- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Mohair Fiber: Sustainability Starts at the Farm-Know your Fashion; Know Where it Comes from

Weiss Marcia1, Faust Marie-Eve2, Bellemare Jocelyn3* and Fontaine Richard4

1Department of Textile Design, Thomas Jefferson University, MFA in Fibers, Savannah College of Art & Design (SCAD), USA

2Department of Strategy, Social and Environmental Responsibility, School of Business and Management (ESG), Université du Québec à Montréal (UQAM), Canada

3Department of Analytics, Operations, and Information Technology, School of Business and Management (ESG), Université du Québec à Montréal (UQAM), Canada

4Department of Accounting, School of Business and Management (ESG), Université du Québec à Montréal (UQAM), Canada

*Corresponding author:Bellemare Jocelyn, Department of Analytics, Operations, and Information Technology, School of Business and Management (ESG), Université du Québec à Montréal (UQAM), Canada

Submission: August 16, 2023; Published: September 05, 2023

ISSN 2578-0271 Volume9 Issue2

Abstract

Sustainability considerations are paramount throughout the entire spectrum of the fashion supply chain. However, there’s an apparent research gap concerning the preliminary stages that come before fiber collection. This paper delves deep into the repercussions of choices made at the farm level on the sustainability of mohair fiber production. A detailed study following the journey of a mohair producer highlights the significant impact of decisions made at the foundational level. This research emphasizes the importance of conscious animal husbandry and environmental awareness in the days leading up to shearing. Detailed interviews with involved parties at the farm shed light on the hurdles and advantages accompanying each step of the process. Our analysis presents hands-on recommendations from the viewpoint of a farmer, corroborated with findings from previous research. The judicious selection of angora goats, considering their genetic traits from both male and female perspectives, validates earlier genetic studies. Providing the goats with ample space for grazing and augmenting their diet with fields sown with indigenous flora promotes a holistic diet rich in organic protein. This mode of nutrition proves pivotal in the conversion of sustenance to fiber, manifesting a strong link between adequate feeding and superior fiber quality. Moreover, embracing holistic pest control mechanisms effectively keeps parasitic infestations at bay, and the strategic positioning of guard dogs not only shields the flock from potential threats but also significantly diminishes stress levels among the animals, mirroring the principles of the Predator Friendly movement. The necessity for transparency in the fashion discipline is also discussed, emphasizing the worth of cultivating personal affiliations with suppliers. Such alliances nurture trust and legitimacy, while also curbing the carbon footprint by supporting local communities. By mapping out the multifaceted steps in the sustainable process from pasture to wardrobe, this manuscript underscores the role of mohair as a legitimate and worthy fiber. This research brings to the forefront the choices made at the farm that promote sustainability in the fashion supply chain, with special emphasis on mohair fiber. Our results provide nuances and actionable tips for agrarians, supporting prior research and paving the way for a fashion industry that’s both sustainable and transparent.

Keywords:Mohair fiber; Farm-level decisions; Animal care; Environmental considerations; Angora goats; Genetics; Pasture roaming; Diet supplementation; Fiber quality; Integrative pest management; Guard dogs; Animal stress; Transparency; Carbon footprint; Local community; Authenticity

Introduction

Sustainability has now become a central concern within the fashion industry, with a growing awareness of the need to adopt environmentally friendly and socially responsible practices [1,2]. Although sustainability is frequently addressed at various stages of the fashion supply chain, there’s a noticeable research gap when it comes to the initial phases preceding fiber collection [3]. This lack is especially pronounced in the mohair production sector, where the period leading up to the shearing day is important in defining sustainable practices associated with fiber production [4]. The primary aim of this study is to highlight the significance of decisions made at the farm level in promoting sustainability in mohair fiber production. Specifically, practices and concerns related to animal care and the environment that take place before and during the shearing day were studied. Through this in-depth analysis, the pivotal role of early decisions taken at the farm in encouraging sustainable methods throughout the mohair supply chain was illuminated.

To achieve this goal, interviews were conducted with key stakeholders and we closely observed the daily operations of mohair-producing farms to gain a better understanding of the challenges and advantages associated with each step of the process. The findings from this research offer valuable guidelines from a farmer’s perspective, thus enriching the current knowledge on sustainable fiber production. Moreover, this study underscores the need for increased transparency in the fashion industry, emphasizing the importance of personal relationships with suppliers and the engagement of local communities to minimize the carbon footprint [3]. By addressing this research void concerning the initial phases of mohair fiber production, the understanding of sustainable practices that can be implemented at the farm level may be enhanced. Ultimately, this knowledge can influence decision-making processes and contribute to the evolution of a more sustainable and transparent fashion industry.

