- Submissions

Full Text

Academic Journal of Engineering Studies

Design a VAT milk pasteurizer in Tanzania

Vicent Marwa*

Department of Mechanical Engineering, Tanzania

*Corresponding author: Vicent Marwa, Department of Mechanical Engineering, Tanzania

Submission: September 21, 2020 Published: April 09, 2021

.jpg)

ISSN:2694-4421 Volume1 Issue5

Abstract

The project presents “Design of micro-VAT milk pasteurizer” The microcontroller temperature regulator provides an automated way of controlling the temperature of a given pasteurizer for pasteurizing the milk at a given temperature (63 oC for 30 minutes). This project is realizable via temperature sensing, signal conditioning and relaying. The temperature sensor senses the current of the said pasteurizer, send it to the ADC (Analogue to Digital Converter) the digitized signal is then sent a controller which through the help of a programmed input (software), does the comparison and control by sending a feedback signal to the heating element thereby bringing about the regulation of the temperature of the said pasteurizer. A great advantage of this project is that it provides automated, and it is reliable, if there can be a constant power supply to the system. It is also economical in construction. Agricultural products such as milk in their raw state have harmful organisms such as viruses and bacterial that are known for causing diseases when consumed. For safe consumption and healthy leaving, this organism needs to be reduced or eliminated.

Introduction

Tanzania is among the fastest growing dairy nation in Africa, accounts for about 1.4% of

global cattle population and 11% of Africa cattle population [1]. With increase in population

and enhancement in lifestyle of the people the demand for the dairy and food products is

increased day by day. Milk and its products are fundamental in human nutrition. Milk

contains essential minerals, high quality protein, fats and vitamins. These makes milk to be

a very important and complete diet on its own. Milk is a perishable foodstuff which when

improperly handled is an excellent medium for the growth of micro-organisms which cause

spoilage [2]. Milk is considered safe for consumption when it contains 5×106 bacterial per ml

[3]. Milk products and their cost are determined by an effective design of a heat treatment

plant. The qualities of consumables and human lifestyle have been affected to a high degree

by the application of heat transfer. Greiner and Bussick, (2000) opined that the understanding

and control of heat flow through heat exchangers, thermal insulations and other supporting

devices are frequently used in solving basic or fundamental human problems which have

made heat transfer a field of importance to Engineering.

A process named after scientist Louis Pasteur which uses the application of heat to destroy

human pathogens in foods. For the dairy industry, the terms “pasteurization”, “pasteurized”

and similar terms shall mean the process of heating every particle of milk or milk product, in

properly designed and operated equipment, at a specific temperature and held continuously

at or above that temperature for at least the corresponding specified time. Pasteurization

is a mild heat treatment applied to ensure microbial safety and to supply milk with longer

shelf life. In this process, milk is heated at 72 ºC for 15s or 63 ºC for 30min [4]. In liquid food

industries, heat exchangers for many years have become an essential component in the process

line Temperature control loops are often used with heat exchangers in a heat transfer process

in other to maintain an accurate and stable temperature. Temperature is a critical parameter

to the health and product quality in the case of food heat treatment. The consumption of

contaminated liquids and other liquid foods (milk inclusive) has been attributed to the

cause of about 80% of infectious diseases including diarrhea, typhoid, cholera in developing

countries. Heat treatment of liquid food is important because the death of over 400 children

per hour in the world and nearly more than four million children per year has been attributed

to diarrhoea by the World Health Organization (WHO). The direct consumption of over the

air water and liquid food without heat treatment has created tremendous stress on both huge

medical bills and health which in turn results into high morbidity. About a thousand faecal coli form per decilitre is found to be contained in surface water and this

is due to pollution from animals and human life activities.

