- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Study on the Effect of Stitch Length on Physical and Dimensional Properties of 100% Cotton Plain Single Jersey Weft Knitted Fabric

Riasat Alam AM*, Tufazzal Haider SM, Taposh Ranjan Sarker and Shafiqul Islam Chowdhury

Department of Textile Engineering, Northern University, Bangladesh

*Corresponding author:Riasat Alam AM, Lecturer, Department of Textile Engineering, Northern University, Bangladesh

Submission: March 26, 2022; Published: June 02, 2022

ISSN 2578-0271 Volume 6 Issue 5

Abstract

The effect of stitch length on the geometrical and dimensional properties of plain single jersey knitted fabric was carried out in this study. The physical and dimensional properties of knitted fabric were changed due to the use of various counts of yarn, types of yarn (ring, rotor, and compact), quality of yarn, stitch length/loop length, structural geometry, fiber composition of yarn, etc. This study focused on the effect of various stitch lengths on plain single jersey knitted fabric enduring other parameters constant. Plain single jersey knitted fabrics with stitch length 2.70mm, 2.80mm, 2.90mm, 2.95mm, and 3.00mm were tested separately for Courses Per Inch, Wales Per Inch, Gram Per Square Meter, stitch density, tightness factor, shrinkage, spirality, abrasion resistance, pilling resistance, bursting strength and the results showed that significantly they differ with variable stitch length. The research will be helpful for the knitted fabric manufacturers as well as for the textile researchers who strive to improve the fabric properties.

Keywords:Single jersey; Stitch length; Weft; Knitting; Quality; Shrinkage

Introduction

Knitted fabrics are becoming increasingly popular as they are easier to make at a cheaper cost and are more pleasant to wear. Knitted fabrics, on the other hand, are less dimensionally stable than woven fabrics because they are made with low twisted yarn and have a loose structure, necessitating careful production while keeping various qualities in account. Changing the stitch length of a weft knitted fabric has a considerable influence on the fabric’s dimensional and physical attributes such as (GSM), Wales Per Inch (WPI), Courses Per Inch (CPI), shrinkage, spirality, and so on. Knitting is a textile structure-building process that involves shaping a continuous length of yarn into columns of vertically intermeshed loops. The distinct features of knitted structures, as well as their capacity to be developed to meet the exact specifications of knitted goods, are in high demand. The physical and dimensional qualities of weft-knitted fabrics with varied fabric constructions are heavily influenced by the loop length. Yarn knitted into the stitch, in particular, is an essential characteristic for determining the quality of knitted fabric. It has been proposed that stitch length is a knitted structure unit parameter that is inversely related to wales and courses per inch [1-11]. It has been suggested that the wales or courses per inch will be separately related to the stitch length through a value of the constant parameter Kc for courses, Kw for wales whereas Ks is the area parameter to stitch density. The uses of constant factors indicate the relative tightness and looseness of a plain knit structure. Smirfitt [12] defined the geometry of the 1X1 rib structure and established that the tightness factor formula is identical to that of a plain knit structure. With the increase of stitch length, the fabric becomes looser and weak in tightness in a v-bed produced rib fabric of different structures. Although Ks is close enough to a constant and independent of the stitch length on the other hand other two parameters (Kc, Kw) are dependent on the stitch length.

Kumar et al. [5] and Oinuma [9] that the loop length of knitted fabric is inversely proportional to the areal density of knitted fabrics. Later more experiments were executed to assess the relation at different conditions on different fabrics. Kavuşturan [3] investigated the bursting strength during different processing like dyeing, finishing, and end-uses. The effect of knit structure on the bursting strength is found as positive by researchers. Sabrina and others experimented on the plain single jersey and their derivatives represent that the bursting strength of knitted fabrics decreases with the increase of stitch length Megeid [7]. Pills are developed on the fabric surface resulting in an unpleasant appearance and initiating the abrasion of garments and can cause wear and tear of the garments. Pilling of fabric increases with the increase of stitch length and plain singe jersey has a lower pilling resistance than others. A recent investigation of Khalil [4] on the plain single jersey at grey stage abrasion resistance decreased with the increase of stitch length. Widthwise shrinkage was decreased while lengthwise shrinkage increased, and the finding was not compatible with finished fabric. It was also found that with the increase of stitch length the spirality was decreased at the grey stage [11].