Literature Review

Before this pandemic, sustainability had become a keyword for many reasons. One of the most prominent reasons was the perception of the apparel trade as one of the world’s most polluting industries. According to Berg et al. [5] in McKinsey & Company and Global Fashion Agenda, more than 4% of worldwide greenhouse emissions are linked to fashion. Challenges posed by climate change, including carbon footprint considerations, have prompted a call for increased transparency in the supply chain. Initiatives such as “Buy America” and the “Panier Bleu campaign” in Quebec/ Canada resonate with local communities. The public is now more aware of social incidents including child labor, low wages, and workplace violations, which have resulted in tragedies like those in Bangladesh and the cotton crisis in India, leading to farmer suicides. According to Adams [6], the industry’s environmental impactsfrom greenhouse gas emissions to microplastics, biodiversity loss, and water ecotoxicity-are now well-known by both consumers and companies. This awareness has necessitated a reevaluation of sourcing and manufacturing processes. Consequently, it is important to revisit the needs of the fashion industry, define the steps needed for textile and apparel reconsolidation, and help to promote supply chain transparency [7].

Supply chain and sustainability

As Charter et al. [8] said, sustainability in the fashion, clothing, and textiles domain is not merely a challenge but a ‘wicked problem’ that has garnered heightened attention due to mounting pressures from consumers, businesses, and policy frameworks. The multifaceted nature of this issue demands a comprehensive approach, blending both academic and industry insights to champion more sustainable pathways in the sector. Keiser et al. [9] assert that the apparel supply chain encompasses companies directly engaged in designing, supplying material components, manufacturing, and distributing apparel. This also includes auxiliary businesses such as design bureaus, software providers, sourcing patternmaking services, testing labs, consultants, and advertising agencies, but often neglects agriculture. According to Campaniaris et al. [10], North American retailers are assuming greater control over the apparel supply chain, with a growing emphasis on sustainable initiatives. These initiatives vary but often start at the manufacturing stage [1].

While discussions on sustainability can be traced back to the 1960s, a clear definition was only provided in 1987 by the World Commission on Environment and Development. They described sustainability as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” [9]. For Birnbaum [11], the challenge facing apparel firms desiring to adopt sustainable practices lies at the intersection of the environmental, social, and economic realms.

According to the director of the Centre for Sustainable Fashion at London College of Fashion (UAL), even luxury companies are not exempt. Their operations typically employ business models rooted in industrialized production. Unfortunately, in these models, the costs to both people’s well-being and the planet are frequently omitted from the balance sheet. Consequently, only a handful of companies truly embody the authentic values of sustainability, which include fostering a culture of care and ensuring that their operations promote better practices. At present, only a limited number of companies emphasize the significance of a “farm to fabric” approach as a sustainable element of their supply chain [9,12]. Concerning mohair, scant academic research exists, particularly since the bulk of its manufacturing shifted to developing countries [13].

'Angora goats: History, economy and sustainability

The Angora goat, with its shiny rag mop appearance complete with horns and dreadlocks, surprisingly boasts a fairly even temperament [14] (Figure 1).

Figure 1:Angora goat.