Speer (1998) acknowledged that the consumption of fresh raw

milk led to the transmission of cow diseases such as typhoid, brucellosis

and tuberculosis. In other to make surface water and dairy

products safe for human consumption, there is therefore needed

to have a design which will heat treat these raw consumables thus,

pasteurization comes in. Milk production in Tanzania is carried out

under two major production systems. These are the traditional and

the dairy production systems. Within the traditional system milk is

mainly produced by indigenous cattle which are kept for multipurpose

objectives. The traditional system is characterized by low productivity,

but high per unit of invested money. the milk produced is

mostly consumed locally and quite often a significant amount is left

for the calves because of the lack of markets. Within the dairy systems,

improved dairy cattle which are mainly crosses of Friesian,

Jersey and Ayrshire to the Tanzania Shorthorn Zebu are the main

dairy cattle breeds in use (MLFD, 2011). Low consumer demand for

milk and dairy products due to high retail prices and low incomes of

the population which hinders the growth of agricultural production

One of the ways to overcome this contradiction is the development

of the free market competition. According to Elliot et al. (2007) the

actual definition of pasteurization is the heating of milk to specific

temperature for a specific time to reduce undesirable enzymes and

bacterial to negligible level. It is important that pasteurization is a

function of time and temperature not just temperature. Imele et al.

[5] reported that pasteurization is a process to prevent the spoilage

of milk. It has been used since the early 1900s (heating raw milk to

72 OC for 15 minutes). It is expected to remove/reduce microorganisms

from milk.

Problem statement

Traditional milk production in Tanzania, milk is mainly produced by indigenous cattle which are kept for multipurpose objectives. The indigenous cattle which constitute the traditional herd are mainly kept in the Central, Northern, Southern Highlands, and Western parts of the country (Figure 1). The traditional system is characterized by low productivity, but high per unit of invested money. In addition, production costs are relatively low. Due to the remoteness and poor infrastructure, collection of milk and marketing constitute the largest bottlenecks. Hence, the milk produced is mostly consumed locally and quite often a significant amount is left for the calves because of the lack of markets. However, some producers who depend on milk for their cash income are willing to exploit the available opportunity in marketing their produce, for example, some traditional producers residing mainly in peri-urban areas near towns or urban centers such as those in the Tukuyu, transport milk by bicycles over long distances, for sale at some collection centers located along the major road highways. Through observations and realization of milk association in Tukuyu area. The researcher discovered that the livestock keeping are experiencing difficulties in milk preservation and therefore a need for design machine to overcome milk spoilage.

Figure 1: Production of milk 2000/01-2009/10 (MLFD,2011).

Method and Equipment

Equipment and method used for studies on electrical water heating system in water jacket for pasteurization of milk. The experiment on performance evaluation were carried out in the Mechanical and Industrial Engineering Department at the college of Mbeya University of Science and Technology, MUST.

Machine description

The mini plant was constructed using stainless steel material and it made of the following components (Figure 2).

Figure 2: Complete assembly of machine source (Researcher).

Heating unit: The vat pasteurizer jacket is a double-walled covering. In the space between the walls, circulating water which heat the product in the vat. This unit is made up of the following sub-component parts, milk tank, water jacket, coil heater milk inlet and outlet valve, water inlet and outlet valve and insulation case.

Agitation assembly: An agitator is designed to keep milk or milk product moving at all times by running constantly during the pasteurization cycle. This results in uniform product and temperature throughout the vat. This unit is made up of the following sub-component parts motor, shaft and bleed.

Control system: A constant pasteurization temperature is maintained by a temperature controller acting on the heater. Any tendency for the product temperature to drop is immediately detected by a sensor in the product line before the holding tube. The sensor then changes the signal to the controller, which turns on the water heater to rise the temperature of water. This increases the temperature of the circulating water and stops the temperature drop in the product.

Frame and support: The design of the stand of VAT pasteurizer machine is essential for this work. Stainless steel material was used in design based on its availability, strength, appearance, food processing standard, and corrosion resistance. The design was based to determine forces acting on machine (Figure 3).

Figure 3:Power curve for turbine type agitator (Saeed Asiri, et al., 2012).

Mode of operation of the machine

The method used in pasteurization is called holding method in which milk or milk product is rapidly heated, but the temperature is not less than 63 ºC and not more than 66 ºC, it retained at that temperature for not less than 30 minutes. Therefore, working operation is to maintain milk temperature in the range of 63 ℃-66 ℃ for not less than 30 minutes it is done by heating milk to 63 ℃ after reaching that temperature we switch off electric heater automatic and start counting time with aid of Arduino, temperature sensor and Liquid Crystal Display (LCD).

