- Submissions

Full Text

Academic Journal of Engineering Studies

Study on the Tribological Performance of Bio-Lubricant Conditions- Review

Shalwan A1*, Talal Alajmi2 and Naser Alajmi3

1Department of Manufacturing Engineering Technology, Kuwait

2Ministry of Information, Kuwait

3Vocational Training Institute, Public Authority for Applied Education and Training, Kuwait

*Corresponding author:Shalwan A, Department of Manufacturing Engineering Technology, Public Authority for Applied Education and Training, Kuwait

Submission: July 11, 2023; Published: August 24, 2023

.jpg)

ISSN:2694-4421 Volume3 Issue2

Abstract

The products based on fossil oils are increasing with the concerns of the environmental sectors and academics as well. In this era, there are challenges to finding alternative resources replacing fossil oil for different engineering applications. One of the fossil oil products is lubricant. Fossil lubricants have many industrial applications and involve millions of dollars each year in the development of lubricants due to their huge needs. Accordingly, and to satisfy the industrial needs with the environmental considerations, alternative environmentally-friendly-Lubricants are nowadays the main aim identity by the tribologists. The main objective of this work is to investigate the usage of vegetarian oils as lubricant. For that, many bio-lubricants based on vegetable oil were studied and investigated the influence of these oils on wear and frictional characteristics of adhesive wear. Also, the results are very encouraging to candy the biolubricant as an alternative to synthetic oils any many industrial applications.

Introduction

Recently, major concerns have emerged over the increasing use of conventional fossil fuels in different industrial products and applications. Vegetable oil, being an important invention, has been the focus of many contemporary researchers in the field of technology and industry. Many studies have been recently done on the possibility of using vegetable oil as a lubricant. The results were promising since vegetable oil showed lots of potential as being a better alternative both economically and environmentally. There has recently emerged a big controversy on how to involve vegetable oil in the industrial and manufacturing field. Science or innovation is not in any way limited. The use of vegetable oil has proved beneficial. Recent studies in the fields of technology and engineering have pointed to the possibility of vegetable oil replacing fossils fuels, not just because of the numerous advantages but also since it is environmentally friendly. This is especially important as the world looks to invest more in green energy. In the contemporary world, Biodiesel has continually received great attention as being an alternative biodegradable and non-toxic renewable source of fuel. Besides, in the industrial world, the attention has further been shifted to the potential use of this invention for lubrication. Initially, petroleum by products were the only ones used for lubrication [1]. This is, however, a thing of the past. The emergence of the use of vegetable oil has inspired the extension of this knowledge to the extent that recent discoveries show it being a better alternative for conventional lubricants. Conventional lubricants having numerous advantages have their share of disadvantages [2]. The fact that conventional fossil fuel petroleum is in abundance is worth noting. However, this should not bring one to the fact that this fuel is exhaustible [3].

This introduces a new twist in the large-scale application of lubricants. Biodiesel, being the better alternatives, continues to show unending promise as researchers invest millions of dollars to try and implement biodegradable alternatives. The application of vegetable oils for lubrication of machinery has been applied for ages. However, much attention shifted the moment cheaper and more available alternatives were found [3]. This attention has since been refocused due to the continued shrinkage of oil fields. Vegetable lubricants have been majorly motivated by the need to conserve the environment. The next decade is likely to experience the use of biodegradable greases and lubes than it has been in any moment of history. The balance, however, tightly hangs in whether this alternative surpasses the conventional lubricants in all aspects. Despite being a renewable source of lubricants and having the advantage in environmental conservation over other sources of lubricants, their demerits cannot be overlooked [2]. Modification of these lubricants is challenging due to issues having to do with viscosity and alteration of their structure. It is for this reason that researchers have tossed their research into this vast field in trying to improve this source since it shows promise as the next generation group of lubricants in the field of tribology [4].

This work has been motivated by the relevant literature and emerging issues in the field of industry. I aim at focusing on the use of the extensive vegetable oil in available in Australia and its potential use in making lubricants. Nowadays there are many issues with using synthetic oil in the industrial field. Vegetarian oil is very important and alternative oils are the goal of the industrial sector and researchers. There is much work that has been done recently on the possibility of using vegetarian oil as a lubricant and they found potential work. There are big debates on how to involve vegetarian oil in the industrial and manufacturing field. Science or innovation has no limit. It is the human being’s responsibility to think and try on using something useful and at the same time environmentally friendly. This work has been motivated because of the literature and the recent issues and I am trying to use available vegetarian oil in Australia as a lubricant for different application. The motivation is what makes me interested in the tribology field is firstly, the mechanical motion aspects, Secondly, the availability to involve vegetable oil into an operation such as in tribology. Thirdly the benefits that is possible to gain and affect positively in nature. The reducing of petrol-based lubricant and the increasing of the vegetable oil will reduce the pollution as well as reacting positively in humanity and animal’s health. It is well known that by the years passing the possibility of use a natural alternative for mechanical operation is needed within the increase of the population as well as the increase of the machines that have been used for humanity, an example is (cars, planes, etc.). The selection of vegetable oil was Canola oil due to its availability and due to its low cost.

