- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Impact of Front and Back Roller Shore Hardness on The Quality of Cotton Carded Yarn in Ring Spinning Frame

Amit Chakrabortty*, Md. Zulfikar Hasan, Joyjit Ghosh and Md. Redwanul Islam

Department of Textile Engineering, Ahsanullah University of Science and Technology, Tejgaon I/A, Dhaka-1208, Bangladesh

*Corresponding author:Amit Chakrabortty, Department of Textile Engineering, Ahsanullah University of Science and Technology, Tejgaon I/A, Dhaka-1208, Bangladesh

Submission: February 03, 2020; Published: February 18, 2020

ISSN 2578-0271 Volume 5 Issue 5

Abstract

Roller hardness of drafting unit in ring spinning frame is very important for controlling the draft and quality of yarn. This research work deals with the impact of cot roller shore hardness on the quality of cotton carded yarn. The five samples were prepared by using the combination of three different cot roller shore hardness (650, 750 and 830) in ring frame. At first, yarn samples of 30Ne were produced by varying front roller cot hardness with constant back roller hardness. Secondly, yarn samples of 30Ne were produced by varying back roller cot hardness with constant front roller hardness. The test results of the samples were carried out. The trends of the obtained results were analyzed. The results showed that softer cots at front line significantly reduced mass variation and hairiness of yarn. On the other hand, harder cots at back line significantly reduced mass variation, imperfection level as well as yarn strength. Among these combinations, 650 at front line and 830 at back line were better for producing good quality yarn. This study will help the spinners of Bangladesh to select the appropriate cot roller with optimum shore hardness of front and back line at the drafting system in a ring spinning frame to get the required quality of the cotton carded yarn.

Keywords: Cot roller; Shore hardness; Durometer; Count Strength Product (CSP); Reiss kilometer (Rkm)

Introduction

Ring spinning technique has greatly influenced on the quality of yarn. There are some

parameters which are greatly affected the quality of ring spun carded yarn such as drafting

system, roller gauge, ring traveler, ring cup diameter, spindle speed, and material throughput

rate etc. Drafting is the most important and fundamental operation in spinning, and it gives a

very important effect to the yarn quality [1]. Drafting components have a significant influence

on yarn quality and production costs in ring spinning (Especially spinning top roller covers

i.e., cots and drafting aprons) [2]. These are the main components of the drafting mechanism

and certainly it has more influence on the quality of the yarn produced Cots are used in draw

frame, comber, speed frame and ring frame, whereas aprons are used only in speed frame

and ring. The purpose of cots is to provide uniform pressure on the fibre strand to facilitate

efficient drafting and use of aprons help to have better grip and control on fibres particularly

floating fibres [3].The degree of the shore hardness is a main property of the top roller cot.

Shore hardness is one of the main properties of top roller cot and varies for different types of

fibre, application etc. Hardness may be defined as the resistance to indention under conditions

that do not puncture the rubber. It is called elastic modulus of rubber compound [4]. Shore

hardness of cot roller to provide uniform pressure on the fibre strand. This facilitates efficient

drafting with the assistance of aprons, which results in a better grip and control of the fibers,

particularly floating fibers which is advantageous for producing good quality yarn with

minimum imperfection level [5]. Generally, Shore hardness of a rubber cot is measured by an

instrument called ‘Durometer’ and the value is expressed in A scale. Cots are available in wide

shore hardness ranging from 63° to 90° shore. A mathematical scale is used to convert the

displacement data into hardness values within a range between 0 and 100 [6,7].

Now days, yarn quality is a prerequisite condition to the economic success of spinning

sector. International competition and market requirements dictate the necessity to produce

quality yarns at an acceptable price. There numerous attempts are taken to maintain the

consistent quality level of yarn, including process modification, process control techniques

and spinning parameters [8]. Among these, spinning parameters such as drafting systems specially spinning top roller shore hardness has great impact on

the cotton yarn properties such as mass variation, imperfection

level, CSP, Rkm and hairiness etc. Optimum shore hardness at front

and back roller of drafting system not only provides good quality

yarn but also its necessary for maintaining consistence quality

level. It varies within different types of fibers and applications [9].

Although many studies have been conducted on cot roller hardness,

but the investigation of combine variation of front and back roller

shore hardness for finer count of 100% cotton fibre is still needed.

