- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Survey of Fabric Simulation

Xinrong Hu, Chen Yang, Jinxing Liang*, Tao Peng And Jin Huang

(Engineering Research Center of Hubei Province for Clothing Information,Wuhan,China)

(School of Computer Science and Artificial Intelligence, Wuhan Textile University,Wuhan,China)

*Corresponding author:Jinxing Liang, Engineering Research Center of Hubei Province for Clothing Information, Wuhan, China

Submission: April 01, 2022; Published: April 20, 2022

ISSN 2578-0271 Volume 6 Issue 4

Abstract

The present work aims to briefly overview the simulation of fabrics in computer graphics, including the rendering of knitted fabrics and the physical simulation or animation of fabrics. The future directions for fabric simulation under the megatrend of deep neural networks are also discussed.

Keywords: Fabric simulation; Knitted fabric; Physical simulation

Introduction

In the computer graphics field, the physical simulation has a long research history, especially the fabrics simulation has achieved considerable research results in the film, game, animation, and other industries. However, the complex structure of knitted fabrics leads to few related studies. With the development of knitting technology, peoples’ aesthetic and functional needs continue to improve. In addition to traditional knitted clothing, more and more functional knitted products, such as medical supplies and sportswear, are also in increasing demand. Knitted fabrics are widely used in garments due to their unique elastic properties, which are fundamentally different from the properties of woven fabrics. The properties of knitted fabrics come from the nonlinear three-dimensional kinematics of long or inter-loop yarns. Despite significant progress in cloth animation, we still do not know how to faithfully model knitted fabrics. Existing cloth simulation solvers mainly employ elastic sheet mechanics models inspired by woven materials, paying less attention to the model itself and more to important simulation challenges such as efficiency, stability, and robustness.

Whether in computer graphics field or others, most research on cloth mechanics has focused on woven fabrics, due to the simplicity of woven fabrics simulation and the widespread use of woven fabrics in many engineering applications. Woven fabrics simulation is the main application of cloth simulation in computer graphics, however, in clothing, knitted fabrics are as commonly used as woven fabrics. Many very ordinary garments, such as T-shirts or leggings, are made of knitted fabrics, not woven fabrics. Meanwhile, realistic complex physics simulators are invaluable to many scientific and engineering disciplines, yet traditional simulators can be prohibitively expensive to create and use. Proposing a simulator can take years of engineering effort, and often must trade off versatility and accuracy within a narrow set of settings. High-quality simulators require a lot of computing resources, which makes scaling very difficult. Even the best method is often inaccurate due to insufficient knowledge or difficulty in approximating fundamental physics and parameters. An attractive alternative to traditional simulators is to use machine learning to train simulation networks directly from observational data, however, standard end-to-end learning methods struggle to overcome large state spaces and complex dynamics. At present, the traditional knitted fabric simulation method is very complex and needs to adjust multiple parameters at the same time, while the learning-based simulation method can only perform simple cloth simulation. Therefore, we think it is very valuable work to study a learning-based method in knitted fabric simulation.

Cloth simulation has a long history

Cloth simulation has a long history in computer graphics. The earliest Baraff and Witkin used a dynamically defined rigid spring model [1], which can prevent penetration between cloths, and applied an implicit integration scheme to improve efficiency. After that, Choi and Ko developed a semi-implicit solution method [2], which can effectively deal with the buckling instability problem. Bridson et al. [3] deal with all point-triangle and edge-edge pair collisions in the mesh through impulse responses. Then Harmon et al. combined asynchronous variational ensemble with dynamical data structures. For collision detection, this can be done with potential barriers, which effectively approximate nested families of quadratic potentials. In the work of Ainsley et al. [4], they further speed up this approach by orders of magnitude.

Otaduy et al. [5] proposed an implicit treatment based on complementary collision constraints and a new solution for large mixed linear complementary problems [6]. However, work in recent years has shown that cloth simulations under implicit time steps can be performed more efficiently by optimizing auxiliary variables to represent strain. Meanwhile, with the recent popularity of the material point method, Jiang et al. [7] also applied the material point method to cloth simulation. They classified particles into three types and performed Euler-Lagrangian space in the material point method respectively. mapping between. Modern simulators use elastic rod theory to simulate the motion of a single yarn or thread [8]. Kaldor et al. [9] pioneered the simulation of yarn-level fabrics, followed by some work on improving collision handling methods [10], and using persistent contact to simulate woven fabrics [11] and knitted fabrics [12].

