modern electronics is progressively concerned with mobility and flexibility of the device fabrication. To assure high performance, enriched durability and inflated efficiency, user-friendliness flexible electronic device research is globally concerned with the well developing advanced materials and technologies. In this context, substrate material plays a very significant role in determining the mechanical properties, robustness, cost effectiveness and bulkiness of the flexible devices. Plastics, foils and fabrics have been potentially recognized as the flexible substrate materials for the fabrication of the flexible electronics circuits and devices. This communication covers a concise but precise and proficient overview related to the flexible electronics materials and technologies.

Introduction

Flexible electronics is the latest form of electronics technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates namely PEEK, PEN, PET, PIM, PIN, or transparent conductive polyester [1]. Flexible electronics is also known as flex circuits. It is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrate. It can be the screen-printed silver (Ag) circuits on polyester. Flexible film electronic devices can be manufactured by using identical components used for rigid printed circuit boards allowing the board to conform to a desired shape or to flex during its use. The recent approaches for flexible electronics involve chemical etchings to thin down the traditional substrate (Si) to micro meter scales o as to obtain reasonable flexibility [2-4]. It ensures superior and pre-qualified performance with reproducibility, uniformity and reliability. Nonetheless, it provokes to exist for the reverse engineering during development and right time design and has high yield for acceptable tolerance and proven sufficiently inservice lifetime [5]. Flexible hybrid electronics has grown as a mega progress from the laboratory to the market. Scores of them has shown immense interests that spread over aviation, consumer electronics, heath cares, robotics, and spacecrafts, military and industrial automation. In a nut-shell, flexible electronics has tremendous potential for enabling rollable, foldable displays, smart patches and smart packaging on paper and plastic substrates. The technological progress for printing sensors and transistors has attracted global electronic industries because of the reason that large area electronics can be fabricated roll-to-roll at lower temperature on plastic substrates.

Features and Actions

The common concept of flexible electronics markedly deals with the features of electronic materials, technology, varying degrees of flexibility, mechanisms of action, mode of utilizations, advantagesdisadvantages and their limitations. Furthermore, flexible electronic materials comprise flexible substrates, backplanes, front planes, encapsulations etc. Flexible substrate is inevitably required to meet the general features of chemical properties, electrical properties, mechanical properties, morphological (surface) properties, optical properties and thermochemical properties. In pursuit of the enriched substrate quality, many more parameters are sought such as better interface smoothness, chemical resistance, moisture resistance, low CTE, low shrinkage, clarity, conductivity etc. The backplane causes to provide or collect power or signal to or from the front planes. The backplane can be active or passive and it may employ silicon thin film transistor, organic thin film transistor and interconnecting (coupler) materials. However, front planes cause to carry out the optoelectronic features for liquid crystal displays, electrophoretic displays, small circuit (RFID), organic light emitting displays, electronic skin, printing sensors and transistors.

Applications and Advantages

It has wide range of applications in automotive industries, wireless communications, displays and human machine interaction, energy management and portable devices, electronics embedded living organisms, lighting and signage, alternative energy (solar energy) and hostile environment electronic systems. It has advantages of low weight and adaptable size, increased circuitry density, preferred design and packaging, flexible and stretchable during its use. It has limited lifetime, incompatible with water environment, tailoring with battery, exorbitant manufacturing cost, expensive initial investments, challenging for component integration and ultra-precision design machine requirement

Materials & Methods

Substrate materials

Plastics: Plastics are the common names for a class of polymers. Plastic substrates are widely used in both inkjet and screen process printing. The most commonly known flexible plastic substrates include PEN, PET, PES, PEEK, PIM, PIN and TCP. The examples for various types of plastics are as follow:

Acrylic: It is also known as methyl methacrylate, acrylate, polyacrylate. Acrylic fibres are well known for garments and furnishings because they are very soft like wool. A plastic in form of a sheet is hard and transparent which can be used as shatter proof and pressure-resistant alternatives to glass in some vehicles, aircraft and greenhouses. These kinds of plastics are cheaper than polycarbonate but are not as strong or very good scratchresistant. However, these do not contain kind of potentially harmful bisphenol-A and hence are non-toxic.