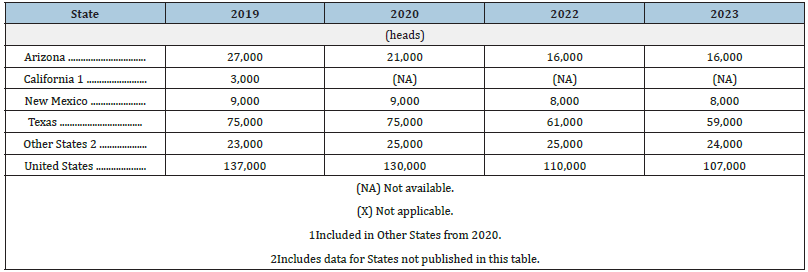

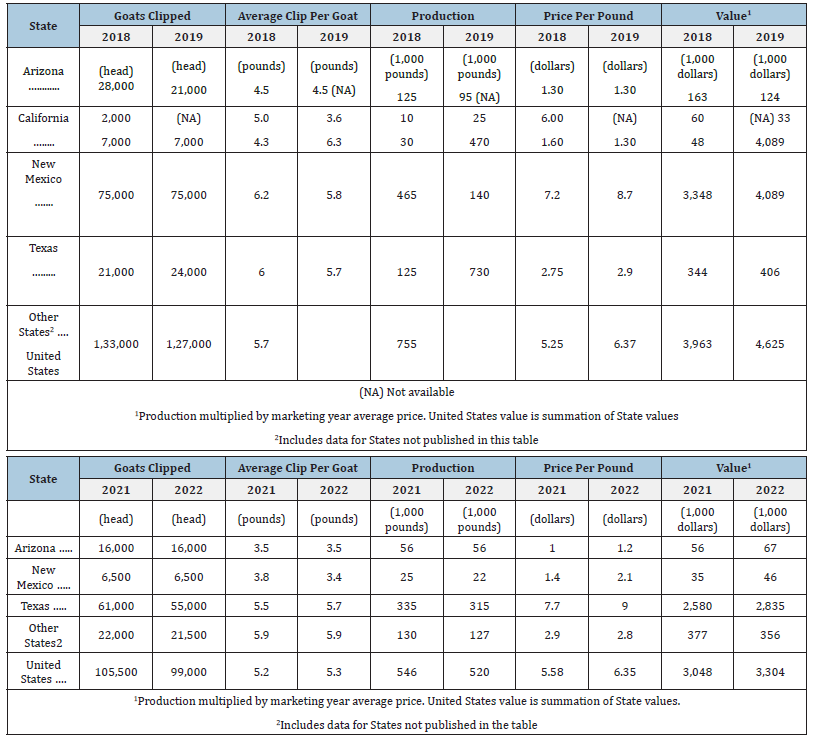

Until the early 19th century, Turkey was almost the exclusive global producer of mohair [15]. The United States began importing Angora goats from Turkey in 1849 [16]. After reaching a peak of nearly two million Angora goats-with 84 percent of them located in Texas-the population in the U.S. experienced a significant decline: from an estimated 1.7 million in 1987 to 260,000 in 2007, further dropping to 130,000 in 2020 [17]. This trend starkly contrasts with the rise in the number of Angora goats in South Africa, which grew from 1.2 million in 1999 to 3.8 million in 2007 [18,19]. In Cape Town, this mohair is considered by many as some of the finest and highest yielding in the world [20].

A factor contributing to the decline in commercially raised Angora goats in the U.S. might be the discontinuation of the mohair subsidy [14,21]. Subsidies were introduced in 1954 under the National Wool Act. This act, established by the U.S. Congress, aimed to diminish reliance on foreign fibers and shield American farmers from overseas competition. As part of this initiative, producers consistently received profits averaging up to $4.63 per pound [16]. As Rauch [14] points out, “if you had clipped your goat, sold the fleece, and provided the receipt to your local Agriculture Department Office, Uncle Sam would compensate you $3.87 for every dollar you earned in the market.” Consequently, during the 1980s, Angora goats represented an annual expenditure of approximately $60 million for the U.S. government. By 2011, the global population of Angora goats stood at 2.6 million, with an annual mohair yield of just under 3 million pounds. This volume of fiber amounted to 0.02 percent of the global textile output, priced between $3.40 and $3.63 per pound [22]. In 2019, influenced by globalization and free trade-and in the absence of subsidies-the total mohair clipped from Angora goats was approximately 730,000 pounds, sourced from 127,000 head, each yielding an average of 5.7 pounds. The market price for mohair stood at $6.37 per pound, valuing the production at around 4.65 million dollars [17] (Tables 1 & 2).

Table 1:Angora Goats and Kids Inventory-States and United States: January 1, 2019, 2020, 2022 and 2023.

Table 2:Comparison of Mohair Production, Price and Value 2018-2019 vs 2022-23.

Mohair occupies a niche segment of the global fiber market, defining luxury through its rarity and scarcity [23]. The looming question is whether mohair will continue to bask in the aura of a luxury fiber or if domestic production will surge, reducing reliance on foreign sources and forging a more sustainable pathway. A useful comparison might be with hemp. Historically embracedhemp was used for the American Flag, and images of farmers harvesting hemp were on the reverse side of the US $10 bill in 1929-it faced prohibitions in the 1940s. However, with the 2018 Farm Bill’s enactment, hemp resurged in popularity. Compared to other plant fibers, like cotton, hemp requires less water, thrives without pesticides, and yields higher returns per acre [12], making it a sustainable alternative.

