- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Discovering Natural Dyes from Camellia Sinensis and Punica Granatum for Eco-friendly Cotton Fabric Dyeing

Md Shamim Alam*, Md Riaj Uddin, Md Tanvir Ahmed Naim and Khorshed Alam

Department of Textile Engineering, Southeast University, Bangladesh

*Corresponding author:Md Shamim Alam, Department of Textile Engineering, Southeast University, Dhaka-1208, Bangladesh

Submission: April 22, 2024; Published: May 16, 2024

ISSN 2578-0271 Volume10 Issue1

Abstract

Natural dyes have garnered a lot of attention these days as a way to avoid ecological problems related to artificial coloring agents. The goal of this research was to investigate the effects of dyes made from Camellia Sinensis and Punica Granatum on 100% cotton knitted fabric and using Citrus Limon liquid as an acetic acid. In order to obtain an appropriate liquor density and enable the dyes to easily permeate the fabric, the extraction process required the use of a blending machine and a small amount of water. A lab dyeing machine was used to carry out the exhaust method of dyeing, and the fastness properties were evaluated, and color dyeing and testing carried out using data color tool analysis (L*, a*, b*) and shade evaluation. After dyeing, the samples show better shade variation. Each sample’s color difference (DE) was comparable, and the samples’ color fastness to washing and rubbing delivered positive results with a grey scale rating of 4-5. The Department of Textile Engineering at Southeast University’s wet processing laboratory was used as the site for the dyeing and other tests.

Keywords:Tea plant leaves; Camellia Sinensis; Punica Granatum; Pomegranate; Natural dye

Introduction

The textile sector is a leading global polluter of the environment due to the high concentration of chemicals and dyes [1]. For their simplicity and less harmful impact on human health, natural dyes are a good substitute for synthetic ones [2]. There have been many natural substances found and reported since the saga began looking for ever-newer sources for natural dyes. Even though natural dyes aren’t always fast-acting and pure, they still have very well adsorption, colorful, are inexpensive, sustainable, safe, don’t cause cancer, don’t cause allergic reactions, and have great fastness qualities. They also offer the benefit of soft hues and vivid colors. Many species of plants, animals, and minerals that yield dyes have been gifted by nature and can be used to color textiles [3]. Due to cheaper costs, a greater variety of vibrant shades, better fastness properties, and to meet the necessary coloration for the world’s textile consumption, the textile dyeing industry currently utilizes an excessive number of chemical-based dyes in comparison to natural dyes [4]. Since natural dyes come from renewable feedstocks, their use for fabric dyeing has a minor impact on the environment. They also provide gentle shades and vibrant colors, which is advantageous. Excellent antimicrobial properties are also possessed by some of them [5].

Natural colorants can be obtained from the leaves of the tea plant (Camellia Sinensis) and the pomegranate (Punica Granatum). Pomegranates are small, spiky, deciduous trees or shrubs. This lovely shrub can withstand harsh weather, resist drought, and live for up to 200 years. Pomegranates are grown all over the world in warm climates. The fruit has a tough, leathery skin and is spherical, with a diameter of up to 12cm. One of the first fruits to be cultivated is the pomegranate, and its rind has been used as a dye. In Bangladesh, one of the most profitable crops is Camellia Sinensis. It’s a small tree or bushy shrub with lots of branches. In Bangladesh, there are 162 tea estates with a total area of 60,179 hectares of tea plantations. These estates produce approximately 67.38 million kg of finished tea annually from Camellia Sinensis leaves, with an average yield of roughly 1270kg per hectare [6]. The weak acid acetic acid, which is similar to citric acid, is found in lemons [7]. Numerous researchers have studied these leaves and pomegranate antimicrobial qualities. Among other qualities, its antimicrobial, antitumor, analgesic, and inflammatory properties have drawn the attention of natural product chemical analysts [8]. In this study, samples of cotton knitted fabric were dyed without the use of mordants using an extract of pomegranate (Punica Granatum) and tea plant (Camellia Sinensis) leaves, along with the addition of lemon peel for acetic acid.

Material and Methods

Fabric

For this study scoured and bleached 100% cotton knitted fabric with 130GSM were used.

Equipment

The equipment used for this work included a sample dyeing machine, dryer, pipette, scissor, electric balance, washing machine, beaker, color matching cabinet, gray scale, and crock meter.

