- Submissions

Full Text

Academic Journal of Engineering Studies

The Effect of Viscosity on the Injectability of Cement Suspensions for Soil Improvement

Christodoulou Dimitrios1* and Tsiatsiava Foteini2

1Assistant Professor, Department of Environmental Sciences, University of Thessaly, Larissa, Greece

2Environmental Engineer, M.Sc., Wastewater Treatment Plant Manager, Hellenic Dairies S.A., Trikala, Greece

*Corresponding author: Christodoulou Dimitrios, Assistant Professor, Department of Environmental Sciences, University of Thessaly, Campus Gaiopolis, Larissa, Greece

Submission: March 06, 2023; Published: March 29, 2023

.jpg)

ISSN:2694-4421 Volume3 Issue2

Abstract

Improvement of the properties and mechanical behavior of soils can be carried out in-situ by carrying out an appropriate injection program. Injection is defined as the process of injecting, under pressure, a fluid material to the required depth from the ground surface. The injection material, which is either a suspension of solid granules in water or a solution of chemicals, displaces soil pore water and sets or solidifies in a short time. The selection of the optimal suspension for the needs of a technical project must be the subject of thorough investigation and documentation and is primarily determined by its properties always combined with the specialized requirements of each application. The criteria, which advocate or not in the selection of an optimal suspension, are related to penetration, setting times, developing strength, stability, rheological properties, permeability, permanence, shrinkage, etc. In this work, the effect of the viscosity and more generally of the rheological properties of cement grouts on injectability is studied with the aim of improving soil formations.

Keywords:Permeation grouting; Cement suspension; Viscosity; Rheological properties

Introduction to Injections

Improvement of the properties and mechanical behavior of soils can be carried out insitu by carrying out an appropriate injection program. Injection is defined as the process of injecting, under pressure, a fluid material to the required depth from the ground surface. The injection material, which is either a suspension of solid granules in water or a solution of chemicals, displaces soil pore water and sets or solidifies in a short time. Suspensions have lower cost and are harmless to the environment but cannot be injected into soils with gradations finer than coarse sands. Chemical solutions can be injected in fine sands or coarse silts but are more expensive and some of them pose a health and environmental hazard. Injections are generally aimed either at increasing the shear strength, density and stiffness of the soil or at reducing compressibility and permeability. The selection of the optimal suspension for the needs of a technical project must be the subject of thorough investigation and documentation and is primarily determined by its properties always combined with the specialized requirements of each application. The criteria, which advocate or not in the selection of an optimal suspension, are related to penetration, setting times, strength, stability, rheological properties, permeability, permanence, shrinkage, etc. Determining and documenting the properties of the suspensions is the first approach to choosing the best solution. The method of soil improvement with cement injections has been the subject of many research efforts [1-9]

Properties of suspensions

The selection of the optimal suspension for the needs of a technical project must be the subject of thorough investigation and documentation and is primarily determined by its properties always combined with the specialized requirements of each application. The criteria, which advocate or not in the selection of an optimal suspension, are related to penetration, setting times, developing strength, stability, rheological properties, permeability, permanence, shrinkage, etc. Determining and documenting the properties of the suspensions is the first approach to choosing the best solution. However, the final choice presupposes the investigation of further influencing parameters such as reasons of economy and particular requirements of each technical project.

Rheological properties

It is now accepted that the rheological properties of a cement slurry significantly determine the success of a grout injection, particularly in those cases where no geometric constraints arise from the size relationship between soil voids and slurry solids. For this reason, it is considered necessary to determine the rheological characteristics of the suspensions during the design phase of an impregnation injection program, so that the optimal suspensions can be selected on a case-by-case basis. In general, determining the rheological behavior of a cement slurry is not an easy task, as there are many factors that interfere with it and have countervailing effects. In the following, information related to the effect of these factors on the rheological behavior of cement suspensions is given. First, however, it is deemed necessary to give a brief introduction to some rheology concepts in order to better understand the information given in this paragraph.