Mohair characteristics

Mohair is the fleece harvested from the Angora goat [14]. The term “mohair” is rooted in the Arabic word “mukhayar”, signifying the choicest or best-selected fleece [24]. Historically celebrated as a luxury fiber, mohair has adorned royalty and sultans for centuries [15]. As the primary specialty animal fiber, mohair stands out for its uniformity, lustrous sheen, and pristine white hue post-scouring [22,24].

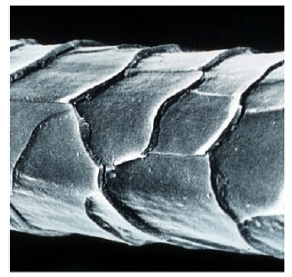

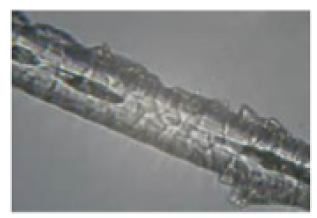

In a fiber-to-fiber comparison against yak cashmere or camel hair, mohair boasts the longest average fiber length. Furthermore, relative to camel hair and cashmere, mohair demonstrates a higher propensity for curls, boasts an impressive crimp rate, and retains a commendable crimp recovery rate-qualities that enhance fiber spinning [25]. Renowned for its durability, resilience, comfort and insulating capabilities, mohair ensures either coolness or warmth without heft. It mirrors the warmth of wool, albeit at a lighter weight. Structurally, mohair’s rounded cross-section, exhibiting fewer scales than wool, imparts to it a silk-like sheen (Figures 2 & 3).

Figure 2:Wool surface.

Figure 3:Mohair surface.

Mohair exhibits uniformity in diameter and, unlike wool, remains resistant to shrinking or felting when exposed to water and agitation. In fact, mohair stands out as the lightest yet warmest among animal fibers [26]. It can be bent or twisted without harming the fiber and can stretch up to 30% of its original length and then rebound. This intrinsic resilience renders mohair impervious to wrinkles, sagging, and stretching. Astonishingly, mohair, of the same diameter, exhibits a tensile strength surpassing that of steel [27]. Such attributes have endeared mohair to many due to its outstanding wear resistance [15]. Additionally, mohair can efficiently wick moisture away from the skin and naturally resists odors. If post-shearing treatments eschew harsh chemical washes, mohair presents minimal environmental concerns. Its fiber predominantly comprises keratin, a natural protein, and it contains no harmful allergens. When dyed, mohair can take on a vibrant range of colors, from gentle pastels and earthy shades to bright hues, thanks to its excellent color retention capabilities [26]. Hence, mohair’s moniker, “the Diamond Fiber,” arises from its capacity for vibrant dyeing [24].

From fleece to fiber

Angora goats serve as an ideal livestock choice in delicate ecosystems, representing a self-sustaining farming venture [26]. With their hair growing at a rate of about an inch per month, these goats are typically shorn twice a year, in early fall and early spring. The fiber length ranges between 4 to 6 inches when sheared biannually [28].

Fiber processing

While mohair has fewer contaminants than wool (with only 5% grease compared to wool’s 15%), its processing demands specialized attention during both wet and mechanical stages. Mohair’s sensitivity to temperature and alkalinity, combined with its natural lack of fiber cohesion, mandates expertise for its transformation into yarn [29]. Achieving textile quality depends on the intricate balance between the fiber’s properties, the resulting yarn, and textile construction and finishing. Handling mohair demands specific experience to thwart entanglement, which can compromise yarn consistency and mar the final textile [30]. Proper lubricants, additives, ambient conditions, and equipment ensure that mohair retains its luster throughout the spinning and dyeing processes [18].

Upon processing, mohair yarn varies from 1 to 14 ply. The fleece sourced from the inaugural shearing of young goats is termed “kid mohair.” This fine 1 to 4 ply mohair is ideally suited for delicate, lightweight yarns. Medium plies like 5, 8, and 10 are often combined with other fibers to craft sweaters, wraps, and shawls. In contrast, the thicker 12 and 14 ply mohair is typically integrated with other fibers to produce bouclé fabrics for children’s items, blankets, scarves, and jackets. Considering these factors, mohair earns its reputation as one of the globe’s most adaptable luxury fibers [31].