Dyes and chemicals

In Bangladesh, leaves of the Camellia Sinensis and Punica Granatum were collected locally. We blended the leaves with a tiny bit of water to create a liquid solution. The chemicals used to complete this research work, viz. Soda ash, Na2CO3, Alum, NaOH, Glauber Salt, Na2SO4.10H2O, Levelling agent, DY LEVEL CN, Detergent, Soaping MC etc. were gathered from the Department of Textile Engineering’s wet processing lab, Southeast University.

The process of extracting dyes

The leaves of the Camellia Sinensis and Punica Granatum were collected locally. The leaves were carefully rinsed with clean water to get rid of dust and other contaminants. To facilitate blending, the leaves were sliced into small pieces and made into a liquid dye solution. 10gm of grated Camellia Sinensis and Punica Granatum leaves was added separately to 1000ml of distilled water and was boiled well until the dye was released in water. This can be done for 30 mins for complete extraction. After the dye is extracted, it is stored for further use. This extracted solution was used for the dyeing process.

Dyeing procedure

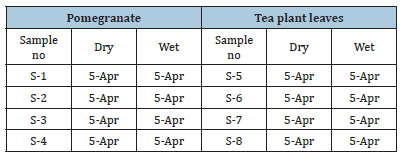

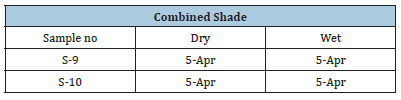

First, the collected scoured and bleached fabric was divided into six batches for ten different sample (four sample for Camellia Sinensis, four sample for Punica Granatum, and others two samples for combined shade), where the amount of fabric in each batch was the same. A summary of the dyeing process and ingredients is given in Table 1.

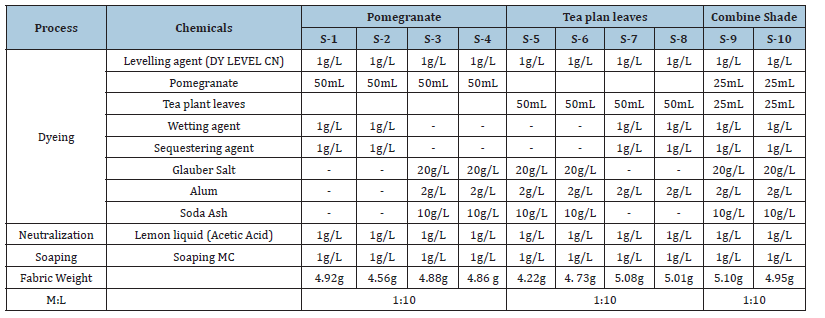

Table 1:Dyes and chemicals.

Ten samples-designated in this article as S-1, S-2, S-3, S-4, S-5, S-6, S-7, S-8, S-9 and S-10 were used with the solution at a 1:10, M:L ratio. S-9 and S-10 were used for combined shade of Camellia Sinensis and Punica Granatum. The dye solution from the tea plant (Camellia Sinensis) leaves was used to dye S-5 to S-8, and the dye solution from the pomegranate (Punica Granatum) was used to dye S-1 to S-4. Glauber’s salt (Na2SO4.10H2O) at 20g/L and soda ash (Na2CO3) at 10g/L were added to S3-S6 and dyed without wetting agent, levelling agent and sequestering agent. S1, S2, S7 and S8 were dyed without salt and soda and added wetting agent, levelling agent and sequestering agent of 1g/L. In a lab dyeing machine, the dyeing was done for 60 minutes at 60 °C. In sample S-9 and S-10 salt, soda and alum were used.

Analyzing the color strength properties

Spectrophotometers measure the amount of light that is reflected or transmitted across the spectrum to create a visual curve that shows the color of the substrate under various lighting conditions. The color measuring tool for the spectrophotometric analysis was iMatch (Version 9.4.10).

Analyzing the fabric’s color fastness for washing and rubbing

The dyed fabric’s color fastness to washing was evaluated as per the method adopted [9] and followed the method of ISO 105-C06, applying a washing solution made with a liquor to material ratio of 1:50 and 2g/L detergent. After washing, the sample is compared to a standard color chart to determine any changes in color. The rating indicates the degree of color change or staining after washing. Colorfastness to rubbing was assessed using the ISO standards 105- X-12 technique. Color fastness to rubbing was evaluated as per the method described [10]. In short, in this test, the fabric samples with dimensions of 14cm x 5cm were placed on a rubbing fastness tester. A white-cotton fabric sample with a size of 5cm x 5cm was used to rub the fabric surface in both wet and dry conditions. Rubbing was performed for 10 cycles, as per the standard.