Literature Review

History of Tribology

The science and engineering of interacting surface is known as tribology. Tribology contains the principles of friction, lubrication, and wear. This area of technology is closely related to mechanical engineering and materials science as reported by Czichos [5]. When two surfaces are touching each other and have a relative motion between them, there are a number of physical phenomena that occur. A friction force can be developed between the surfaces to retard the relative motion between them. During this force development, mechanical energy is converted to other forms such as heat. The surface topography of the material can get altered due to these forces and heat generation. Haessig Jr & Friedland [6] Stated that the proper analysis and understanding of these interactions and solving the technological problems inherited in these situations comprises a major part of tribology. In current engineering technologies, especially in mechanical engineering, sliding, and rolling surfaces are one of the most important things to study. In designing the machine elements, it is essential to have a good understanding about the tribology principles [3]. When two flat looking surfaces are brought in to contact, the surface roughness causes the points of the two surfaces to be contacted at discrete positions and it creates interfacial adhesion. Then friction occurs when the two bodies try to move relative to each other [7].

Due to these friction forces either surface or both surfaces experience the wear or removal of material. When this happens for a long period of time, the dimensions of the mechanical parts get altered and the machine’s optimal functionality gets reduced. As an example, if pistons of engines wear out then there can be gas leaks from the places where the dimensions get reduced. This can affect the performance of the engine to a greater extent [8]. Progress in the philosophical sense is vivid in the field of manufacturing. In contemporary times engineers focus on reducing both the damage to the environment, energy loss and damage to the frictional components of machines [9]. Therefore, overcoming friction becomes a very large percentage of many energy consumptions. Tribology has always been present in order for man to achieve his technological needs. This dates back from the use of fats obtained from animals in order to grease chariots and the application of sand for use in lifting heavy loads and blocks used in the building of pyramids in ancient Egypt [10].

Very few advances are seen having been present from ancient times to the renaissance period. This was majorly due to the stagnation in civilization in the times described as dark ages. Towards the 15th century, Leonardo da Vinci made major advances and experimented on friction thereby deducing laws of friction. These laws remained buried until the turn of the 17th century when they were unraveled by Carnes [11]. Besides this, the other major mark of tribology in the field of industry was the discovery of oil and the expansion of railways that needed continuous lubrication. From this time, until the 1940s, there was no major change until the time when there was need for better lubrication since wars demanded use of machinery that turned at high speed while having corrosive surfaces. The gas turbine especially introduced new challenges in the field of industry and tribology.

By the end of 1964, it became clear that the whole concept of lubrication had not been fully explored and there was still much to unravel. The new shortages in the oil industry with worries of oil depletion prompted researchers to direct most of the resources in the field of tribology into finding alternative renewable class of lubricants. The emerging issues with the use of this kind of lubricant are, However, numerous. There have emerged new concerns over the efficacy and viscosity of this generation of lubricants leading to many resources being channeled towards modification and improvement of this source as the world gears towards biodiesel and alternative lubricants that are both environmentally friendly and renewable [12]. Dowson [13] has in his books surveyed tribology and his application pitting his research and investigations alongside many laws in this field. His books and many works comprehensively explore the development and evolution of tribology over the years dating from prehistory, early civilization and eventually developing through the end of the 20th century. Reti [14] is however credited for having stated two laws of friction. It is this that inspired the introduction of a center of tribology named Leonardo center for tribology. Leonardo observed that the force that would be needed to overcome friction would double if the weight doubled. However, these findings remained unpublished for a long time. Even if the name tribology is new, the interest in this science has a very long history. It is found that the drills made in the Paleolithic period had bearings made of antlers or bones [15].

Also, potter’s wheel or stones for grinding cereals had bearings to reduce friction. During the 1500s, many developments occurred in bearing materials. In 1684, Hooke [16] found that the steel shaft and bell-metal bushes are good for wheel bearings. Even though the laws of viscous flow were founded by Newton & Whiteside [17], the understating of the lubricated bearing operations did not emerge until the end of the nineteenth century. The study of wear has a shorter history than friction. Scientific studies of wear developed in the mid-twentieth century, [18]. In modern machinery, tribology is a crucial issue. Examples of productive frictions are Brakes, Clutches, Driving wheels, Bolts, Nuts. Examples of productive wear are Pencil, Machining, Polishing, and Shaving. Examples of unproductive wear and frictions are internal combustion engine, Aircraft engine, Gears, Cams, Bearings, and Seals [19].