Mohair as a trend and a distinctive local fiber

Projections for the fall and winter of 2021-22, post-lockdown, from fashion capitals like New York, London, Milan, and Paris, indicate the continued dominance of relaxed sartorial choices. The integration of work and home environments has propelled knitwear to the forefront, offering comfort over the rigid designs of woven clothing [32]. As Casey [33] highlights, comfort-centric outfits will remain in vogue. Knitted outfits have surged in popularity, with knit dresses witnessing a 42% uptick from the previous year. Additionally, cardigans and popovers remain in vogue. Concurrently, there’s a tilt towards sustainable consumption. Consumers are veering towards organically procured natural fibers, rendered in neutral hues, devoid of bleaching, or colored with plant-based dyes. Mohair, with its versatile textures and designs, stands poised to cater to this evolved consumer preference.

Reshoring and local fiber?

The textile domain has witnessed evolving trends in fiber utilization, aligning with the fluid dynamics of supply and demand. Richard Gough of St. Albans Textiles, an Australian purveyor of natural fiber products, notes a consumer inclination towards purity in purchased fibers. There’s a desire for traceability within the manufacturing process and an inclination to invest in luxury, especially if accompanied by a backstory [34]. Richard Simons, of the Canadian retail brand, echoes this sentiment, expressing a desire to increase local production and enhance transparency in response to growing demand. This heightened demand for comfortable, lightweight clothing following the COVID-19 pandemic, combined with the adaptability of angora goats to American terrains, places mohair in a pivotal position in local markets. Mohair’s unique blend of softness, warmth, and texture can stimulate demand for local, traceable fibers like mohair and cashmere [35,36]. As Fletcher [36] suggests, while the concept of local fashion can borrow cues from local food movements, it also necessitates strategies tailored to the sector’s specific nuances. With a resurgence in knitting and a thriving artisanal community, mohair’s allure is poised to grow.

The literature confirms that Mohair, derived from the Angora goat, stands out among animal fibers due to its lightness, warmth, and unique resilience, placing it in a luxury category. However, the processing and transformation of this fiber requires specific expertise because of its delicate properties. In the current context, where fashion leans towards comfort and sustainability, mohair, with its intrinsic qualities, emerges as a favored option. Writings confirm that this trend is heightened by a more conscious consumption movement seeking purity, traceability, and authenticity. Moreover, the adaptability of Angora goats to diverse terrains, coupled with a growing demand for local products, positions mohair as a fiber with significant growth potential in the future [37-42].

Methodology: Immersion with the Master of the Domain

To delve deeper into sustainable mohair fiber production, a comprehensive methodology was employed. This was mainly based on interviews and observations carried out over a period of 1 year to understand the complete production cycle. The study focused on a renowned expert, Glen Cauffman, who holds the distinction of being the Mid-Atlantic Master Farmer of the Year. The selection of this expert was rooted in his expertise and commitment to sustainable farming practices. The methodology began by obtaining informed consent from the participant. This included the objectives of the study, how the information would be used, as well as seeking his permission to use his quotes in future publications. He was also informed that he would be at the heart of the study. An initial interview was then conducted with Glen Cauffman, with open-ended questions to explore his knowledge and experience in sustainable mohair cultivation. This interview took place both on the university campus and off-site, providing a comprehensive view of his perspective. During the on-campus discussion, an audience was present, which allowed for enhanced interaction and the opportunity for additional questions. Both the presentation and the interviews were recorded for future analysis. To enhance this interview, a field visit was organized on a special day, shearing day, deemed essential to grasp the sustainable practices associated with mohair production. Contrary to popular belief, the supply chain does not start with the shearing day, but understanding the processes and considerations leading up to this point is vital. The visit aimed to observe and document the day’s activities and dynamics, thereby offering invaluable insights into the entire procedure [43-47].

Throughout the study, a detailed and rich narrative was acquired, capturing various facets of sustainable mohair production. This included a description of a typical shearing day at the farm, highlighting the importance of every detail. Glen Cauffman’s mission and innovative farming framework were also studied, unveiling the principles and values guiding his practices. Moreover, the farmer provided a thorough breakdown of the entire process from the ecosystem to fiber production, illustrating the interconnectedness of various factors in achieving sustainability. The methodology adopted in this study facilitated an in-depth exploration and understanding of the sustainable practices related to mohair fiber production. By engaging with a master in his field and documenting his experiences and insights, invaluable knowledge was gathered, thereby setting the stage for the ensuing analysis and discussion. Subsequent sections will address the findings and implications of this research, adding to the existing body of knowledge on sustainable fashion supply chains [48-56].

Discussion

The fashion industry, known for its dynamism, now faces the urgent imperative of adopting sustainable practices. Mohair emerges as an important fiber for these practices. Derived from nature itself, its production and application in fashion offer invaluable insights. Glen Cauffman’s endeavors in producing mohair stand out for their harmonious blend of environmental consciousness and animal welfare. This approach brings forth a more comprehensive perspective on the sustainable fashion pathway.

