- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Fluorine-Free Developments for Lyophobic Textile Finishes

Cordelia Zimmerer1, Marén Gültner2 and Frank Simon1

1Leibniz Institut für Polymer for schung Dresdene V, Germany

2Sächsisches Textil for schungs institute V, Germany

*Corresponding author: Cordelia Zimmerer, Leibniz Institut für Polymer for schung Dresdene V, Germany

Submission: September 25, 2019; Published: September 27, 2019

ISSN 2578-0271 Volume5 Issue4

Opinion

Current development status, political targets and perspectives

In many cases it is necessary and useful that personal protective equipment (PPE), especially protective clothing, is endowed with strongly hydrophobic and oleophobic properties. For outdoor and sports clothing, the combination of these properties is not required. Of course, outdoor clothing should protect against rain, moisture and dirt. The repellence of mineral oils and other organic liquids of low polarity is not really needed neither for hiking nor mountaineering [1]. However, producers as well as distributors have to respect the more or less formed to habit expectations of consumers. Hence, casual wear is often coated with per-or polyfluorinated compounds (PFC) [2] that make them lyophobic and finally easy to clean. From the technological point of view, the application of the PFC repelling polar and nonpolar liquids does not require much effort and essentially no additional cost. The beneficial properties of PFC on textile surfaces are opposite to environmental and human ecological risks [3,4]. Due to their persistence and bioaccumulation, PFC are in public discussion for almost 50 years. The water solubility of the PFC’s degradation and by-products formation, in particular the perfluoro-alkane surfactants, allow the rapid spread in ecosystems, and the long-term stability of the organo-fluorine compounds leads to increase their concentrations in soils, waterbodies and air [5,6]. Through the food webs they enter plants, animals and finally humans, where they were not accumulated like most persistent organic pollutants in the fatty tissue, but in organs like the liver, the kidneys and the gallbladder. In 2008 a study documented the accumulation of PFC in the blood of the human organisms [7].

In the frame of the Stockholm Convention on Persistent Organic Pollutants [8] ratified by the countries of the European Union [9] and the majority of the other countries, national laws to prevent or minimize the production, distribution and use of PFC were passed. The Commission Regulation No 757/2010[10] does not allow substances and preparations to contain more than 10 mg.kg-1 PFC and products must not contain more than 0.1% PFC (with special exemptions for individual industries). Also, for the physiologically and ecologically similar acting perfluorooctanoic acid (POFA) and other per-fluorinated carboxylic acids consisting of longer alky chains (C11-C14) as well as their conjugate bases and salts there are efforts to limit their applications in the future [8,11]. The textile and finishing industries can make a big contribution to containment the use and spreading of PFC. A substitution of the longer-chain PFC by shorter-chained PFC substances (such as C6) does not appear to make sense neither in the frame of their physiological and

