- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

The Market Challenge and Solution of Warby Parke

Yuyao Zhao*

Shanghai University of Engineering Science, China

*Corresponding author:Yuyao Zhao, Shanghai University of Engineering Science, School of Textiles and Fashion, Shanghai Songjiang district, Long Teng Road. No 333, China

Submission: October 12, 2023; Published: October 26, 2023

ISSN 2578-0271 Volume9 Issue3

Abstract

Recently, online shopping has become more and more popular, Warby Parker, an American online retailer which was launched in 2010 and sells eyeglasses and sunglasses. It was founded with a rebellious spirit and a lofty objective: to offer designer eyewear at a revolutionary price, while leading the way for socially conscious businesses (official website,2017). By now Warby Parker has opened several retail stores in Los Angeles and New York City and has showrooms in Chicago and Philadelphia. Therefore, It is really important that this fashion brand concentrates on marketing strategy and tries to handle marketing challenges properly in the future and makes it more successful.

In this report, the main subject will be the marketing challenge of Warby Parker, namely the supply chain management for long term improvement Now that the main supply chain factories are located in Asia especially China, and the high-counterfeiting makes are booming, the quality of products is becoming more seriously. The solution of this problem can be used by supply chain characteristic elements, which is related to the supply chain relationships.

Keywords:New York fashion brand; Latest fashion; Raw material; Fashion enterprises

Introduction

Warby Parker is a New York fashion brand and thinks it can convince consumers to purchase eyewear online, it has clear brand position as well as latest fashion, low prices, high quality and special customer service. Warby Parker also represents a standard model of online commerce, by using approaches taken in vertical strategy. John Gerzema, the president of Brand Asset Consulting, mentioned in 2011 that “it is very much a new model.” Meanwhile, the target is to decrease the risk of purchasing online by providing superior consumer service following a model launched by companies, such as Blue Nile. While the purpose of many other websites is to enable customers to purchase products as much as possible, Warby Parker seeks to support consumers to consider it carefully.

These facts all illustrate that Warby Parker is aware of the importance of brand management and has huge space for improvement. Neil Blumenthal said it before that ‘the internet has changed everything,” customers want to understand the inspiration and stories behind the products of the company and how they are related to the brand. Therefore, there could be lots of things and situations that the managers cannot control well, they must know what difficulties and opportunities the company will face in the future.

This case study will discuss the development of supply chain and critically examine the marketing challenge in the future of Warby Parker, and how to maximize deal with the challenge for this brand, the purpose is to try to put forward some pragmatic advice to this brand.

Marketing challenge

Supply chain: The main supply chain of Warby Parker is located in China and the raw material are come from a family-owned Italian producer, which has business both in Asia and Italy. The supply chain in Asian countries probably can decrease the costs due to the relatively low labor cost. However, the supply chains in Chinese and Italian factories have some problems recently, not only in China, but also in the whole world. So, in the near future, the marketing challenge to Warby Parker is the supply chain strategy and management for long term. Supply chain management is a key factor to the success of fashion enterprises, and that is the reason why many people choose to discuss it. Not only this, supply chain process includes raw material stage through information flow and transformation of products, from the primary design stage to the last of end user, information and cash flows form is also a part of supply chain activities. For the British government, the productivity is still an essential part of the UK economy and composed the companies by the association of economy [1]. In addition, the supply chain dynamics can be reached by decreasing system delays, changing the order of individual echelon of decision rules and fine-tuning the existing policy parameters. It can be proved that the capability to administer supply chains is a center of competence for an organization [1]. There are lots of examples that can explain the business success business depending on this capability. For instance, Amazon.com and ASOS are associated with new e-retailing organizational developments, dealing with the online store and customer orders. Warby Parker is also an online retailer, the internet is changing quickly, so the supply chain of capability is important to every e-retailing brand. Supply chain strategies are focused on improving efficiencies and reducing costs or based on providing high quality services to make the company more impressive to consumers as well as producing high valueadded products [1]. Warby Parker’ has its own special supply chain strategies: buy one pair, it would donate a pair to someone is need, that means the added value is to create a sense of charity and impress the society. Vertical integration is also a specific supply chain strategy of Warby Parker which means ownership and management of the vertically integrated companies in the system. Consequently, if they want to be long-term partners, the suppliers must try its best to meet all the needs of the retailers. Meanwhile, retailers measure supplier’s performance by comparing them with variable other competitors, such as faults, service, quality and on-time deliveries. Therefore, management of the supplier network’s advantages can be realized in the conventional economic sense of the term without necessity of vertical integration. But this strategy certainly has risks too, especially when supplies are temporarily limited [1]. Warby Parker is probably using a supplier network, because the supply chain producers are not in the US, so communication with the suppliers can be a risk. These all demonstrated that the supply chain management are extremely important to their company, and they must focus on the relationship between suppliers and retailers, as supplier network or long-distance cooperation can be instable, and the choice of supply factories must be scrutinized carefully. Because of the changes of consumption patterns, high counterfeit markets are teeming. Due to the globalization of the supply chain, counterfeiting is a worldwide problem, it should be resolved at the worldwide level, and there is no method of combating counterfeiting the suits all countries in the world. At the global market, cultural and financial differences may lead to substantial differences in morality, and different ethical standards can directly impact on customers’ attitudes on the counterfeiting. An insight into counterfeiting is always based on understanding the differences in culture. A more impressive way can be taken to alleviate this problem [2]. Although there are various product counterfeiters that establish business all over the world, but generally speaking, counterfeiting industry in China is bring the most serious counterfeiting problem in world history, and this gray industry is still growing in China. According to a survey based on the Chinese government’s conservative estimate, the whole value of counterfeiting goods domestically produced and marketed amounts to US$16.1 billions (Hung 2003).

