- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Technical Considerations and Specifications for Conductive Machine Embroidery

Rachel J Eike1*, Ava Depping2 and Allyson Cliett3

1Apparel Merchandising and Design, Iowa State University, USA

2Apparel Design & Product Development, Iowa State University, USA

3Baylor University, USA

*Corresponding author: Rachel J Eike, Apparel Merchandising and Design, Iowa State University, USA

Submission: February 19, 2020; Published: March 04, 2020

ISSN 2578-0271 Volume 6 Issue 1

Abstract

Advancements in wireless body area networks (WBANs) involve the integration of circuitry into softgood products that provide a low profile and desirable tactical hand for consumers/users. One way in which to integrate technology into soft goods is through embroidery, more specifically conductive machine embroidery. This paper provides foundational details on how substrates (i.e., soft-good textiles) are formed, outlines key details to assist in the reporting of all technical considerations of conductive machine embroidery, and provides recommendations from observations of a conducted study to streamline the machine embroidery manufacturing process for future researchers to replicate, verify, and build upon disseminated works.

Keywords: Conductive embroidery; E-textiles; WBANs; Smart garments; Textile antennas

Introduction and Rationale

Wireless body area networks (WBANs) are a form of wearable technology that

A. employs body-worn sensors to gather physiological data and

B. utilizes wireless communication to transmit that data for analysis [1-11].

WBANs have amassed popularity in the past several years, particularly in sports and health/wellness applications. Physiological monitors have functioned in the medical industry for decades, but technological advancements have led to much smaller devices that are now self-manageable, affordable, and widely available. The most common example of these WBANs is the smartwatch, which may measure a variety of sensor-related functions such as heartrate, movements/steps, and sleep monitoring. With further advancements in WBAN technology, demand increases for even smaller devices that are fully integrated into soft-good products. Conductive embroidery has shown potential in achieving this end goal [3], and the technique is now driving research among engineers and fashion designers aiming to devise “smart” apparel (clothing) or other soft-good products.

Conductive embroidery is the stitched application of finely drawn wire, metallic yarns, or threads spun from conductive polymers onto a textile/fabric substrate [4]. The technique transforms a traditional textile into a conductive textile and is of interest to researchers and manufacturers who work towards creating an effective, customizable, and low-profile WBAN. Interdisciplinary teams of experts in the fields of textiles, design, and electrical engineering are necessary to conduct this research, and methodology must be transparently shared amongst disciplines to make progress in ‘smart garment’ developments (also referred to as electronic textiles, e-textiles, smart textiles, smart clothing, or functional fabrics). At present, the research field is quite fractured, exhibiting a lack of collaboration and inadequate communication between industries. In investigating techniques for conductive embroidery, the authors discovered a lack of published details for proper replication of methods where many studies do not disclose the various material properties needed to properly replicate conductive embroidered designs. For example, fiber type, fabric weight, fabrication structure, and finishes applied to yarn or fabric, are all important specifications that must be considered alongside electrical conductivity, resistivity, and dielectric constant. All of these variables must be considered, detailed, and reported for replication and research advancement., indepth discussion of techniques, equipment, and manufacturing challenges are required for evolving production - and eventually scaled mass-production - of conductive soft-good products. Additionally, discussion for end product potential is essential early on in the development phase to make appropriate decisions for sampling and testing to ensure a final product that is functional for a consumer/user.

Overall, the purpose of this paper is to highlight important variables that need to be communicated between disparate fields of study; the most common examples being between textile scientists, engineers, and apparel designers. A clear specification of materials and methods provides all researchers with the knowledge needed to develop WBAN products that consider user comfort while maintaining system reliability. Detailed reporting of all technical considerations is reported in this paper to allow future researchers to more adequately evaluate and replicate optimal operations for applying embroidery with conductive thread into a design. Support for detailing these technical specifications are also included. Additionally, this paper makes considerations to streamline the embroidery manufacturing process for scaled production.

Textile Components and Fabrication Methods: An Overview

In the fabrication of conductive embroidery samples, many decisions must be made in the forefront to ensure high quality and intended end-product outcomes. The following sections provide an overview of some of the key considerations and specifications in order to produce and replicate conductive embroidery samples. These sections include a brief overview of textile elements and fabrication methods, addressing the textile development process from fiber to fabric including the application of finishes. This section is followed by a brief summary the embroidery process with visual aids. Finally, an outline is recommended for carrying out experimental research involving conductive embroidery with recommendations for trouble-shooting embroidery challenges experienced by the authors.