Therefore, in this research work, it was observed that the variation

of front and back roller cot shore hardness how much impact on the

quality of ring spun carded cotton yarn and also tried to find out

which combinations were better for producing good quality yarn.

Materials & Methods

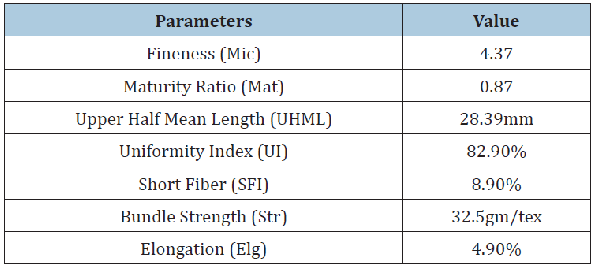

Cameroon cotton fibre was selected as raw materials. The properties of fibre were given below Table 1.

Table 1:Fibre properties.

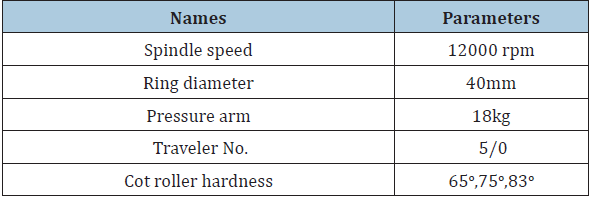

Table 2:Technical parameters.

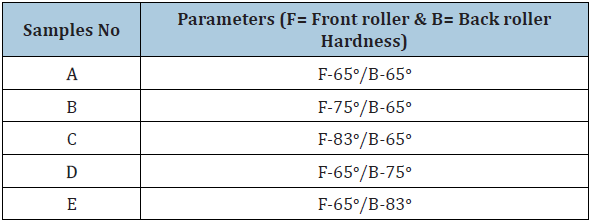

Table 3:Samples matrix.

Working Procedure

1. The five samples were prepared by using the combination of three different cot roller shore hardness in ring frame (Rieter, G5/1). The process of sample preparation is given below with their respective things: Sample A was prepared by remaining same cot roller shore hardness at front- and back-line drafting zone of ring frame. Sample B (F-75o/B-65o) and Sample C (F-83o/B-65o) were produced by varying front roller shore hardness with constant back roller shore hardness whereas Sample D (F- 65o/B-75o) and Sample E (F-65o/B-83o) were prepared by varying back roller cot hardness with constant front roller cot hardness which was mention in the above Table 3. During these times of sample preparation, roller pressure (18kg) and the other parameters of ring frame machine were remained constant. During testing, the standard temperature (20±2 ℃) and RH% (65±2%) were maintained in the testing lab.

2. Necessary tests were carried out for sample A, B, C, D and E respectively by using Uster Evenness Tester- 5, Wrap reel, Uster auto sorter 5 and Lea strength tester.

3. The test results were analyzed to observe the effect cot roller shore hardness of on the quality of produced yarn.

Results and Discussion

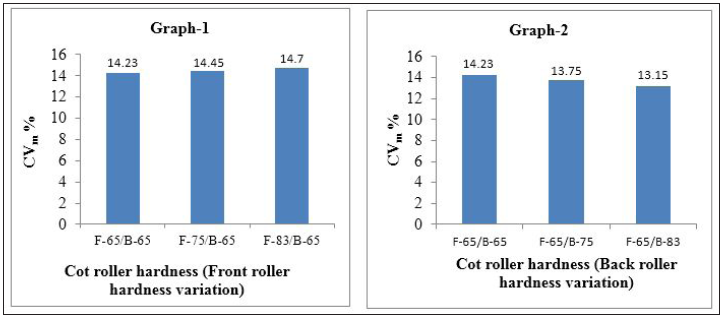

Impact of different roller hardness on mass variation (CVm%) of yarn

Figure 1 (Graph-1) represents the mass variation of yarn against the variation of front roller and back roller cot hardness with remaining constant back roller hardness. From this bar chart it can be concluded that mass variation also increased with increasing front roller cot hardness. Yarn obtained from sample A (F-650/B-650) showed lower mass variation than sample B (F-750/B-650) and sample-C (F- 830/B-650). In case of sample-A, softer cots (F-650) in front line gives additional guidance because only few fibers remain in the strand and these exhibits a tendency to slide apart. And it reduces the possibility of fiber breakage. As a result, it reduces the mass variation of the yarn. On the other hand, Figure 1 (Graph-2) indicates the mass variation of yarn against the variation of back roller cot hardness with remaining constant front roller hardness. From this graph, it can be explained the mass, variation decreased with increasing back roller cot hardness. Yarn obtained from sample-E (F-650/B-830) showed lower mass variation than sample-A (F-650/B-650). Harder cots at back line is suitable because it provides better gripping and also decrease the chance of producing floating fibres in the drafting zone that leads to reduce the mass variation of yarn.