Mylar: It is also called Melinex and Hostaphan or BoPET (biaxially-oriented polyethylene terephthalate). It is used for special and effective printing and various industrial applications. Helium filled greetings balloons are often made from Mylar. Mylar was invented by DuPont and is it is the trade name for stretched transparent PET film with a thin metallised layer (of various colours) on one side.

PET: It is also called polyethylene terephthalate. Various other compounds are often added to modify its properties for specific applications. These are known as co-polymers. For instance, printable sheet materials are often made from PET-G (polyethylene terephthalate glycol-modified) where glycol is added to lower the melting temperature. PET-G can also be used for thermoformed applications. PET is quite versatile and is widely used for packaging, especially clear plastic bottles and signage materials including backlit displays and popups.

Polycarbonate: It is also called Lexan, Makrolon, Makroclear (trade names). It is mostly used as a rigid, smooth-surfaced and highly transparent material. It is also shatter proof and is very strong alternative to glass and is widely used in CDs and DVDs. Technically polycarbonate is a collective name for a group of similar plastics derived in different ways from bisphenol-A and phosgene. Polyethylene: It is also called PE, polythene, polyethene, polymethylene. It is commonly used for milk bottles, butter tubs and similar containers as well as woven banner material. While medium density polyethylene is used for shrinking films, carrier bags and screw tops. They can be combined with other compounds as copolymers, for example to form acrylics. Plastic carrier bags comprise similar films and containers including bottles. There are many different types, often differentiated by density so for instance high density polyethylene.

Polypropylene: Polypropylene is very popular, and it is used owing to the reason that it is highly solvent resistant and waterrepellent which makes it hard to print on with many inks. Flexible UV inks can work on self-adhesive labels with suitable adhesives. It is mostly used for packaging (bottles, tubs, containers, bottle caps, items with integral hinges, boxes, cases), making posters, wall charts, POS, over laminating films and some synthetic papers.

Polystyrene: Adhesive labels or card sleeves tend to be used for vac formed containers, but direct printing of foam containers is possible with inkjet heads on filling lines. Polystyrene is widely used as plastic. However, polystyrene can be injection moulded (it is used for plastic model kits and CD cases for instance) or extruded as sheets for vacuum forming of food containers or foamed into expanded polystyrene for the familiar heat-retaining fast food containers as well as ceiling tiles and packing materials.

Static cling film: It is also called polypropylene, vinyl and PVC. It is very commonly used for window graphics. Various types for static cling film incudes clear, frosted and white films. As there is no adhesive in it, its removal leaves no residue. This is a thin statically charged form of either PVC or polypropylene that adheres to many clean, fairly smooth surfaces including other plastics, glass, metal, wood, cardboard and brick.

Foils: Majority of the materials are mixed with Epoxy. They are well-known because of their excellent electrical performance owing to the lower dielectric constant and low loss tangents as compared to the other thermoset materials. Following are some major types of foils:

1) Polyimide: (Kapton) blend of polyimide resin with epoxy or 100% polyimide has the best reliability of high-density and it is used in rough environmental conditions.

2) Some are with BT mixture of bismaleimide and PPE (polyphenylene oxides polymer).

3) Cyanate Ester (cyanide group) chemical substances generally based on a bisphenol.

4) The newest materials are the growing number of laser drillable prepress.

5) Acrylates (polymers as plastic).

Fabrics

Membrane materials: Most fabric structures are composed of actual fabric rather than meshes or films. Typically, the fabric is coated and laminated with synthetic materials for increased strength, durability, and environmental resistance. Among the most widely used membrane materials are polyesters laminated or coated with polyvinyl chloride (PVC) and woven fibre coated with polytetrafluoroethylene (PTEE)

Polyesters: Strong, durable, cost-effective and stretch make polyesters are most widely used as fabric materials. Polyesters that are laminated or coated with PVC films are usually the least expensive option for long-term fabrications.

Vinyl-laminated polyesters: A laminated fabric usually is composed of a reinforcing polyester pressed between two layers of unsupported PVC film. Mostly for practical applications, two or more layers of fabric or film are joined by heat, pressure and an adhesive to form a single ply as desired.