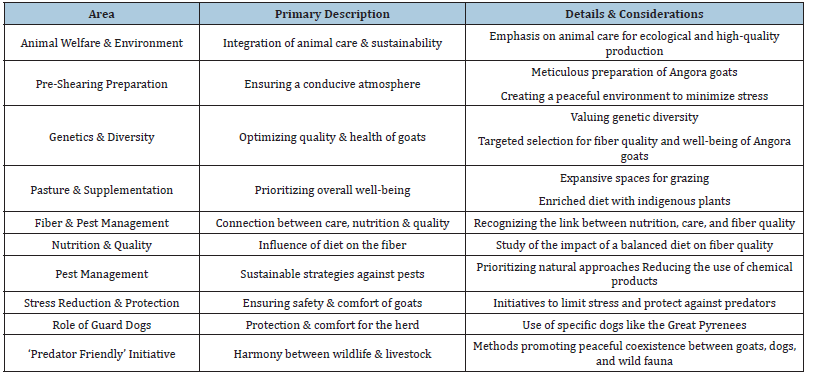

The health and well-being of Angora goats become central to the narrative. Their environment, nutrition, and overall care are not mere details but key determinants in the quality of mohair. It is evident that meticulous pest management, ensuring a balanced diet, and fostering a serene environment for these animals enhance fiber quality. The “Predator Friendly” initiative presents a pioneering vision. It is not just about protecting livestock but achieving an equilibrium in the ecosystem. This vision signifies that with a thoughtful approach, livestock and wildlife can coexist, respecting each other’s space and role in nature. Consumers in the fashion realm are no longer passive recipients. They seek transparency, authenticity, and a clear line of sight to a product’s origin and its environmental footprint. In this light, the ethically driven and sustainable mohair production advocated by Cauffman aligns seamlessly with contemporary demands (Table 3).

Table 3:Optimization of Cauffman’s Best Practices for Sustainable Mohair Production.

However, the journey doesn’t end at producing sustainable fibers. The value of authenticity transcends the product and becomes embedded in every facet of the production chain. What makes sustainable mohair distinct is its homage to the ecosystem, its commitment to animal welfare, and the tangible positive reverberations it sends across local communities. As the fashion industry introspects and recalibrates its strategies, integrating such values can pave the way for genuine, meaningful transformations.

Ultimately, the sustainable mohair production paradigm serves as a guide. It is not just a model for producing a specific fiber but an ethos that other segments of the fashion industry can emulate. The confluence of ethics, environmental reverence, product quality, and unadulterated authenticity sparks optimism for forthcoming endeavors in fashion. Glen Cauffman’s emphasis on the synergies between animal welfare and environmental stewardship in mohair production is illuminating. He stresses the significance of genetic diversity, apt nutrition, and organic pest management. Aspects like pasture quality, meticulous preparation before shearing, and the strategic deployment of guard dogs, especially breeds like the Great Pyrenees, become cornerstones in ensuring the well-being and protection of Angora goats. The ‘Predator Friendly’ initiative is more than just a protective measure; it is a testament to the fact that sustainable farming and wildlife can indeed flourish side by side.

Contribution

This article fills a research gap by focusing on the preharvest stages of mohair, an area previously overlooked. It offers recommendations for farmers, highlighting best practices for sustainable mohair production. By validating prior research, especially regarding the genetics of Angora goats, it confirms the significance of genetic selection for quality and sustainability. The article emphasizes the importance of transparency and champion authenticity in the fashion industry, while also spotlighting the positive impact of cooperating with local suppliers. In essence, it enhances knowledge about sustainable mohair, encourages transparency, and promotes genuine and sustainable practices.

Limits and Managerial Implications

One could argue that the authors have spent a limited amount of time with the farmer and only one day on site. It would be interesting to spend more time on site to discuss everyday activities. This research could be expanded to other types of animals and fibers. One may think of sheep/wool, alpaca or cashmere goats. Nevertheless, after spending the entire day from sunrise to sunset, learning all of these details, walking in the pastures, interacting with the animals, the authors believe it is important to promote the message that “before shearing” is part of the fashion supply chain. If people are indeed looking at a sustainable business model, if they embrace local, natural fibers, if they avoid cheap labor and imports where quality and cost are reduced as much as possible, companies could link with farmers to value the entire supply chain as described in this paper.

