- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Fourth Industrial Revolutions: Prospects and Challenges for Textile Industry

Faujia Mushtari* and Tarikul Islam

Department of Textile Engineering, Jashore University of Science and Technology, Bangladesh

*Corresponding author:Faujia Mushtari, Department of Textile Engineering, Jashore University of Science and Technology, Jashore-7408, Bangladesh

Submission: July 18, 2022; Published: August 18, 2022

ISSN 2578-0271 Volume 7 Issue1

Abstract

Industry 4.0 is a revolution in manufacturing, a worldview based on the premise that every manufacturing value will be digital. Control and collaboration over all processes, devices, information, and logistics must also become digital. The use of Cyber-Physical Systems (CPS) for Industry 4.0 aims to connect computer systems with physical systems to create a virtual “smart factory” where various components can be interconnected, sensors collect data from these devices and send them back to the cloud; analytical models analyses on these data; cloud infrastructure allows this analysis to be shared among colleagues worldwide through databases; intelligent algorithms perform automated actions on large amounts of data set by humans & robotic units through machine learning. There are, however, several challenges that must be overcome first. In this article, we will discuss some issues regarding them in order to prepare for the next steps required for these technologies.

Keywords: Industry 4.0; Smart factory; Artificial intelligence; Cloud computing

Keywords:CPS: Cyber-Physical Systems; ICT: Information and Communication Technology; IIoT: Industrial Internet of Things

Introduction

Industry 4.0 applies information and communication technology (ICT) to multimodal production processes, including machines and robotics [1]. The concept refers to a new phase in organizations revolutionizing companies manufacturing and distributing methods [2]. Industry 4.0 combines the best of digital and traditional technologies to enable businesses to optimize their operations while reducing costs and improving economic performance [3].

Cyber-physical systems are the basis of Industry 4.0 [4]. Cyber-physical systems (CPS) are physical and computational systems created by merging computational hardware, software, sensors, and actuators-the combination of which provides new capabilities in product design, prototyping and development, remote control, services, and condition monitoring [5]. Artificial intelligence, also known as machine learning, can increase the efficiency and quality of manufacturing processes by providing systems with the ability to learn with experiences [6].

Industry 4.0 is a concept and an emerging trend where machines and systems inside factories are connected, enabling autonomous decision-making processes and monitoring assets and operations in real-time [7].

Prospects

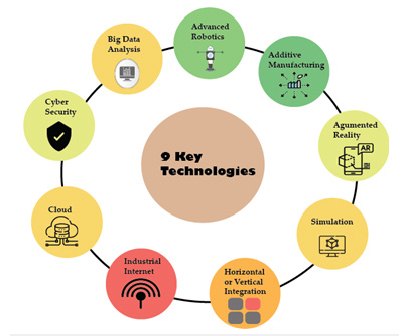

Industry 4.0 depends on nine key technologies: Autonomous robots, additive manufacturing, augmented reality & simulation, horizontal or vertical integration, Industrial lot, Cloud, cyber security, and Big Data and Analytics [8] (Figure 1).

Figure 1:9 Key Technologies used in Industry 4.0.

Increasing flexibility and efficiency is essential for all businesses, but it is vital in the fast-paced fashion industry to remain competitive [6]. As a result of the international competition, manufacturers constantly seek ways to streamline their design, production, and distribution processes [9]. For many years industrial processes have seen a marked improvement in quality and efficiency due to automation [10]. Adaptive manipulation systems have been used in the textile industry to improve production processes, especially regarding work pieces’ high consistency and preciseness [9]. The efficient application of robotics mechanisms has allowed the creation of both flexible and reliable methods [11]. The robotic manufacturing process aims to increase a company’s productivity, quality and competitiveness by reducing costs and improving responsiveness [12]. Cost reduction and production increment can be achieved by increasing work piece efficiency and accuracy on automated equipment, increasing automation capability in factories such as numerical controls, machine vision, etc., and managing robots autonomously via programming or even autonomous robots [13]. Automation is brought about by combining engineering with computers to control various processes from material production to finished products and customer service [14]. Robotics have performed successfully in textile manufacturing facilities, such as carding machines, spinning, and weaving machines, as well as in activities related to customer service or inspection [10].

The Internet of Things (IoT) is the term used to describe the connection of physical objects to the internet to collect or process data [11]. An intelligent factory essentially consists of machines connected and the internet using advanced sensors and interface devices [15]. This mechanization and connectivity make it possible for large amounts of valuable data to be collected, analyzed, and exchanged by these machines, allowing a company to improve its production process and efficiency [8] continuously.

Cloud computing provides the ability to store, process, and analyze vast amounts of data [15]. Smart manufacturing requires network connectivity, integration and collaboration between systems and processes [16]. Cloud can help you grow faster by supporting smart manufacturing and Industry 4.0 solutions at scale [7]. Once your product or service is on cloud, it’s accessible anywhere [17].

Augmented and virtual reality can give a ‘WOW’ factor feeling in shopping instead of the traditional boring practice of dragging yourself to a mall, finding a place to park, spending hours searching for the item you need, waiting in line in the dressing-room, etc. [13]. Retailers and manufacturers are using Augmented and virtual reality in different ways in the fashion industry. Like in-store navigation, interactive display panels, virtual try-on, virtual fitting rooms, virtual tailors, virtual makeovers spreading awareness, keeping customers engaged, enhancing loyalty, and so on [6,18].