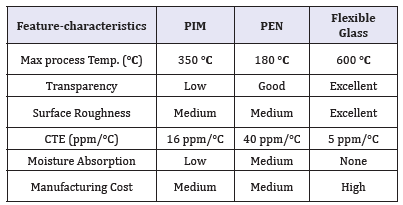

Vinyl-coated polyester: Vinyl coated polyester is the most frequently used material for flexible fabric structures. It is made up of a polyester scrim, a bonding or adhesive agent, and exterior PVC coatings. The scrim supports the coating which is initially applied in liquid form and provides the tensile strength, elongation, tear strength, and dimensional stability of the resulting fabric. Vinylcoated polyester is manufactured in large panels by heat-sealing an over-lap seam with either a radio-frequency welder or a hot-air sealer (Table 1).

Table 1:Feature-characteristics of some flexible substrate materials.

Fabrication Technologies

Fabrication by additive printing

Additive printing or 3D printing is a process of joining materials layer upon layer to make objects from 3D model data whether the material is plastic, metal, fabrics, foils, etc. The method relies on a digital data file being transmitted to a machine that builds the component. It is opposite to subtractive manufacturing methodologies. There are different types of additive manufacturing technologies such as VAT photo polymerization, powder bed fusion, binder jetting, material jetting, sheet lamination, directed energy deposition etc [6,7].

Subtractive manufacturing

Subtractive manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material. Subtractive manufacturing can be done by manually cutting the material but it is most typically done with a CNC Machine. Advanced CNC machines utilize multiple tools and cut around at least three (x, y, and z) axes such that they minimize the requirement for designers to flip the block. One of the principal advantages to subtractive manufacturing is the ability to machine an extremely thin piece of plastic into a living hinge. This kind of process is simply not yet possible in a 3D printer. For those prototypes, that require living hinge components, it is very useful to produce certain parts using additive manufacturing while using the CNC machine for specialty components like a living hinge [7]. The schematic route for subtractive technology and additive technology printing for flexible electronics as designed by Wu et al. [8] has been shown in Figure 1.

figure 1:Schematic route for subtractive technology and additive technology printing for flexible electronics.

Fabrication by batch processing

The batch processing method is used to fabricate electronic display panels, circuits and devices. Flexible foil substrates, cut to sheets, will be the drop-in replacement for the rigid glass plates or silicon wafers. Rigid substrates are best suited to free standing and loose mounting [9]. The schematic diagram for the fabrication of flexible transparent circuits using graphene as electronic ink and quartz as substrate material designed by Xiao et al. [10] has been shown in Figure 2.

figure 2:Schematic representation for the fabrication of flexible transparent circuits using graphene

Fabrication by roll to roll processing

The three essential steps of roll to roll fabrication process technology are deposition, patterning and packaging. Firstly, a transparent conducting oxide is deposited on the top of the flexible substrate (ITO) so as to act as the gate electrode for the TFT. If the technology matures as hoped within the next decade, new substrate materials (plastic, foils and fibres) and cheap, innovative patterning techniques must be combined with creative product development teams to come up with compelling flexible electronics applications [11]. Flexible electronics are naturally associated with roll-to-roll processing. Roll-to-roll fabrication of large-area electronics including solar cells is desirable for cost reduction. The roll-to-roll photolithography and etching tools available today are not capable of 2μm resolution and overlay registration, particularly when combined with the tensioning applied for winding and with process cycles at elevated temperature both of which cause substrate deformation. The goal of roll-to-roll fabrication of flexible electronics is stimulating innovations in equipment and process design process recipes and system integration. Tools for roll-to-roll processing that are available today include web cleaner, PECVD, sputtering, plasma etcher, die punch, evaporator, laser writer, inkjet printer, screen printer, and inspection devices [12].