Result and Discussion

Evaluation of shades for pomegranate (Punica Granatum)

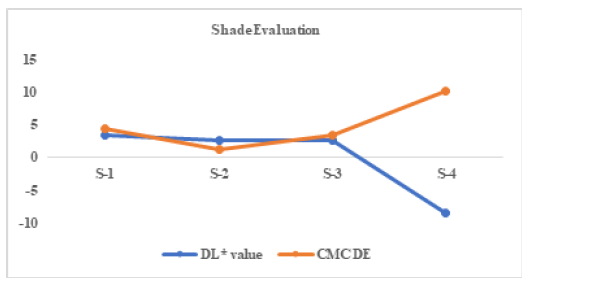

S-3 was selected as the standard sample. The S-1 and S-2 had lighter tones than S-3 because their respective DL values 3.44 and 2.68 were positive. On the other hand, S-4 were darker because the values were negative, at -8.51. The S-2 samples have a total color difference DE value of 1.22, meaning they match the S-3 samples. S-1 and S-4 have DE values of 4.32 and 10.2 respectively, indicating that the S-1 sample is more or less similar to the standard sample. S-3 and S-4 are not particularly close to the standard sample S-3, shown in Figure 1.

Figure 1:The comparison of shade between the pomegranate dyed samples.

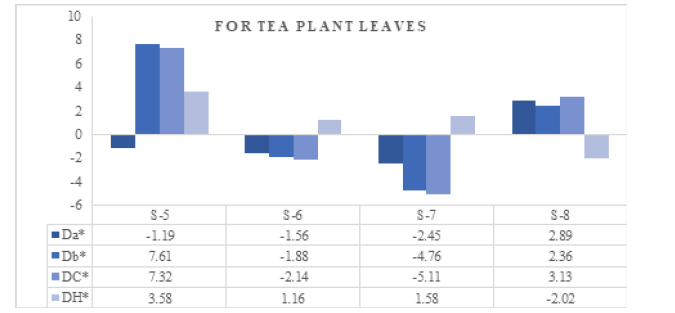

Evaluation of shades for tea plant leaves (Camellia Sinensis)

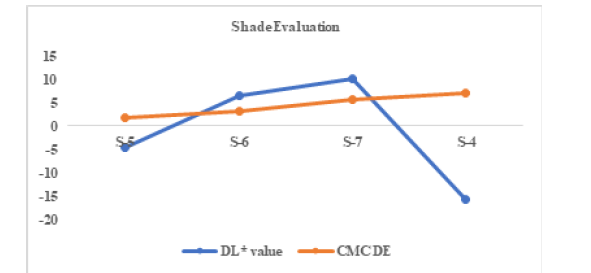

S-6 was selected as the reference sample. S-7’s tone was lighter than S-6’s because its DL values were higher (10.19) than S-6’s. On the other hand, S-5 and S-8, whose values were -4.47 and -15.83, were darker. The S-5 samples’ overall color difference DE values of 1.92 show that they match S-6 samples. The DE values of other samples S-7 and S-8 are 5.8 and 6.94 respectively indicates that the S-7 sample are very close to the standard sample S-6 and S-8 are not that much close or nearer to the standard sample S-6, shown in Figure 2.

Figure 2:The comparison of shade between the pomegranate tea plant leaves dyed samples.