Materials & Method

Materials

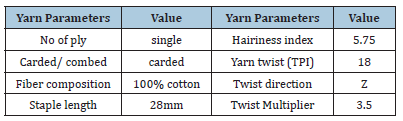

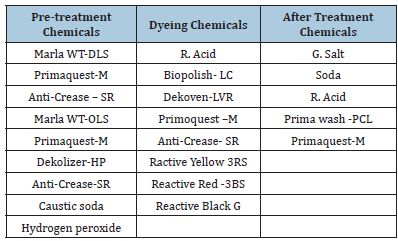

Sample Fabric Manufacturing begins with the grey stage that requires yarn preparation. The cotton raw material is taken to produce 30’s Ne combed ring yarn. Various yarn properties are mentioned in Table 1 to carry on the study. The dyeing and finishing stages involve the pre-treatment, dyeing, and after-treatment procedures. Materials used to continue these procedures are listed in Table 2. A single jersey circular knitting machine was selected for this study since it is widely used. At the dyeing and finishing stage dyeing machines, dryer, and stenter machines were used [13].

Table 1:Yarn properties.

Table 2:Chemicals applied.

Methods

An experimental method was adopted for carrying out this study. The experiment is carried out by manipulating a variable (Stitch length) called the independent variable and the changes in other properties such as WPI, CPI, GSM, Shrinkage, spirality bursting strength, etc. are called dependent variables, and relations of them with stitch length are measured. Yarn from the same lot is placed in the creels carefully for knitting.

Knitting:Plain single jersey fabric was produced with five different stitch lengths, ranging from minimum to maximum.

Dyeing:Scouring is performed following the flowchart.

Finishing:After knitting the samples were dry relaxed and then processed at 65% Relative Humidity (RH) and 30 °C±2 °C. After relaxation, the following tests were carried out for 10 samples. All tests were carried out at 27 °C±2 °C and 65% RH.

Determination of Stitch Length:With the help of the HATRA coarse length tester, the coarse length of different produced fabrics is measured. Coarse length = π ×diameter of the machine × Gauge × Stitch length. So, Stitch Length = (coarse length)/ (π × diameter of the machine ×Gauge).

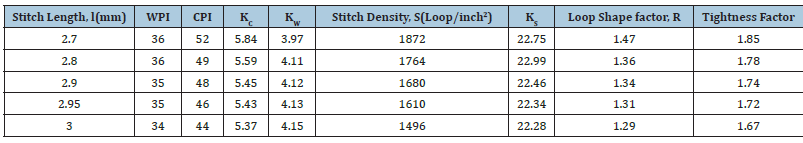

Determination of WPI, CPI, Stitch Density and Loop Shape factor:With the help of counting glass, WPI and CPI of various stitch lengths were measured. We calculate stitch density and loop shape factor. Stitch density(S) = WPI × CPI Loop shape factor(R) = CPI/WPI

Determination of Fabric Weight (GSM):After relaxation and conditioning of knit fabric samples, GSM of the samples was tested by taking test samples with the help of a GSM cutter and weighting balance.

Determination of Fabric Width:After relaxation and conditioning the tubular fabric was turned into open width form by slitting along the slit line measuring tape, the width of the fabric is measured for different stitch lengths containing samples.

Determination of Spirality % and Shrinkage %:Test was done according to AATCC Test Method 96-2009 for shrinkage and for spirality AATCC Test Method 179-2004.

Determination of bursting strength:In the industry, 5 samples were tested for busting strength according to ASTM Test Method D3787.

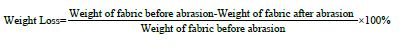

Determination of abrasion resistance and pilling resistance:The abrasion properly was tested with the help of a Martindale abrasion tester according to ASTM D3884.

Pilling resistance test:Pilling resistance was assessed according to the ASTM D3512 method.