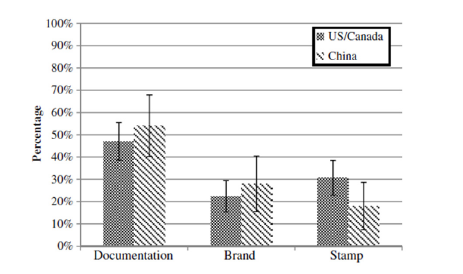

As can be seen from above, Figure 1 shows the most common methods of counterfeiting. According to these figures, the number of reported fraudulent paperwork was far larger than that of what the public is most familiar with falsified brand’s logos, names and trademarks. In practice, only 22% (United States/Canada) and 28% (China) of all counterfeited goods choose to fake brand names, logos and labels. These figures prove that the products counterfeiting is more serious than people think, since the producers are using smarter ways that are much more difficult for ordinary customers to distinguish, to produce counterfeited goods. It appears that a non-structural item or product possibly has a longer development period during which no dangers appear [2].

Figure 1:Most common methods of counterfeiting. Source: Journal of Construction Engineering and Management © ASCE / JAN 2013.

Warby Parker’s glasses are famous for fashionable design, due to the brand identity, it is not well known in the world, so it is quite possible that make many counterfeiters produce and sell fake glasses and make customers confused about Warby Parker’s brand identity. In the meantime, the firm’s direct relations with its raw material suppliers are uncommon in the industry, but the main supply chain of frames and the assembly lines of Warby Parker are in two Chinese factories, this tactic probably can help the company save lots of money. Although the managers’ choices of factory are depended on their value, but they still can bring high risks and the Italian eyewear supplier also has more competitive environment than before. If a supply chain disruption happened, how a company can efficiently recover from a disruption hinge on its recovery capability [3].

The symbol of “made in China” and the high counterfeiting can get the firms in trouble, and the long distance of the producers can also to cause some troubles. Thus, how to cooperate with the producers in Asian and control the product’s specificity and high quality may become a challenge to this brand.

Solution

Supply chain relationships: As the importance of supply chain management has become manifest to each fashion firm, the strategies of supply chain must establish a suitable solution to Warby Parker’s challenge. Recently, with smaller quantities, rising customer needs, less inventory and essentially higher levels of unsteadiness than before in the environment, more and more businesses are attaching importance to their supply chain endto- end. This requires need all company’s staff from top-down to support the touch with supply chain. It also demands the assurance of expanding the technologies, people and processes, which makes supply chain strategist from paper to reality. The number of the staff of Warby Parkers is not too large, so this is easier to resolve. Previously, supply chain strategy has usually been underestimated as a cause of competitive merit, at present, organizations are shifting from concentrating on their supply chain effects on functional advantage to regarding their supply chain as a strategic capability [4]. The Supply chain’s weakness has been recognized throughout lots of strategies, for example, process-improvement, the capacity and adoption of flexibility and responsiveness dramatically increase (Chopra Sodhi 2004), supply chain dexterity and the relationship of cooperation (Shankar F, Banwet 2006, Saad K 2005). A lot of researchers have concentrated on supply chain weakness management in different industries, for instance, retail industry, aerospace supply chain (Sinha W, Malzahn 2004), and consumer electronics industry (Sodhi L 2007). Supply chain flexibility has an advantageous affect to a firm’s weakness recovery capability, and supply chain visibility expands a firm’s disruption capability. Furthermore, high levels of disruption capability improve a company’s recovery capability. Therefore, the solution of supply chain management is the understanding the action of supply chain characteristic elements [3].

