- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Smart Natural Fibers Pretreated with Natural products and Dyed by Some Natural Dyes

Eman Mohamed El Khatib1* and Nagia Farag Ali2

1Department of Proteinic and Man-made Fibers, National Research Centre, Egypt

2Department of Dyeing, Printing and Auxiliaries, National Research Centre, Egypt

*Corresponding author:Eman Mohamed El Khatib, Department of Proteinic and Manmade Fibers, National Research Centre, Dokki 12311, Egypt

Submission: February 14, 2023; Published: March 24, 2023

ISSN 2578-0271 Volume 8 Issue2

Abstract

Purpose: In recent years, there has been an increase in the number of new technologies for antimicrobial fibers and growing awareness of cleaner environments and healthy lifestyles. The fast development of functional fibers and their final uses lead to several needs for the application of novel procedures for dyeing and finishing in textile manufacturing. Innovative high-value-added finishes for textile fibers are also highly appreciated by the demanding consumer market. Consumers are now aware of the hygiene of their lives and need textiles with antimicrobial properties. Design/methodology/approach: This paper reviews the work conducted by several researchers in developing the utilization of natural products for finishing textiles with antimicrobials has been noted. There is now a strong interest in using natural dyes in textile colors worldwide. This is due to the alleged environmental standards in several countries concerning the toxic and allergic reactions of synthetic dyes. Findings: Natural dyes are biodegradable, harmless, and environmentally friendly, creating highly attractive and smooth shades. Fabrics colored with natural dyes and pretreated with natural products, usually have antimicrobial properties. Originality/value: This review paper aims to summarize research studies conducted related to various natural fibers pretreated with natural products and dyed by some natural dyes. Smart fabrics and textiles can be useful in several fields, simply observing their applications in design and fashion. Smart fabrics are so important in the textile industry, especially in the health sector.

Keywords:Natural fibers; Natural products; Natural dyes; Antimicrobial activity

Introduction

Natural colors in textile dyeing have been popular worldwide since ancient times. Natural colors are eco-friendly and need cheap tools and small procedures. The characteristic properties of textiles give good media for the growth of microorganisms. Antimicrobial fabrics with enhanced properties have several applications in the hygiene and medical industries [1,2].

Textile fabrics based on chemical antimicrobial compounds such as organometallic, triclosan, quaternary ammonium compounds, and phenols, have been improved. Though the chemical antimicrobial agents are very efficient toward microorganisms and give a stable influence on fabrics, it leads to water contamination. Thus, there is a big request for natural antimicrobial fabrics based on environmental compounds which not only support the reduction of health hazards to microorganisms’ growth on fabrics material but also enhance the environment [3]. The usage of natural compounds like chitosan [4,5] and natural colors for the antimicrobial finishing of fabrics has been described [6-7]. Other natural herbal compounds, like Aloe Vera, and tea tree oil extracts, also could be used for that target [8,9]. There is a great source of medical plants that have active antimicrobial components. The research on natural products rich in antimicrobial compounds is limited and not documented. The reactions of herbal products compared to chemical pharmaceuticals are known to be very cheap and eco-friendly for textile applications.

Textile products are prone to host micro-organisms responsible for diseases, unpleasant odors, color degradation, and deterioration of textiles. Antimicrobial textiles can be used to produce many goods such as sportswear, outdoor apparel, undergarments, shoes, furnishings, upholstery, hospital linens, wound care wraps, towels and wipes. Self-sterilizing fabrics could have potential benefits to reduce disease transfers among hospital populations, biowarfare protection, and other applications.

Recent developments

Novel improvements in medical plants have new opportunities in research. Most of the researches in this area focuses on applying natural products. A review of the natural product for antimicrobial agents for textiles has been reported [10]. Customers are now attentive to a healthy lifestyle and there is a demand for fabric products finished with antimicrobial activity in natural materials. Nowadays antimicrobial fabrics have become so important in both scientific research and industry due to their properties of providing safe life to individuals [11]. This review presents the smart properties of textile fibers. Furthermore, smart textile fibers are mostly used in medical care, military clothes, and sportive products which have a great interest for upcoming industries [12]

Methodology

A. Environmentally eco-friendly pre-treatment of textile fibers

with natural compounds

a) Chitosan: It is an ideal antimicrobial agent

b) Nano-Chitosan: It has a large surface area which gives

several strong reactivities.

c) propolis: It is used against many types of bacteria.

d) Neem oil extract: It is a natural insecticide. It also has

antibacterial, antifungal, and medicinal properties.

e) Moringaoleifera seed oil extract: It is composed of phenolic

compounds, flavonoids, alkaloids and minerals. It has

antibacterial and antifungal properties.