Overview of textile elements and fabrication methods

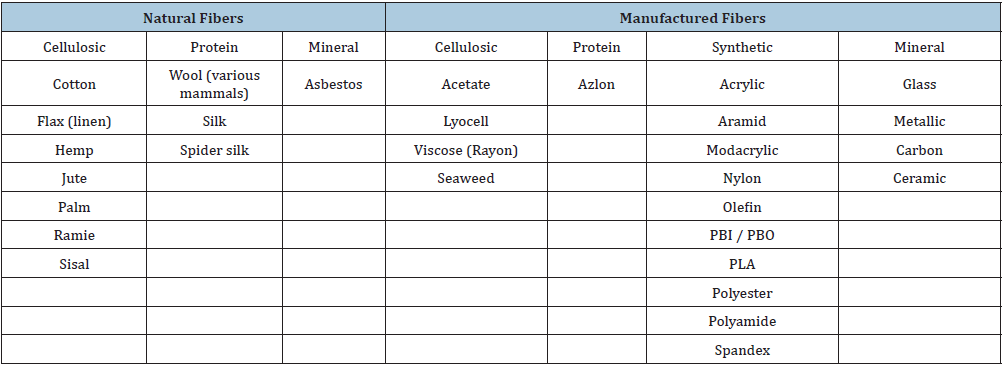

Fibers: Fibers are hair-like structures with very high length to width ratios. They are the smallest, most basic unit of all fabrics and they define textiles. The physical and chemical properties of fibers determine the performance characteristics and quality of fabrics. Fibers may be grouped into two categories: natural and manufactured (or man-made). Natural fibers are those which naturally grow into fiber form from plant, animal, or mineral sources. They are organized into cellulosic (plant), protein (animal), and mineral classifications. Manufactured fibers are made from natural materials or synthetic chemicals, often petrochemicals, and are extruded into fiber form in manufacturing facilities. Table 1 lists natural and manufactured fibers (note: this is not a comprehensive list of all fibers available on the market, please contact the authors for additional resources).

Table 1:Fiber classifications.

Note: From Textiles by S Kadolph [6].

The classification of fibers, their morphology, and their chemical nature have a significant impact on textile characteristics. Generally, natural plant fibers tend to be absorbent, heavy, flammable, and sensitive to acids and mildew. Synthetic fibers are generally nonabsorbent, lightweight, chemical resistant, and melt under high heat. These natural and synthetic fiber properties, along with many others not mentioned here, are imparted onto fully formed textile products.

Yarns: Once the fiber is selected, it is formed into a yarn. A yarn is a continuous, long strand of fibers arranged together through twisting or layering that may be further developed into a textile fabrication (i.e., substrate). Yarns are often referred to as thread or string, but “yarn” is the more scientific term used in the textile and apparel industry. Just as fibers impart their characteristics upon textiles, so do yarns. The fiber content of the yarn, fiber length (staple or filament), size, structure/ply, gauge, twist direction, twist per inch (tpi), and the end-product usage dictate the yarn production process and characteristics of the finished product.

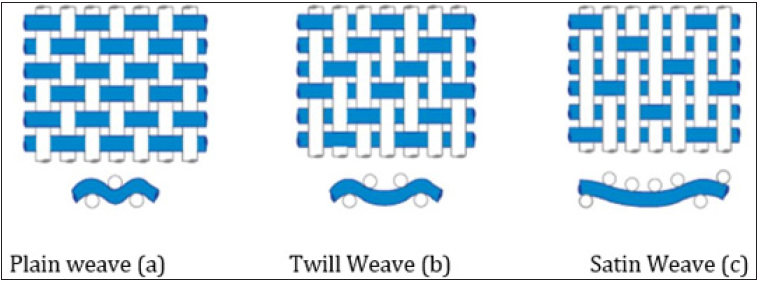

Textile structure: Textile structures fall into three distinct categories: wovens, knits, or nonwovens. Woven fabrics are made from two or more sets of yarns interlaced at right angles and having two basic components: warp yarns and filling yarns (also referred to as weft yarns). Depending on weaving pattern of the yarns, myriad different weaves are produced, the three most basic being plain, twill, and satin (Figure 1). Each of these three basic weave structures has countless variations, providing an extremely diverse selection of commercial fabrics.

Figure 1: Woven fabrication structures: Plain, twill, and sateen/satin.

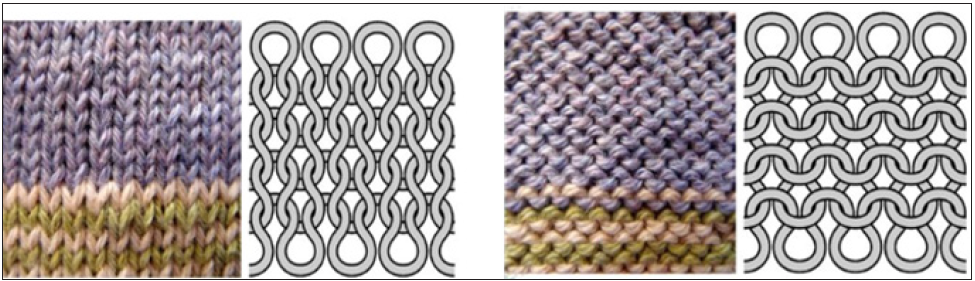

Knitted fabrics are formed by a single yarn or a series (sets) of yarns interloping together for form a textile (tubular, flat, or product-shaped, depending on manufacturing equipment). Knits have become more popular in mass market apparel due to the expansion and recovery performance of the textile structure which aids in comport for the wearer as they move throughout the day. Figure 2 illustrates the fabrication structure of a jersey knit (knitted structure of a t-shirt) in yarn form and illustration diagram. The figure shows (a) technical face (face knit stitches) and (b) technical back (back knit purl stitches) of the fabric. Textiles that are formed through non-woven fabrication are assembled by the enmeshing of fibers to create a sheet. This web-like entanglement of fibers may be achieved through mechanical bonding with adhesive, heat, or chemical. The term “nonwoven” denotes textiles that are neither woven nor knitted. Compared with woven and knitted structures, nonwoven textiles are fairly affordable due to the ease and speed in which the textile can be fabricated. However, compared with woven and knit textiles, the structural integrity of the nonwoven is unstable under presser and is typically best suited for stabilizers (mentioned below) and craft purposes.