Nowadays, the customers often have increasingly higher expectations and needs, so supply chain flexibility and agility are important differentiators for achieving competitive merit. Warby Parker has put itself in risk when launched, the inventory in factories is not quiet and sufficient, but the customers increasingly need made Warby Parker demand began to exceed supply, because of the supply chain agility and flexibility are not perfect. It has never been more significant to knit complicated supply chains together. It can keep the numbers of excellently advanced supply chain planning [5].

Warby Parker’s challenge in the future is the supply chain management, the main factories are in Asian especially in China. However, the counterfeiting in China is getting more and more serious than before, and the symbol of made in China may not give people a good impression, also the long distance between producer and retailer makes the two ends of the supply chain difficult to communicate and management each other, which can have negative influence in the product quality, finish time and delivery time. According to Hines [1], the supply chain relationships theory can be used for the solution of Warby Parker’s challenge. The relationships are one idea, but it can be divided into four small parts, quality, buyer-supplier, purchasing and globalization focus. The solution will focus on the two most important parts: globalization and quality. Many different ideas and importance of supply chain relations have already been discussed through this essay, but the quality and globalization focus can make the process of production become improved and enhance the firms’s business and market.

The effect of the quality movement probably highlighted appearing on Deming’s fourth point of his fourteen ideas about quality, he believed that fewer suppliers are very much close to organizations work (Deming,1982). The supply chain of Warby Parker must focus on the quality, maybe for now the quality of products has no problem, but for the long run, the quality of the product is usually the reason of success of fashion brands, and the high quality can make the real product easier to be distinguished from other counterfeited goods. For a long-term development of control, the quality, the best way is to strictly control the production of each process, and as the main factories are in the Asian especially China, it can create a new and small department in Asian, such as special supervise section on Asian. That is to say the new department does not have to be too big, it is only enough to provide the space for staff to check the quality of the goods, so it would not cost too much money. Additionally, the reason of doing these things is two. Firstly, strictly supervising can help Warby Parker save more costs, and by reducing material and resources used in the production, it can also protect the environment, because of the brand identity of Warby Parker probably is charity brand, due to the strategy of buy one pair and another will be free. Meanwhile, to administrate the produce of every process can help retailers communicate better with producers, and the producers can totally understand what retailer’s request is and need, there are no longer distance existing Secondly. If a new section is established in Asian, it could create more job opportunities to more people, this method may also create a chance to help Warby Parker enter a new market and expand the global market. Until now, Warby Parker has only well-known in American, and Warby Parker always pays attention to its company’s culture, so the culture becomes more and more international [6].

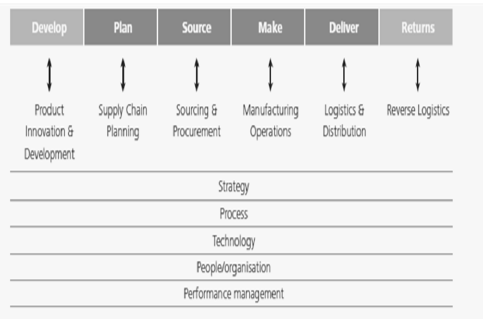

As can be seen in Figure 2, the process of supply chain is made up of six parts, the most significant part is planning the supply chain and enhancing them, for example, the technology of product should be expanded, the organization of this factory should be chosen more carefully, the manufacturing in Asian factories especially in China should be inspected more strictly. At the same time, the new product’s design should be keep secret, so that counterfeiters would not know the details about it. And counterfeited goods would not appear so frequently in the eyewear market [7].

Figure 2:Integrated supply chain method. Source: Deloitte, Supply Chain Strategy: Leveraging the backbone of your business as a source of competitive advantage, 2011.