Materials selection

Small scale soya milk production and pasteurization plant was designed and fabricated in the workshop at Mbeya University of Science and Technology (MUST) using stainless steel materials. All parts of the plants that will get in direct contact with the product were made with stainless steel materials in order to avoid contamination [6]; (Figure 3).

Testing and statistical analysis

Experiments were conducted to test the performance of the mini plant. Two different cow milk samples were subject for the period of 168 hours. The samples used were sample (A) raw milk stored at room temperature, (B) raw milk and stored at temperature below 4 ℃ (C) pasteurized milk and stored at room temperature and (D) pasteurized milk and stored at temperature below 4 ℃.

Design analysis of machine components

10 liters capacity batch pasteurizer is analyzed below with 304 grade stainless steel. The size was selected considering the daily quantities of marketed milk by trader’s in Tukuyu Table 1. It has required to find the quantity of heat required to rise the temperature of water for successive pasteurization, geometric parameters of the water jacket (water bath thickness) and design of agitator with the following preset parameters.

Table 1:Initial design parameter.

Geometric parameter of tanks

V = Π / 4D2 h (1)

Where,

V= Volume of tank

D= Diameter of tank

h= height of tank

Geometric parameter of milk tank

0.0102 =π / 4D2 ×0.8D

D=253.2mm≅260mm

From equation (2)

h=0.8×260

h=208mm

Geometric parameter of milk tank

0.0102 =π / 4D2 ×0.8D

D=253.2mm≅260mm

From equation (2)

h=0.8×260

h=208mm

Geometric parameter of water tank

Since all tank are cylindrical assume the water jacket 50 mm

wider than the milk tank

Diameter of water tank D=360mm

Height of water tank h=258mm

Volume of water in jacket

Vw=volume of water tank-volume of milk tank (2)

Vw = 0.0182m3 (Table 2).

Analysis of heat transfer

Table 2:Dimensional specification of milk bath and water jacket.

The quantity of heat spent to heat milk

Q = Gm ×Cm ×ΔT (3)

Where:

Gm = The mass of heated milk (kg)

Cm =Milk heat capacity (KJ/kg)

ΔT =change in temperature in milk.

Gm=ρ×V (4)

Gm=1027×0.01

Gm=10.27kg

Specific heat capacity of milk depends on the temperature. Heat

capacity of milk at the average temperature of 51 ℃ is Cm=3.973kJ/

kg.K

Q=10.27×3.973×(65-37)

Q=1142.476kJ

The motivity of thermal process is temperature difference.

According to the second law of thermodynamic, heat transfer will

carry out from the warmer body to a less heated. The physical sense

of heat transfer is the exchange of energy between molecules, atom,

and free electron, this means that all the heat lost by the water goes

into heating milk.

Heat lost by water = Heat gained by milk (5)

1142.476 =15.2× 4.2× (100-t0)

So, equilibrium temperature of water will be t0 = 81.20C

Logarithmic mean temperature difference

Large temperature difference ΔTl = 100 0C −37 0 C = 63 0C

Small temperature difference ΔTs =82.1 0C −65 0 C = 17.1 0C

(6)

(6)

Amount of heat spent on heating the milk can be found with

Q = K ×ΔT × F (7)

Where

Q= Amount of heat spent on heating the milk

ΔT = Temperature difference

K= Coefficient of heat transfer

F = Heat exchanger area

The heat transfer coefficient can be found with

(8)

(8)

Where

α1=coefficient of heat transfers out of the water to the wall

α2=coefficient of heat transfers from the wall to the product

ƛ= thermal conductivity of stainless food steel

δ= thickness of the material

Convection heat transfer coefficient α

(9)

(9)

Where:

Nu= nusselt number, dimensionless heat transfer coefficient

Rew= Reynolds number, fluid motion criterion regime

Rew= Prandtl number for liquid, dimensionless characteristics

of thermal properties of the fluid

Prwall= Prandtl number for liquid in the boundary layer

Reynold number

(10)

(10)

Where:

Re = Reynold number for liquid in the tube

w = liquid velocity in the tube of the heat exchanger (ms-1)

D = The heat exchanger tube diameter(m)

v= The kinematic viscosity of liquid (m2s−1)

Convection thermal conductivity

(11)

(11)

Where

α=Convection thermal conductivity

Nu=Nusselt number, dimensionless heat transfer coefficient

ƛ=Thermal conductivity of liquid

Coefficient of heat transfers out of the water to the wall

To improve the heat transfer from the water to the wall of heat exchanger need to create a turbulent flow of fluid motion [7].

