- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Looking For Eco‐Friendly Clothing That Coexists With The Environment

Shen‐Kung Liao*

Department of Fiber and Composite Materials, Feng Chia University, Taiwan

*Corresponding author: Shen‐Kung Liao, Department of Fiber and Composite Materials, Feng Chia University, Taiwan

Submission: June 17, 2020; Published: July 08, 2020

ISSN 2578-0271 Volume 6 Issue 1

Abstract

It is impossible for human life to meet the king naked in “The King’s New Clothes”. The pursuit of the sustainability of the textile industry is inevitable. How to contribute to the sustainability and environmental protection of the earth in the field of textile industry is exactly. Here the key focus that supercritical fluid dyeing technology mainly uses carbon dioxide instead of water. Both of polylactic acid fiber (PLA) and polypropylene fiber (PP) are fiber materials on environmental protection in the text. Finally, the concept of using a single material on environmentally friendly textiles with innovative designs is also worth promoting way. In the near future, the development of textile technology can continue to break through, creating a way for people and the environment to live together in the world.

Introduction

Human life is inseparable from food, clothing, housing, and transportation. “Clothing” is a category covered by the textile industry. It can be seen how important the textile industry is to people. With the evolution of human civilization and the improvement of the quality of life, the field of “clothing” is ever-changing and all-encompassing. It is no longer just the basic need to wear clothing to keep warm. The textile industry in the 21st century is concerned about the waste and the threats and damage to the environment caused by the booming fashion economy. It is also the social cost and responsibility that the textile industry needs to face for its sustainable development. According to statistics, the water consumption of a pure cotton T-shirt produced by the traditional process can reach 2.7 thousand liters; in the past, the main source of clothing raw materials was cotton. The extensive use of pesticides during the cotton planting process also severely damages groundwater and soil layers. These situations are indeed alarming, so how to transform the textile industry towards environmental protection and sustainability is an urgent issue today.

Invisible pollution under beautiful clothes

Technology always comes from human nature, and human wisdom constantly reminds

that the fashion economy should develop under the premise of protecting the global

environment. However, today’s fashion industry is the second largest polluting industry in

the world, second only to the petrochemical industry. How much social cost is hidden behind

the gorgeous clothing under the window? When people take a deeper view of “fashion”

and explore the background behind the glory of fashion, how much unnecessary waste,

pollution, and destruction the earth bears because of the name “fashion”? Should people give

themselves the opportunity to think and examine whether this is desire and vanity, or is it

really necessary?

The clothes that are indispensable in daily life seem ordinary but are not simple. To make

a piece of clothing, from the acquisition of fibers, complex dyeing to the final treatment, up

to a thousand kinds of chemicals may be used; textiles and garments are complicated The

production process is as follows:

Fiber material→ Spinning → Weaving →fabric inspection →Singeing → Desizing → Scouring → ercerizing → Bleaching or fluorescent whitening → Dyeing → Fabric finishing →Clothes design → Pattern making → Sewing→ Garment→ Catalogue→ E-commerce marketing or physical sales

In this process, a large amount of water is used as the treatment

medium in the desizing, scouring, mercerizing, bleaching, dyeing

and finishing stages. On average, the global production of textiles

in the dyeing and finishing industry is about 28 billion kilograms

per year. For the dyeing and finishing process alone, it is estimated

that 100-150 liters of water is required for each kilogram of

textile production, and the amount of water consumption could be

imagined. The textile industry is considered to be an industry that

consumes a lot of water resources and highly polluted wastewater.

With the global awareness of sustainable environmental

protection rising, international brands are also actively demanding

green and environmentally friendly products. The dyeing and

finishing sections with high water consumption and high pollution

in the textile process have to be transformed and upgraded. It is

important to apply supercritical fluid technology to fiber dyeing

and finishing. This green technology uses carbon dioxide as a dyeing

medium, not only does it not waste water at all, but carbon dioxide

can also be fully recovered, which can be called the environmental

savior of the textile industry.

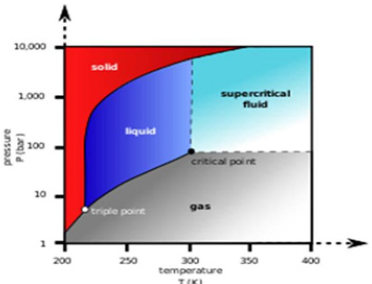

Figure 1: The phase diagram of carbon dioxide.

It is the key focus that supercritical fluid dyeing technology mainly uses carbon dioxide instead of water. Through temperature and pressure control, when the carbon dioxide exceeds its critical temperature and critical pressure, the gas-liquid interface disappears and forms a fluid state, which is called supercritical fluid state. The operating principle of this technology is to use the characteristics of dyes that can be dissolved in supercritical fluid carbon dioxide for fiber dyeing. When carbon dioxide is supercritical, that is, the temperature is higher than 31.1 ℃, and the pressure is greater than 7.28 atmospheres (7.38bar). In the state the dye molecules gradually diffuse into the fiber through supercritical carbon dioxide for dyeing, as shown on Figure 1. After the dyeing is completed, when the dyeing tank is returned to normal pressure (1 atmosphere), carbon dioxide and dye will automatically form a solid gas separation of the dye molecule (solid state) and carbon dioxide (gaseous state). At this time, both of dye and carbon dioxide can be recovered and reused individually, so that the dyeing and finishing process reaches the highest level of no pollution, no wastewater, and no waste. In addition to making dyeing use zero water resources, this technology can effectively reduce the use cost of 68% textile chemicals and 34% energy, and carbon dioxide can be fully recovered, 100% reused, in line with today’s environmentally friendly production trends. (The triple point is −56.6 °C and 5.11atm, which means that liquid CO2 cannot exist at pressures lower than 5.11atm. At 1atm, solid CO2 sublimes directly to the vapor while maintaining a temperature of −78.5 °C, the normal sublimation temperature.)