B. These natural products are characterized by

a) Nontoxicity

b) Biodegradability

c) Chemical reactivity

d) Compatibility with other ingredients

C. Environmentally friendly pre-treatment of wool and silk

fibers

Pre-treatment of wool and silk fibers by natural products was carried out using different methods such as conventional, microwave heating, and ultrasonic methods. The pretreatment by natural products was applied at different concentrations of natural products, time intervals, and temperatures.

Pretreatment of textile fibers with Chitosan

Chitosan, which is deacetylated chitin; is non-toxic, an inhibitor for microorganisms, and biodegradable. The antimicrobial action of chitosan is affected by many factors including the type and degree of deacetylation of chitosan, molecular weight, pH, and ionic strength. Chitosan is considered an antimicrobial material for the fabric industry. The applications of chitosan in textile finishing are effective against a variety of microbes. Several methods have been established to evaluate the effectiveness of antimicrobial textile fibers such as dynamic shake test and agar diffusion test.

Wool fibers pretreated with chitosan and dyed with rhubarb dye:Ultrasonic coloring is a modern technique to save time, cost, and energy and offers a high value of dye uptake. Wool fibers pretreated with chitosan and dyed with rhubarb, illustrated in Figure 1 as a natural dye by conventional and ultrasonic methods. Factors affecting dye extraction, concentration, temperature, time of extraction, and pH were investigated.

Figure 1:Rhubarb plant.

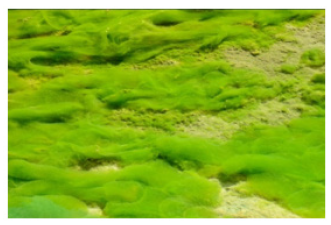

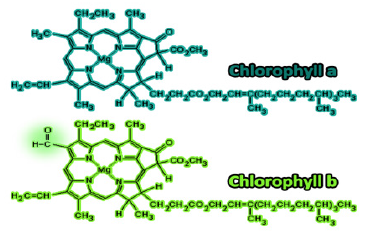

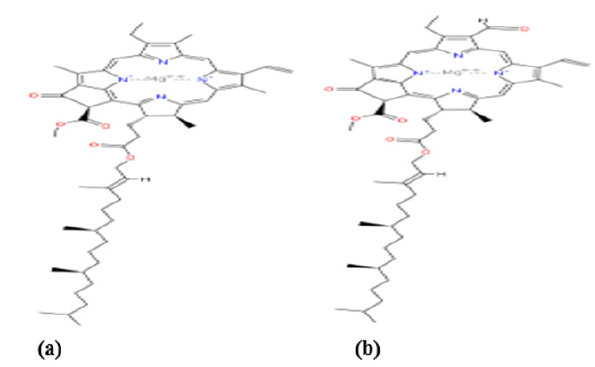

Wool fibers pretreated with chitosan and dyed with natural dye extracted from green algae: The natural dye extracted from green algae illustrated in Figure 2&3 is used for coloring wool fibers which are used in handmade carpets. Eco-friendly pre-treatment with chitosan and tannic acid was used for improving the dyeability of wool fibers. Factors influencing the coloring properties such as concentration of dye and dyeing time with microwave heating were investigated. Color strength was estimated for dyed wool fibers. Dyestuff: Algal Pigments

Figure 2:Algal Pigments.

a. Scientific classification:

b. Kingdom: Protesta

c. Division : Chlorophyta

d. Family: Zygnemataceae

e. Genus: Spirogyra

Figure 3:Chemical structure of Chlorophyll (a) and Chlorophyll (b).

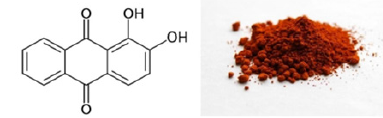

Wool fibers pretreated with chitosan and dyed with natural dye extracted from the Madder plant: Wool fibers were colored with natural dye extracted from the Madder plant, illustrated in Figure 4 using conventional and microwave heating methods. Wool fibers pretreated with chitosan and tannic acid. The dyeing properties were affected by some factors such as concentrations and extraction of dye, pH values, and the dyeing time. Color strength was measured for dyed samples. The fastness properties such as rubbing, washing, perspiration, and light of colored fibers were measured.