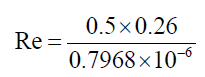

Velocity of water in jacket we will mark as ww = 0.5ms-1

Kinematic viscosity of water at average temperature of 910C is νw= 0.3377×10-6M2/C

Diameter of water jacket 50mm

Re > 4000movement of water in the jacket is considered to be turbulent [8]

Prandtl number of waters in the exchanger with an average temperature of 91 °C is 2.028 Pγw =

In the boundary layer water temperature would be 2 °C below than in existing the heat exchanger [7]

Prandtl number of water in the boundary at temperature of 80 °C is Pγwall 2.516

Nu = 302.88

Thermal conductivity of water depends on temperature [9]. Thermal conductivity of water at average temperature of 91 °C ƛw=0.6782 W/mK

α1 = 4108.26W / m2.K

Coefficient of heat transfers from the wall to the product

Diameter of milk bath 260mm

kinematics viscosity of milk at 51 0C νm =0.7968× 10-6 m2 / s

Velocity of milk in bath we will mark as wm = 0.5ms-1

Re =163152.61

Re > 4000 movement of milk in the jacket is considered to be turbulent [9]

Prandtl number of waters in the exchanger with an average temperature of 51 °C is Pγm= 5.547

In the boundary layer temperature of the milk would be 2 °C high than the temperature required for pasteurization [10]

Prandtl number of milk in the boundary at temperature of 67 °C is Pγwall=4.14

Thermal conductivity of milk depends on temperature [10]. Thermal conductivity of water at average temperature of 51 °C ƛm =0.578 W/m.K

Lateral surface area of the bath can be found by formula to find lateral surface of cylinder

s = 2.π .γ . h (13)

s = 2×3.14×0.13×0.208

s = 0.1698m2

When comparing the heat transfer area F and lateral surface area S of the bath, we obtain that S>F consequently, heating milk in the bath will right selected heat exchanger is possible.

Design of agitator

Power required for agitation

Power required to operate an agitator depends on several factors such as the properties of the liquid, agitator type and size, the tank or vessel size and speed of agitation [11]

P = N × N3 ×Da5 ×ρ (14)

Where

P= Power required for agitation

Np=Power number

N= Speed of agitator

Da= Agitator diameter

ρ = Density of liquid

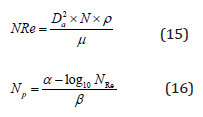

In unbaffled vessel the relation between function power number N_p and Reynold number Re is given

Where

NFr= Fraude number

μ=Dynamic viscosity

α and β are given as the function of diameter of the agitator (Table 3).

Table 3: Value of α and β are given as the function of diameter of the agitator.

(17)

(17)

Using the velocity of milk in the bath as Wm = 0.5ms−1 then N ≅ 1.5rps then

From the graph above Np= 1.02

Considering 10% gland losses and 20% losses P=36.6W, so motor selection power P=50 W

Design of agitator shaft: A shaft is a rotating machine element which is used to transmit power from one place to another. The power is delivered to the shaft by some tangential force and the resultant torque (or twisting moment) set up within the shaft permits the power to be transferred to various machines linked up to the shaft. In order to transfer the power from one shaft to another, the various members such as pulleys, gears etc., are mounted on it [12]. The agitator shaft was made from a standard AISI type 316 stainless steel that is Austenitic

τmax =0.3Syt (19)

τmax = 0.3Syt (20)

For the selected material of Shaft S316

The ultimate tensile strength, Sut = 515N/mm2

The Yield stress, Sut = 515N/mm2

Therefore, the allowable shear stress ( τmax ) is;

τmax=0.3× 205 = 61.5 N/mm2

τmax=0.3× 205 = 61.5Nmm2

We take the smallest one,

τ_max= 61.5N / mm2

Agitator shaft will undergo only twisting moment

From the formula

Design of DC power supply

Power supply data analysis

From the block diagram of power supply, first consider transformer only (step down transformer). The transformer steps down AC voltage to DC voltage from 220-224VAC to 12VAC. The ratio of the number of turns on each coil called the turn’s ratio, determine the ratio of the voltages.