Tribology, manufacturing, and industries

Surface interactions in a tribological interface is highly complex. The understanding of it requires the knowledge in many areas such as, Physics, Chemistry, Applied mathematics, Solid mechanics, Fluid mechanics, Thermodynamics, Heat transfer, Material sciences, Rheology, Lubrication, Machine design, Performance, and reliability [20]. According to some estimates, losses from neglecting the tribology in United States is about 6 per cent of the gross national product (or $200 billion per year in 1996). So it is important to study and apply necessary technology in tribology to save energy and money [21]. The savings that can be obtained from proper tribology practices are substantial and significant. The main objective of tribology is to reduce and eliminate the losses resulting from friction and wear from two interacting surfaces. The research in tribology leads to greater plant efficiency, better performance, fewer breakdowns, and significant savings.

Wear is defined as the removal of materials from one body when subjected to contact and relative motion with another body and there are six fundamental wear modes such as abrasive wear, scratching, adhesive wear, Galling, Scuffing, fretting/fretting corrosion, erosive wear, cavitation, impact, electro-arcing, rolling contact fatigue, spalling, delamination, and tribo-corrosion. When assessing the tribology requirements followings should be considered such as material, coating, lubricant, contact area, surface roughness, sliding speed, sliding mode (unidirectional, reciprocating, multidirectional), duty cycle (Continuous contact, intermittent), environment, atmosphere [22]. With the advancement of world economies with many countries pointing towards industrial expansion, the field of tribology seems important. There seems to be no way industries will expand without focusing on how friction can be improved. From numerous literature and advanced research in recent times, there have emerged concerns over the huge percentage of energy that goes to friction when dealing with machinery. Industrial advancement means that we should be focusing more on reducing the input while multiplying on the output. This will only be possible if the losses made on friction are explored. Friction not only consumes energy meant for productions, but it also leads to great wear and tear of numerous machine parts leading to numerous losses [13].

Tribology in itself has numerous applications. Towards the end of 1990, numerous uses of tribology emerged. These include green tribology and bio tribology. These areas, being inter-displinary in the technological sense explore wear and tear and lubrication of Nano scale [23]. The application of tribology, although focused on bearing design, has recently expanded to include other fields to the extent that it is applied to all aspects of technology. In any product that involves moving parts or parts rubbing against each other, there is the involvement of very complex tribological interactions [22]. Tribology plays a very central role in production and manufacturing. Increased wear and tear mean that there will be increased costs for production per unit. This will result in very frequent and unnecessary tool replacement [24].

Concept of lubricants: One of the effective ways to reduce the friction and wear of two contacting surfaces is to use lubricants in the contacting surfaces. This will provide smooth running conditions for the machine and can extend the lifetime of the machine to a considerable amount. This lubricant can be liquid, solid or gas. To apply a particular lubricant to a given situation depends on many factors such as, role of surface roughness, mechanism of adhesion, friction and wear, physical interaction between the lubricant and surfaces, and chemical interaction between the lubricant and surfaces. By considering these factors, a suitable lubricant can be chosen for the better performance of the machinery parts. The roles of the lubricants are Reducing friction, prevent or minimize wear, transporting debris away from interface and provide cooling. The key factors of lubricant effectiveness are Fluid shear properties (Viscosity, viscosity index), Reactivity of the surface, Extreme pressure constituents, Shear strength of solid lubricant or coating and Heat capacity [25]. Due to the development of the proximal probes, especially tip-based microscopies (atomic force microscope and scanning tunnelling microscope) and surface probe apparatus, and other computation technique development, it is easy to study and analyze the surface interactions of two moving surfaces. These microscopes have high resolution hence the structure can be modified or manipulated on a nanoscale.

These developments pave the path for extensive research in developing the basic understanding of the behaviour of friction and wear in the atomic level and this will allow better design of material properties for mechanical applications. These developments have led to a new technology called micro-nanotribology. This technology allows exploration more into interfacial processes and scales from atomic and molecular to the micro scale. Micronanotribology techniques are very important to narrow the gap between engineering and science when it comes to tribology. The word tribology was first reported in a landmark paper by Sliker & Jost [26]. The word came from the Greek word “tribo” which has the meaning of rubbing. So, The English translation is the science of rubbing. In dictionaries, it is defined as the science and technology of interacting surfaces in relative motion and of related subjects and practices. Tribology is applied in many engineering applications ranging from household appliances to spacecraft.