It is known that a fluid is deformed under the influence of a certain force, a phenomenon that is perceived by an observer as a flow. This force is called shear and its ratio with respect to the unit surface area of the fluid gives the shear stress, τ, (shear stress), which is what causes the flow. The ratio dv/dy is called the velocity gradient and is the measure of the speed with which the fluid is deformed due to the effect of a certain shear stress. For this reason, the velocity gradient is better known as shear rate or simply shear rate. The relationship between shear stress and shear strain rate is fundamental in the theory of fluid motion, as it is the one that primarily describes their rheological behavior.

In Newtonian Fluids the two quantities are proportional to each other and are related through the constant μ, which is known as “absolute” or “dynamic” viscosity. According to ASCE, viscosity is defined as the internal force of fluids, which allows them to resist flow [10]. The mathematical expression of the above relationship is as follows:

The value of the potential viscosity is determined experimentally by viscosity measurements, which are carried out using suitable instruments called viscometers. It can be seen that for each Newtonian fluid the value of the viscosity is unique and is independent of the value obtained by the rate of shear deformation during the experimental process. In contrast, in non- Newtonian fluids the relationship between shear stress and shear strain rate is not constant but depends on the value of the shear strain rate. More specifically, when performing viscometry in a non- Newtonian fluid the reading of the viscometer changes depending on the value of the shear strain rate with which the experiment is performed. The indication obtained in these cases corresponds to the so-called “viscosity effect”, which represents the behavior of a fluid at a specific shear rate. By taking a series of such apparent viscosity measurements a flow curve is produced by plotting shear stress as a function of shear rate. Curves of this type are called rheological and are extremely useful, as depending on their form fluids are classified into various rheological models, which are used to describe their rheological behavior.

Based on the type of rheological behavior they exhibit, depending on the rate of shear deformation they undergo, non- Newtonian fluids are classified as pseudoplastic, dilatant or viscoplastic (or simply viscoplastic). Pseudoplastic fluids show a decrease in viscosity when the shear strain rate increases. This phenomenon can be likened to a “thinning” of the fluid and for this reason this behavior is called “shear thinning”. In contrast, swelling fluids exhibit an increase in viscosity with increasing shear rate and accordingly this rheological behavior is called “shear thickening”. Fluids are called viscoplastics, which under resting conditions behave as solids and can flow if subjected to a shear stress greater than a characteristic value called “coherence” or “yield stress”. Any viscoplastic fluid, once the value of the consistency it displays is exceeded, it is possible to behave either as pseudoplastic or as swelling or even as Newtonian. The simplest form of viscoplastic fluid is the “Bingham-type” fluid, which once in flow exhibits Newtonian behavior. The motion of Bingham type fluids is described mathematically by the following equation:

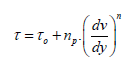

The slope of this line with respect to the horizontal is equal to the plastic viscosity, np, while the cohesion, the, corresponds to the point of intersection of the line with the shear stress axis and is equal to the stress that must be overcome for the fluid to begin to flow. flows. The concept of plastic viscosity is very important as it is equivalent to the viscosity value that the Bingham type fluid would have if it behaved Newtonian, under the influence of the same shear strain rate. Finally, non-Newtonian fluids can be classified as either rheopectic or thixotropic, depending on how their rheological behavior changes as a function of shear time and under constant shear rate conditions. Fluids that show an increase in viscosity with an increase in shear time are considered rheopectic, while on the contrary, thixotropic fluids show a decrease in viscosity with an increase in shear time. In general, the Bingham-type fluid model is used to describe the rheological behavior of cement suspensions [11-13] as it is considered simplistic [14,15] but at the same time quite effective and particularly practical in field applications [14]. However, it is generally accepted that the behavior of cement suspensions is more complex, as viscosity tests have shown that the plastic viscosity does not remain constant, and the cohesion cannot be precisely defined [14]. In particular, it has been shown that cement slurries with low water-to-cement ratios (≤1:1) behave as viscoplastic fluids exhibiting pseudoplastic behavior after the initiation of flow [16-18]. Probably, in those cases where the concentration of solids is high, the use of the Herschel-Bulkley rheological model-mathematically described by the following equation-is a better choice for describing the rheological behavior [19].