Results and Discussion

Variation of dimensional and physical properties

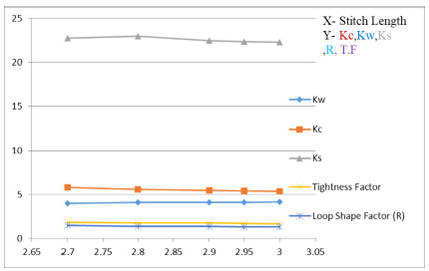

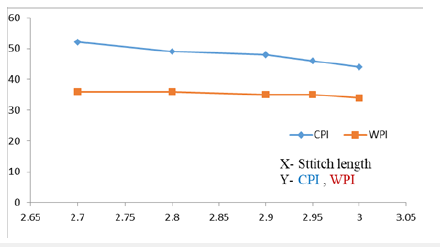

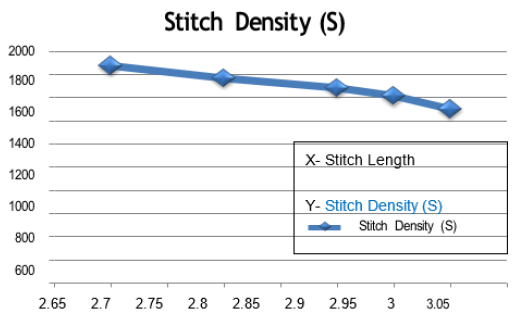

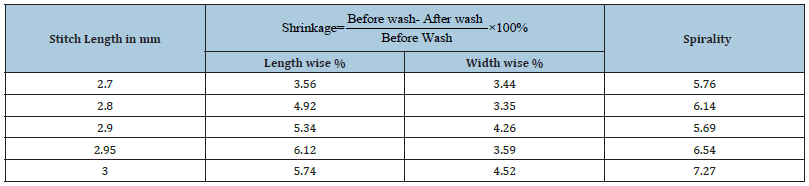

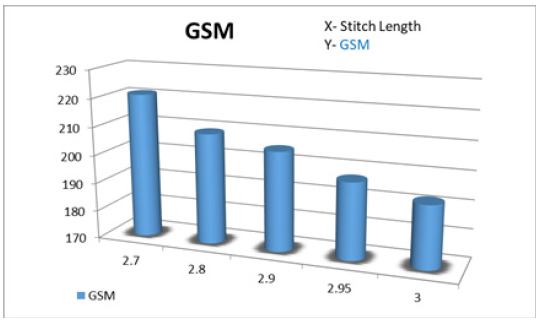

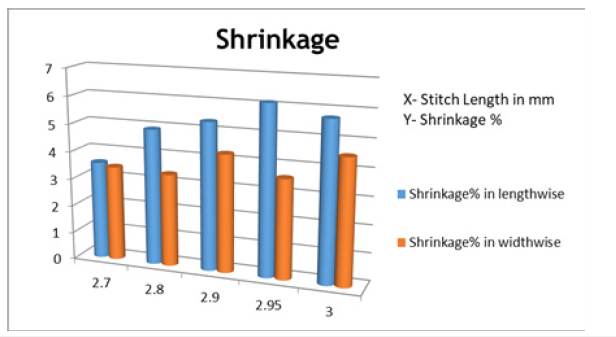

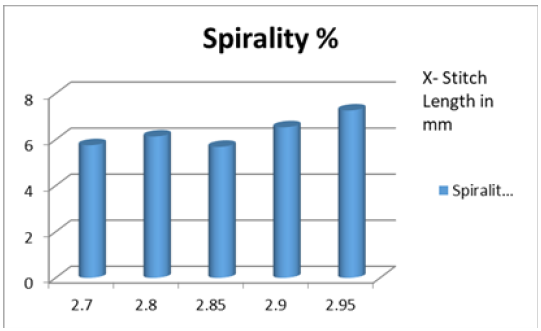

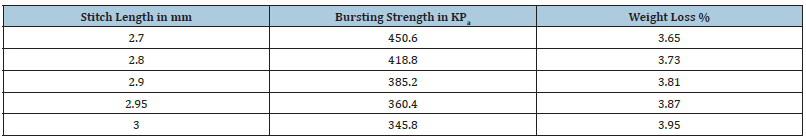

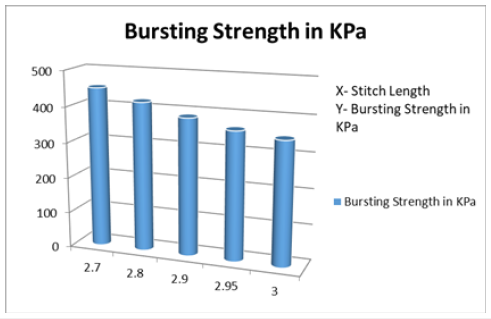

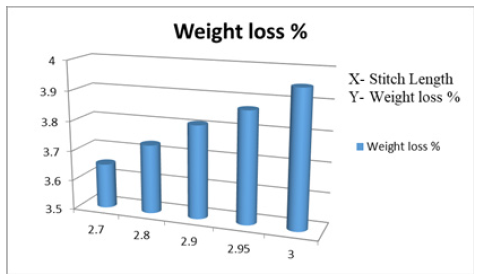

Changes in WPI, CPI, stitch density, loop shape factor, and tightness factor are shown in Table 3 for different stitch lengths in different types of fabrics. From Figure 1 & Figure 2 it is found that Kc, Kw, Ks, R, and Tightness Factor has no significant change with the increase of stitch length in single jersey fabric. Kc, Ks, R and tightness factor values decrease slightly with the increase of stitch length, but kw values slightly increase with the increase of stitch length. Stitch density means the number of loops per square inch. Figure 3 shows that with the increase of stitch length, stitch density decreases. Stitch Lengths of 2.70mm, 2.80mm, 2.90mm, 2.95mm, 3.00mm were taken to determine the respective GSM Table 4. With the increase of stitch length, there must be more open space in the fabric hence areal density of the fabric will decrease. The Figure 4 shows that with the increase of length GSM of the fabric decreases. With the increase of stitch length lengthwise and widthwise shrinkage increases gradually as shown in Figure 5. Spirality is the distortion of the place of loops where they formed. The higher the loop length the higher the distortion of the place of loops. From Figure 6 it is found that with the increase of stitch length spirality of single jersey fabric increases. According to Figure 5 it is seen that if the stitch length increases bursting strength is decreased Table 5. This is due to the fact that when stitch length is less, no. of loops per square inch is more. Therefore, the resistance towards the force is more in case of less stitch length of fabric. The formula to calculate the weight loss (%) is given by,

Table 3:Data for single jersey fabric.