Petro based lubricants: Petro based lubricants have many similar properties as bio-based lubricants, but the environmental impact is much more different. Petro-based lubricants are commonly used as they are cheap and readily available. Bio based lubricants on the other hand have good physical properties, they are clean and renewable [27]. Petro based lubricants are widely used due to following reasons low cost, readily accessible for the demand, drain interval is long enough. Even if they have these attractive properties, they are non-renewable and can be toxic to the environment. If these lubricants are not properly disposed, they can absorb into water systems which causes infections or death to many organisms. Some machines used in offshore drilling and in agriculture work closely with water resources, and using petrol-based lubricant can be dangerous to the environment. In such a situation, biobased lubricants are the only alternative. Bio based lubricants can be derived from either synthetic manner or from animal fats. But the vegetable-based bio lubricants have many advantages over the rest. Bio based lubricants have high lubricity, high flash point, viscosity index is stable, clean process and recyclable, non-toxic and degradable. There are some limitation or disadvantages of usage bio-based lubricants such as rapid oxidization, cost is quite high comparing to the petrol-based lubricant, restricted to be applied in a moderate temperature such as room temperature of 25ᵒ and using bio lubricant as an alternative to petrol-based lubricant surely will affect the food production.

As the public becomes more conscious about environmental issues, research on bio lubricants has increased extensively. Chemical processes and bio engineering are used to improve the physical properties of bio-based lubricants. In some research, additives are used to improve the physical properties of vegetable oils. Vegetable oils rich in Oleic acid such as rapeseed, sunflower and soybean become the most preferred raw material for biobased lubricants production. These oils with high Oleic provide stable lubricants that provide slow oxidization levels. Conventional soybeans contain only 20 percent Oleic acid, but the bio engineered ones have a percentage of 83 per cent. In hydraulic pump test, these derived oils have shown thirty times more oxidative stability than the conventional soybean oil. Nutritionally, these soybeans have no difference to conventional soybeans but due to the processing the cost is much higher than the normal soybean [27].

The double Carbon bond in the molecular structure of vegetable oils creates poor thermal stability and higher oxidization levels. The following techniques are used to saturate vegetable oils such as (transesterification, selective-hydrogenation and selective-hydrogenation via epoxidation). Annually, epoxidation produce 200000 tons of soybean oil. This particular process uses Hydrogen Peroxide with the presence of mineral acid to break the Carbon-Carbon double bond in triglyceride and form proxy acids. The resulting structure is more oxidatively stable but increases the pour point which limits the epoxidized vegetable oils to higher temperature applications. Bio based lubricants have high pour points, which restrict it to be used in low temperature applications. By treating soybean oil with beached alcohol with a presence of a catalyst, the pour point can be taken down to -15 degrees Celsius. This altered product maintains the viscosity and biodegradability as other oils [27]. There are three major aspects to be considered which will allow the bio-based lubricants to be used as an alternative, it will be applicable in the industry if the cost is low, when offering a sufficient number of lands for growing vegetables, if social, physical, and political infrastructure applied to support such an idea. Even if the bio-based lubricants are more costly than the petrol-based lubricants, it provides energy savings due to high lubricity which can attract potential buyers. Bio based lubricants lower the coefficient of friction at the pitch point to a greater extent than petrol-based oils. The increment of lubricity of bio-based lubricants with temperature is higher than that of petrolbased lubricants. This will allow bio-based lubricants to be used in high temperature applications such as injection mounding and heated presses.

Bio-Based lubricants

Research is carried out to improve the physical properties of bio lubricants which will allow it’s used widely in many applications. Bio based lubricants are usually more expensive than petroleumbased lubricants. As these lubricants are taken from vegetable oil, care should be taken when deciding the amount to be allocated for lubricant production as this will affect food production. In the current situation, there is not enough land for the production of bio lubricants, so collaboration of government and industry is required in making policies to enhance the production of bio-based lubricants [27]. Worldwide consumption of lubricants is around forty million. This ranges from airplane engines to office chairs. The widely used lubricant type is petrol-based lubricants. As the oil resources are decaying day by day, soon it will not be able to make. Bio based lubricants create less emission as they have higher boiling point esters. These products are completely free of aromatics and more than 90 per cent biodegradable and non-water polluting. The reduction of oil mist or oil vapor reduces the inhalation of it to reduce health risks. They have good skin compatibility and less dermatological problems with high cleanliness. The polar esters create a high wetting tendency which leads to less friction which in turn increases the tool life. Higher viscosity is desirable for high temperature applications. High safety can be obtained as it has high flash point and savings can be obtained from maintenance, manpower, storage, and disposal cost. Vegetable oils also reduce upstream pollution as it derived from plant based rather than extraction and refining pollution done by petrol-based lubricants. From the point of workers’ safety, plant-based lubricants are much safer than petroleum-based lubricants as they have low toxicity, high flash point and low volatile organic compound emissions [28].