Figure 2: Jersey knit fabrication structure.

Fabric weigh: Fabric weight or fabric mass describes how much a fabric weighs for a given area or length of fabric. Fabric weight consideration early in the prototype or sample-making phase is important because it is used to identify fabric appropriateness for end use. Selecting a fabric which would not function or perform as expected in the end product, yet using for samples, may yield inaccurate results or drastically extend the product development timeline.

Finishes: Finishes are the chemical application to a yarn or textile substrate that modify performance properties to achieve end product goals. The term finish may also be interpreted as an applied ‘coating’; a common reference for metallic component application onto fabric components. Some common finishes applied in soft-goods industries include flame –retardant, antimicrobial, ultraviolet-absorbent (SPF), water repellent, and wrinkle-free finishes.

How substrates are made to be conductive

Textiles may gain electrical conductivity through the application of metallic coatings, either applied to the surface of a fabric or to the yarns that are knitted or woven to form a final textile structure [4]. When fixed to the surface, metals may be added through dipcoating, roll-coating, or more recently, through ink-jet printing of circuitry [7].

Overview of the embroidery process

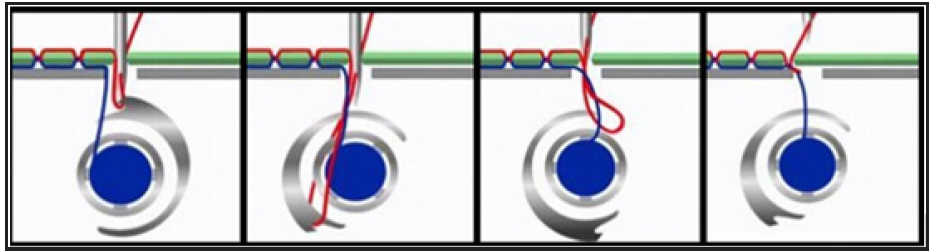

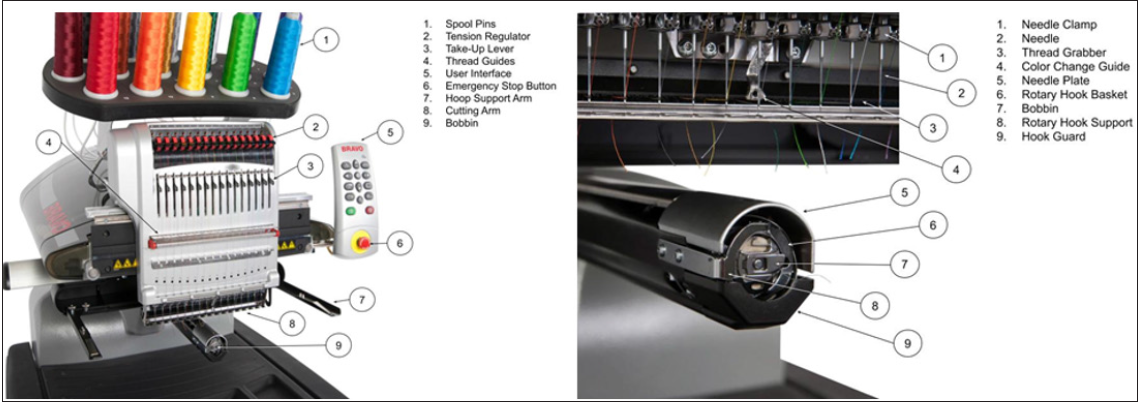

In general, the embroidery process involves an interlocking stitching system. When the needle point passes through the fabric from the top position, it pulls a small loop of thread from one side to the other (underside of substrate). A mechanism underneath the fabric (termed ‘bobbin’) grabs this loop and wraps it with another thread creating an interlocking stitch Figure 3 illustrates this stitching process. Embroidery machines may be classified into two categories: personal/home and industrial. In many personal-style embroidery machines the top thread experiences more thread guides and tension units than compared to the bobbin thread. However, industrial embroidery machines, such as the Melco® EMT16X embroidery machine, (Figure 4 and used in the study detailed below), permits top thread tension precision adjustment through the use of electronic acti-feed setting. The top thread is fed from a large spool that passes through multiple tension units before entering the eye of the needle. The bottom thread is fed from a small spool wound separately and then inserted into the bobbin casing. Figure 4 illustrates the main assembly and details of the bobbin case.

Figure 3: Stitching process visual aid.

Figure 4:Melco® EMT16X commercial embroidery machine structure.

Embroidery with conductive thread: The electronic actifeed tension adjustment feature allows the conductive thread to be placed in the top thread position for embroidery stitching without breakage. Embroidery stitching with conductive thread in the top thread position on the personal-style machine has been unsuccessful – limiting conductive thread placement in the bottom/ bobbin location [3]. Embroidery stitching with conductive thread from the top position and the bottom position simultaneously is possible using an industrial-style machine, such as the Melco® model used in this study. Using conductive thread in both top and bottom threading positions allows for increased stitch density of the conductive threads.

