- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Optimization of Time and Temperature for Stone Washed Denim Fabric

Kamrun Nahar*, Marzia Islam, Jannatul Ferdush and Tarifun Akter

Northern University Bangladesh, Bangladesh

*Corresponding author:Kamrun Nahar, Northern University Bangladesh, Bangladesh

Submission: September 04, 2019; Published: September 16, 2019

ISSN 2578-0271 Volume5 Issue3

Abstract

Denim is one of the most popular choice for garments industry in today’s world, so the production process of denim requires swift method for faster production cycle. Moreover, the vogue of denim depends on its outlook which is accomplished by different washing techniques. In this study one of such quotidian washing method is used but main motive is to find out the minimum time and temperature in which stone washed denim fabric provide satisfactory results. Here denim samples are washed with pumice stone rather than using any kind of enzyme. Washing is done in two ways such as at fixed temperature (28 0C) with various time duration (30,35,40,45minutes) and at fixed time cycle (25minutes) in different temperature (40,45, 50 and 55 0C). After washing, different color fastness values such as color fastness to wash, water, perspiration and rubbing are determined along with tear strength value and pH value to measure the strength and comfortability of the washed denim.

Keywords: Color fastness; Denim fabric; Metamerism index; Pumice stone; Stone wash

Introduction

Garments washing is the process where garments are treated to modify the appearance, size, outlook, comfortability and fashion of the garments [1]. Through this process products can obtain a glassy look with suppleness [2]. Washing carried out in mostly for the full processing cycle of a product. To fulfill the buyer requirement washing is the substantial term in case of garments. For this reasons surfeit washing plant has been set up in Bangladesh [3]. During the manufacturing process of apparel, most of the products remain in harsh and stiff condition, so they require washing treatment. Denim is a type of stiff, rigid and hard cloth because of its sturdy twill structure that need subsequent washing treatment for supple hand.

On the other hand, arrantly washing process can be classified into two major ways: dry wash and wet wash. Dry washing process are applied to denim or other garments for creating scraping, spraying, whispering, damages, spots, rubbing effects. While, wet washing imparts to textiles to coin a better look or effects by normal wash or rinse wash, pigment wash, caustic wash, silicon wash, enzyme wash, stone wash, stone enzyme wash, bleach wash and acid wash [4]. To refurbish the denim appearance, comfortability, outlook and fashion of the dress various types of washing are done on denim garments. Stone wash is one of the most familiar wash on denim. Stone wash is applied to yield “Used effect” or “Vintage effect” on the garments. Pumice stones are the key elements of stone wash which scrap off dye particles from the surface of the yarn of the denim fabric and due to this a faded, worn out and brilliance effect is created in the denim fabric.

Monoroma Hossain, Md. Shakhawat Hossain Rony, K. M. Faridul Hasan, Md. Kawsar Hossain, Md. Azharul Hossain, and Yang Zhou studied on different washing process in garments washing. This study gives an indication of different types washing process and the change of physical and chemical properties due to application of wet and dry washing processes as an imparting desired effect on garments [5]. Joy Sarkar, Elias Khalil, Md. Solaiman worked on combined enzyme and stone wash with pumice stone. In this study garments were washed using an enzyme concentration of 1.5,2.0 and 2.5g/l for 40 minutes in 55 °C temperature with addition of 0.5owg (On the weight of garments) pumice stone [6]. After effects of enzyme wash on tensile properties has been experimented by C.W. Kan. This this paper will investigate the effect of enzyme washing on the tensile property of denim fabric under different treatment duration [7]. Washing effects on color properties of various denim washing has been underscored in the empirical work of Mushtaq Mangat, A. M. Rehan Abbasil and Jakub Wiener.In their study traditional denim made by using 100% cotton and novel denim [8]. This experiment is an attempt to give denim fabric a distressed look with minimum tear and wear following the optimum time and temperature.

Material and Methods

Materials

Substrate

Fabric Type: Denim

Fabric Construction: Composition-70% cotton and 30% viscose, EPI/ PPI- 70*49, Weave- Z-Twill, GSM-450

Color: Dark blue

Stone: Pumice stone

Methods

Stone washing recipe

Desizing agent 0.7gm/l

Detergent-1gm/l

Pumice stone- one third volume of sample.