Challenges

Two significant trends to achieving Industry 4.0 are Robotics and 3D printing [19]. These are both advancing rapidly, and many companies are trying to use them in their business activities, but there are some concerns regarding them as well [9]. The challenges that need to be overcome include technological and ecosystemrelated difficulties such as scalability and efficiency [20].

The integration of the IT and OT functions is challenging [18]. Both IT and OT have different cultures, and their different skill sets are not always a good match for each other [8]. When organizations design systems or applications that require the use of both groups, there are conflicts between their expectations, needs, training needs, and operational requirements, which makes it hard for them to work together effectively [10].

Data compliance is a big issue [21]. Data compliance questions are all about understanding how your organization handles and protects your consumer data through the different stages of that data’s life cycle, such as how it is collected and handled by your company, how it is shared with other companies, and what happens to that information once it leaves your organization [18]. Managing risk and lowering costs remain in focus [2,3]. Unpredictability and complexity can be found in all supply chains [22].

Conclusion

Industry 4.0 is similar to previous industrial revolutions that dominated manufacturing over the last century but is much more focused on data and control. Information can be gathered from all over the factory through sensors connected to the internet; algorithms then determine which actions should take place based on the results returned by these sensors. The significant challenges this scenario must overcome are privacy, security, and economics. One of the first steps needed is to understand how these technologies work to take the next step.

References

- Kumar R, Singh RK, Dwivedi YK (2020) Application of industry 4.0 technologies in SMEs for ethical and sustainable operations: Analysis of challenges. Journal of Cleaner Production 275: 124063.

- Luthra S, Mangla SK (2018) Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Safety and Environmental Protection 117: 168-179.

- Weyer S, Schmitt M, Ohmer M, Gorecky D (2015) Towards Industry 4.0-Standardization as the crucial challenge for highly modular, multi-vendor production systems. Ifac-Papersonline 48(3): 579-584.

- Sharma AK, Bhandari R, Pinca Bretotean C, Sharma C, Dhakad SK, et al. (2021) A study of trends and industrial prospects of Industry 4.0. Materials Today: Proceedings 47(10): 2364-2369.

- Moktadir MA, Ali SM, Kusi Sarpong S, Shaikh MAA (2018) Assessing challenges for implementing Industry 4.0: Implications for process safety and environmental protection. Process safety and Environmental Protection 117: 730-741.

- Sommer L (2015) Industrial revolution-Industrie 4.0: Are German manufacturing SME's the first victim of this revolution? Journal of Industrial Engineering and Management 8(5): 1512-1532.

- Sehuh G, Gertzen T, Rodenhanser T, Marks A (2015) Promoting work-based learning through industry 4.0. In: The 5th Conference on Learning Factories, Elsevier, Auchen, UK, pp: 82-87.

- Saldivar AA, Chen YW, Zhan ZH, Chen LY (2015) Industry 4.0 with cyber physical system integration: A design manufacture perspective. In: Proceeding of the 21st International conference on automation and computing, University of strathclyne, Auchen: Elsevier, Glasgow, UK.

- Deloitte Audit Tax Consulting Corporate Finance (2014) Industry 4.0: Challenges and solutions for the digital transformation and use of exponential technologies.

- Hahn T (2014) Future of manufacturing-view on enabling technologies. Siemens Corporate Technology.

- Deltabid (2014) Procurement: Key performance indicators.

- Lazi H, Fettke P, Kemper HG, Feld T, Hoffmann M (2014) Industry 4.0. Business & Information Systems Engineering 6(4): 239-242.

- (2017) Industrial Internet of Things: Cyber-manufacturing Systems. In: Jeschke S, Brecher C, Song H, Rawat D (Еds.), Springer International Publishing, Switzerland.

- Hu H, Wen Y, Chua TS, Li X (2014) Towards scalable systems for big data analytics: A technology tutorial. IEEE Access 2: 652-687.

- Zbarazska LO (2016) Neo-industrialization in Ukraine: conceptual national models. Economy of Industry Journal 3: 5-32.

- Geissbauer R, Vedsø J, Schrauf S (2016) A Strategist's Guide to Industry 4.0: Global businesses are about to integrate their operations into a seamless digital whole, and thereby change the world.

- Kochhar R (2015) A global middle class is more promise than reality. Pew Research Center.

- Brettel M, Friederichsen N, Keller M, Resenberg M (2014) How virtualization, Decentralization and network building change the manufacturing landscape: An industry 4.0 perspective. International Journal of Information and Communication Engineering 8(1): 37-44.

- Davisa J, Edgarb T, Porterc J, Bernadend J, Sarli M (2012) Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Computers and Chemical Engineering 47: 145-156.

- Federal Ministry of Education and Research (2013) Securing the future of German manufacturing industry: Recommendations for implementing the strategic initiative INDUSTRIE 4.0-Final report of the industry 4.0 Working Group, Germany.

- Mian SH, Salah B, Ameen W, Moiduddin K, Alkhalefah H (2020) Adapting universities for sustainability education in industry 4.0: Channel of challenges and opportunities. Sustainability 12(15): 6100.

- Reiman M, Ruckriegel C (2017) Road2CPS priorities and recommendations for research and innovation in cyber-physical systems. Steinbeis-Europa-Zentrum: Steinbeis-Edition, p. 56.

© 2022 Faujia Mushtari. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)