Spectrophotometric assessment of dyed samples

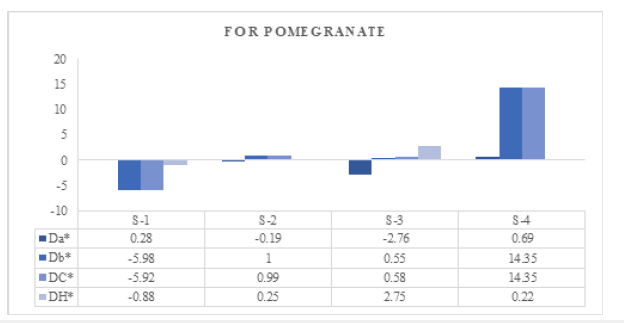

Color parameters of light shade for pomegranate dyed cotton knitted fabric are showed in Figure 3. Here, Da is -2.76, -0.19, 0.28 and 0.69 G for S-3, S-2, S1 and S4 respectively that means the standard sample S-3 is Greener or Less Red than the others S-2, S-1 and S-4 respectively. Here Db is 0.55 for standard S-3 sample and -5.98, 1 and 14.35 for S-1, S-2 and S-4 sample that means the standard sample is Yellower or Less Blue than S-1 sample but a little Bluer than S-3 and Bluer than S-4 sample. Here DC more means the sample is Brighter than the other sample, and DH more means the sample has less Hue than the other sample so we can say standard sample S-3 has less hue than others sample.

Figure 3:Light shade of pomegranate dyeing cotton knit fabric.

Color parameters of light shade for tea plant leaves dyed cotton knit fabric are shown in Figure 4. Here Da is -2.45, -1.56, -1.19 and 2.89 G for S-7, S-6, S5 and S8 respectively that means the standard sample S-6 is Greener or Less Red than the S-7 and redder or less green than S-5 and S8 sample. Here Db is -1.88 for standard S-6 sample and -4.76, 2.26 and 7.61 for S-7, S-8 and S-1 sample that means the standard sample is Yellower or Less Blue than S-7 sample but a little Bluer than S-8 and Bluer than S-5 sample. Here DC more means the sample is Brighter than the other sample, and DH more means the sample has Less Hue than the other sample so we can say standard sample S-5 has less hue than others sample, shown in Figure 4.

Figure 4:Light shade of tea plant leaves dyeing cotton knit fabric.

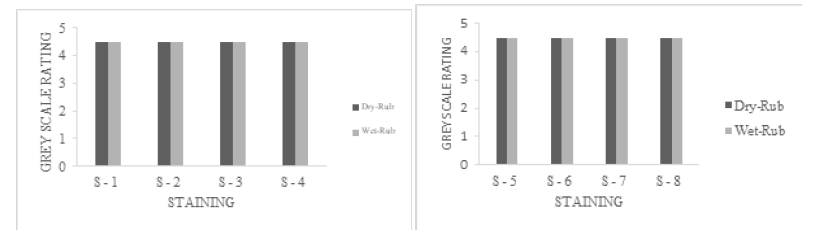

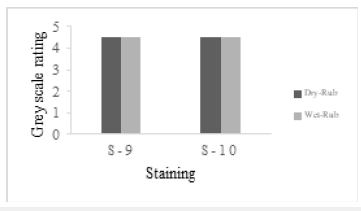

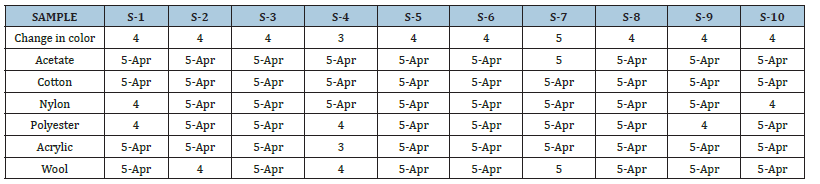

Effect of color fastness to rubbing

For pomegranate (Punica Granatum): The color fastness to rubbing test results are shown in Table 2 and Figure 5a. It has been observed that color fastness to rubbing is not affected by the fabric structure. All samples that were rated as 4-5 according to the ISO standard had excellent both for dry and wet rubbing fastness. The sample with the highest grade, rated 4-5, was found in all samples.

Table 2:Colorfastness to rubbing.

For tea plant leaves (Camellia Sinensis): The color fastness to rubbing test results for tea plant leaves are shown in Table 2 and Figure 5b. It has been observed that color fastness to rubbing is not affected by the fabric structure. All samples that were rated as 4-5 according to the ISO standard had excellent dry and wet rubbing fastness. The sample with the highest grade, rated 4-5, was found for all samples.

Combined shade of pomegranate and tea plant leaves: The color fastness to rubbing test results for combined shade are shown in Table 2 and Figure 5a. It has been observed that color fastness to rubbing is not affected by the fabric structure. All samples that were rated as 4-5 according to the ISO standard had excellent both for dry and wet rubbing fastness. The sample with the highest grade, rated 4-5, was found in all samples.

Figure 5:Color fastness to rubbing rating of a) Pomegranate, and b) Tea plant leaves.