(23)

(23)

Rectifier

Consider Figure 4,

Figure 4:Bridge rectifier circuit (Source: Author).

Filter

Unfiltered dc (Voltage Peak rectified)

Vp(rect)=Vpeak(sec) − 1.4V= 16.55 −1.4 =15.15V

Taking ripple factor of 3.97%, then capacitor will be.

(Figure 5)

Figure 5:Power supply (Source: Author).

Microcontroller selection

The Table 4 shows data gathered for different microcontrollers. The ATmega32 and ATmega8 are rejected and ATmega328p is selected to be used with board because of the following features.

Table 4:Data gathered for microcontrollers.

a. Low power device compared to other

b. Wide voltage range compared to other two devices

c. High operating speed

d. Low cost

The reason for using atmega328p with Arduino boards is that,

i) Inexpensive-Arduino boards are relatively inexpensive

compared to other microcontroller platforms

ii) Its programming language is simple (Arduino language)

iii) No need of external programmer

iv) Ease to use, as it has built in pins outs for providing you

with 5v, 3.3v, ground, analog input, digital output, SPI, 12C etc.

v) Cross-platform-The Arduino software runs on

windows, Macintosh SX, and Linux operating systems. Most

microcontroller system are limited to window

The transistor switch design

The transistor switch is used to drive the electromagnetic relay to switch on or off the appliances (electric heater). The type of the electromagnetic relay is 12V single pole double throw and the resistance of the coil 240𝜴 (Figure 6).

Figure 6:Relay switch.

The transistor switch analysis

The input voltage = 5V

The power supply source = 5V

The relay coil resistance = 240Ω/ 5VF

The collector current of the transistor:

The base resistance of the transistor:

The best choice of the transistor to use is 6.869kΩ .

Designed circuit diagram

(Figure 7).

Figure 7:Designed circuit (Source: Researcher).

Result and Discussion

The results and discussion of the experiment carried out during evaluating the performance of Electrical water heating system assisted with heat exchanger to study its application for pasteurization of milk are presented in this chapter in order to fulfill the objective for which the project was undertaken. The data recorded during the course of investigation were analyzed suitably and presented as per the need. The results have been discussed, inferences are drawn and possible reason for them are given under the following subheadings along with the table and suitable illustrations.

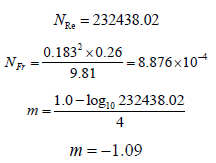

Performance evaluation of heat exchanger

The performance of heat exchanger was evaluated using

electrical heated water. This experiment was carried out four times

for each volume of milk at 4,6,8 and 10 liters and the volume of

water in a jacket at 5, 10,15,20 liters. The parameter like rate of

heat transfer on the basis of heat transfer from hot water in jacket

to milk in milk tank and on the basis of time taken to reach the

temperature were calculated during the course of experiment.

Rate of heat transfer (Q): Rate of heat transfer (Q) is the

measure of the quantity of heat transferred from one medium to

another. in order to evaluate heat required to rise the temperature

of milk till pasteurization temperature, the heat rate from hot water

to cold milk was calculated. Effect of effect of volume of hot water

and volume of milk on the heat transfer rate (Q_h). The values of heat transfer from hot water (Q_h) was calculated by putting the

value of different variables like mass flow rate of hot water (M_h),

specific heat of hot water (C_ph) and the difference between

temperature of hot water, same data were calculated and is shown.