Conversely, cement suspensions with high water-to-cement ratios (≥ 4:1) can be considered as Newtonian fluids, since the value of cohesion in this case takes very low values [12,20,21]. Regarding the characterization of the rheological behavior of cement suspensions as a function of time, it has been found that they can exhibit either thixotropic [16,17] or photocoagulation behavior [22]. This observation, however, applies to suspensions with low water-to-cement ratios (≤1:1), as it has been found that thinner suspensions do not change their viscosity as a function of shear time. In general, the use of thixotropic suspensions is preferred in cases of filling large voids, as it is desired that the viscosity remains low during turbulent flow but increases significantly when the suspension is at rest [12].

As noted earlier, the basic rheological characteristics of cement suspensions are consistency and plastic viscosity. Cohesion is considered to play an important role in the injectability and penetrability of the grout, as it determines the distance a suspension can penetrate. This is because it defines the value of the impregnation pressure required to start flow and determines the penetration length at which the impregnation pressure equalizes, and flow stops. On the other hand, viscosity controls the rate of impregnation, and it depends on the behavior of the suspension when it is in a flow state [12,18,23]. Cohesion and viscosity values must be adjusted appropriately so that control is not lost, and the injection process is optimized [12]. The process of optimizing the rheological characteristics of cement suspensions is not particularly difficult, as there are several methods by which they can be controlled. These methods provide either the addition of certain components to the composition of the suspensions or the use of an appropriate type of cement or the change of the water-tocement ratio.

Pure cement slurries exhibit viscosities ranging from 5cP to 100cP [24] and increased cohesion, indicating that, in general, improvement of their rheological characteristics is required. According to Gouvenot [25], in order to achieve satisfactory results in impregnation injections, suspensions with a viscosity no greater than 5cP should be used, while Kutzner [24] states that the consistency of suspensions should not exceed 50Pa in applications field. The most popular method of reducing the viscosity and consistency of cement suspensions is the use of super fluidizers [26,27]. In fact, the use of super fluidizers can lead to significant variations in the rheological model to which cement suspensions obey, as it is possible from viscoplastic fluids with pseudoplastic behavior during flow to be transformed into Newtonian fluids [28]. The range of reductions achieved in viscosity and consistency values depends on both content and type of super fluidizer [12,16,29,30]. Of course, an uncontrolled increase in the super fluidizer content can lead to a change in the behavior of the suspensions and bring about the opposite of the desired results. Also, incompatibility phenomena between cement types and some superplasticizers have been observed and for this reason, any formulations of superplasticizer suspensions should be checked by preliminary tests in the laboratory [29]. Many times, and especially in cases where it is desired to limit the penetration length, the combined use of super fluidizers with flow regulators (e.g., welan gum) is suggested, which causes an increase in consistency and viscosity [31]. In this way, the effect of the super fluidizers is balanced, the quality of the suspension is not altered and consistency and viscosity values closer to the desired ones can be obtained [30]. There are other chemical improvers that are used in cement suspension compositions, but for other reasons, which indirectly affect the rheological characteristics of the suspensions. Characteristically, the use of setting accelerators (e.g., calcium chloride, sodium silicate) is reported to cause an increase in viscosity [26,32]. while the use of Isopropyl Alcohol (IPA) as a retarding agent causes a drastic reduction in viscosity [16].

The use of certain additives causes undesirable effects regarding the rheological characteristics of cement suspensions. It is considered known that cement-bentonite suspensions behave as Bingham-type fluids [33]. It has been found that the presence of bentonite causes an increase in cohesion and less in viscosity [5,14] while at the same time it induces thixotropic behavior in cement suspensions [26,34]. For this reason, bentonite should be used as an improving rheological agent only in those cases where it is desired to limit the permeability of suspensions [33]. In Italy, with the production of MISTRA suspensions, a significant reduction of the negative effects caused by the use of bentonite on the rheological behavior of the suspensions has been achieved [21]. Cement slurries containing fly ash, silica fume and natural pozzolan exhibit similar behavior [29,35]. In fact, the presence of silica fume in cement suspensions is reported to induce thixotropic behavior characteristics in the suspensions [36].