Threads for stitching: In general, machine embroidery stitching utilizes polyester thread as this fiber content is very strong and durable and the thread needs to withstand going into and out of the fabric numerous times to complete the stitched design. Note: machine stitching embroidery uses different thread than hand stitching embroidery and different thread than general sewing machine thread. Thread is described in a similar manner as a yarn, as technically they are the same thing - a long continuous stand of fibers. What differentiates these terms is how they are used in the construction process: the term yarn is used to describe the formation of a textile (specifying lengthwise and crosswise grain/ warp and weft yarns) while the term thread is used in the stitching process of a product (applying thread through embroidery or joining pattern pieces together through seams).

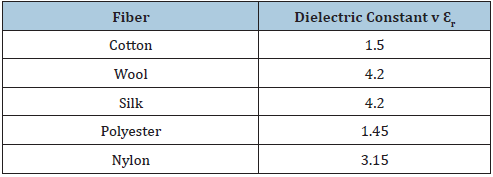

Conductive threads for embroidery: A non-conductive thread can be used opposite of the conductive thread (either in top-thread position on the machine or in the bobbin position) to make the manufacturing process more cost-effective. However, the dielectric constant of the non-conductive thread must be considered to best observe the ability of the conductive thread. Table 2 below has been crafted from multiple source for a general idea of dielectrics for common textile fibers [1,9,10]. It is very important to note that the environment (air, moisture content, etc.) will impact the dielectric constant value and this reading should be conducted in the working environment before implementing into a sample or product. embroidery is capable of creating an interlock stitch (which is achievable on home style sewing machines), however, the design capabilities for the stitch pattern or configuration of stitches is potentially endless (depending on design or digitizing technology and functionality of the embroidery machine). The single stitch, a line from point to point, is the building block for everything stitched with the embroidery machine. Use of an embroidery machine allows for control in the direction of stitches, stitch lengths (distant between needle drops/stitches) and spacing of the stitches (which impact the finished stitched shape). Many embroidery machines come pre-set with a series of stitch patterns or configurations built into the system. The most commonly used stitches for embroidery in soft-goods include the ‘straight stitch’ which is a line of repeated single lock stitches (termed ‘contour stitch’ by some conductive embroidery authors) and the ‘satin stitch’ (also termed ‘column stitch’) which is stitch that tracks back and forth over an area, alternating between an angled stitch and a straight stitch – creating a zig-zag motion in which threads fill the desired shape/space. Satin stitches typically have a shinier appearance due to the long floats between drops in the needle to create the stitches. Most embroidery machines are programed to create satin stitches with a maximum stitch length of 12mm. Note: these long stitches tend to be loose and susceptible to snagging during product use.

Table 2:Somatic diseases and concomitant OMD.

Stabilizers: Stabilizers are a separate textile (typically nonwoven) used in conjunction with the textile for machine embroidery stitching. Stabilizer textiles help to regulate the uniformity of the stitches while the embroidery machine is operating. Since the embroidery machine’s needle moves very quickly over a taunt fabric, the use of a stabilizer textile is recommended while the stitching is taking place. Most commonly stabilizer types used with machine embroidery are cut-away, tearaway, and dissolvable/water soluble. After the machine embroidery is complete, the stabilizer may be removed. The type and weight of stabilizer tend to be selected to align with substrate properties and product (use and placement).

Experimental conductive embroidery research: Rationale for specifications

Reasoning for outlining specifications: Fiber content, fabrication structure (weave/knit/non-woven) and fabric weight all have a significant impact on dielectric constant achieved through the quality of stitches achieved during conductive thread machine embroidery. These factors impact the overall performance of the finished sample or end product. The sections below briefly support rationale for clearly identifying these components for sample making before moving into product prototyping.

Fiber content: Specifying textile fiber content is essential because fiber properties determine textile properties. Fibers influence product aesthetics, durability, comfort, appearance retention, care, environmental impact, sustainability, and cost. Inappropriate fiber selection can produce a non-functional and undesirable product. Fiber density impacts yarn density, which in turn impacts fabric density and overall weight. These are necessary considerations when selecting the fiber content of the substrate for conductive embroidery applications to achieve end product goals and expectations.

Fiber selection contributes to overall textile performance. Depending on the end product, fiber selection may be based on the following:

A. Abrasion and pilling resistance for products that must withstand surface friction and wear

B. Strength and tear resistance for products that may sustain frequent pulling or snagging

C. Absorbency and wicking for products that come into contact with skin (comfort)

D. Wrinkle recovery and resiliency for products that may be bended, twisted, or folded

E. Thermal retention for products intended to hold heat

F. UV resistance for products subjected to sunlight

G. Electrical conductivity/resistivity/dielectric properties

Many additional performance properties exist, and standardized test methods have been developed by ASTM and AATCC to accurately test and measure these properties.

Textile fabrication structure: When selecting a fabric for end product use, textile structure is a crucial consideration. Woven fabrics are more rigid and stable than knits, are less air and water permeable, and are generally more economical. However, woven textiles tend to ravel or fray along cut edges. Knit structures wrinkle less than wovens, have more stretch, less dimensional stability, and are more permeable to air and moisture. Knits also have a tendency to snag with wear and shrink with laundering. The authors highly recommend considering end-product application to align textile fabrication in the sample-making phase so as to ensure accurate readings connected to conductivity. It is suggested to collaborate or consult with professionals in soft-good areas such as apparel design and product development and/or textile science.