Fiber materials on environmental protection

How to deal with textiles after they are eliminated? Become

general garbage into the incinerator? After recycling, send it

to the desired country or region? In the end, these textiles will

inevitably become waste, causing environmental pollution and

burden? Therefore, it is an urgent task to develop fibers that can

be biodegraded or returned to the natural environment without

causing pollution, and to replace the world’s largest polyester fiber.

Polylactic acid fibers have properties that are high crystallization,

good flexibility, heat-resistant and very durable. This product has

superior performance and may replace polyester fibers in daily use.

The main advantage is that polylactic acid fibers are biodegradable.

On disposal a microorganism will be released to allow fermentation

and breakdown the high polymer chain within the fiber. In addition,

hydrolysis of PLA is autocatalytic in nature because the degradation

starts when PLA comes in contact with water molecules naturally.

The carboxylic acid produced by the hydrolysis of polylactic acid

will catalyze its further hydrolysis, namely the autocatalytic effect.

The main form of degradation of polylactic acid is hydrolysis, which

can be carried out simultaneously with thermal degradation. The

hydrolysis rate also has a great relationship with crystallinity.

Polylactic acid will decompose causing non-crystallization of the

fiber that then becomes a low molecular compound. It will crack

the fiber and the surface will corrode and wrinkle. Finally, it will

turn into water and carbon dioxide. Therefore, it will not cause

more pollution in the environment [1-4].

Polypropylene Fiber (PP) can be also called environmentally

friendly fiber. Although the raw material source is petroleum,

the molecular chain structure is composed of carbon and

hydrogen elements. Therefore, the composition of the fabric after

polymerization, spinning and weaving is only carbon and hydrogen.

After being buried, incinerated or exposed to sunlight for a long

time, polypropylene fibers will naturally be cracked and reduced

to carbon and hydrogen, and the carbon will return to dust, and

hydrogen will become water. It will not produce toxic gases that are

harmful to humans and can also be recycled 100%. Therefore, it

is classified as an environmentally friendly fiber and is currently

recognized as the most environmentally friendly petrochemical fiber in the world. It is not only light-weight (specific gravity 0.91g/

cm3), warm (thermal conductivity coefficient 0.21~0.26W/m- ℃ ),

quick-drying and comfortable (water content 0.05%, drying speed

11.1%/min), and it covers the entire process from production to

recycling In the process of carbon footprint, the required production

energy and the pollution generated are also the lowest among all

petrochemical fibers.

Conclusion

It is impossible for human life without clothes. The pursuit of the sustainability of the textile industry is inevitable. How to contribute to the sustainability and environmental protection of the earth in the field of textile industry is exactly. Although the supercritical fluid dyeing technology can completely solve the problem of dyeing and finishing wastewater pollution in the textile industry, today’s technology still has the problem of expensive equipment to be overcome. Also, the development and application of environmentally friendly fibers have more challenges. In addition to the need to improve these technologies again, humans can immediately contribute to the protection of the earth’s environment by changing consumer habits. While pursuing fashion, they support the purchase of environmentally friendly and energy-saving carbon-reduced textiles to avoid the proliferation of clothing waste. Through the recycling and sorting of PET bottles, it is used to make raw materials for products made of polyester, including polyester fibers used for the production of clothes and carpets. On the other hand, the concept of using a single material on environmentally friendly garments with innovative designs is also worth promoting, because the use of single-material textiles will make recycling and reuse convenient and feasible. Soon, the development of textile technology can continue to break through, creating a way for people and the environment to live together in the world.

References

- Wang WV, Kramer EJ, Sachse WH (1982) Effect of high-pressure carbon dioxide on the glass transition temperature and mechanical properties of polystyrene. Journal of Polymer Science, Polymer Physics Edition 20(8): 1371-1384.

- Wessinger RG, Paulaitis ME (1987) Swelling and sorption in polymer-CO2 mixture at elevated pressures. Journal of Polymer Physics Part B: Polymer Physics. 25: 2497- 2510.

- Kazarian SG, Brantely NH, Eckert CA (1997) In situ spectroscopy of polymers Subjected to Supercritical CO2: Plasticization and dye impregnation. Applied Spectroscopy 51(4): 491-494.

- Sayed AI, Radzuan R, KuZilati K, Nurlidia M (2017) Reaction-multi diffusion model for nutrient release and autocatalytic degradation of PLA-coated controlled-release fertilizer. Polymer 9(3): 111-124.

© 2020 Shen‐Kung Liao. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)