This effect of additives on the rheological characteristics of cement suspensions is attributed to the fact that these are finegrained materials with a grain size smaller than that of cement grains. This has the effect of increasing the specific surface area of the solids within the suspensions which leads to the capture of a greater amount of water reducing that remaining available for the flow of the suspension. This phenomenon takes on even greater dimensions in those cases where a finer cement than common cement is used as the basis of the suspension [11,29]. which is due to the greater reactivity of the cements. in relation to pozzolans. In general, it has been observed that increasing the specific surface area of cement leads to the preparation of suspensions with significantly higher values of cohesion and viscosity [26,37,38]. For this reason, during the preparation of fine-grained cements, the use of super fluidizers is considered imperative [14,38] while the use of bentonite should be avoided [14]. In addition, it has been shown that the type of cement plays an important role in the rheological characteristics of the suspensions. In particular, suspensions based on fine slag cements show significantly lower viscosity and cohesion values than corresponding Portland cement suspensions of comparable fineness, which is a consequence of the low reactivity of the slag [16]. In fact, suspensions of finegrained slag cements show a lower viscosity and cohesion than suspensions of ordinary Portland cements. This difference in viscosity values is more significant at lower water-to-cement ratios (≤1:1) and decreases considerably at higher W/C ratios [3,29]. The

effect on the magnitude of viscosity and consistency of cement suspensions caused by the W/C ratio is significant. Increased W/C ratios provide greater amounts of water available for suspension flow, which translates into suspensions as a reduced viscosity and consistency value, as documented by many research efforts [13]. These decreases are more evident at lower W/C ratios (≤ 2:1) and appear to display an exponential form [16,39]. Conversely, at high ratios (W/C ≥ 4:1) the variations in viscosity due to a change in the W/C ratio can be considered negligible. This is attributed to the fact that at high W/C ratios the cement grains are separated quite well so that the contacts between them - which could affect the viscosity are few [13,29]. Mixing time has a similar effect on the consistency of suspensions, but only in cases where the W/C ratio is low enough [39]

Discussion

Based on the available literature, the following conclusions can

be advanced:

a. The rheological properties of a cement slurry significantly

determine the success of a grout injection, particularly in

those cases where no geometric constraints arise from the size

relationship between soil voids and slurry solids.

b. The Bingham-type fluid model is used to describe the

rheological behavior of cement suspensions.

c. The behavior of cement suspensions is complex, as viscosity

tests have shown that the plastic viscosity does not remain

constant, and the consistency cannot be precisely defined.

d. In cases where the concentration of solids is high, using the

Herschel-Bulkley rheological model is a better choice to

describe the rheological behavior.

e. Cement slurries with high water-to-cement ratios (≥ 4:1) can

be considered as Newtonian fluids, since the value of cohesion

in this case takes very low values.

f. Regarding the characterization of the rheological behavior of

cement suspensions as a function of time, it has been found

that they can exhibit either thixotropic or reocoagulation

behavior.

g. The use of thixotropic suspensions is preferred in cases of

filling large voids, as it is desired that the viscosity remains

low during turbulent flow but increases significantly when the

suspension is at rest.

h. Viscosity controls the rate of impregnation and on this depends

on the behavior of the suspension when it is in a flow state.

References

- Markou IN (1995) Crushed greek lignite fly ash as a suspension-type injection material for the in-situ improvement- reinforcement of soils. Ph.D. Thesis, Department of Civil Engineering, University of Patras, Greece.

- Christodoulou DN (2009) Groutability ratios’ investigation and improvement of suspensions for soil grouting. Ph.D. Thesis, Department of Civil Engineering, Democritus University of Thrace, Xanthi, Greece, p. 370.

- Atmatzidis DK (1990) Improvements of soils with injections. University Notes, University of Patras, Greece.

- Saada Z, Canou J, Dormieux L, Dupla JC, Maghous S (2005) Modelling of cement suspension flow in granular porous media. International Journal for Numerical and Analytical Methods in Geomechanics 27(7): 691-711.

- Bruce AD, Littlejohn S, Naudts CA (1997) Grouting materials for ground treatment: A practitioners guide. In: Vipul Anandan C (Ed.), Proceedings, Conference on Grouting: Compaction, Remediation, Testing, New York, USA, 66: 306-334.

- Christodoulou DN, Droudakis AI, Pantazopoulos IA, Markou IN, Atmatzidis DK (2009) Groutability and effectiveness of microfine cement grouts. In: Hamza (Ed.), Proceedings, 17th International Conference on Soil Mechanics and Geotechnical Engineering: The Academia and Practice of Geotechnical Engineering, IOS Press, Alexandria, Egypt, 3: 2232-2235.