Bio lubricants in industries: Industries and research are searching for alternative renewable source for lubricants to be used owing to replace the fossil oils. Bio based lubricants have many properties that give more advantage over the petrol-based lubricants, but they still have some undesirable properties which allow petrol-based lubricants to be used in many applications. Research is conducted to improve the quality of physical properties and reduce the cost of using bio-based lubricants to compete with the petrol-based lubricants [29]. There are now policies to improve the use of bio-based lubricants but still there are some issues with the perception and allocation of land for this purpose. Countries cannot completely change from petrol-based lubricants to bio-based lubricants in a day or two. This must be a gradual process which requires the support from government, agriculture, research, and industry. Due to the rapid economic growth in Asia alone, the world demand for lubricants rose to a great extent [12]. Nagendramma & Kaul [12] reported that it is predicted that the demand for lubricants will increase 1.6 percent annually for at least another three years from the current demand of 40 million. Even though the consumption is so high, only a small percentage is being recycled. So the need arises to find an alternative which is renewable to compete with the growing need. Bio based lubricants are of limited use and applied in a number of environmentally sensitive industries such as Agricultural machines and other machinery used under or very close to water resources. The reasons for this are Nontoxic, Create a very small disturbance to the echo-system.

Table 1:Vegetable oil production for different countries, [32].

Energy saving by use bio lubricants: Here are the approximation energy savings that would be gain through using bio-based lubricant in some applications in the industry field such as plastic injection molding - 2-3 per cent saving, hydraulics - 1-3 per cent saving, Spur gear - 1-5 per cent saving and worm gears - 15-30 per cent saving [27]. Bio based lubricants can elongate the life of the machine and reduce the maintenance cost as it decreases the coefficient of friction to a greater extent. The initial cost of the lubricant is negligible compared to the savings in energy and maintenance cost. As opposed to biofuels, a specialized crop is needed for quality lubricants which has high Oleic acids [30]. Modified soybean is the only crop that has nutritional quality with high Oleic acids. A hectare of land can produce 446 liters of soybean oil annually, but this is only sufficient to lubricate a heavy caterpillar for half a year [31]. Following is the table for vegetable oil production for different countries as reported by Shukla and Srivastava [32] (Table 1).

Base stock comes with a number of properties such as high biodegradability, low volatile, ideal cleanliness, high solvency for lubricant additives, miscibility with other types of fluid and negligible effect on seals. The aspects are dependent on the synthetic additives are lubricity, antivirus protection, load carrying capacity, corrosion prevention, acidity, ash content, color, foaming, de-emulsification, water rejection Hence, when an oil is checked for its suitability for an application, first the base stock properties are evaluated. In addition to that, followings also analyzed such as cleanliness, compatibility with minerals, homogeneity during long term storage, water content and acidity, viscosity, viscosity index, pour point, cloud point, cold storage, volatility, oxidative index, and elastomers compatibility. There are the four main vegetable oils that dominate the industry such as Soybean 31-35 per cent, palm oil 28-30 per cent, rapeseed oil 14-15 per cent and sunflower oil 8-10 per cent (Table 2).

Table 2:Solidification points of different oils, [33].

Limitations of Bio Lubricants: in developing bio lubricants, the greatest challenge for the research is to improve the physical properties without harming the biodegradable, tribological and environmental properties. Controlling behaviour consists of following aspects control hydrolytic stability, control of the physicochemical characteristics, control environmental characteristics, control compatibility with materials and seals, control temperature and control oxidative stability [33,34]. Researchers have explored biodiesel tribological issues for close to three decades now. The evaluation, when looked at from a quantitative point of view, the amount of metal gives the various engines a component of wear and tear. The analysis, quantitatively, attempts to give a source of these metals. Lubricity issue is very central. With the introduction of low sulfur diesel fuels by regulators in countries such as the United States, has led to the failing of various engine parts such as injectors, [35].

This is due to the fact that the pumps and injectors are lubricated by the same fuel. The main challenge of using biodiesel emanates from the concerns over the issue of viscosity when compared to fossil fuels [36]. Viscosity cannot be altered and any attempts to influence the viscosity of tribological compounds leads to a significant change in the structure and efficacy of these lubricants. These lubricants are delicate in the sense that any little alteration in their structures leads to an effect in the efficacy of these compounds therefore making them less potent and less useful. There have been great obstacles in trying to make the tribological compounds more useful while trying to avoid any alteration in their structure [37]. This has, however, proved difficult due to the tight balance between conserving both the structure and potency while trying to maintain the usefulness of the product.