Time- 25,30,35,40,45min

Temperature- 28,40,45,50,55 0C.

M: L- 1:10

Stone washing procedure

All the specimen first desized with desizing agent and detergent. And then fabrics are washed with only pumice stone at different temperature and time to find out the feasible optimum temperature and time for stone washing process.

Different testing methods

Color-coordinate value: As the color of all the washed sample is likely similar so color co-ordinate value can differentiate the small discrepancy of the samples very accurately. Following the CIE LAB and LCH method color co-ordinate value such as L, a, b, c, h is measured using Spectrophotometer 650.

Metamerism index: Metamerism is the incongruence of samples under different light source. And metamerism Index can be expressed as MI, which is formulize as MI=√ [(Change in Lightness of sample in two light source)2+ (Change in a of sample in two light source)2+ Change in b of sample in two light source)2]

Evaluation of color fastness: Color fastness to wash, rubbing and perspiration (acid and alkali) has been investigated by following the ISO method in the rating of 1-5.

Determination of GSM: GSM stands for Gram per Square Meter, as it related to production so to determine GSM accurately is an essential task during denim washing, whether it reduce too much weight or not. GSM is measured by the GSM cutter in a most convenient way.

Tear strength testing: Strength test is being done on washed denim fabric as it undergoes several process so ultimately what amounts of load it can bear without tearing is paramount for any washed fabric. In this process 20cm× 5cm fabric have been taken from both warp and weft way and then fixed to machine’s jaw and measuring the tearing loads.

Determination of fabric pH: pH is measured to test whether the fabric is acidic or alkaline after dyeing, printing, finishing and washing. Since apparel is remained in direct contact with skin, so when it becomes too acidic and alkaline it irritates our body and causes itching to the human body. As a result, pH value should be maintained in neutral and slightly acidic range. So. it is necessary to determine the pH value after apparel manufacturing. And here pH is measured by following the test method of DIN ISO 3071.

Result and Discussions

Visual assessment

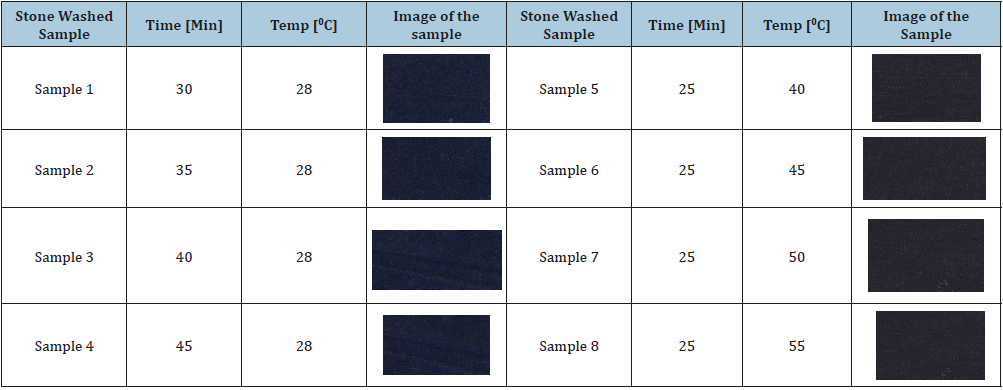

Table 1:Pictorial view of stone washed denim.