- Pantazopoulos IA, Markou IN, Christodoulou DN, Droudakis AI, Atmatzidis DK, et al. (2012) Development of microfine cement grouts by pulverizing ordinary cement. Cement and Concrete Composites 34(5): 593-603.

- Markou IN, Christodoulou DN, Papadopoulos BK (2015) Penetrability of microfine cement grouts: Experimental investigation and fuzzy regression modeling. Canadian Geotechnical Journal 52(7): 868-882.

- Krizek RJ, Helal M (1992) Anisotropic behavior of cement grouted sand. In: Borden RH, Holtz RD, Juran I (Eds.), Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics, Geotechnical Publication No. 30, New York, USA, 1: 541-550.

- Saleh K, Mirza J, Ballivy G, Mnif T (1993) Selection criteria for portland and microfine cement-based injection grouts. Proceedings, International Conference on Grouting in Rock and Concrete, Balkema, Salzburg, Austria, pp. 97-105.

- Littlejohn GS (1982) Design of cement-based grouts. In: Baker WH (Ed.), Proceedings, Conference on Grouting in Geotechnical Engineering, New Orleans, Louisiana, USA, 1: 35-48.

- Chuaqui M, Bruce DA (2003) Mix design and quality control procedures for high mobility cement-based grouts. In: Johnsen FL, Bruce AD, Byle JM (Eds.), Proceedings of the 3rd International Conference on Grouting and Ground Treatment, Geotechnical Special Publication No. 120, ASCE, New York, USA, 2: 1153-1168.

- Axelsson M, Gustafson G (2007) Grouting with high water/solid-ratios-Literature and laboratory study. Technical Report No. 2007, Department of Civil and Environmental Engineering, Division of GeoEngineering Research Group of Engineering Geology, Chalmers University of Technology, Göteborg, Sweden.

- Bremen R (1997) The use of additives in cement grouts. International Journal of Hydropower and Dams 4(1): 71-76.

- Ancey C, Balmforth NJ, Frigaard I (2007) Visco-plastic fluids: From theory to application. (Preprint submitted to Elsevier), Workshop on Viscoplasticity: From Theory to Application, Organised by EPFL, Monte Verita, Ticino, Switzerland.

- Schwarz LG, Krizek RJ (2000) Evolving morphology of early age microfine cement grout. Proceedings of the GeoDenver 2000 Conference “Advances in Grouting and Ground Modification”, Geotechnical Special Publication No. 104, ASCE, Reston, VA, USA, pp. 181-199.

- Saric CM, Khayat KH, Tagnit HA (2003) Performance characteristics of cement grouts made with various combinations of high-range water reducer and cellulose-based viscosity modifier. Cement and Concrete Research 33(12): 1999-2008.

- Eklund D (2005) Penetrability due to filtration tendency of cement-based grouts. Doctoral Thesis, Division of Soil and Rock Mechanics, Royal Institute of Technology, Stockholm, Sweden.

- Hansson P (1996) Filtration stability of cementitious injections grouts with low w/c ratio. Conference Paper of Concrete in the Service of Mankind Concrete Repair, Rehabilitation and Protection, Dundee, Scotland, pp. 303-311.

- Arenzana L, Krizek RJ, Pepper SF (1989) Injection of dilute microfine cement suspensions into fine sands. In: Balkema AA (Ed.), Proceedings of the International Conference on Soil Mechanics and Foundation Engineering, Rotterdam, The Netherlands 2: 1331-1334.

- De PB, Bosco B, Granata R, Bruce DA (1992) Fundamental observations on cement-based grouts (1): Traditional material. In: Borden RH, Holtz RD, Juran I (Eds.), Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics, Geotechnical Publication No. 30, New Orleans, Louisiana, USA, 1: 474-485.

- Guan X, Hu S, Guan B (2002) Research on properties of microfine cement-based material for grouting. Proceedings in Mining Science and Safety Technology, pp. 582-587.