Effect of effect of volume of hot water and volume of milk on the

heat transfer rate (Q_h) is shown in Figure 8. The values obtained

for rate of heat transfer in the present study were in alignment with

the trend observed by Alawa et al. [13], Kee et al. [14] & Agrawal

and Bhagoria [15] They also reported that when flow rate of hot

water increased, the rate of heat transfer increased simultaneously.

The statistical analysis was done to evaluate the effect of each

independent variable (volume of hot) on the dependent variable

(heat transfer rate from hot water) (Table 5).

Figure 8:Effect of volume of hot water and volume of milk on the heat transfer rate (Source Researcher).

Table 5:Rate of heat flow.

Quality of pasteurized milk

The effect of electrical water heating system on quality of pasteurized milk was studied and compared with raw milk. The sample of raw and pasteurized milk were analyzed for parameter like number of days the milk sample can stay fresh. Nwobosi et al. [16] reported that the major disadvantage of spoilage organism in milk is that they easily multiply and cause unwanted effect. Analysis and comparison were made among two samples of cow milk and stored under the temperature of 4 °C as shown in the Table 6; [17-20].

Table 6:Results of milk sample.

Conclusion

Despite the existence of pasteurization and its advocacy worldwide, most marketed milk in a developing country like Tanzania are sold raw by the locals [21-25]. Boiled milk ends up curdling which results into a loss of nutrients, so it is not beneficial to treat milk by this method. Therefore, adequate pasteurization of raw milk before consumption must be enforced, demands that it’s readily affordable in terms of cost and maintenance which at the moment, plants of such small capacities for pasteurization of milk are rare. The mini plant was designed, fabricated (using stainless steel materials) and tested. The findings of the study were analyzed, and these conclusions were made [26-29]. The machine input capacity was 10 liters of milk after 30 minutes. The selected pasteurization temperature and time were 65 °C and 30 minutes. The machine was able to increase shelf life of raw cow milk from 1 to 2 days when stored under room temperature and to 6 days when stored at temperature of 4 °C [30-34].

Recommendation

Based on the results obtained and the experience gained from the present study, some suggestions for future research [35-39]. Milk pasteurization could be improved and made even more feasible by optimizing the heating capacity of heating element to reduce heating time and hence the total pasteurization time. Providing some means to milk chilling immediate after pasteurization to be cold to temperature of 4 °C.

References

- Food and agriculture Organization (FAO) of the United Nations Region office for Asia and the Pacific bangkok, 2014.

- Atia MF, Mostafa MM, Salam A, El Nano MA (2011) Solar energy utilization for milk pasteurization.

- O Conner CB (1994) Rural diary technology training manual no 1. Addis Ababa: Internal livestock research Institute (ILRI), Kenya.

- Walstra PJ, Wouters TM, Geurts TJ (2006) Dairy science and technology. (2nd edn), CRC Press, Taylor and Francis Group, Florida, USA.

- Imele H, Kamage A, Mendi S (2000) Effect of pasteurization temperature on the total milk flora. Animal Health and Production in Africa 48(3): 177-181.

- Gbabo A, Gana IM, Dauda SM (2012) Effect of blade types on the blending efficiency and milk consistency of a grains drink processing machine. Academic Research International 2(3): 41-49.

- Fellows P (2000) Food processing technology: Principles and practice. (2nd edn), Woodhead Publishing Limited and CRC Press LLC, England and USA.

- Smith PG (2011) Introduction to food process engineering (2nd edn), Springer, Berlin, Germany.

- Singh RP, Heldman D (2013) Introduction to food engineering. (5th edn), Elsiever, Amsterdam, Netherlands.

- Ginzburg AS, Thunders MA, Krasovskaya GI (1980) Thermal and physical characteristics of food products. (2nd edn), Publishing House, Moscow, Russia.

- Asiri S (2012) Design and implementation of differential agitators to maximize agitating performance. Saudi Abrbia 2(6): 98-112.

- Khurmi RS, Gupta JK (2005) Machine design. (5th edn), Eurasia Publishing House, New Delhi, India.

- Alawa BTL, Ohia IO (2013) Performance evaluation of heat exchanger in a polyethylene Plant. International Journal of Engineering and Technology Innovation 3(1): 49-57.