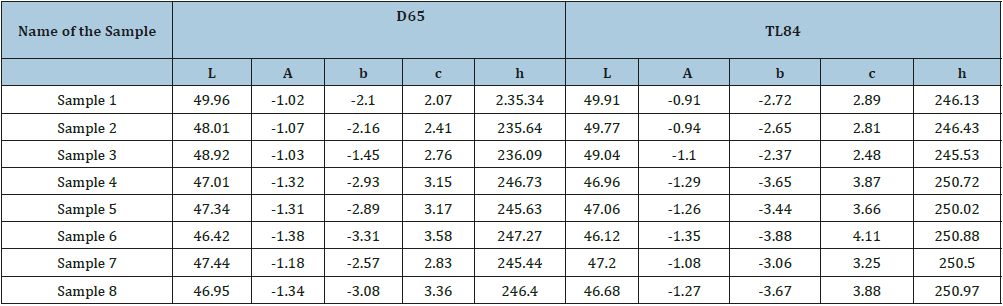

From the pictorial view, it can be said that there is very subtle discrepancy among all the sample. But it is observed that, time variation has slightly more effect on the specimen than temperature variation during stones wash. Since the visual countenance of all the specimen are tantamount, so color coordinate value can able to differentiate their actual variation. And it is observed that denim fabric washed with stone at 25 mins at 45 0C, 55 0C and 28 0C for 45 mins give more deeper and blue tone rather than other samples. So, in case of color degradation after washing (Table 1&2).

Table 2:Color-coordinate value in two light sources.

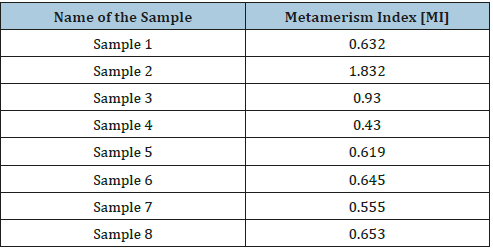

Metamerism Index

Metamerism Index refers to the color consistency in different light source. The lower the MI value the better the effect of samples is obtained. For this case, metamerism Index of sample 4 and sample 7 and 8 is lower than any other samples (Table 3).

Table 3:Metamerism Index of all sample.

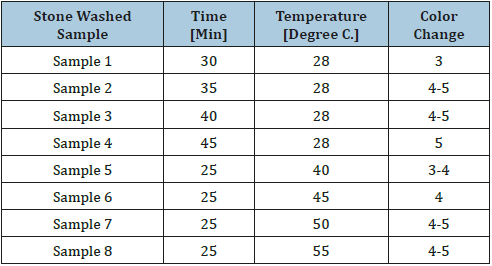

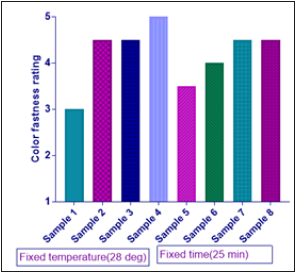

Color fastness to wash

Color fastness to wash test reveals that when denim washed at comparatively higher time duration colorfastness rating becomes excellent although at same temperature. On the other hand, for 25min exposure of time yields good wash fastness both for stone washing at 50 0C and 55 0C (Table 4) (Figure 1).

Table 4:Colorfastness to wash grading of washed sample.

Figure 1:Colorfastness to wash of all samples according to time and temperature variation.

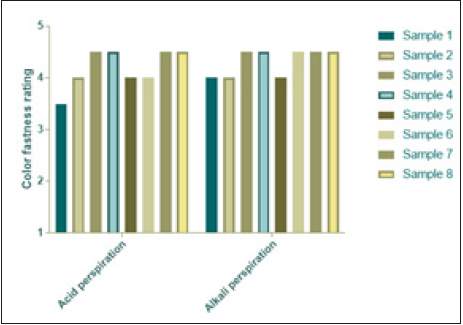

Color fastness to perspiration

Acidic perspiration has more deleterious impact on stone washed denim especially during the denim is exposure to stone wash for time 30mins at 28 0C. As result sample 1 has moderate acid perspiration fastness rating and alkali fastness rating is 4. In contrast, when at the same time difference samples are washed at various temperature (40. 45, 50, 55 0C), samples washed at 50, 55 0C exhibits same fastness rating (4-5) (Table 5) (Figure 2).

Table 5:Colorfastness to perspiration rating of washedsample.

Figure 2:Colorfastness to perspiration of all samples according to time and temperature variation.

