- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Experimental Measurements of the Shapes Adopted by Textiles when Subject to Wind Loading

Jason Knight1*, Joanna Harding Pitt2 and Diogo Montalvão3

1Senior Lecturer, BRAC Business School, BRAC University, Bangladesh

2McCann and Partners, Faraday House, Terra Nova Way, Penarth Marina, UK

3Department of Design and Engineering, Faculty of Science and Technology, Bournemouth University, UK

*Corresponding author:Jason Knight, School of Mechanical and Design Engineering, University of Portsmouth, Portsmouth PO1 3DJ, UK

Submission: August 24, 2022; Published: September 29, 2022

ISSN 2578-0271 Volume 7 Issue2

Summary

An investigation of the behaviour of Nylon and Polyester textiles subjected to wind loading was undertaken in an experimental study. Variable parameters of wind speed, incidence and excess length of the textiles were studied. As expected, increasing wind speeds and amount of slackness led to higher deflections above 4 degrees incidence. Below this angle large instabilities are found. Polyester with a higher air permeability, experienced greater levels of deflection at low slackness when compared to the Nylon. Only small differences in deflection were found between the textiles when using higher slackness ratios.

Introduction

Textiles are highly flexible surfaces which are used in sails, kites and parachutes. They are also used as canopies and as part of temporary building structures. However, most research has been conducted in their use as wings. Béguin [1] investigated the effect of prestress. Mancini [2] has studied the unsteady effect of rapid movements, whereas Tian [3] has investigated the effect of flapping. In previous work [4], we have investigated their use in convertible car roofs. In this investigation we concentrate on the amount of excess length or slackness with varying incidence.

Result

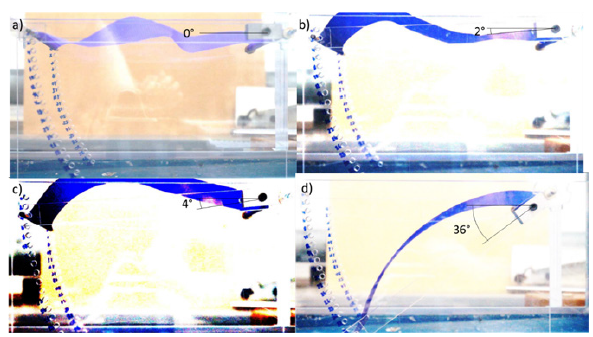

An adaptable rigging system to support the textile within the test area of the wind tunnel was designed, possessing elements to ensure simple variation of the incidence, slackness and membrane material. The two materials were then subjected to the same conditions within the wind tunnel, with the behaviour captured by taking a photograph, allowing deflection to be determined and to observe the planform deformation. The distance between the front and rear supports was 325mm. The photographs of the Nylon textile of 358mm length (10% excess length) with a windspeed of 4m/s are shown in Figure 1 with angles of attack of 0°, 2°, 4° and 36°.

At low incidences, the textile showed the most unstable behaviour (Figure 1a). The incidence of 0° lead to the most ‘flapping’, as the textile showed oscillating patterns. As the incidence increased, the stability improved. While a small amount of oscillation was still present, at 2° and 4° (Figures 1b & 1c), a more controlled and near parabolic-shaped deformation was achieved when compared to that at 0°. The peak deflection was observed to lie downstream of the membrane central axis. At all increments after 6°, the peak deflection point moved further upstream towards the central axis. The deformation further improved with regards to stability and adopted the form shown in Figure 1d. However, there where some additional instabilities around 12° due to flow separation from the top surface. These results lead to the conclusion that as the incidence of a flexible wing increases, flapping or unstable oscillations decrease with the exception of near the stall angle of 12°. This in turn increases predictability of behaviour with regards to deflection as the incidence increases.

Figure 1:Images to compare wing deformation shapes at 4m/s using 10% excess length at incidences of a) 0° b) 2° c) 4° and d) 36°.

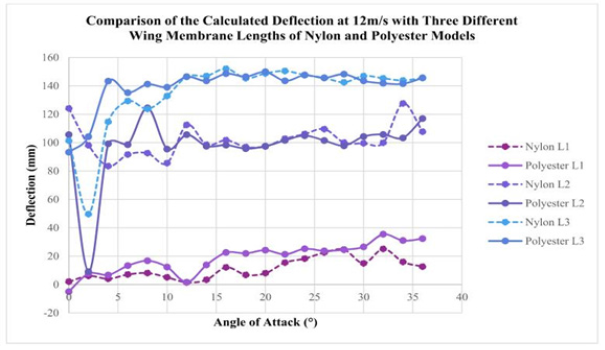

Different values of slackness of the Nylon are next investigated and compared to a polyester textile with higher air permeability. An increased wind speed of 12m/s is used with the same slackness of 10% excess length as well as reduced excess lengths of 5% and 0%. The amount of deflection for the 2 textiles with varying slackness are shown in Figure 2 for varying incidences.

Figure 2:Relationship between incidence and deflection with varying wing excess lengths of Nylon and Polyester textiles at a wind speed of 12m/s.

As expected, the textiles with highest slackness experienced the largest deflections and show the most variation in wing membrane shape. At lower incidences there is a high level of uncertainty as expected and shown in Figure 1. At higher incidences the results are more stable and differ much less. The lowest slackness textiles with 0% excess length (L1), generally show an increasing defection with increasing incidence. In addition, the Polyester textile generally experience a higher deflection than the Nylon textile. However, at larger slackness ratios with increased textile lengths of 5% and 0% (L2, L3) the pattern is not the same as there is little difference between the deflections of the 2 textiles. The defection using L1 is caused by extension of the textile whereas at higher lengths L2, L3 the deflection is predominantly due to the slackness or excess length itself.

References

- Béguin B, Breitsamter C (2014) Effects of membrane pre-stress on the aerodynamic characteristics of an elasto-flexible morphing wing. Aerospace Science and Technology 37: 138-150.

- Mancini PM, Jones AR, Granlund KO, Michael V (2015) Unsteady aerodynamic response of a rapidly started flexible wing. International Journal of Micro Air Vehicles 7(2): 1-12.

- Tian FB, Luo H, Song J, Lu XY (2013) Force production and asymmetric deformation of a flexible flapping wing in forward flight. Journal of Fluids and Structures 36: 149-161.

- Knight JJ, Lucey AD, Shaw CT (2010) Fluid-structure interaction of a two-dimensional membrane in a flow with a pressure gradient with application to convertible car roofs. J Wind Engng Ind Aerodynamics 98(2): 65-72.

© 2022 Jason Knight. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)