Conclusion

This research underscores the pivotal role of on-farm decisions in advancing sustainability throughout the fashion supply chain. Through progressive farming practices, coupled with knowledgedriven care and selection of Angora goats, we have demonstrated the potential for producing socially responsible and environmentally sustainable fibers. As Cauffman aptly stated to the cohort of Textile Design and Fashion students: “Know your fashion, know where it comes from.” Every stage, from soil management to supply chain partner selection, is integral in realizing the highest caliber of sustainable diamond fiber.

Acknowledgement

We deeply acknowledge Glen Cauffman, whose influence on this research remains tangible despite his absence. His passion and dedication were a guiding light for all of us. This paper is dedicated to his memory, reflecting the excellence he constantly strived for.

References

- Henninger CE, Alevizou P, Goworek H, Ryding D (2017) Sustainability in Fashion A Cradle to Upcycle Approach. Palgrave Macmillan Publisher, Gewerbestrasse, Switzerland.

- Fletcher K, Grose L (2012) Fashion and sustainability, design for change. Laurence King Publishing, UK.

- Burgess R (2019) Fibershed, growing a movement of farmers, fashion activits, and makers for a new textile economy, Chelsea Green Publishing, White River Junction, Vermont, USA.

- Parkes C (2007) The knitter's book of yarn: The ultimate guide to choosing, using, and enjoying yarn. Potter Craft, New York, USA.

- Berg A, Granskog A, Lee L, Magnus KH (2020) Fashion on climate, How the fashion industry can urgently act to reduce its greenhouse emissions, McKinsey & Company and Global Fashion Agenda.

- Adams, Angela (2021) Senior sustainability consultant at quantis, stated: Quantis attends textile sustainability conference to accelerate sustainability in fashion.

- Trejo HX, Smith HA, Trejo NK, Lewis TL (2019) Made in New York: A collaborative model to encourage slow fashion. Clothing and Textiles Research Journal 37(3): 139-154.

- Charter M, Pan B, Black S (Eds.), (2024) Accelerating sustainability in fashion, clothing and textiles. Abingdon, Routledge, UK.

- Keiser SJ, Vandermar D, Garner MB (2017) Beyond design, the synergy of apparel product development. (4th edn), Bloomsbury Publishing Inc. New York, USA.

- Campaniaris C, Murray R, Hayes S, Jeffrey M (2015) The development of an apparel industry business model for Canada. Journal of Fashion Marketing Management 19(3): 328-342.

- Birnbaum D (2010) Comment: Garment sector well-placed to sell sustainability.

- Hobbs J (2019) American hemp, how growing our newest cash crop can improve our health, clean our environment, and slow climate change. Skyhorse Publishing, New York, USA.

- Martin C (1964) Que sais-je? La laine, N° 464 Published by Presses Universitaires de France Edition originale, (1st edn), 1951.

- Rauch J (1991) The golden fleece. National Journal.

- Mahapatra N (2009) Processing of mohair fibre in textile industries. Colourage 56(1): 78-80.

- Lupton CJ (1996) Prospects for expanded mohair and cashmere production and processing the United States. Journal of Animal Science 74(5): 1164-1172.

- National Agricultural Statistics Service (NASS), Agricultural Statistics Board, United States Department of Agriculture (USDA), (2020). Sheep and Goats.

- Braun AL, Roux JA (2004) Progress in the uitilization and promotion of South African indigenous goats for cashmere production, 8th International Goat Congress, Pretoria, South Africa, p. 4.

- FAO (2007) FAOSTAT.

- Braun AL (1999) Cashmere and mohair quality and value adding potential by SMME’s. Workshop, Commercialization of South African Goats. Witwatersrand Agriculture Show, p. 4.

- Sahlu T, Dawson LJ, Gipson TA, Hart SP, Merkel RC, et al. (2009) ASAS centennial paper: Impact of animal science research on United States goat production and predictions for the future. Journal of Animal Science 87(1): 400-418.

- Atav R, Yurdakul A (2011) Effect of the ozonation process on the dyeability of mohair fibres. Coloration Technology 127(3): 159-166.

- Mostovicz I (2012) The classic rules of exclusivity, rarity and scarcity must be adaptable.

- Hunter L (1993) Mohair: A review of its properties, processing and applications. CSIR Division of Textile Technology, Port Elizabeth, South Africa.

- Qin X, Qu L (2022) Study on properties of yak cashmere fiber. International Journal of Clothing Science and Technology 34(1): 79-95.