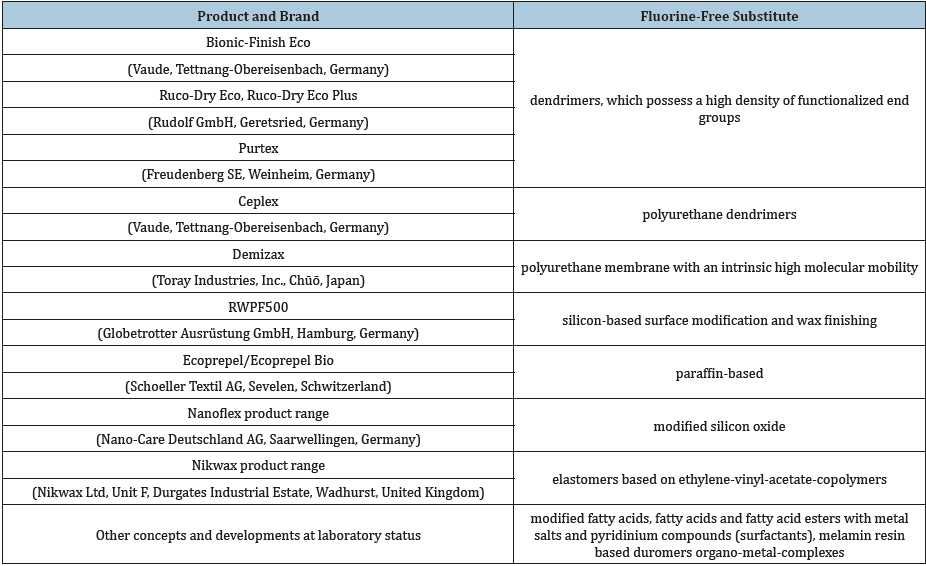

ecological properties nor in the frame of the dynamics in the steady tightening of international and national regulations. In addition, C6 show weaker functional effects which, in particular, only inadequately fulfil the required oil-repellent properties for high- performance applications in the protective textile sector. More sustainable strategies for textile finishing are based on the development of application-specific finishes and less on an all-round solution. For example, outdoor and sports clothing does not need to have any super-oleophobic finish against non-polar carbon hydrogen compounds. Thus, new developments follow the trend of minimizing strong interactions between liquids and fabrics. The key requirement for the finishing-substitutes is a reduction of the surface free energy to such an extent that alkane compounds are no longer wetting. The summary of market-ready product developments shows that oil- , chemical-, and solvent-repellent properties do not necessarily have to be achieved strategically for outdoor and sportswear. Even though intensive research has been carried out in the field of finishing textiles with fluorine-free coatings, there are currently no alternatives to the application of PFC according to the state of the art for the production of outdoor and sports clothing and in particular for protective fabrics with high safety standards. Lyophobic developments that will establish themselves on the market in the long term should be based on formulations and technologies that achieve an optimum balance between productspecific performance and human ecological safety (Table 1).

Table 1: Different market-ready developments and alternative solutions to replace PFC in textile finishing.

References

- Josef Lingg (2019) Mammut Sports Group AG, Conference Textilinnovativ Lindau, Germany

- These are mostly polymeric organo-fluorine compounds carrying for example fluoro-surfactants, such as derivatives of perfluoroalkane carbonic or sulfonic

- Biegel Engler A, Staude C, Vierke L, Schulte C (2013) Per- and polyfluorinated chemicals (PFC): use with consequences. Umwelt Bundesamt, pp. 12-17.

- Vierke L, Schulte C (2016) Fluorchemikalien: Funktionalität und Umweltschutz. Nachrichten ausder Chemie 64: 969-971.

- Greenpeace: Footprints in the snow-Hazardous PFCs in remote locations around the globe. Greenpeace: Leaving Traces-The hidden hazardous chemicals in outdoor gear.

- Biegel Engler A, Vierke L, Apel P, Fetter E, Staude C (2017) Mitteilungendes Umweltbundesamteszu per-und polyfluorierten Chemikalien (PFC) in Trinkwasser. Bundesgesundheitsbl 60: 341-346.

- Dietz R, Bossi R, Rigét FF, Sonne C, Born E (2008) Increasing perfluoroalkyl contaminants in East Greenland polar bears: A new toxic threat to the Arctic Environ Sci Technol 42(7): 2701-2707.

- Stockholm Convention on Persistent Organic New York, USA.

- Regulation (EC) no 850/2004 of the European Parliament and of the Council of 29 April 2004 on persistent organic pollutants and amending Directive 79/117/EEC. Official Journal of the European Union 158: 7-49.

- Commission Regulation (EU) No 757/2010 of 24 August 2010 amending regulation (EC) No 850/2004 of the European Parliament and of the Council on persistent organic pollutants as regards annexes I and III. Official Journal of the European Union L 223: 29-36.

- Commission Regulation (EU) No 317/2014 of 27 March 2014 amending regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) as regards Annex XVII (CMR substances). Official Journal of the European Union L 93: 24-27. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/fact-sheet-20102015-pfoa-stewardship-program

© 2019 Cordelia Zimmerer. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)