Figure 4:Madder dye and Chemical structure of Madder dye Dyestuff.

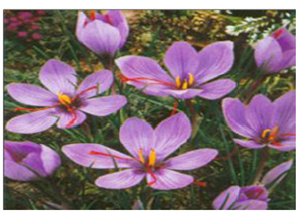

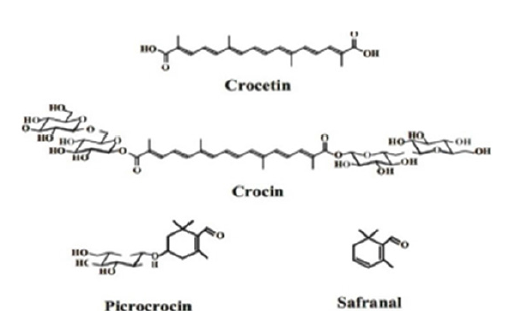

Figure 5:Saffron plant.

Silk fabrics pretreated with chitosan and dyed with natural coloring matter extracted from saffron: The antimicrobial activity of silk fabrics dyed with natural coloring matter extracted from saffron (Crocus sativus), is illustrated in Figure 5 using

conventional and microwave heating techniques. Some types of bacteria and fungi were used. The antimicrobial activity of chitosan pre-treated silk fabrics is measured by diffusion agents. Tested organisms such as Pseudomonas aeruginosa, Asperigillus flavus, Asperigillus niger, Bacillus subtilis, staphylococcus aureus and Escherichia coli were used in this investigation. Factors affecting the properties of dyeing such as dye extraction amount and concentration, time of extraction, and time of treatment with microwave were investigated. Silk fabrics were colored with natural dying matter extracted from Saffron (Crocus sativus).Factors affecting the dyeing characteristics like extraction quantity of dying, concentration, pH, temperature, and duration of dyeing were investigated. Eco-friendly pre-treatment with chitosan was used as a replacement for mordant. Color strength (K/S) values were assessed for the dyed silk fabrics. The fastness properties such as light, washing, and perspiration of dyed fabrics were measured. The dye extraction and color strength (K/S) of silk fabrics show that microwave is more effective than conventional heating. The data show great fastness properties. It is essential to promote ecofriendly natural dyes, with cheap equipment and simple techniques. Our goal is to illustrate the possibility of providing high-quality natural dyes extracted from plants, which could improve ve environment and allow the textile industry to follow the consumer needs towards more aesthetic textiles with natural products [6].

Pretreatment of textile fibers with Nano-Chitosan

Chitosan is a perfect antimicrobial agent. The applications of chitosan in fabrics have received great attention in many studies due to its great properties. The high molecular size and high viscosity of chitosan polymer limit its penetration into the fiber. Reducing the size of particles of chitosan to the Nano level improves the extent of penetration into fiber structure and maintains the characteristic of wool fibers. To obtain more advantages of chitosan, recent research has been focused on nano-sized chitosan particles by using nanotechnology [13].

Wool fibers pretreated with chitosan and Nano-chitosan and dyed with a saffron red and yellow mixture:In the textile industry, Nano-chitosan usage is a relatively new material. Nanoparticles have unique properties, like the large ratio of surface to volume, surface-active multi centers and high surface reactivity of chitosan Nano-materials have emerged as Nano-chitosan with good physicochemical properties. It is bioactive and regularly used in several industrial sectors including textiles. Improving the properties of wool fibers pretreated with chitosan and nanochitosan dyed with saffron natural dye. Wool fibers pretreated with chitosan and Nano-chitosan and dyed with the saffron red and yellow mixture as a natural dye by using the microwave heating method. The effect of chitosan and Nano-chitosan concentrations on color strength (K/S) was measured. Fastness properties and the color yield of the dye on wool fibers were studied.