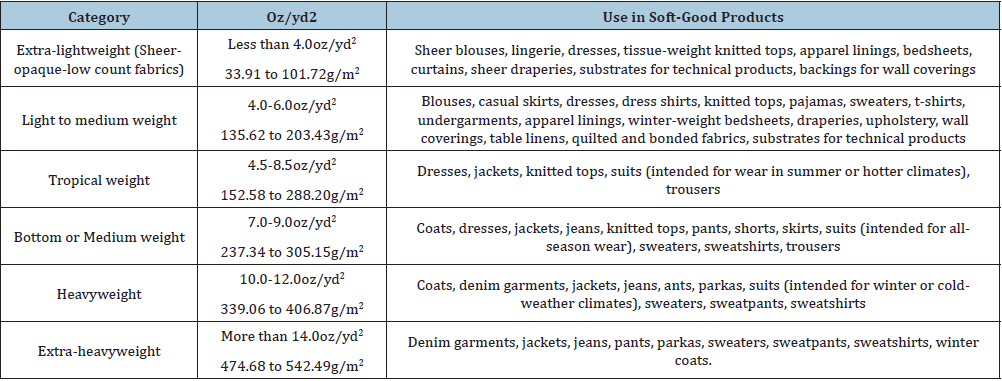

Fabric weight: The fabric weight of the substrate impacts the thread-feed settings of an embroidery machine (if the embroidery machine allows for adjustability). It can affect not only the quality of stitches the machine produces but the density of the (conductive) thread stitches (and therefore conductivity). Table 3 outlines fabrics weight categories and lists soft-good products examples.

Table 3:Fabric weight categories.

Note: Compiled from Textiles by S Kadolph [6].

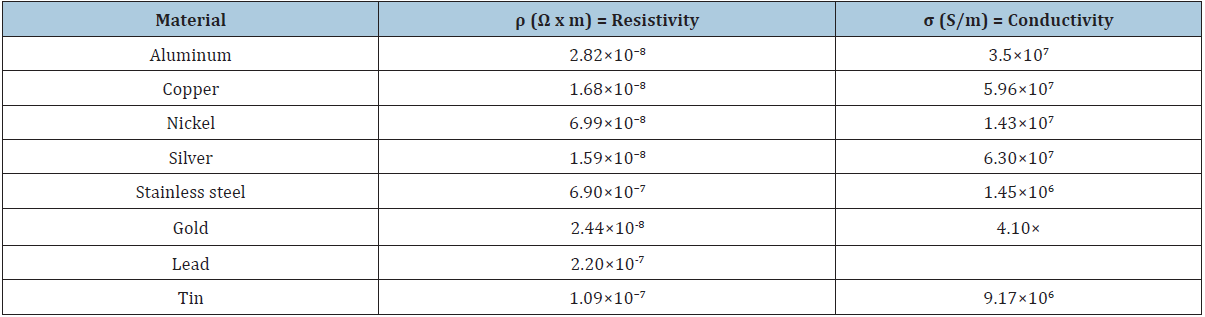

Conductive threads for embroidery stitching: Conductive thread is a thread that can carry a current in the same way as electronic wires. Some conductive threads are composed of 100% metallic fibers, while other conductive threads are natural or synthetic (or blended) and coated with a metallic finish. The metal (copper, silver, tin, nickel, etc.) and percentage of the metal in the thread will impact the overall conductivity of the resulting stitch pattern. Table 4 presents the electrical resistivity and electrically conductive of a sampling of metal materials that may be incorporated into thread or textile (integrated into yarn/textile formation or applied through coating finish). Electrical resistivity, represented with the Greek letter ρ (rho), is a measure of how strongly a material counters an electrical current. The lower the resistivity reading from a particular material, the more capable it will allow electrical flow. Electrical conductivity is complementary to resistivity. Conductivity is a measure of how well a material conducts an electric current. Electrical conductivity may be represented by the Greek letter σ (sigma), κ (kappa), or γ (gamma) [5]. It is important to note that readings are susceptible to area of material, length of the conductor, and environmental conditions Table 4. These details will also impact the ability to successfully complete stitching without thread breakage and current breakage (either through hand embroidery or machine). It is essential to report metallic component, percentage, application of metal (integrated or applied), and thread manufacturer or brand for others to build upon research works.

Table 4:Table of resistivity and conductivity at 20 °C.

Note: Compiled from data by Guler et al., [4], Helmenstine [5], Muhammad & Umar [8].

When communicating a desired stitch pattern, the four aspects that need to be communicated are the

A. Specific measurements of the design to be stitched,

B. Stitch direction (referencing alignment with grainline of textile),

C. Stitch type (described and embroidery machine referenced), and

D. Stitch length and spacing (as this impacts thread density).

The design will depend on the purpose and type of antenna being produced. The available stitch types will vary depending on the capabilities of the embroidery machine being used to produce the stitch pattern. The stich type and its direction, in regard to the current flow, can directly reduce or increase the resonance frequency of the antenna. Increased stitch density may also increase antenna performance. The impact of these variables on WBANs continue to be investigated.

Technical recommendations for conductive embroidery

This section of the paper outlines technical recommendations for experimenting with conductive machine embroidery, as observed by the authors. The end result of the experiment was to create flexible dipole antenna with guidance from previous work in this area [3]. Challenges and operational findings of this study prompted the development of this paper.

Textile component details

Fiber content: Different fibers have varying dielectric constants. To best observe the efficiency of the conductive threads, 100% natural cotton fibers are recommended as cotton’s dielectric constant is closest to 1.0, or in other words the conditions within a vacuum.