Thin-Film Flexible Electronics

Thin-film flexible electronics (TFFE) is a novel category of electronic devices primarily made up of plastics. It has numerous advantages and enables to fabricate very small devices with micrometer size in thickness. It is flexible and transparent by nature. It is an ideal technology for ubiquitous electronic devices in billions and billions of objects using novel materials and largearea manufacturing. It initiates a range of new applications and can be adhered to many objects such as bottles, patches, clothes, food, packages, machines, sensor for medical application and cars. It combines state-of-the-art technologies and advanced manufacturing facilities with a history of excellence in thin-film IC design to offer custom development, prototyping and sheetto- sheet production. The schematic diagram showing assembling process of soft flexible cardiac sensor in a thin elastic enclosure as proposed by Lee et al. [13] has been shown in the Figure 3.

figure 3:Schematic diagram for assembling process of soft flexible cardiac sensor in a thin elastic enclosure.

Opportunities and Market

Flexible electronics describes significant versatility in applications and the prospect of low-cost manufacturing processes. These represent important technological advance in terms of its performance characteristics and potential range of applications. These technologies have a dependence on efficient manufacturing that currently requires improved technology, processes, tooling, materials, and ongoing research. In order to capture the global market opportunity in flexible electronics, corporate sectors have initiated dedicated programs duly supported with significant government funding to develop and acquire new technologies, refine them and manufacture them within national borders. These investments are significantly larger and more weighted toward later stage applied research and development. Flexible, printed and organic large area electronic components are thus potentially increasing. The globalrevenue ratio of stretchable, flexible, and rigid electronics as proposed somewhere else [14] has been shown in the Figure 4. Further, the global supply capacity area ratio of rigid electronics as compared to the flexible electronics as illustrated somewhere else [15] has been shown in the Figure 5. With the current estimated market of $200 million, its international market is likely to increase by $800 million by 2020.Flexible electronics enables academicians, researchers, scientists, engineers and professionals for the global entries and mega opportunities in nano fabrications, nano formulations and nano electronics manufacturing.

figure 4:Global revenue ratio of stretchable, flexible, and rigid electronics.

figure 5:Global supply capacity area ratio of rigid electronics as compared to the flexible electronics

Health and Environment

Nowadays, consumer electronics such as cell phones, tablets and many other portable electronic devices are made up of nonrenewable, non-biodegradable, and sometimes potentially toxic (Ga, As etc.) materials. These electronic products are frequently upgraded or discarded leading to hazardous environmental contamination. The reduction of environmental threats from such electronic goods necessitates development of electronic systems consisting of renewable and biodegradable materials and minimal amount of potentially toxic materials. For this purpose, high-performance flexible microwave and digital electronics that consume the smallest amount of potentially toxic materials on bio based, biodegradable and flexible cellulose nano fibril papers can be employed. Furthermore, one can use GaAs microwave devices in a transferrable thin-film form. Successful fabrication of key electrical components on the flexible cellulose nano fibril paper with comparable performance to their rigid counterparts and clear demonstration of fungal biodegradation of the cellulose-nano fibril-based electronics suggest that it is feasible to fabricate highperformance flexible electronics using eco-friendly materials [16].

Risks and Hazards due to Flexible Electronics

On a global scale, the rapid growth and increasing importance of the electronics industry results in the fabrication of semiconductor wafers, printed circuit boards and the assembly of semiconductor devices. The process carries the risk of various work hazards including exposure to irritants and allergens during common operations such as soldering, cleaning operations, materials handling, and procedures for control of static electricity and low humidity in the work environment. Even the use of protective clothing may be associated with the risk of dermatitis. The risk for work-related skin disorders among electronics workers appears to be low when compared to other industries. Exposure to chemicals in the workplace can cause acute or long-term detrimental health effects. Some of the major flexible electronics manufacturing hazardous materials include as per the following:

a. Solvents such as acetone, ethanol, glycol ether mixture, isopropyl alcohol, methanol, methylene chloride, methyl ethyl ketone, n-butyl acetate, 1,1,1-trichlorethane, and xylene.

b. Gases which are corrosive, explosive, flammable, pyrophoric and/or toxic such as arsine, boron trifluoride, diborane, hydrogen chloride, phosphine, and silane.

c. Metals and/or their salts such as aluminium, antimony, arsenic, boron, chromium, gallium, gold, magnesium, mercury, nickel, silver, and phosphorus.