Another supply chain relation is globalization that is also a solution of Warby Parker’s challenge, but this solution still belongs to supply chain relationships. As mentioned before, the brand publicity of Warby Parker is not so famous all around the world, but if a company wants to expand their business, globalization is the only way. Bennett and Riddalls (2002) mention that some mistakes can be costly in the supply chain, and it can make many different crisis, for instance, being unable to meet consumers’ needs, rises in costs, long lead-times and stock-outs. When these things happen, how to recover from them becomes a big challenge to each producer. So, the supply chain factories of Warby Parker’s being only in Asian does not comply with the idea of globalization. The factories can be located in not only in Asian, but other countries can also be taken into consideration. The international competitive environment of business, globalization has established a longer and more complicate supply chains, which is weaker to business disruptions in the world (Noe R, Dallari 2005) (Figure 2).

In the global market of increasing competitiveness, Warby Parker could be associated with suppliers and producers or consumers cooperation and work together, it should try to understand the demands of market, and make the company’s culture become more colorful. Not only this cooperating together, establishing and choosing supply chain factories in different countries is a valid method to resolve the challenge. If the firms want to enter a new market, it can choose a supply chain factory in that country, and factories in each area and managers must do these things that can make the globalization strategy become more efficient. The first thing is responsiveness, which is a staff’s ability to recognize the risk and make quick responses to them, and quickly make remedies about them; The second thing should be focused on the flexibility, that means the ability to achieve the same aim even in different process or different facilities application; The last thing is speed, such as produce the products on time, and complete a project as soon as possible [8].

Conclusion

Warby Parker is an online retailer, which is also a fashion eyewear brand. With a brand identity for sales affordable vision fashion eyewear and giving back to the community, which is throughout “buy a pair, donate a pair” charity program, so the brand image is wanting to create a charity brand image. In addition, the producing of glasses of this brand is simple and provide high quality Italian material for eyeglasses frames, which are then manufactured and cut in two Chinese factories.

Warby Parker ‘s supply chain strategy is vertical integration strategy, which means one company directly deals with raw material supplier. The advantage is providing an important ability to control and reduce costs throughout the producing process and more strictly control over the value of supply chain (Neil 2007). Nerveless, due to the competitive environment, the factories in Asian has lots of problems, the counterfeiting is getting more seriously than before, not only this, the raw material supplier of Warby Parker in Italy also have challenges. In the future, China will continue to be counterfeited more different goods than other countries (U.S. International Trade Commission, 2011). Meanwhile, the main products of Warby Parker are produced by Chinese factories, the high-quality control, counterfeits and the long distance between the supplier and retailer is a doubt and question for customers. For the long term, this is a challenge to Warby Parker.

According to the supply chain relationship opinion of Hines [1], this challenge can be resolved by one main solution, which can be divided into two small parts. Establishing a new and small department in Asian or China to supervise the supply chain factories stricter, and letting suppliers and producers or consumers cooperate and work together. Finally, globalization strategy means that it might try to choose more factories in different countries, to enter a new market and create more opportunities.

References

- 20Hines T, Bruce M (2007) Fashion marketing contemporary issues. (2nd edn). Elsevier Ltd, Oxford, UK.

- Minchinin RE, Asce M, Russell CW, Raymond I (2013) Sino-Americ-an opinions and perceptions of counterfeiting in the construction supply chain. Journal of Construction Engineering and Management 139(1): 1-8.

- Shao XF (2013) Supply chain characteristics and disruption mitigation capability: An empirical investigation in China. International Journal of Logistics Research and Applications: A Leading Journal of Supply Chain Management 16(4): 277-295.

- Deloitte (2011) Supply chain strategy: Leveraging the backbone of your business as a source of competitive advantage. Creative Studio at Deloitte, Belgium.

- Kokemulle N (2014) The advantages of a vertical integration strategy.

- Li L (2012) Effects of enterprise technology on supply chain collaboration: Analysis of China-linked supply chain. Enterprise Information Systems 6(1): 55-77.

- Marquis C, Villa LV (2012) Warby Parker: Vision of a "good" fashion brand. Harvard business school, USA.

- Toole M (2013) Warby Parker, one million eyeglasses, and the next generation of brands.

© 2023 Yuyao Zhao. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)