Pretreatment of textiles fibers with PropolisPropolis (bee glue), illustrated (Figure 6&7) is a sticky resinous material produced by honeybees from different sources of plants like leaves, flowers, and bud exudates, modified by bee secretions and wax [14]. Many groups of researchers documented that all types of propolis expressed antibacterial properties which have antibacterial effects against both Gram-positive and Gram-negative microorganisms including multidrug-resistant bacteria like Methicillin-resistant Staphylococcus aureus (MRS) [15,16].

Figure 6:Honey comb.

Figure 7:Chemical structure of the main constituent of Propolis.

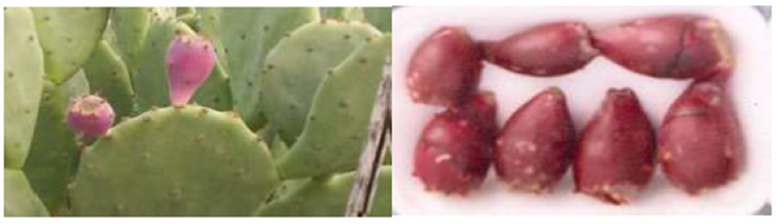

Wool fibers pretreated with Chitosan-propolis nanomaterial and dyed natural dye extracted from red prickly pear: The natural dye extracted from red prickly pear illustrate in Figure 8, using microwave heating was used for coloring wool fibers. Chitosan-Propolis Nano-composite was used as pre-treated on wool fibers before dyeing using microwave and ultrasonic techniques. The color strength of dye, concentration, pH and fastness properties of dyed wool fibers were studied.

Figure 8:Fruits of red prickly pear.

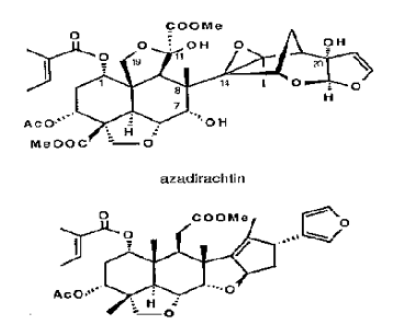

Pretreatment of textiles fibers with Neem Oil

Figure 9:Neem oil extract.

Figure 10:Chemical structure of main constituents of neem oil.

Neem oil, as illustrated in Figures 9&10 is a natural insecticide that possesses antimicrobial and medicinal properties.

Wool and silk fibers pretreated with neem oil extract and dyed with chlorophyll, saffron red, and saffron yellow dyes: The antimicrobial activity of wool and silk fibers pretreated with neem oil extract and dyed with chlorophyll, saffron red, and saffron yellow dyes illustrate in Figure 11-14 using economic methods such as ultrasonic and microwave heating. Factors affecting the dyeing properties such as concentration of dye and dyeing time with microwave and ultrasonic were investigated. The effect of neem oil concentration on color strength (K/S) was evaluated.

Figure 11:Chlorophyll plant.

Figure 12:Chemical structure of Chlorophyll (a) and Chlorophyll (b).

Figure 13:Saffron plant and Saffron red and yellow dyes.

Figure 14:Structures of the chemical constituents of saffron..

A. Natural Dyestuff: Chlorophyll dye, (Chlorophyll-100-

WSP), Saffron yellow and red dye (Saffron is the dried stigma of

flowers of Crocus sativus L.)

B. Chlorophyll dye: λmax 440, Saffron red dye: λmax 520,

and Saffron yellow dye: λmax 385.

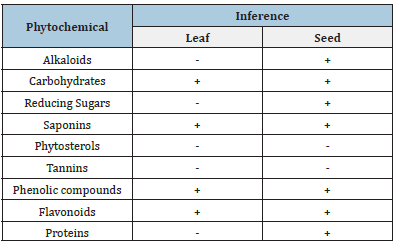

Pretreatment of textiles fibers with Moringaoleifera seed oil extract

Moringaoleifera seed oil extract, as illustrated in Figure 15 is composed of phenolic compounds, alkaloids, flavonoids, and minerals. It has antibacterial and antifungal properties. Table 1 indicates the Phytochemical composition of Moringaoleifera leaves and seeds.

Figure 15:Moringaoleifera leafs.

Table 1:Phytochemical composition of Moringaoleifera leafs and seed.

+ indicates presence. - Indicates absence of component.