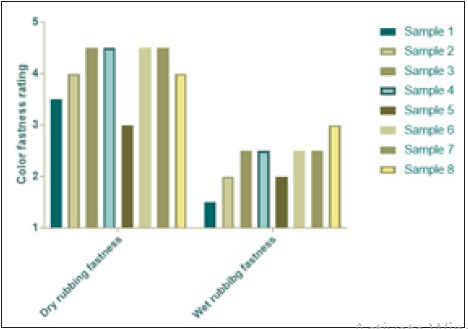

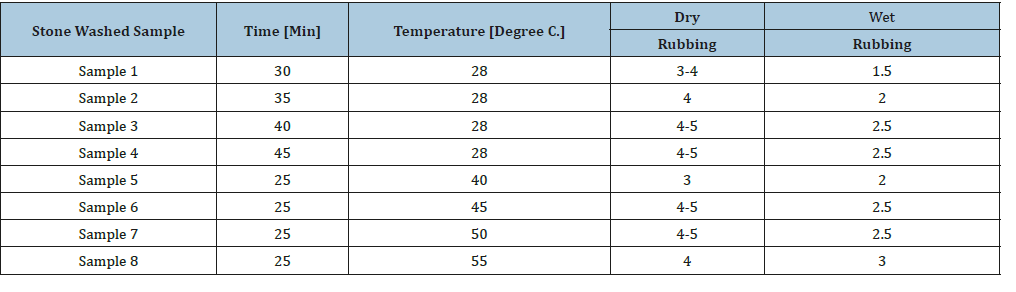

Figure 3:Colorfastness to rubbing of all samples according to time and temperature variation.

Table 6:Colorfastness to rubbing test result.

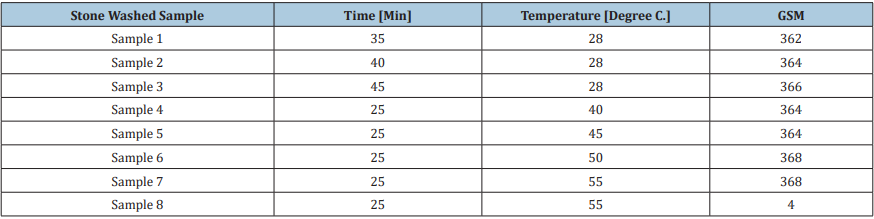

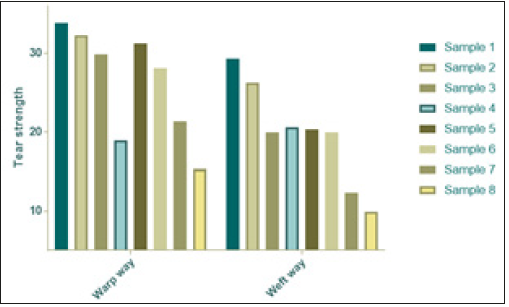

GSM variation of stone washed sample with different time and temperature

With the incongruous of time and temperature, denim shows erratic change of GSM (Gram per Square Meter). In case of, fixed lower temperature (28 0C) with gradual increase of time exposure provides high GSM (366) for 45minutes. On the other side of coin, for the fixed lower time (15min) duration there is no variation of GSM (364) between 40 and 45 0C as well as 368 GSM for both 50 and 55 0C. So. it is clear that GSM is much more compatible for lower time duration at higher (55 0C) energy consumption (Table 7) (Figure 4).

Table 7:Changes of GSM after stone washing.

Figure 4:GSM variation of all samples according to time and temperature.

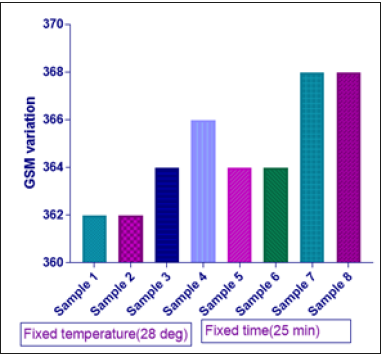

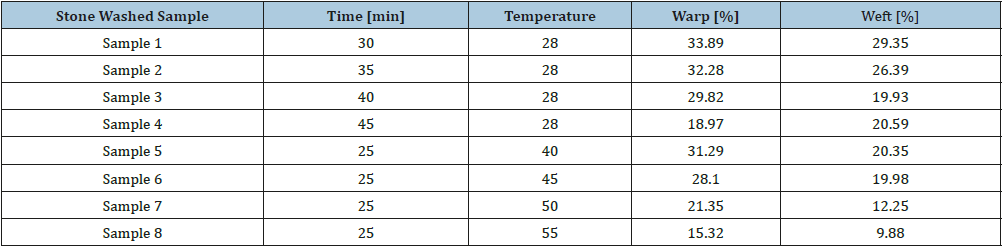

Tear strength test with variation of time & temperature of stone washed denim

It is observed that tear strength at warp way of stone washed denim is comparatively greater (33.89) at lower temperature (28 0C) and 30 min time exposure. In addition to that, for weft yarn low time and temperature have to be maintained to get better tear strength. So, low time and energy consumption germane tear strength of warp and weft way of stone washed denim (Table 8) (Figure 5).