d. Acids such as acetic acid, chromic acid, hydrochloric acid, hydrofluoric acid, nitric acid, phosphoric acid and sulphuric acid.

e. Silica (crystalline) and silicon compounds such as polycrystalline silicon, silicon dioxide, and silicon nitride.

f. Ionizing and non-ionizing radiation compounds for infrared (IR), lasers, radiofrequency (RF) and X-rays.

g. Caustics such as ammonium hydroxide, hydrogen peroxide, and sodium hydroxide.

h. Cryogens such as argon, carbon dioxide, oxygen and nitrogen.

i. Photoresists - positive and negative.

j. Electrical and machinery.

k. Nanoparticles.

l. Nuisance dust.

m. Cyanides.

Conclusion

Flexible electronics is an ever-evolving thin film materialdevice and is progressively paving the ever-new technological paths for innovative applications with huge demand for flexible electronics products in future. The impact of handling plastic, foils and fabrics is least detrimental to the human health for all purpose use. Therefore, the use of these basic materials is quite safe and without any problem for human health.

Acknowledgement

The authors express sincere thanks to Professor Rajiv Shekhar, Director Indian Institute of Technology (ISM), Dhanbad for his constant encouragement in this communication.

References

- Shavit D (2007) The developments of LEDs and SMD electronics on transparent conductive Polyester film; Vacuum International 1(2007): S-35.

- Mohamed GT, Nasir A, Sevilla T, Galo A, Hossain F, et al. (2016) Out-ofplane strain effects on physically flexible fet CMOS. IEEE Transactions on Electron Devices. 63 (2016): 2657-2664.

- Mohamed GT, AZidan M, Khaled SN, Muhammad HM (2014) Towards neuromorphic electronics: Memristors on foldable silicon fabric. Microelectronics Journal 45(11): 1392-1395.

- Jhonathan RP, Mohamed GT, Chadwin YD, Muhammad HM (2013) Metal capacitors on silicon (100) Fabric. IEEE Transactions on Electron Devices 60(10): 3305-3309.

- Gleskova H, Wagner S, Gaspar K, Kova C (2001) Amorphous silicon thin film transistor technology for polyimide susbtrate. J Electrochem Soc 148(7): G370-G374.

- Ge T, Chang JS, Lin T, Lei Z, Soon LG (2014) In circuits and systems (MWSCAS). IEEE 57th International Midwest Symposium pp. 825-828.

- Newman ST, Zhu Z, Dhokia V, Shokrani A (2015) Process planning for additive and subtractive manufacturing technologies. CIRP Annals 64(1): 467-470.

- Wu Z, Ko SH, Lee D (2017) Flexible and stretchable electronics.

- Gurnani H, Anupindi R, Akella R (1992) Control of batch processing systems in semiconductor wafer fabrication facilities. IEEE Transactions on Semiconductor Manufacturing 5(4): 319-328.

- Dai X, Wu J, Qian Z, Wang H, Jian J, et al. (2016) Ultra-smooth glassy graphene thin films for flexible transparent circuits. Science Advances 2(11): e1601574.

- Park H, Kang H, Lee Y, Park Y, Noh J, et al. (2012) Fully roll-to-roll gravure printed rectenna on plastic foils for wireless power transmission at 13.56MHz. Nanotechnology 23(4): 344006.

- Schwartz E (2006) Roll to roll processing for flexible electronics. Cornell University MSE 542 (2006): 1-24.

- Lee SP, Ha G, Wright DE, Ma Y, Sen-Gupta E, et al. (2018) Highly flexible, wearable, and disposable cardiac biosensors for remote and ambulatorymonitoring. npj Digital Medicine 1(2018): 2.

- Poor A (2014) Wearable displays get flexible.

- Flexible AMOLED makers expand production capacity this year.

- Jung YH, Chang T, Zang H, Yao C, Zheng Q, et al. (2015) High-performance green flexible electronics based on biodegradable cellulose nanofibril paper. Nature Communication 7170 (2015).

© 2018 Choudhary RB. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)