Leaf et al. [13] proposed a GPU-operated approach to interactively author and edit periodic small yarn patches that reproduce a large number of quiescent stitches and patterns under tension. Yuksel et al. [14] proposed a grid of stitches to create large-scale virtual knitting patterns. Then Wu et al. [15] ensured that they could actually be made. Narayanan et al. [16] introduced a set of tools for converting virtual knitted patterns into machinemade garments. In the computer graphics field, researchers often think of cloth as an elastic solid whose potential energy increases as it deforms from a resting state. Typical methods for discretizing such elastic solids are particle-spring networks [17], discrete thin shells [18], Finite-difference-based continuum mechanics solutions [19], finite elements [20] and Material point method [21]. When it is necessary to simulate the cloth structure at the macro scale, there is an open-source finite element shell solver project. Although these methods have high accuracy in the simulation field, it is difficult for traditional simulation methods to balance accuracy and computational efficiency in computer graphics. So, in recent years, people have begun to pay attention to data-driven learning-based related methods.

Data-Driven Simulation Methods

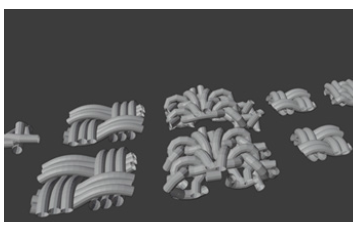

Data-driven simulation [22] has been an important area of applied research in physics and graphics. Compared wit engineering model simulators, data-driven simulators can predict complex phenomena more effectively [23]: for example, some works use simulation networks that learn partial fluids to make faster simulation predictions [24]. In recent studies, related work based on graph neural networks [25] has been proposed. And Graph Networks (GN) [26] have been shown to learn the dynamics of forward computation in various environments involving interactions between many entities as Effective. GN maps an input graph to an output graph with the same structure but possibly different node, edge and graph-level attributes. And it can be trained to learn a form of message passing [27], where latent information is passed between nodes through edges. GNs and their variants, such as interaction networks, can learn to model rigid bodies, mass-spring, many-body problems, robotic control systems [28], and non-physical systems such as multi-body Agent dynamics [29], algorithm execution [30] and other dynamic knowledge graph settings [31]. Ummenhofer et al. [32] proposed to use continuous convolution (CConv) as a solver for simulation, which is a nongraph structure-based fluid simulation method. Recently, Sanchez-Gonzalez et al. [33] proposed Graph Network Based Simulation (GNS), which encodes discrete particles in a fluid into a graph structure with adjacency information. Then they used the graph network as a solver to compute gradients and decode back to the original space. However, these methods cannot be directly used in the simulation process of the cloth because the structural characteristics of the cloth are different from those of the general freely constrained particles. Currently, there is also some work to learn material models for cloth from example data. Wang et al. [34] proposed a low-cost setup for measuring the characteristics of fabrics under tensile and flexural tests and optimized a piecewise linear material model. Miguel et al. [35] developed a measurement device to capture more complex 3D deformations of cloth with complete position and force data. And Miguel et al. [36] showed how to inexpensively measure the internal tensile and bending friction of cloth and optimize the required parameters based on sparse data. Further studies discussed incremental fitting of separable models for convex hyperelastic materials [37] and orthotropic models for woven fabrics based on commercial tests [38]. In recent years, with the popularity of graph networks for simulation, Pfaff et al. [39] used graph networks to simulate cloth (Figure 1).

Figure 1:Sample of knitted fabric model..

Meanwhile, data-driven learning-based methods have also been used to add details to coarse simulations. Wang et al. [40] used a pre-computed database of high-resolution simulations to add detailed wrinkles to coarse simulations at an interactive rate. Zhang et al. [41] proposed a multi-network framework to learn high-definition details from low-resolution clothing fold textures. The framework can enhance the normal map of different folds for cloth of different materials through a classifier. However, the current research on data-driven simulation still has a lot of research space for the simulation of yarn-level knitted fabrics with complex loop texture structures.