Textile structure: Medium-weight (7oz.) cotton twill fabric was utilized in this study and recommended for sample-making of dipole antennas. Use of fabric in the medium-weight category spans a multitude of soft-good products for future developments, while selection of the twill weave supports a strong woven structure (compared to plain and satin weave) that would work well for highspeed embroidery application. This twill substrate may be viewed as the textile for end-product application or for patch development that would then be adhered to a final product. Twill weaves are often used for sturdy work apparel because soils and stains are less noticeable on this fabric due to the uneven surface created by the woven yarns [6]. Additional details of fabrication used in this study include pre-shrunk, 100% Global organic textile standard (GOTS) certified cotton, certified and sustainable process for dyeing and finishing, white in color, Item number UM-149 (purchased from fabric.com).

Machine embroidery details

Thread and stitch patterns: Shieldex® 117/17 dtex 2 ply conductive thread was utilized in this study and recommended for future works of conductive machine embroidery. The thread makeup consists of 1% nylon polyamide filament (6.6 high tenacity round) and 99% pure silver. The silver alloy is metal plated (coated) onto the 2 ply, Z twist thread structure. This thread was purchased from v-technical textiles, Inc. in hobby cone form (item number: 260151011717). Silver-based thread was selected as the metallic component as it has low resistivity and high conductivity ratings. Cotton thread was also utilized in this study to serve as thread opposite of the conductive thread during machine embroidery due to its low dielectric constant. Aurifil 100% cotton thread (white in color) was sampled in both 40 and 50 weights to experiment with accurate stitch formations. Small spools of the cotton thread were purchased from a local retailer, but information on the thread may be found at aurifil.com. This study observed little difference between the 40 and 50 cotton weight threads, in terms of stitch formation performance, but both were prone to breakage (due to thread tension and high stitch-pace) in comparison to the polyester threads commonly used in soft-goods machine embroidery (for aesthetic/design).

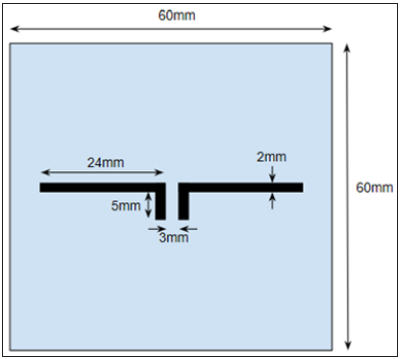

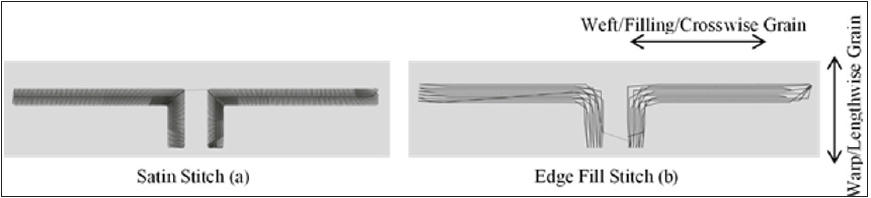

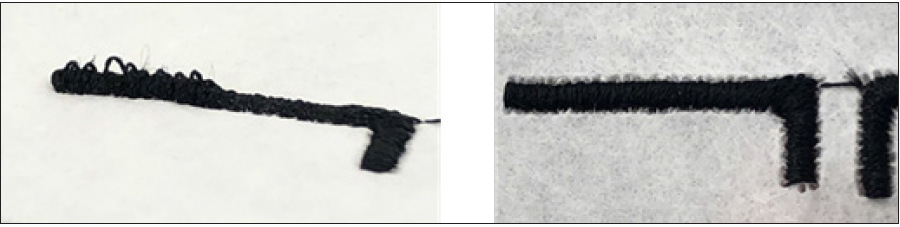

Stitch patterns explored in this study included the satin and edge fill (contour). Figure 5 illustrates the specific measurements and spacing of the dipole antenna stitched through conductive embroidery. Figure 6 illustrates the digitized dipole design generated through the machine embroidery software for both the satin (a) and edge fill (b). In general, stitching direction started at the center of the dipole, then stitched upward along the short edge of the ‘L’ shape, rotated at the corner, and continued towards the outer edge – then returned to the center of the dipole to create the other leg of the antenna. These stitch patterns were chosen due to their high stitch density, which is most advantageous for high dipole performance. The information settings on the software for each stitch type included a stitch density of 60% for both antennas and a stitch length of 50 points for satin and 40 points for edge fill. Neither the satin nor edge fill pattern were necessarily difficult to digitize for stitching application using the embroidery machine’s design programming software. Figure 7 illustrates the conductive machine embroidery samples produced in this study. Note: images have been cropped to more clearly showcase the stitching area from the 60mm x 60mm sample. The satin stitch and the edge fill stitch, although similar in the number of stitches used to create the design, were not similar in stitch density. The satin stitch’s zigzag fill pattern makes it far denser than the edge fill’s straight lines which may impact overall resistivity, conductivity, and resonance frequency of the machine embroidered stitched antenna. From observations and knowledge on density of conductive thread needed to signal transfer, it is recommended to pursue future research with satin stitch configurations and well as explore alternative stitch patterns that yield dense stitches for potential in WBAN applications.

Figure 5: Design measurements for dipole antenna.

Figure 6: Digitized designs of dipole antenna for embroidery.

Figure 7:Physical samples of dipole antenna stitched through machine embroidery.