Silk fabric pre-treated with Moreingaolefera and dyed with natural coloring matter extracted from madder: The antimicrobial activity of silk fabric was pre-treated with Moreingaolefera and dyed with natural coloring matter extracted from madder using microwave-eating techniques. Madder dye is a natural coloring material. The coloring compounds were extracted from Madder plant, illustrated in Figure 4. Factors affecting the dyeing properties such as concentration and time of dyeing with microwave were investigated. Color strength was evaluated for dyed Silk fabric.

Eco-friendly pretreatment with Moreingaolefera was used instead of using mordant for enhancing the dyeability of Silk fabrics. Factors affecting the dyeing properties such as concentration and time of dyeing with microwave were investigated.

Result and Discussion

Pretreatment of textile fibers with Chitosan/

Wool fibers pretreated with chitosan and dyed with rhubarb dye: The results indicated that wool fibers pretreated with chitosan and dyed with rhubarb showed higher color strength (K/S) and fastness properties than the untreated wool fibers. Pretreated wool fibers can be dyed at lower temperatures by ultrasonic technique as compared with the conventional method. The measurement of chromaticity values such as L*, a* and b* was used to evaluate the dyed wool fibers obtained by conventional method and ultrasonic technique. The chromaticity values were comparable for all dyed fibers. The value of a*, which represents the redness effect for dyed fibers was significantly higher in the ultrasonic method compared to the conventional method. This indicated that the dyed fibers by using the ultrasonic method were reddish-orange whereas the rest of other dyed fibers were more yellowish-orange. The antimicrobial activities against some microorganisms were evaluated. The results indicated that the wool fibers pretreated with chitosan and dyed with rhubarb showed a higher reduction percentage than the untreated fibers. Rhubarb (C.I. Natural Yellow 23) is a member of the family Polygonaceae, as are Japanese Indigo and Dock, and is indigenous to Asia Figure 1. Rhubarb is a perennial plant, which has long and large triangular leaves, these leaves can be used as a mordant. Rhubarb has a thick petiole and small greenish-white flowers, which grow from underground rhizomes. Its roots contain two main coloring matters named Gallic acid and tannins. The roots of rhubarb produce light fast shades of yellow and orange and the roots are considered an important source of dye [17].

Wool fibers pretreated with chitosan and dyed with natural dye extracted from green algae: Wool fibers pretreated with chitosan and tannic acid and dyed with natural dye extracted from green algae lead to high color strength than the untreated wool fibers. The antimicrobial property of dyed wool fibers pretreated with chitosan and tannic acid was investigated against some forms of bacterium and Fungi. The obtained data showed that the pretreated wool fibers showed a higher growth reduction % than the untreated wool fibers. Microwave heating saves time and energy for dyeing and is eco-friendly [5].

Wool fibers pretreated with chitosan and dyed with natural dye extracted from the Madder plant: The color strength of dyed wool fibers by dye extraction from the Madder plant showed that microwave heating is a more effective technique than the conventional heating method. The wool fibers pretreated with chitosan gave higher results in color strength than the untreated samples. The results explained that the pre-treatment samples by chitosan in citric acid are higher than chitosan dissolved in acetic acid compared to untreated dyed samples. The microwave technique is eco-friendly, saving time and energy of dyeing, economic, and enhances the dyeing properties. The results also showed good fastness properties. It is necessary to promote nonpolluting natural dyes, which involve inexpensive equipment and small-scale operations [18].

Silk fabrics pretreated with chitosan and dyed with natural coloring matter extracted from saffron:Silk fabrics pretreated with chitosan and dyed with natural coloring matter extracted from saffron exhibit a higher inhibition zone than the untreated fabrics. Environmentally friendly pre-treatment with chitosan was used instead of using a mordant. Color strength (K/S) was measured for dyed Silk fabrics. The results of the dye extraction and color strength (K/S) of Silk fabrics showed that the microwave heating method is better than conventional methods. The antimicrobial activity of silk fabrics dyed with saffron dye using microwave heating is highly effective [8]. Chitosan is an effective antimicrobial agent against all tested microorganisms. Asperigillusniger and Pseudomonas aeruginosa are highly affected by chitosan pre-treatments of each microbe respectively. Escherichia coli shows a moderate effect. Silk fabrics treated with chitosan and dyed with saffron natural dye showed high growth reduction of microbes because the amino groups of chitosan afford dyeing sites for the dye. The antimicrobial activity for colored fabric pre-treated with chitosan was increased compared to the untreated fabric. The antimicrobial activity also increases by increasing the concentration of chitosan [19]. Antimicrobial activity expressed as a growth reduction of the bacteria and fungi could be explained as follows. The amino groups in chitosan interfere with bacterial metabolism by stacking at the cell surface and binding with DNA to inhibit gene expression [4]. Chitosan of higher molecular weight shows more of a tendency to deposit on the surface of the fabrics, resulting in amino groups more easily available to bacteria and fungi [20,21].