Lubricants based on Vegetarian Oils

Debates on Vegetable Oil: Petroleum is a non-renewable natural resource, and it is finite. Currently, the resources that produce petroleum are getting scarce with the development of industrialization. As a result of this fuel and lubricant prices will increase rapidly which will impact in an adverse manner to the economy. On the other hand, plant oils are natural resources which are highly renewable. Recent research has proven that the oils derived from following crops have similar structure to petroleumbased oils. The structural similarity comes from the long chain hydrocarbons which incorporate numerous physical properties to be used as a lubricant. There are concerns about the petroleumbased lubricants with regard to the threat to the environment. Vegetarian based oils on the other hand causes minimal threat to human health and to the environment.

Considerations in vegetable lubricants: The key properties that should be concerned when selecting a vegetarian oil for lubricant purposes are selected crop should be sustainable, minimal effect on food sources, cost should be economically competitive and environmental and user friendly Research have confirmed that the mesostructured fatty acids in oils derived from plants, as examples, oleic and plasmatic are regarded as the most suitable candidate for lubricants and hydraulic oils [38]. Plants that have a high concentration of saturated linear fatty acids are not suitable for lubricant applications as they become solid at room temperatures. Among other types, Oleic acid has become the most desirable mono-saturated acid for lubricant applications. This type of acid can be found in the following crops canola, rapeseed, and castor seeds.

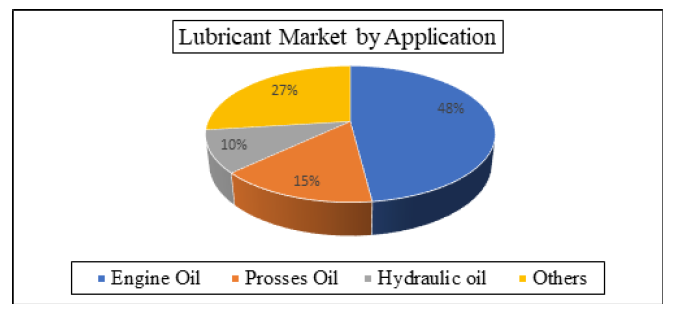

Vegetable oil advantages: The basic advantages of vegetarian oil against the petroleum based oil are bio mass used to produce bio lubricants are renewable, they can be genetically changed to get good qualities, easily biodegradable, nontoxic, low I evaporation loss, prolong the life of the machines due to higher wetting tendency, cost-effective, easy to handle and less maintenance loss Figure below illustrates the application of bio lubricant in different fields (Figure 1) [39].

Figure 1:Lubricant marks in the recent years.

Modern machinery such as engines and tools demand high performance lubricants to decrease the wear and tear. Petroleum based lubricants contain only the base material, but bio lubricants have base materials with some additives which can provide many useful properties to the lubricant. The first step to select a crop for bio lubricant is to study the structure of the plant oil. The composition is dependent on the plant type, but the following also have an effect over the structure such as soil type, climatic conditions, season, and the mount of sunlight [40] (Table 3).

Table 3:The percentages of fatty acid in vegetable oils, [40].

Fatty acid: Vegetarian oils contain triacylglycerol with other fatty acids. Following table shows the percentages [40]. The fatty acid on plants contains different acid types such as capric Acid, lauric Acid, myristic acid, palmitic acid, stearic acid, omega 6, omega 3 and alpha linolenic. The following table lists the composition (percentage) of these acids for saturated fatty acids for different plant types [40] (Table 4 & 5).

Table 4:Acids for saturated fatty acids for different plant types, [40].

Table 5:List the composition (%) of these acids for unsaturated fatty acids for different plant types, [40].