Embroidery equipment and thread placement: From study observations, it was found that the industrial embroidery machine performed most effectively (i.e. streamline stitching of multiple samples) when the conductive thread was placed in the bobbin position with an alternative cotton thread stitched from the top position. However, conductive thread placement in the bottom position is not effective for scaled production. Stitching with conductive thread in both the top and bottom positions was achievable, but the threads would frequently knot or fray, leading to thread entanglement or breakage and the need to stop production. These stitching errors were most likely caused from the friction created between the two equally rough conductive threads. It is important to note that the threads of the 117/17dtex conductive hobby cone came pre-lubricated. If experimenting with conductive threads in larger cone size (such as the industrial cone) the threads are not pre-lubricated and the purchase of a lubricator mechanism that may be mounted onto the embroidery machine may be helpful to reduce thread friction. V-technical textiles, Inc. suggested the use of a silicone lubricant (DuPont). It is worthwhile to investigate additional lubrication of yarns (even if pre-lubricated from the manufacturer) to test for reduced fraying and breakage. It is noteworthy to identify that samples were produced at approximately 800spm (stitches per minute), a relatively high stitching speed. This study recommends, based on efficient largescale production of conductive machine embroidery, to place the conductive thread in the top thread position and the cotton thread in the bobbin.

Stabilizers: Two stabilizers were experimented for use in conjunction with the cotton twill substrate for conductive thread machine embroidery in this study. These two stabilizers were: Lightweight, fiberweb, cut-a-way stabilizer (Pellon 884) comprised of 60% polyester and 40% rayon and Ulta-lightweight, fiberweb, wash-n-gone® stabilizer (Pellon 541) comprised of 100% polyvinyl alcohol. Note: numerous other stabilizer types and weights exist. When considering a stabilizer for the embroidery process, we observed that the samples created using the cut-a-way stabilizer appeared to produce the most uniform stitches and decreased the number of stitching errors during the manufacturing process compared to the wash-n-gone® stabilizer or use of no stabilizer. While uniform stitches can be achieved without use of a stabilizer, the set-up process was slightly more difficult due to fluctuation in the tightness of the hoop around the substrates (best results of stitching without stabilizer occurred with the acti-feed was set to 3 or 4pts). It is recommended to use the cut-a-way stabilizer for conductive machine embroidery and adjust the acti-feed settings to 2pts. Additional performance testing is required to establish if stitch formation significantly influences resistivity, conductivity, and resonance frequencies. The recommendation for stabilizer use is based on technical stitch consistency.

Troubleshooting errors

Stitching errors: Stitching errors during machine embroidery can occur if the acti-feed (tension) settings are not properly adjusted to align with substrate materials. These settings must be carefully monitored and adjusted according to thread, substrate, stabilizer, and tightness of the embroidery hoop used when creating samples. If looping errors occur in the stitch formation (e.g., embroidery stitches appear as irregular raised loops on top of the substrate-a) image in Figure 8), then the acti-feeds points must be decreased. If pulling errors occur from the bobbin thread position (e.g., the bobbin thread is pulled to the top of the substrate during stitching and visible-(b) image in Figure 8), then the acti-feed points must be increased. In this study, the acti-feed was set to either 2, 3, or 4 points for optimal stitching. Figure 8 illustrates how these stitching errors may appear during production. Please note that conductive thread was not used for illustration of these errors (black thread was selected to contrast against the white substrate for visual detection through image form).

Figure 8: Embroidery machine stitching errors.

Cutting challenges: As outlined in previous sections, different fiber contents have different properties. These properties also impact the ability for the embroidery machine to automatically cut threads. When placing conductive thread in the top thread, the cutting arm cannot efficiently cut the thread, leading to a stop in production and manually cutting the thread to avoid thread snappage (which then requires the re-threading of the machine). Sharpening or replacement of the cutting blade, located on the cutting arm of the machine, is recommended through conductive embroidery stitching, however, researchers may find it equally time efficient to stop production and manually clip with fabric scissors or snips. Cutting issues were not prevalent when the conductive thread was placed in the bobbin/bottom position. Keeping the blade sharp throughout production also ensured clean cutting of the cotton threads.

Thread coiling: The conductive thread, particularly when beginning a new spool, experienced coiling. When the thread was cut (either machine or manual) the remaining thread tail would coil and would not be long enough to start the next sample. Therefore, it is recommended to manually stop the machine in between samples, cutting the thread, and pulling more top thread (from the eye of the needle) between each sample. When winding the bobbin with conductive thread, challenges to wind the entire bobbin to full capacity were experienced. This challenge may be due to the thickness or coiling nature of the threads. It is recommended to manually slightly separate the tension disks on the bobbin winding apparatus during the winding process to assist the equipment in filling the bobbin. Researchers used a Brother Bobbin Winder for PR (Multi needle) series machines, model PR-BW1.