The dye extraction and color strength (K/S) of silk fabrics show that microwave is more effective than conventional heating. The data show great fastness properties. It is essential to promote eco-friendly natural dyes, with cheap equipment and simple techniques. Our goal is to illustrate the possibility of providing highquality natural dyes extracted from plants, it could improve the environment and allow the textile industry to follow the consumer needs towards more aesthetic textiles with natural products.

Pretreatment of textile fibers with chitosan and Nano- Chitosan

Wool fibers pretreated with chitosan and Nano-chitosan and dyed with a saffron red and yellow mixture:The results indicated that wool fibers pretreated with chitosan and Nanochitosan recorded higher color strength than the untreated fibers. The results indicated that color fastness to rubbing, washing, and perspiration of all dyed wool fibers are excellent to good [22].

The results obtained indicated that the reduction percent of bacteria and fungi for fibers pre-treated with Nano-chitosan was higher than chitosan it gave values from 75-87% comparison of chitosan and Nano-chitosan in dyeing, fastness properties, tensile strength, elongation, and surface morphology were investigated. The results showed improvements in properties of wool fibers. Chitosan pre-treatment of the wool fibers creates additional functional groups on the surface which improve hydrophobicity. K/S values of pre-treated fibers in comparison to untreated fires gave higher values and good fastness properties. Nano-chitosan exhibited better properties due to its large surface area and small size when compared with bulk chitosan. However, pretreatment with chitosan and Nano-chitosan showed a protective effect and improved tensile strength. Pretreatment of wool fibers with chitosan and Nano-sized chitosan is ecologically acceptable. It’s more applicable and promising for the sustainable textile industry.

Wool fibers pretreated with Chitosan-propolis nanomaterial

Wool fibers pretreated with Chitosan-propolis nanomaterial and dyed natural dye extracted from red prickly pear:The results showed that wool fibers pre-treated with Nano samples exhibited better properties than the untreated fibers. The nanocomposite of chitosan and propolis exhibited antimicrobial activity against some pathogenic microorganisms. The obtained data showed that the antimicrobial activity of the natural dyes under study was better with the nanomaterial. The morphological structure of the untreated and pre-treated wool fibers was scanned by electron microscopy (SEM). The antimicrobial activities of wool fibers dyed with red prickly pear pre-treated with chitosan-propolis Nanocomposite were studied using standard methods (serial dilution and plate count) [23]. Chitosan-propolis nanomaterial pre-treatment of wool fibers improved the dye uptake and color strength. The fastness properties of dyed wool fibers such as light, washing, and perspiration were improved after pre-treatment by the prepared Nanocomposite. The color strength and dye extraction of wool fibers showed that microwave heating is better than ultrasonication. Microwave is an eco-friendly and economical technique and it saves time and energy in dyeing and increases dye uptake as compared to the ultra-sonication method.

Pretreatment of textiles fibers with Neem Oil

Wool and silk fibers pretreated with neem oil extract and dyed with chlorophyll, saffron red, and saffron yellow dyes:The results indicated that wool and silk fibers pretreated with neem oil lead to high dye uptake than the untreated fibers. The antimicrobial activity with some kinds of bacteria and fungi was investigated, and the results indicated that the fibers pretreated exhibited higher inhibition percent than the untreated fibers [24]. Neem (Azadirachta indica), an evergreen tree of India, belongs to the plant family Meliaceae (mahogany). It has been documented as one of the most sources of materials with insect control, antibacterial and medicinal properties. Neem has been used as a traditional medicine against several human ailments from ancient times in Egypt. But neem has also established much attention worldwide for its possible use as an herbal pesticide and other healthcare preparations in many countries such as the United States, China, India, France, Italy, and Germany. The active components of neem are found in all parts of the tree but in general, seed, bark leaves, and roots are used for extraction. The most important limonoids Ares planning and azadirachtin. The neem extracts have been widely used in herbal pesticide preparation because its insect repellent properties have the potential to prevent the growth of both Gram-positive and Gram-negative bacteria [25]. However, research on the seeds has increased since the isolation of azadirachtin as a natural pesticide. It has many uses mostly for soap, pesticides, and pharmaceuticals [26]. It also has antimicrobial and medicinal properties [27]. The aim of this study is to the pretreatments for wool and silk fibers with neem oil to improve dyeing and antimicrobial activity. It is necessary to avoid cross-infection by pathogenic microorganisms. These pre-treatments control the infection by microbes. This research used natural pigments extracted from plants such as chlorophyll, and saffron red and yellow dyes for dyeing wool and silk fibers. Natural dyes have been used for coloring fibers to protect the environment and prevent pollution caused by industries. The dyeing was carried out by using economical methods such as ultrasonic energy and microwave heating which is better than conventional methods.