Future

Data-driven fabric simulation has only slowly emerged in the recent environment where graphics are influenced by deep learning. It is a relatively new direction, especially the simulation of knitted fabrics, because it is more difficult than woven fabrics and the patterns are more complex. So, there is a huge research space. We believe that we can use the classical model simulation as the framework, use the neural network as the solver to converge the energy, and map the texture of the knitted fabric to the mesh through the network. Compared with the previous method, this not only improves the efficiency, but also the actual simulation effect is closer to the real effect. Therefore, we believe that there are the following problems to be solved: First, the model needs to be redesigned for the deep network, and a suitable encoding method needs to be found to convert the relevant parameters of the model in the traditional method into the data that the deep network can learn. Second, we should obtain the corresponding data, that is, the generation of the data set. The existing data sets are mainly for simple simulation scenarios of fabrics and the knitted fabrics are relatively lacking. So, the simulation and data extraction of knitted fabrics is a key point. Last, we should correspond he local knitted fabric model to the primitive on the global cloth mesh.

References

- Baraff A, Witkin (1998) Large Steps in Cloth Simulation. In Proc Acm Siggraph, pp. 43-54.

- Choi, Ko H (2002) Stable but responsive cloth. ACM Trans Graph 21(3): 604-611.

- Bridson R, Fedkiw, Anderson J (2002) Robust treatment of collisions, contact and friction for cloth animation. ACM Trans Graph 21(3): 594-603.

- Ainsley E, Vouga E, Grinspun, Tamstorf R (2012) Speculative parallel asynchronous contact mechanics. ACM Trans Graph 31(6): 1-8.

- Otaduy R, Tamstorf D, Steinemann, Gross M (2009) Implicit contact handling for deformable objects. Comp Graph Forum 28(2).

- Bouaziz S, Martin T, Liu L, Kavan, Pauly M (2014) Projective dynamics: Fusing constraint projections for fast simulation. ACM Trans Graph 33(4): 1-11.

- Jiang C, Gast T, Teran J (2017) Anisotropic elastoplasticity for cloth, knit and hair frictional contact 36(4): 1-14.

- Miklós B, Basile A, Etienne V, Max W, Eitan G (2010) Discrete viscous threads. In ACM Transactions on Graphics (TOG) 29(4): 1-10.

- Jonathan MK, Doug LJ, Steve M (2008) Simulating knitted cloth at the yarn level. In ACM Transactions on Graphics (TOG) 27(3): 1-9.

- Jonathan MK, Doug LJ, Steve M (2010) Efficient yarn-based cloth with adaptive contact linearization. In ACM Transactions on Graphics (TOG) 29(4): 1-10.

- Gabriel C, Jorge LM, David M, Miguel AO (2014) Yarnlevel simulation of woven cloth. ACM Transactions on Graphics (TOG) 33(6): 1-11.

- Gabriel C, Jorge L, Miguel AO (2015) Efficient simulation of knitted cloth using persistent contacts. In Proceedings of the 14th ACM SIGGRAPH/Eurographics Symposium on Computer Animation, pp. 55-61.

- Jonathan L, Rundong Wu, Eston S, Doug LJ, Steve M (2018) Interactive design of periodic yarn-level cloth patterns. In Siggraph Asia.

- Cem Y, Jonathan MK, Doug LJ, Steve M (2012) Stitch meshes for modeling knitted clothing with yarn-level detail. ACM Transactions on Graphics (TOG) 31(4): 37.

- Kui W, Hannah S, Cem Y (2019) Knittable stitch meshes. ACM Transactions on Graphics (TOG) 38(1): 10.

- Narayanan V, Albaugh L, Hodgins J, Coros S, McCann J (2018) Automatic machine knitting of 3D meshes. ACM Transactions on Graphics 37(3): 1-15

- Baraff D, Witkin A (1998) Large steps in cloth simulation. In Proceedings of the 25th annual conference on Computer graphics and interactive techniques, pp. 43-54.

- Grinspun E, Hirani AN, Desbrun M, Schröder P (2003) Discrete shells. In Proceedings of the 2003 ACM SIGGRAPH/Eurographics symposium on Computer animation pp. 62-67.