Suggested design for experimental study of conductive machine embroidery

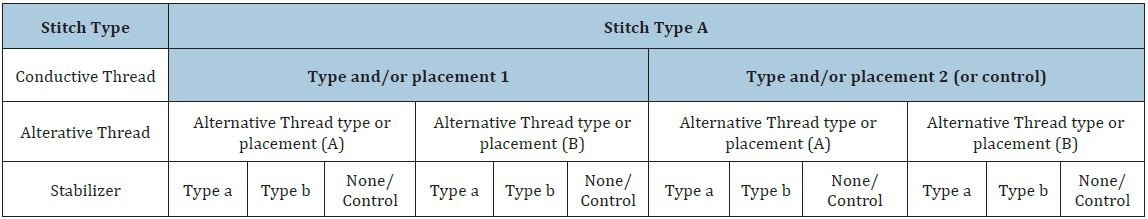

As outlined earlier in document, there are many factors that may influence accurate resistivity and conductivity readings when performing conductive embroidery. One approach to carry out the experimental research is through a factorial design. In this study, independent variables were stitch patterns at 2 levels, (satin stitch and contour stitch); conductive thread placement at 4 levels, (top thread, bottom/bobbin thread, a combination of both top and bottom/bobbin thread placements and one control group that did not include conductive thread); an alternative thread, (cotton, at 2 levels, 40 weight and 50 weight); stabilizer inclusion at 3 levels (cut-a-way (CA) and water-soluble (WS) stabilizer and one control group (--) that does not include the use of a stabilizer). Reference Table 5 for a basic schematic diagram which outlines one approach to allocate independent variables in an experimental study.

Table 5: Schematic diagram for variables.

When fabrics are dipped, rolled, or constructed from metallic yarns, the resulting material is often unsuitable for use in garments. Not only are these conductive fabrics measurably uncomfortable, they also pose a risk for skin irritation in wearers with contact allergies to included metals, often nickel and copper [12]. Thus, apparel designers must protect the wearer from direct contact with metallic e-textiles, limiting their use to small areas on the exterior of garments. Fortunately, this limitation is immaterial in the development of patch antennas and conductive embroidery, as patches and embroidery are, by their very nature, applied, external surface components. Note: This irrelevancy is only the case when conductive thread is placed in the top stitching position and a nonconductive thread is placed in the bobbin position or the placement of stitching onto substrate would place the non-conductive threads next to the body/interior of garment. It is recommended that metallic materials, such as nickel and copper, never come in direct contact with the skin as the wearer may experience skin irritation or more serious health issues.

The suggested approach to experimental research involving conductive embroidery is most applicable for those involved with the fabrication of the conductive embroidery as these considerations and decisions made early on in the sampling phase may significantly impact performance readings and provide misinformation upon moving into the product prototyping and development phases.

Discussion and Conclusion

Overall, the purpose of this paper was to highlight important variables for improved communication between disparate fields studying WBAN technologies. In such a relatively new and rapidly growing field of technology, it is vitally important that textile scientists, engineers, product developers, and other researchers communicate complete technical specifications throughout the sampling and product development phases. Without adequate reporting and documentation, it can be challenging to replicate, verify, and build upon the work of others, which may impact the advancement rate of this dynamic wearables field. Based on the research conducted by the authors, the majority of the variables and their impacts on the industry are only most commonly recognized by individuals connected to textiles and soft-good products, such as apparel. For this reason, the authors recommend a collaboration between disciplines to ensure the relevancy in domains and representative consideration for scaled production.

Effectiveness during the manufacturing process is a key aspect of producing high quality items that will perform as intended while meeting consumer/user expectations. Investigating the effectiveness at which a scaled production approach to conductive machine embroidery can be carried-out (performance and evaluation) is essential for future growth in the field of wireless body area networks. By utilizing the observations and documenting the recommendations outlined in this study for research dissemination, future researchers will be able to increase and improve the efficiency of their experimental works. Overall, it is utmost importance to keep the end-product goal in mind while investigated WBANs so that considerations for materials, production methods, and performance (of technology and product) may be outlined early in the experimental phase to ensure accurate operations and user expectations.

References

- Errera J, Sack HS (1943) Dielectric properties of animal fibers. Industrial & Engineering Chemistry 35(6): 712-716.

- Fazal MZ (2019) Knitting Introduction.

- Gil I, Fernández-García R, Tornero JA (2018) Embroidery manufacturing techniques for textile dipole antenna applied to wireless body area network. Textile Research Journal 89(8).

- Guler SD, Gannon M, Sicchio K (2016) Crafting wearables. Blending technology with fashion, New York, USA.

- Helmenstine AM (2019) Table of electrical resistivity and conductivity.

- Kadolph SJ (2010) Textiles. (11th edn), Upper Saddle River, Pearson Prentice Hall, USA.

- Matsuhisa N, Kaltenbrunner M, Yokota T, Jinno H, Kuribara K, et al. (2015) Printable elastic conductors with a high conductivity for electronic textile applications. Nature Communications.

- Muhammad UK, Umar S (2013) Experimental performance investigations and evaluation of base metals thermocouples. International Journal of Modern Applied Physics 3(1): 26-37.

- Murali SD, Muni BM, Varma YD, Chaitanya SV (2014) Development of wearable antennas with different cotton textiles 4(7): 8-14.

- Sankaralingam S & Gupta B (2010) Determination of dielectric constant of fabric materials and their use as substrates for design and development of antennas for wearable applications. IEEE Transactions on Instrumentation and Measurement 59(12): 3122–3130.

- Xu B, Eike RJ, Cliett A, Cloud RM, Li Y (2018) A short review of textile applications in antenna design. Trends in Textile Engineering & Fashion Technology 1(5).

- Yoshihisa Y, Shimizu T (2012) Metal allergy and systemic contact dermatitis: An overview. Dermatology Research and Practice, pp.1–5.

© 2020 Rachel J Eike. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)