Table 8:Result of tear strength testing

Figure 5:Tear strength of all samples according to time and temperature.

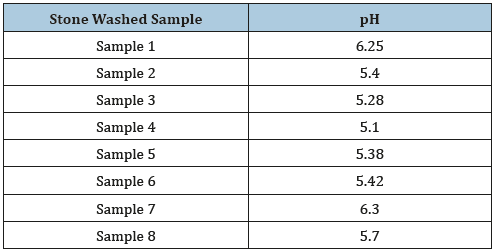

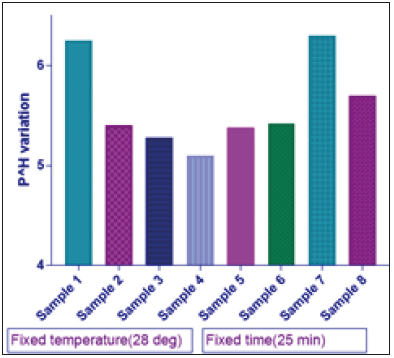

pH range of stone washed denim

After pH test of all stone washed denim specimen reveal that comfortable and suitable pH (6.25) is obtained when denim is washed at 28 0C for 30minutes. As well as at 50 0C and 25minutes yield appropriate pH value that is 6.30. As a result, it can be said that time plays crucial role in controlling pH value when time is low temperature should be higher to control the pH (Table 9) (Figure 6).

Table 9:Variation of pH after washing.

Figure 6:Tear strength of all samples according to time and temperature.

Conclusion

This study is an attempt to find out the feasibility of stone washing by maintaining optimum parameters that can curtail the extra temperature and time utilization during washing. In this regard, after washing no softener is used which affect the rubbing fastness properties of washed denim. And it was noticed that after washing denim at 28 0C temperature for 45minutes or at 45 0C for 25minutes all the fastness properties and strength values are better than general stone washing process which is done at 60 0C for 30- 45mins. It can be clearly seen that minimization of temperature (at 45 0C) and time (for 25mins) can promote good result in comparison to generally required time and temperature. After assessing all the fastness properties and other values, it can be deducted that the optimum temperature and time which is mentioned above (45 0C and 25mins) can be applied instead of general procedure to get the desired effect with satisfactory properties.

References

- Brenner RA, Hardaway AH (1988) High performance washing process for vertical axis automatic washer. USA.

- Pazarlıoǧlu NK, Sariişik M, Telefoncu AL (2005) Production by trametes versicolor and application to denim washing. Process biochemistry 40(5): 1673-1678.

- Molnar BD, McGrath DT, Dausch ME, Badami VV, Whipple W (1994) Machine for cleansing articles, USA.

- Kalliala E, Talvenmaa P (2000) Environmental profile of textile wet processing in finland. Journal of Cleaner Production 8(2): 143-154.

- Monoroma Hossain, Shakhawat Hossain R, Faridul Hasan KM, Kawsar Hossain, Azharul Hossain, et al. (2017) Effective mechanical and chemical washing process in garment industries. American Journal of Applied Physics 2(1): 83-86.

- Joy Sarkar, Elias Khalil, Solaiman (2014) Effect of enzyme washing combined with pumice stone on the physical, mechanical and color properties of denim garments. International Journal of Research in Advent Technology 2(9): 2321-9637.

- Kan CW (2014) Effect of enzyme washing on the tensile property of denim fabric. Advanced Materials Research 933: 75-178.

- Mushtaq Mangat AM, Rehan Abbasil, Jakub Wiener (2014), Evaluation of change in color of denim fabric after various industrial washing processes with different fiber composition. World Journal of Engineering 11(2): 107-110.

© 2019 Kamrun Nahar. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)