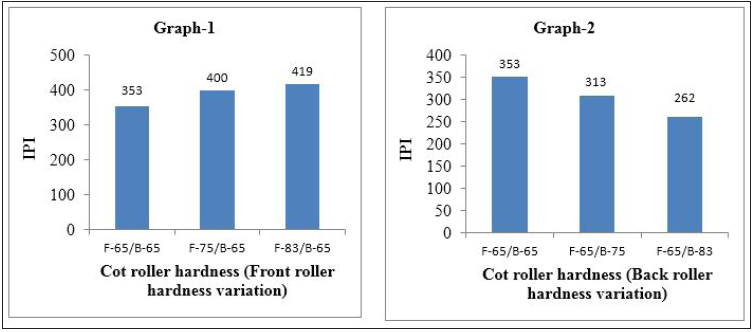

Impact of different roller hardness on the IPI of yarn

Figure 2 (Graph-1) represents the IPI of yarns against the variation of front roller cot hardness with remaining constant back roller hardness. From this bar chart it can be concluded that IPI also increased with increasing front roller cot hardness. This indicate that softer cots in the front zone produce a lower imperfections level of yarn. Softer cots at front line attribute to the decrease in the uncontrolled length between the aprons and the nipping point of the front roller. This led to a more controlled flow of fibres [10]. In case of Figure-2 (Graph-2); it indicates the imperfections level decreased with increasing back roller cot hardness. Harder cots at back line improved the imperfection level of yarn because better gripping at back line decrease the possibility of producing drafting waves in drafting zone.

Figure 1: Impact of different roller hardness on the mass variation of yarn.

Figure 2: Impact of different roller hardness on imperfection index (IPI) of yarn

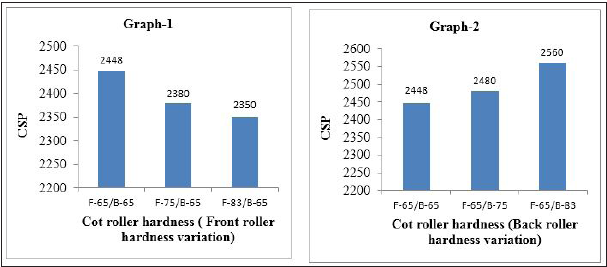

Impact of different roller hardness on the count strength product (CSP) of yarn

Figure-3 (Graph-1) represents the CSP of yarn against the variation of front roller cot hardness with remaining constant back roller hardness. From this bar chart it can be concluded that CSP also decreased with increasing front roller cot hardness. Harder cots at front increased imperfection level as a result; it produced more weak places in yarn. It creates disturbance in the twist insertion. Due to reason; it showed lower CSP. In case of figure-3 (Graph-2); it indicates the CSP increased with increasing back roller cot hardness. At back line with the harder cots produced lower imperfections of yarn resulting in it increased the strength of the yarn.

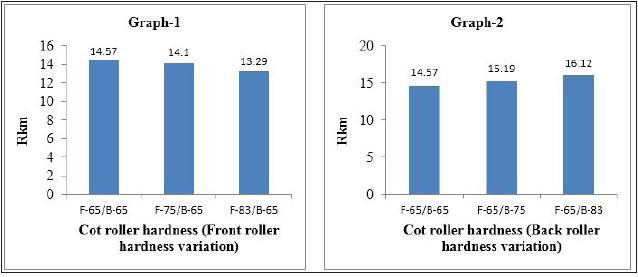

Impact of different roller hardness on the RKm Value of yarns

RKm stands for Reiss kilometer in German and Resistance Kilometrique in French. It is also known as ‘free breaking length’ or ‘self-support length.’ This is the theoretical length of a fiber, yarn or rope at which it breaks under its own weight when hanging freely in a vertical direction [11].Figure-4 (Graph-1) represents the RKm of yarn against the variation of front roller cot hardness with remaining constant back roller hardness. It can be concluded that RKm decreased with increasing front roller cot hardness. Harder cots at front line increase the possibility of fibre breakage. It increases the floating fibres in the spinning triangle that contributes to the imperfection level of yarn. In case of figure-4(Graph-2) it shows the RKm also increased with increasing back roller cot hardness with remaining constant front roller cot hardness. Sample-E showed higher Rkm value than sample-A because it produced by using cot roller shore hardness (F-650/B-830) at front and back line. Softer cots at font line and harder cots at back line reduce the imperfection level of yarn which shows better than other samples.