Pretreatment of textiles fibers with Moringaoleifera seed oil extract

Silk fabric pre-treated with Moreingaolefera and dyed with natural coloring matter extracted from madder:Color strength of dyed Silk fabric from, the obtained data showed that Silk fabric pretreated with moreingaolefera leads to gh dye uptake than the untreated silk fabrics. The antimicrobial activity with me types of bacteria and fungi was tested st some types of organisms, and the results showed that t pretreated silk fabrics have hi er an intuition percentage than untreated silk fabrics Other additional advantages of these methods, are that they are eco-friendly, cheap, and more economical compounds [28,29].

Conclusion

Natural dyes are biodegradable, harmless, and environmentally friendly, creating highly attractive and smooth shades. Fabrics colored with natural dye usually have weak properties of dyeing and can be corrected by pre-treatment with natural products, which is called environmentally friendly pre-treatment. Fabrics colored with natural dyes and pretreated with natural products have antimicrobial properties.

Smart textiles and their applications are an important interest nowadays in textile research. Smart Textile is the cornerstone of high-tech functional textiles. It can improve healthcare lifestyle textiles and increase the added value of products. It can meet the requirements of the consumers. It is an important economic growth point for the textile industry in the future, but it is still an emerging industry and not yet fully established. Smart fabrics serve medicines through clothing for future work and applications. With the advancement of science and technology and the efforts of science, smart textiles will bring more convenience to our lives and bring more comfortable changes in people’s lives.

References

- Joshi M, Wazed Ali S, Purwar R (2009) Ecofriendly antimicrobial finishing of textiles using bioactive agents based on natural products. Indian Journal of Fibre & Textile Research 34: 295-304.

- Jothi D (2009) Experimental study on antimicrobial activity of cotton fabric treated with aloe gel extract from Aloe vera plant for controlling the Staphylococcus aureus (bacterium). African Journal of Microbiology Research 3(5): 228-232.

- Hebeish AA, Ali NF, Abd El Thalouth JI (2012) Green strategy for the development of antimicrobial printed textile fabrics. Research Journal of Textile and Apparel 16(1): 77-81.

- Shin Y, Yoo Dl, Jang J (2010) Molecular weight effect on antimicrobial activity of chitosan treated cotton fabrics. Journal of Applied Polymer Science 80(13): 2495-2591.

- El Khatib EM, Ali NF, El Mohamedy RSR (2016) Enhancing dyeing of wool fibers with colorant pigment extracted from green algae. Journal of Chemical and Pharmaceutical Research 8(2): 614-619.

- El Khatib EM, Ali NF, Ramadan MA (2014) Environmentally friendly dyeing of silk fabrics using microwave heating. International Journal of Current Microbiology and Applied Sciences 3(10): 757-764.

- Shokry GM, El Khatib EM, Ali NF (2010) Ultrasonic assisted eco-friendly dyeing of silk fabrics. Al-Azhar Bulletin of Science 21(1-A): 21-34.

- Ali NF, El Khatib EM, El Mohamedy RSS, Ramadan MA (2014) Antimicrobial activity of silk fabrics dyed with saffron dye using microwave heating. International Journal of Current Microbiology and Applied Sciences 3(12): 140-146.

- Sanjay R Malpani, (2013) Antibacterial treatment on cotton fabric antimicrobial activity of chitosan treated cotton fabrics. Research Journal of Textile and Apparel 16: 77-81.