Canola Oil as lubricant

Vegetable Oil Types are many. Canola oil is one of the most important types of oil. Canola oil is available around the world it is price is low and reasonable. Now in Canada Canola oil is third most important product [4]. Canola oil can be blended with different oils which make it one of the best choices. Canola oil is rich of oleic and linolenic acids which lead to a healthier life. Canola oil is extracted from the seeds of canola plants. The canola plant was developed from rapeseed oil plant by plant breeders since rapeseed oil plant had limitations to human and animal consumption [41]. Rapeseed oil contains a large percentage of erucic acid. Erucic acid is not good for human consumption. Animal meals produced from rapeseed oil have been found to contain large content of glycosylates which have been found to suppress animal growth rates when consumed in high doses. It is for these reasons that plant breeders embarked on the development of rapeseed plant varieties with low content of erucic acid: low-erucic acid rapeseed (LEAR) and also low on glycosylate content, [42]. In Canada, rapeseed plant breeders named LEAR canola for the purposes of marketing. With low levels of erucic acid, glycosylate, and saturated fats, LEAR (canola oil) appealed to consumers conscious with their health and this increased its demand. The production of canola oil has increased dramatically since World War II. In industrials, Canola oil is also used for the production of biodiesel, a form of biofuel used to run automotive engines. Besides being used to produce biodiesel, [43], canola oil has been also used to produce a variety of consumer and industrial products such as lubricants because of its non-toxicity, [44]. The content of the triacylglycerol in plants varies with the plant type. As an example, yellow mustard contains triacylglycerol about 27% and brown mustard contains 36% of triacylglycerol [40] (Table 6).

Table 6:The table below list the triacylglycerol percentage for different plant types, [40].

Conclusion

The results revealed that vegetable oils can be beneficial for

certain applications in which low viscosity is required such as

bearings, bushes, and slides. Some specific findings of this work can

be found in the following points:

A. The viscosity of vegetable oils with synthetic oil is significantly

dependent on the environmental temperature. The increase in

the temperature reduces the viscosity of the lubricant.

B. From the results of the review, the operating parameters have

played the main role in controlling the wear and frictional

behaviour.

C. Vegetable oil continues to show great promise in its efficacy in

the use as a tribological compounds. The use of this alternative

exploits the structures of biofuels and how this closely knit

structure can be used to be just as good an alternative to fossil

fuels. The use of biodiesel in the field of tribology means great

promise since these fuels are a form of renewable sources

which can be exploited without worries of depletion.

References

- Sahoo PK (2009) Comparative evaluation of performance and emission characteristics of jatropha, karanja and polanga based biodiesel as fuel in a tractor engine. Fuel 88(9): 1698-1707.

- Berthe D (1989) Tribological design of machine elements. Elsevier, 1st (edn), 14: 519.

- Stachowiak G, Batchelor AW (2013) Engineering tribology. Butterworth-heinemann.

- Shalwan ABF, Yousif FH, Alajmi, Alajmi M (2021) Tribological behavior of mild steel under canola biolubricant conditions. Advances in Tribology, Article ID 3795831, pp. 1-13.

- Czichos H (2009) Tribology: a systems approach to the science and technology of friction, lubrication, and wear. 1st (edn), Elsevier, Amsterdam, Netherlands, p. 399.

- Haessig Jr DA, Friedland B (1991) On the modeling and simulation of friction. San Diego, CA, USA.

- Williams J (2005) Engineering tribology. Cambridge University Press, USA.

- Bedewi MAA (1985) Non-steady state lubrication of counter formal contacts. University of Leeds, England.

- De Marchi JA (1998) Modeling of dynamic friction, impact backlash and elastic compliance nonlinearities in machine tools, with applications to asymmetric viscous and kinetic friction identification. Rensselaer Polytechnic Institute, Troy, New York, USA.

- El Adly RA, Ismail EA (2011) Lubricating greases based on fatty by-products and jojoba constituents. Tribology-lubricants and lubrication. IntechOpen, pp. 201-222.

- Carnes K (2005) The ten greatest events in tribology history. Tribology & Lubrication Technology 61(6): 38-44, 45-47.

- Nagendramma P, Kaul S (2012) Development of ecofriendly/biodegradable lubricants: An overview. Renewable and Sustainable Energy Reviews 16(1): 764-774.

- Dowson D (1979) The History of Tribology, Longman, London.

- Reti L (1968) The two unpublished manuscripts of leonardo da vinci in the Biblioteca Nacional of Madrid-II. The Burlington Magazine 110(779): 81-91.

- Clark JGD, Thompson MW (1954) The groove and splinter technique of working antler in Upper Palaeolithic and Mesolithic Europe. Proceedings of the Prehistoric Society. Cambridge University Press 19(2): 148-160.

- Hooke R (1968) Micrographia, or some physiological descriptions of minute bodies made by magnifying glasses, with observations and inquiries thereupon. Micrographia. Holzer.

- Newton I, Whiteside DT (2008) The mathematical papers of Isaac Newton. The Mathematical Papers of Isaac Newton, p. 648.

- Blau PJ (2005) On the nature of running-in. Tribology International 38(11-12): 1007-1012.

- Bhushan B (2013) Introduction to tribology. John Wiley & Sons, Hoboken, New Jersey, USA.

