- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

The Major Consumer Requirement for Innerwear Apparel Clothing -Tactile Comfort Properties

Desalegn Atalie*

Ethiopian Insitute of Textile and Fashion Technology,Ethiopia

*Corresponding author:Desalegn Atalie, Textile Production Research and Innovation Center, Ethiopian Institute of Textile and Fashion Technology, Bahir Dar University, Bahir Dar, Ethiopia

Submission: August 24, 2020; Published: October 23, 2020

ISSN 2578-0271 Volume 6 Issue 2

Abstract

In recent years, tactile comfort is coming as key point and the basic quality requirement for apparel clothing especially direct contact cloths with human body like innerwear which is essential to impart good feelings and not cause unpleasant. During purchasing, consumers have a big interest to identify the tactile comfort of cloths by using their hand or fingers and estimate how it will feel with the skin during wear.

Introduction

Clothing comfort is an ongoing research area and many researchers are contributing in

different ways. Clothing comfort is defined the pleasant sensation of wearer and generally,

comfort can be classified in to three, psychological, thermal and sensorial/tactile comfort.

Tactile comfort properties of textile apparel clothing have received attention than the physical

and mechanical properties. Customers purchasing textiles always feel textile fabrics by for

its sensorial behaviors indicating that they are inquisitive about sensorial or tactile comfort

rather than other properties [1]. Currently, comfort is one of the most considerable properties

by manufacturer during clothing manufacturing due to demanded by consumers. Poor sensory

comfort properties will cause discomfort during wear and may influence work efficiency and

human health [2]. Tactile comfort is enclosed smoothness, stiffness, scratchiness, clinginess,

and low stress mechanical properties like bending, tensile strength, shear and compression

behaviors very crucial parameters [3]. In the field of the textile, sensorial comfort is known as

hand feel property or handle and tactile comfort. Tactile comfort of apparel clothing is formed

by between human skin and fabric surface interaction and resulting one or combination of

the following feelings such as softness, stiffness, smoothness, itchiness, prickliness, warmth,

or coolness properties [4].

Numerous researchers [4-9] have investigated the effect of different type of fibers,

blend ratio, fiber and yarn morphology, yarn characteristics, fabric structure and finishing

treatments on the tactile or sensorial properties of different type of fabrics. The earlier

researcher [10] stated that fabric sensorial comfort properties are significantly affected

by thread and areal density. In other research work, found that apparel cloths made from

natural fibers, especially cotton clothing was the most comfortable. The authors observed

that besides the participants’ visual observation to know about the quality and comfort of the

textile cloths, they were carried out comfort emulation procedures by touching, squeezing,

and pulling using their hands. These results were effective only for the studied group and not

for a specific clothing type [11].

Tactile comfort evaluation-subjective method

Before objective methods are introduced, clothing comfort was evaluated by trained personnel in subjective assessment using hand and fingers sensation. The rating method is performed in blind or opened eye condition and ranked in contrast way as example mostsmooth, moderate-smooth and least-smooth. Other method of rating is using numerical value 1 up to 5. All tactile comfort properties can be evaluated by squeezing, bending, move the fingers on the surface of the fabric, stretch by two fingers and compressed down, and ranked by sensing the comfort level of fabrics.

Surface smoothness and roughness evaluation-objective method

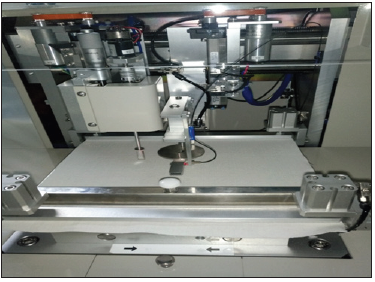

For tactile comfort properties of clothing surface smoothness and roughness is critical and effective factor to forecast the reaction between human body and cloth surface. As mentioned in above textile smoothness and roughness were evaluating using hand and fingers which are subjective tests for years. Thanks to technologist, these subjective methods are transferred to objective evaluation system. FAST (Fabric Assurance by Simple Testing), FTT (Fabric Touch Tester) and KAWABTA instruments are some of the recent independent technology output to measure tactile comfort properties of textiles. The most commonly used objective evaluation of tactile comfort in textile fabrics and garments is Kawabata System (KES) and it can measuring the bending, shearing, tensile, surface smoothness and roughness properties [9] KESFB3-AUTO-A Surface Tester Figure 1 is one of Kawabata module and used to evaluate smoothness and surface roughness properties of textile cloths. In the KES method, the data is measured by two measuring sensors namely frictional coefficient (MIU) and geometrical surface roughness means deviation (SMD) of the surface fabric instantaneously in three different places within a fabric area of 20cm x20cm. The MIU is measured by integrator in 0 to 20mm distance of test specimen then an average of the output will be recorded. A higher MIU value indicates less slipperiness of the fabric. In KESFB4 module, the second test parameter is SMD (geometrical surface roughness means deviation) and this value obtained by removing the least frequency harmonic wave by means of filtering the measurement curve through the low-cut filter. The SMD designates the evenness of surface physical, and a larger value indicates uneven surface.

Figure 1:KESFB4-AUTO-A: Surface friction and roughness test.

Conclusion

Fabrics’ tactile properties greatly influence human comfort throughout wear, and it is one of the fundamental requirements to purchase innerwear cloths. Generally, wearers are often checking smoothness and roughness of apparel cloths before they are purchasing. These frequent trends indicate high customer perception in sensorial comfort. Therefore, manufacturers should consider all factors to produce the desired clothing with optimum sensory or tactile properties.

References

- Atalie D, Gideon RK, Ferede A, Tesinova P, Lenfeldova I (2019) Tactile comfort and low-stress mechanical properties of half-bleached knitted fabrics made from cotton yarns with different parameters. J Nat Fibers.

- Atalie D, Gideon R (2020) Prediction of psychological comfort properties of 100% cotton plain woven fabrics made from yarns with different parameters. Tekstilec 63(1): 60-67.

- Atalie D, Ferede A, Rotich GK (2019) Effect of weft yarn twist level on mechanical and sensorial comfort of 100% woven cotton fabrics. Fash Text 6(1).

- Das A, Alagirusamy R (2011) Improving tactile comfort in fabrics and clothing in improving comfort in clothing. Elsevier 216-244.

- Kayseri GO, Özdil N, Mengüç GS (2007) Sensorial comfort of textile materials. Woven Fabr 235-266.

- Bishop DP (1996) Fabrics: sensory and mechanical properties. Text Prog 26(3): 1-62.

- Mooneghi SA, Saharkhiz S, Varkiani MH (2014) Surface roughness evaluation of textile fabrics: A Literature Review. J Eng Fiber Fabr 9(2): 1-18.

- Sülar V, Okur A (2007) Sensory evaluation methods for tactile properties of fabrics. J Sens Stud 22(1): 1-16.

- Atalie D, Rotich GK (2020) Impact of cotton parameters on sensorial comfort of woven fabrics. Res J Text Appar 24(3).

- Çay A, Atav R, Duran K (2007) Effects of warp-weft density variation and fabric porosity of the cotton fabrics on their color in reactive dyeing. Fibres Text East Eur 15(1): 91-94.

- Kamalha E, Zeng Y, Mwasiagi JI, Kyatuheire S (2013) The Comfort Dimension: A review of perception in clothing 28(6): 423-444.

© 2020 Desalegn Atalie. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)