- Eriksson M, Stille H (2003) A method for measuring and evaluating the permeability of grouts. In: Johnsen FL, Bruce AD, Byle JM (Eds.), Proceedings of the 3rd International Conference on Grouting and Ground Treatment, Geotechnical Special Publication No. 120, New York, USA, 2: 1326-1337.

- Kutzner C (1982) Grout mixes and grouting work. In: Balkema AA (Ed.), Proceedings, Symposium on Recent Developments in Ground Improvement Techniques, Rotterdam, The Netherlands, Boston, MA, USA, pp. 289-298.

- Gouvenot D (1996) State of the art in european grouting technologies. In: Yonekura R, Terashi M, Shibazaki M (Eds.), Proceedings, Conference on Grouting and Deep Mixing, Tokyo, Japan, AA Balkema, Rotterdam, The Netherlands, 2: 833-850.

- Tolpannen P, Syrjanen P (2003) Hard rock tunnel grouting practice in Finland. Sweden, and Norway: Literature study. Technical Report, Finnish Tunnelling Association.

- Mollamahmutoglu M, Yilmaz Y, Kutlu I (2007) Grouting performance of microfine cement and silica fume mix into sands. Journal of ASTM International, Pennsylvania, USA, 4(4).

- Lau D, Crawford A (1986) Grouting for the underground containment of radioactive waste. Report Prepared for Atomic Energy of Canada Ltd, Dept. of Civil Engineering, University of Torondo, Torondo, Ontario, Canada.

- Perret S, Palardy D, Ballivy G (2000) Rheological behavior and setting time of microfine cement-based grouts. ACI Materials Journal 97(4): 472-478.

- Svermova L, Sonebi M, Bartos PJM (2003) Influence of mix proportions on rheology of cement grouts containing limestone powder. Cement and Concrete Composites 25(7): 737-749.

- Warner (2007) Good rheology assures quality work. Geotechnical Special Publication, Grouting for Ground Improvement: Innovative Concepts and Applications (GSP 168) Geo-Denver 2007: New Peaks in Geotechnics, Proceedings of Sessions of Geo-Denver, Denver, Colorado, USA, (168).

- Vipulanandan C, Ata A, Mebarkia S (1994) Fracture behavior of cement grouted sand. Proceedings of the ASCE National Convention, Fracture Mechanics Geotechnical Special Publication No. 43, ASCE, New York, USA, pp. 147-159.

- Deere DU (1982) Cement-bentonite grouting for dams. In: Baker WH (Ed.), Proceedings, Conference on Grouting in Geotechnical Engineering, ASCE, New York, USA, 1: 279-300.

- Hakansson U, Hassler L, Stille H (1992) Rheological properties of microfine cement grouts with additives. In: Borden RH, Holtz RD, Juran I (Eds.), Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics, Geotechnical Publication No. 30, ASCE, New York, USA, 1: 551-563.

- Santagata MC, Bonora G, Collepardi M (1997) Superplasticized microcement grouts. Proceedings of the CANMET-ACI Conference on Superplasticizers and Other Admixtures in Concrete, Rome, Italy, pp. 177-195.

- Domone PL, Tank SB (1986) Use of condensed silica fume in portland cement grouts. In: Malhotra VM (Ed.), Proceedings, Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, 2nd International Conference, Madrid, Spain, 2: 1231-1260.

- Mollamahmutoglu M (2003) Treatment of medium to coarse grained sands by fine grained Portland cement (FGPC) as an alternative grouting material to silicate-ester grouts. Cement, Concrete and Aggregates, ASTM International, Pennsylvania, USA, 25(1): 1-6.

- Henn R, Ganse P, Bandimere S, Smoak G, Warner J (2001) Comparison of penetration test results of grouts made with various ultrafine cement products. In: Amsterdam BV (Ed.), Proceedings of the Rapid Excavation and Tunneling Conference, Elsevier Science, pp. 345-361.

- Ziming W, Daneng H, Yaosheng X (1990) Investigation of the rheological properties and groutability of fresh cement pastes. In: Banfill PFG (Ed.), Proceedings, Rheology of Fresh Cement and Concrete, International Conference organized by the British Society of Rheology, University of Liverpool, UK, E & FN Spon, London, England, pp. 207-213.

© 2023 Christodoulou Dimitrios. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)