- Kee RJ, Almand B, Blasi J, Rosen B, Hartmann M, et al. (2011) The design, fabrication, and evaluation of a ceramic counter-flow microchannel heat exchanger. Applied Thermal Engineering 31(11-12): 2004-2012.

- Agrawal Y, Bhagoria JL (2011) Heat transfer characteristics of a copper- nickel multi tube with corrugated copper fins in a cross-flow heat exchanger. Indian J Science and Technology 4(11): 1532-1536.

- Nwobosi PNU, Isu NR, Agarry OO (2013) Influence of pasteurization and use of natural tropical preservatives on the quality attributes of tiger nut drink during storage. International Journal of Food and Nutrition Science 2(1): 27-31.

- Baldwin EE, Sokol GJ, Coffin LB (1998) Cyclic strain fatigue studies on AISI type 347 stainless steel. Am Soc Test pp. 17-25.

- Bhandari VB (2010) Design of machine elements. (3rd edn), McGraw Hill Education Publisher, USA.

- Cromie SJ (1991) Microbiological aspect of extended shelf-life products. Australian Journal of Dairy Technol 46(2): 101-104.

- De (2012) Outline of dairy technology. Oxford University Press, UK.

- Ryser ET, Marth EH (2007) Listeria, listeriosis and food safety. (3rd edn), CRC Press, Florida, USA.

- Goddik L, Sandra S (2002) Liquid milk product/pasteurized milk. Encyclopedia of Dairy Science. Academic press, Amsterdam, Netherlands 3: 1627-1632.

- Goksenli, Eryurek IB (2009) Failure analysis of a mixing shaft. Engineering failure analysis.

- Grant IR, Ball HJ, Rowe MT (1999) Effect of higher pasteurization temperature and longer holding times at 72 °C, on the inactivation of mycobacterium paratuberculosis in milk. Letter in applied microbiology 28(6): 461-465.

- Haq IU, Israr K, Salman M, Marry Y, Ali I, et al. (2014) Effect of heat treatment on sensory characteristics and shelf-life of skimmed milk. African Journal of Food Science 8(2): 75-79.

- Holsinger VH, Rajkowski KT, Stabel JR (1997) Milk pasteurisation and safety: A brief history and update. Rev Sci Tech Off Int Epiz 16(2): 441-451.

- Mukhametgaliyev FN, Avkhadiyev FN, Gaynutdinov IG (2011) Specialized reference book of agro-industrial complex industry. Publishing house of the Kazan University, Kazan, Russia.

- Kutz M (2007) Handbook of farm dairy and food machinery.

- Santos MV, Fonseca LFL (2000) Milk quality and mastitis control. lemon Editorial, Sao Paul, Brazil, p. 175.

- Saxena M, Rai P (2013) Microbiological and chemical analysis of raw, pasteurized and UHT milk during preservation in India. International Journal of Chem Tech Research 5(6): 2804-2809.

- Wilson GS (1943) The pasteurization of milk. British Medical Journal 1(4286): 261-262.

- Shah RR, Sekulic DP (2003) Fundamentals of heat exchanger design. John Wiley and Sons, New Jersey, USA.

- Sharma KS, Sehgal N, Kumar A (2003) Dry reagent strips for testing milk pasteurization. Swiss Society of Food Science and Technology 36(6): 567-571.

- Srairi MT, Moudnib J, Rahho L, Hamama A (2006) How do milk condition affect the hygenic guality of raw milk, case study from Moroccan dairy farms. Livestock Research for Rural Development.

- (2010) United Republic of Tanzania, Economic Survey, Tanzania.

- (2017) WAFP. Pasteurizer Operator.

- Winarso D, Herawati, Foekh B (2011) The study of temperature effect and length of pasteurization heating on milk quality. Journal of agriculture and Food Technology 1(8): 137-144.

- Duffie JA, Beckman W (2006) Solar engineering of thermal processes. (3rd edn), John Wiley and Sons, New York, NY.

- Inox E (2007) The welding of stainless. (2nd edn), Materials and Applications Series. Luxembourg.

© 2021 Vicent Marwa. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)