Figure 1:Relation of Stitch length with Kc, Kw, Ks, Loop shape factor (R) and Tightness Factor.

Figure 2:Relation of stitch length with CPI and WPI.

Figure 3:Relation of stitch density with stitch length.

Table 4:Data for shrinkage and spirality.

Figure 4:Relation of stitch density with stitch length.

Figure 5:Relation of shrinkage with stitch length.

Figure 6:Relation of spirality with stitch length.

Table 5:Data for bursting strength and weight loss (%).

Referring to Figure 7 & Figure 8 it is observed that, Single jersey fabric showed higher abrasion loss% due to its soft nature on the surface with the increase of stitch length.

Figure 7:Relation of Bursting Strength with Stitch Length.

Figure 8:Graph for Abrasion Resistance.

Conclusion

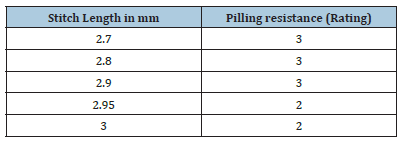

The relation of stitch length with plain single jersey fabric’s geometrical and dimensional properties are analyzed. The study conveyed that the CPI and WPI, Stitch density decreases with the increase of stitch length. Secondly, Kc, Kw, R and Tightness factor decreases as well as GSM also decreases with the increase of stitch length. But spirality and shrinkage increase with the increase of stitch length. Further observations show that bursting strength decreases with the increase of stitch length. Lastly, abrasion resistance and pilling resistance gets poorer with the increase of stitch length Table 6. Using the same count for the experiment confined the study a little bit. Statistical analysis with a good number of samples can be conducted with more stitch lengths. This study will help the industrial fabric manufacturers to understand these geometrical and dimensional impacts on single jersey fabric with various stitch lengths.

Table 6:Pilling resistance test.

References

- Doyle PJ, Hurd JCH (1953) Fundamental aspects of design of knitted fabrics. Journal of the Textile Institute 44(8): 561-578.

- Ichetaonye SI (2013) Effect of stitch length on the physical properties of (3x1, 4x1, 5x1, 6x1) rib knitted fabrics. International Journal of Fiber and Textile Research 3(3): 63-65.

- Kavuşturan Y (2002) The effects of some knit structures on the fabric properties in acrylic weft knitted outerwear fabrics. Tekstil Maraton, pp. 40-46.

- Khalil E, Solaiman M (2014) Effect of stitch length on physical and mechanical properties of single jersey cotton knitted fabric. International Journal of Science and Research 3(9): 593-596.

- Kumar V, Sampath VR, Vigneswaran C (2014) Study on geometric and dimensional properties of double pique knitted fabrics using cotton sheath elastomeric core spun yarn. In JTATM 8(4): 1-13.

- Manonmani G, Chettair V, Ramachandran T (2010) Suitability of compact yarn for manufacturing of eco-friendly processed weft knitted fabrics. Journal of Textile and Apparel Technology and Management 6(3): 1-18.

- Megeid ZA, Al-bakry M, Ezzat M (2011) The influence of stitch length of weft knitted fabrics on the sewability. Journal of American Science 7(8): 610-617.

- Munden DL (1959) 26-The geometry and dimensional properties of plain-knit fabrics. Journal of the Textile Institute Transactions 50(7): T448-T471.

- Oinuma R (1990) Effect of stitch length on some properties of cotton 1×1 rib knitted fabrics. Journal of the Textile Machinery Society of Japan 36(3): 91-95.

- Prakash C, Koushik CV (2010) Effect of loop length on the dimensional properties of silk and model union knitted fabric. Indian Journal of Science and Technology 3(7): 752-754.

- Ramgulam RB, Amirbayat J, Porat I (1993) The objective assessment of fabric pilling. Part I: Methodology. Journal of the Textile Institute 84(2): 221-226.

- Smirfitt JA (1965) Worsted 1× 1 rib fabrics part i. dimensional properties. Journal of the Textile Institute Transactions 56(5): T248-T259.

- Spencer DJ (2001) Knitting technology. CRC Press, Florida, USA.

© 2022 Riasat Alam AM. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)