- Nesa SHS, Tarangini K (2023) A review on augmentation of natural fabric materials with novel bio/nanomaterials and their multifunctional perspectives. Hybrid Advances 2: 100020.

- Abdel Aziz E, Bakr M, Zayed M, Othman H, Hassabo AG (2022) Microencapsulation and its application in textile wet processing: A review. Journal of Textiles, Coloration and Polymer Science 19(2): 189-202.

- Gulati R, Sharma S, Sharma RK (2021) Antimicrobial textile: Recent developments and functional perspective. Polymer Bulletin 79: 5747-5771.

- El Khatib EM, Ali NF, Nassar SH, El Shemy NS (2022) Functionalization of natural fibers properties by using TiO2 nanoparticles to improve its antimicrobial activity. Bio-interface Research in Applied Chemistry 12(3): 4177-4191.

- Simone Finstrom M, Borba RS, Wilson M, Spivak M (2017) Propolis counteracts some threats to honey bee health. Insects 8(2): 46.

- Ramadan M, El khatib EM, Nassar S, Montaser A, Kantouch F (2019) Printed cotton fabrics with antibacterial properties based on honey gum containing printing paste formulation. Egyptian Journal of Chemistry 62(12): 2175-2182.

- Ali NF, Abd Elsalam IS (2020) Antimicrobial characteristics of wool fibers treated with chitosan-propolis nanocomposite and dyed with natural dye extracted from Red Prickly Pear. International Journal of Agricultural Technology 16(2): 223-236.

- Ali NF, El Khatib EM, EL Mohamedy RSR (2019) Improvement in properties of wool fibers pretreated with chitosan and nano-chitosan and dyed with saffron natural dye. Egyptian Journal of Chemistry 62(Special Issue (Part 1) Innovation in Chemistry): 357-366.

- Ali NF, El Khatib EM (2016) Green strategy for dyeing wool fibers by madder natural dye. Journal of Chemical and Pharmaceutical Research 8(4): 635-642.

- Ali NF, El Khatib EM (2010) Modification of wool fabric to improve its dyeability. Journal of Natural Fibers 7(4) 276-288.

- El Khatib EM, Ali NF (2011) Cationized wool for improving the dyeability and antimicrobial activity. Research Journal of Textile and Apparel 15(4): 62-69.

- Ali NF, El Mohamedy RSR, El Khatib EM (2011) Antimicrobial activity of wool fabric dyed with natural dyes. Research Journal of Textile and Apparel 15(3): 1-10.

- Ali NF, El khatib EM, Elmohamedy R, Nassar S, Elshemy N (2019) Dyeing properties of wool fibers dyed with rhubarb as natural dye via ultrasonic and conventional methods. Egyptian Journal of Chemistry 62(1): 119-130.

- Ben David A, Davidson CE (2014) Estimation method for serial dilution experiments. Journal of Microbiological Methods 107: 214-221.

- El Khatib EM, Ali NF, El Mohamedy RSR (2020) Influence of Neem oil pretreatment on the dyeing and antimicrobial properties of wool and silk fibers with some natural dyes. Arabian Journal of Chemistry 13(1): 1094-1104.

- Ketema A, work A (2020) Antibacterial finishing of cotton fabric using stinging nettle (Urtica dioica L.) plant leaf extract. Journal of Chemistry 2020: 1-10.

- Sidhu OP, Kumar V, Behl HM (2003) Variability in neem (Azadirachta indica) with respect to azadirachtin content. Journal of Agricultural and Food Chemistry 51(4): 910-915.

- Imam H, Hussain A, Ajij A (2012) Neem (Azadirachta indica A. Juss): Nature’s Drugstore: An overview. International Research Journal of Biological Sciences 1(6): 76-79.

- Ali NF, El Khatib EM, El Mohamedy RSR (2015) The antimicrobial activity of pretreated silk fabrics dyed with natural dye. International Journal of Current Microbiology and Applied Sciences 4(6): 1166-1173.

- Tawfik TM, El Masry AM (2021) Preparation of chitosan nanoparticles and its utilization as a novel powerful enhancer for both dyeing properties and antimicrobial activity of cotton fabrics. Biointerface Research in Applied Chemistry 11(5): 13652-13666.

© 2023 Eman Mohamed El Khatib. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)