- Gabriel N (2012) The handknitter’s yarn guide, a visual reference to yarns and fibers. Roto Vision New York, USA.

- Pure American Naturals.

- Kadolph SJ, Langford AL, Hollen N, Saddler J (2010) Textiles. International Edition, Prentice Hall PTR, New York, USA.

- Cyr A (2014) The guide to textile fibers: fashion and clothing industry. (French Edition), CreateSpace, Montréal, Canada.

- Wang X, Khan Z (2000) Mohair fibre drafting in ring spinning Part 1: pinned apron. Journal of the Textile Institute 91(1): 16-20.

- Parkes C (2009) The knitter's book of wool: The ultimate guide to understanding, using, and loving this most fabulous fiber by Potter Craft, New York, USA.

- Parrot N (2002) The Stiff and the Cool, a story of knitwear, fashion and freedom. NIL Editions, Paris, France.

- Casey C (2021) Collection review: Key items -women's knitwear, A/W 21/22, WGSM by Ascential, pp. 1-15.

- Deschamps MJ (2012) Luxury fibres and fabrics: some sourcing trends. just-style.com 1 Nov. 2012. Business Insights: Global, Richard Gough, managing director of Australia's St. Albans Textiles in Deschamps.

- Faust, M-E. (2013) The Lux-story supply chain, told by retailers to build a competitive sustainable competitive advantage. International Journal of Retail & Distribution Management 41(11-12): 973-985.

- Fletcher K, Vittersø G (2018) Local food initiatives and fashion change: Comparing food and clothes to better understand fashion localism. Fashion Practice: The Journal of Design, Creative Process & the Fashion Industry 10(2): 160-170.

- De Beer EF (2009) Sustainable mohair industry production guidelines: pre-farm gate.

- Engert S, Rupert RR, Baumgartner J (2016) Exploring the integration of corporate sustainability into strategic management: a literature review. Journal of Cleaner Production 112(4): 2833-2850.

- Franck R (2001) Silk, mohair, cashmere and other luxury fibers. Woodhead Publishing Limited, Cambridge, England.

- Gamino D (2008) Offering a local spin on fleece. Austin American Statesman, ProQuest.

- HT Media Ltd (2009) Texas wool production down seven percent. US Fed News Service.

- Kapner S, Dulaney C (2015) With sales slowing, Macy’s Goes Upscale. Wall Street Journal- Eastern Edition, 265(112): B1-B2.

- Leal Filho W (2011) About the role of universities and their contribution to sustainable development. High Education Policy 24: 427-438.

- McGregor BA, Butler KL (2004) Contribution of objective and subjective attributes to the variation in commercial value of Australian mohair: Implications for mohair production, genetic improvement, and mohair marketing. Australian Journal of Agricultural Research 55(12): 1283-1298.

- McGregor BA, Butler KL (2008) Variation of mean fibre diameter across mohair fleeces: Implications for within flock animal selection, genetic selection, fleece classing and objective sale lot building. Small Ruminant Research 75(1): 54-64.

- McGregor BA, Butler KL (2009) Variation of mohair staple length across Angora goat fleeces: implications for animal selection and fleece evaluation. Journal of Agricultural Science 147: 493-501.

- McGregor BA (2011) The influence of mohair style and character on processing and market value. Mohair, Australia.

- Predator Friendly® (1991).

- Quantis (2021).

- Razalan DM, Bickle MC, Park J, Brosdahl D (2016) Local retailers’ perspectives on social responsibility. International Journal of Retail & Distribution Management 45(2): 211-226.

- Simons R (2021) Personal. Interview with Owner Retail January 10th, 2021.

- Stannard CR (2020) An investigation of the lifestyles and selling strategies of farmers with small fiber farms on Etsy. Fashion Practice: The Journal of Design, Creative Process & the Fashion Industry 12(3): 351-370.

- Towers N, Perry P, Chen R (2013) Corporate social responsibility in luxury manufacturer supply chains: an exploratory investigation of a Scottish cashmere garment manufacturer. Journal of Retail & Distribution Management 41(11&12): 961-972.

- Trejo HX, Lewis TL (2017) Slow fashion and fiber farming: Nexus for community engagement. Fashion Practice: The Journal of Design, Creative Process & the Fashion Industry 9(1): 120-142.

- Vejar K, Rodriguez A (2020) Journeys in natural dyeing, techniques for creating color at home. Abrams the Arts of Books, New York, USA.

- Vogel J (2013) Meet the 2013 master farmers. American Agriculturist.

© 2023 Bellemare Jocelyn. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)