- Trent E (1988) Metal cutting and the tribology of seizure: I seizure in metal cutting. Wear 128(1): 29-45.

- Mansouri S, Wong V (2005) Effects of piston design parameters on piston secondary motion and skirt-Liner Friction. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 219(6): 435-449.

- Bahadur S (2000) The development of transfer layers and their role in polymer tribology. Wear 245(1-2): 92-99.

- Bart JC, Gucciardi E, Cavallaro S (2012) Biolubricants: Science and Technology. Elsevier, USA.

- Chryssolouris G (2013) Manufacturing systems: Theory and practice. 2nd (edn), Springer Science & Business Media, New York, NY, USA, pp. 599-603.

- Jorge Luiz Raposo Jr, Silvana R Oliveira, Jose A GN, Joaquim A Nobrega, Bradley Todd J (2011) Determination of silicon in lubricant oil by high-resolution continuum source flame atomic absorption spectrometry using least-square background correction and internal standardization. Analytical letters 44(12): 2150-2161.

- Sliker T, Jost J (1966) Linear electro-optic effect and refractive indices of cubic ZnTe*. JOSA 56(1): 130-131.

- Ing A (2009) Biobased Lubricants: a viability study. Proceedings of the 53rd Annual Meeting of the ISSS-2009, Brisbane, Australia.

- Lehtinen J, et al. (2013) Occupational hygiene in terms of volatile organic compounds (VOCs) and bioaerosols at two solid waste management plants in Finland. Waste Manag 33(4): 964-973.

- Ramadhas A, Jayaraj S, Muraleedharan C (2004) Use of vegetable oils as IC engine fuels- A Review. Renewable energy 29(5): 727-742.

- Kiepper BJ, Governo, Zacharias H (2001) Characterization of the generation, handling and treatment of spent fat, oil, and grease (FOG) from Georgia’s food service industry. College of Agricultural & Environmental Sciences, Department of Biological & Agricultural Engineering, Engineering Outreach Program, University of Georgia, USA.

- Zappi M (2003) A review of the engineering aspects of the biodiesel industry. MSU E-TECH Laboratory Report ET-03-003.

- Shukla A, Srivastava VK (2013) Vegetable oil, biodiesel-An unconventional and environmental friendly source of liquid fuel. Indian Research Journal of Genetics and Biotechnology 5(02): 88-97.

- Yao L, Hammond EG, Wang T (2009) Melting points and viscosities of various diol and polyol esters as potential biolubricants. Synthesis of fatty acid derivatives as potential biolubricants and their physical properties and boundary lubrication performances, p. 49.

- Agunsoye J, Talabi SI, Awe O, Kelechi H (2013) Mechanical properties and tribological behaviour of recycled polyethylene/cow bone particulate composite. Journal of Materials Science Research 2(2): 41.

- Lin CY (2013) Strategies for promoting biodiesel use in marine vessels. Marine Policy 40: 84-90.

- Sangeeta M, Sudheshna M, Maneesha P, Monika R, Ruchi G, et al. (2014) Alternative fuels: An overview of current trends and scope for future. Renewable and Sustainable Energy Reviews 32: 697-712.

- Danilov A (2015) Progress in research on fuel additives. Petroleum Chemistry 55(3): 169-179.

- Stohr T (2015) Proteomic analysis of the Endoplasmic Reticulum of developing castor bean seeds-Testing the feasibility of ER membrane topology elucidation using a sample of purified ER. Durham University, England.

- Singh Y, Abid F, Aamir R, Muhammad Arif M, Surbhi Jain (2017) Sustainability of a non-edible vegetable oil based bio-lubricant for automotive applications: A Review. Process Safety and Environmental Protection 111: 701-713.

- Fan J, Andre C, Xu C (2011) A chloroplast pathway for the de novo biosynthesis of triacylglycerol in Chlamydomonas reinhardtii. FEBS Lett 585(12): 1985-1991.

- Day L (2013) Proteins from land plants-potential resources for human nutrition and food security. Trends in Food Science & Technology 32(1): 25-42.

- Aachary AA, Thiyam HU, Eskin MN (2014) Canola/rapeseed proteins and peptides. Applied Food Protein Chemistry, pp. 193-218.

- Bassam NE (2013) Energy plant species: Their use and impact on environment and development. Routledge, Milton Park, Abingdon-on-Thames, Oxfordshire, England, UK.

- Mobarak H, E Niza Mohamad, Masjuki HH, Kalam MA, Al Mahmud KAH, et al. (2014) The prospects of biolubricants as alternatives in automotive applications. Renewable and sustainable energy reviews 33: 34-43.

© 2023 Shalwan A. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)