Table 3:Colorfastness to rubbing.

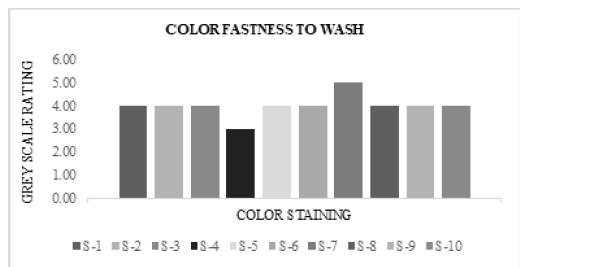

Effect of color fastness to wash: Table 3 and Figure 6, illustrates how the percentage of shade effects on wash fastness. It has been observed that colorfastness to wash has little effect by shade percentage. The samples with the lowest color staining were S-4, which was rated as 3 (according to ISO standards for staining to acrylic). On the other hand, the staining of all other samples to multifiber was rated as excellent, receiving a 4-5 grade. The dye liquor extracted from Camellia Sinensis leaves and Punica Granatum was applied to the samples of bleached and scoured cotton knit fabric for dyeing. The dye fiber interaction and likely dye structure were not assessed using an NMR/FTIR instrument. It can be done in the upcoming projects (Table 4) (Figure 7).

Figure 6:Color fastness to rubbing rating of combined shade.

Table 4:Effect of color fastness to wash.

Figure 7:Color fastness to wash rating, S-1 to S-4 For pomegranate; S-5 to S-8 For tea plant leaves; S-9 and S-10 For combined shade..

Conclusion

In conclusion, it was discovered that the dyes taken from pomegranate (Punica Granatum) and tea plant (Camellia Sinensis) leaves worked well as coloring agents when applied to cotton textiles. Two distinct natural sources viz., pomegranate and tea plant leaves have been used to extract dyes. Compared to pomegranate dyes, tea plant leaf dyes have a higher content of coloring agent. It was successful to dye cotton fabric using every dye that was acquired from various places. Colors showed shades of yellow. As a result, lighter shades of yellow, yellowish-green, or red can be produced. There is little environmental pollution during the dyeing process, which is environmentally benign. Protein fibers will be dyed using the extracted dyes in subsequent research. Future research will include a financial feasibility analysis of the extracted dyes as well as a detailed mechanism of dyeing using them.

References

- Werede E, Jabasingh SA, Demsash HD, Jaya N, Gebrehiwot G (2021) Eco-friendly cotton fabric dyeing using a green, sustainable natural dye from Gunda Gundo (Citrus sinensis) orange peels. Biomass Convers Biorefin 13(6): 5219-5234.

- Berhanu M, Jabasingh SA, Kifile Z (2017) Expanding sustenance in Ethiopia based on renewable energy resources-A comprehensive review. Renewable and Sustainable Energy Reviews 75: 1035-1045.

- Iqbal S, Ansari TN (2021) Extraction and application of natural dyes. Sustainable Practices in the Textile Industry.

- Merdan N, Eyupoglu S, Duman MN (2017) Ecological and sustainable natural dyes. Textile Science and Clothing Technology pp. 1-41.

- Jabasingh SA, Sahu P, Yimam A (2016) Enviro-friendly biofinishing of cotton fibers using Aspergillus nidulans AJSU04 cellulases for enhanced uptake of Myrobalan dye from Terminalia chebula. Dyes and Pigments 129: 129-140.

- Sreekumar S, Sithul H, Muraleedharan P, Azeez JM, Sreeharshan S (2014) Pomegranate fruit as a rich source of biologically active compounds. BioMed Research International 2014: 686921.

- Merizka E, Bin Harun H (2023) The effectiveness of citrus limon extract as a substitute for glacial acetic acid solution in the turks solution article history. Jurnal Ilmu dan Teknologi Kesehatan 10(2): 268-281.

- Haji A, Haji A (2019) Dyeing of cotton fabric with natural dyes improved by mordants and plasma treatment.

- Alam MS (2016) Analysis of depth of shade on mercerized and unmercerized fabric among different woven fabric structures. Journal of Materials 2016: 1-6.

- Shamim Alam M (2017) Aloe vera skin: A new biomaterial for the coloration of silk fabric and evaluation of fastness and color strength. Advancements in Materials 1(1): 14.

© 2024 Md Shamim Alam. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)