- Terzopoulos D, Platt J, Barr A, Fleischer K (1987) Elastically deformable models. ACM Siggraph Computer Graphics 21(4): 205-214.

- Narain R, Pfaff T, O’Brien TJF (2013) Folding and crumpling adaptive sheets. ACM Transactions on Graphics (TOG) 32(4): 1-5.

- Guo Q, Han X, Fu C, Gast T, Tamstorf R, et al. (2018) A material point method for thin shells with frictional contact. ACM Transactions on Graphics (TOG) 37(4) : 1-15.

- Grzeszczuk R, Terzopoulos D, Hinton G (1998) Neuroanimator: Fast neural network emulation and control of physics-based models. In Proceedings of the 25th Annual Conference on Computer graphics and Interactive Techniques, pp. 9-20.

- He S, Li Y, Feng Y, Ho S, Ravanbakhsh S, et al. (2019) Learning to predict the cosmological structure formation. Proceedings of the National Academy of Sciences 116(28): 13825-13832.

- Wiewel S, Becher M, Thuerey N (2019) Latent space physics: Towards learning the temporal evolution of fluid flow. In Computer Graphics Forum, pp. 71-82.

- Scarselli F, Gori M, Tsoi AC, Hagenbuchner M, Monfardini G (2008) The graph neural network model. IEEE Transactions on Neural Networks 20(1): 61-80.

- Battaglia PW, Hamrick JB, Bapst V, Gonzalez SA, Zambaldi V, et al. (2018) Relational inductive biases, deep learning, and graph networks. arXiv preprint arXiv:1806.01261.

- Gilmer J, Schoenholz SS, Riley PF, Vinyals O, Dahl GE (2017) Neural message passing for quantum chemistry. In Proceedings of the 34th International Conference on Machine Learning 70: 1263-1272.

- Gonzalez SA, Bapst V, Cranmer K, Battaglia P (2019) Hamiltonian graph networks with ode integrators. arXiv preprint arXiv:1909.12790.

- Sun C, Karlsson P, Wu J, Tenenbaum JB, Murphy K (2019) Stochastic prediction of multi-agent interactions from partial observations. arXiv preprint arXiv: 1902.09641.

- Velikovi P, Ying R, Padovano M, Hadsell R, Blundell C (2020) Neural execution of graph algorithms. In International Conference on Learning Representations.

- Manessi F, Rozza A, Manzo M (2020) Dynamic graph convolutional networks. Pattern Recognition 97:107000.

- Ummenhofer B, Prantl L, Thurey N, Koltun V (2020) Lagrangian fluid simulation with continuous convolutions. International Conference on Learning Representations.

- Gonzalez SA, Godwin J, Pfaff T (2020) Learning to Simulate Complex Physics with Graph Networks [J].

- Wang H, O’Brien JF, Ramamoorthi R (2011) Data-driven elastic models for cloth: modeling and measurement. In ACM Transactions on Graphics 30: 1-12.

- Miguel E, Bradley D, Thomaszewski B, Bickel B, Matusik W, et al. (2012) Data-driven estimation of cloth simulation models. In Computer Graphics Forum 31(2pt2): 519-528.

- Miguel E, Tamstorf R, Bradley D, Schvartzman SC, Thomaszewski B, et al. (2013) Modeling and estimation of internal friction in cloth. ACM Transactions on Graphics 32(6): 1-10.

- Miguel E, Miraut D, Otaduy MA (2016) Modeling and estimation of energy-based hyperelastic Objects. In Computer Graphics Forum 35: 385-396.

- Clyde D, Teran J, Tamstorf R (2017) Modeling and datadriven parameter estimation for woven fabrics. In Proceedings of thea ACM SIGGRAPH/Eurographics Symposium on Computer Animation pp. 1-17.

- Pfaff T, Fortunato M, Gonzalez SA, Battaglia PW (2020) Learning mesh-based simulation with graph networks[J].

- Wang H, Hecht F, Ramamoorthi R, O’Brien JF (2010) Example based wrinkle synthesis for clothing animation. In Acm Transactions on Graphics 29(4):1-8.

- Zhang M, Wang T, Ceylan D, Mitra NJ (2021) Deep detail enhancement for any garment[C]. Computer Graphics Forum 40(2): 399-411.

© 2022 Jinxing Liang. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)