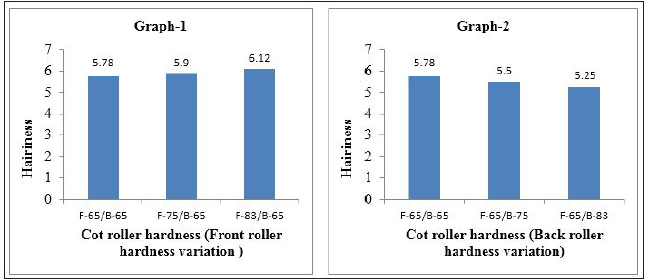

Impact of different roller hardness on the hairiness of yarn

In figure-5 (Graph-1) shows the Hairiness of yarn against the variation of front roller cot hardness with remaining constant back roller hardness. It can be explained that hairiness was also increased with increasing front roller cot hardness. Soft coverings at front line shift the nipping point of front rubbers rollers slightly forward, due to the increased of cross-sectional area. It reduces the spinning triangle, which causes the twist to be inserted in a better way. Better twist insertion reduces the hairiness of yarn. On the other hand, harder cots increased the fibre breakage which caused the higher value of hairiness. Figure-5 (Graph-2) it indicates the hairiness decreased with increasing back roller cot hardness. At back line with the harder cots, there is less chance of lap formation and breakage. The selvedge fibers almost fully integrate into the yarn thus resulting less hairiness in yarn [5].

Figure 3:Impact of different roller hardness on CSP of yarn

Figure 4:Impact of different roller hardness on Rkm of yarn

Figure 5:Impact of different roller hardness on Hairiness of yarn

Conclusion

By conducting this research work it can be concluded that softer cots at front line and hand, harder cots at back line of drafting zone influenced the mass variation, imperfections level, CSP and Rkm of the yarn. With the increment of shore hardness at front line, mass variation and hairiness of yarn also increased. On the other hand, with the decreasing of shore hardness at back line, imperfection level also decreased. Harder cots at back line gives lower imperfection level of yarn. Among these five combinations of cot roller shore hardness, front roller-650 and back roller 830 shore hardness showed better performance for producing good quality yarn with minimum irregularities and imperfections level.

References

- Sundaresan S, Dhinakaran M, Arumugam A (2015) Impact of bearing vibration on yarn quality in ring frame. IOSR JPolymer Text Eng 2(3): 50-59.

- Kane CD, Ghalsaso SG (1992) Studies on ring frame drafting-part 1. Indian Text J, p. 78.

- Parn PK (1999) Latest trends in cots and aprons. J Textile Assoc, p.

- Eyasu F, Sakthivel S, Bewuket T (2018) Effect of spinning top front roller rubber cots shore hardness on yarn quality. Int J Ind Eng 2(1): 7-14.

- Akbar AR, Zeshan M, Neaz M, Cai Y, Lin L (2017) Effect of ring machine front roller rubber cot hardness on properties of coarser yarn. In Matec Web of Conferences 130: 02003.

- Subramanian V, Mohammed A (1991) Effects of apron spacing and break draft on double rove yarn quality in short staple spinning. Text Res J 61: 280-285.

- https://www.astm.org/DATABASE.CART/HISTORICAL/D2240-15.htm

- Balasubramanian N (1969) A study of the irregularities added in apron dr Text Res J 39(2): 155-165.

- Bagwan AS, Policepatil R, Pawar S (2016) Optimizing effects of cots shore hardness on cotton yarn properties at ring frame. J Text Sci Eng 6(1): 238.

- Klein W, Stalder H (2008) The rieter manual of spinning. 4: 193.

- Uddin AJ (2013) Breaking length. Physical Characterization of Textile Fibres, 253.

© 2020 Amit Chakrabortty. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)