- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Extraction and Application of Moringa Oleifera Seed Kernel Starch for Warp Yarn Sizing in Textile Industry

Selamu Temesgen*, Mekdes Endale, Mekdelawit Barega, Meskerem Habte and Salim Ahmed

Kombolcha Institute of Technology, Wollo University, Ethiopia

*Corresponding author:Selamu Temesgen, Kombolcha Institute of Technology (KIOT), Wollo University, Ethiopia

Submission: July 30, 2017; Published: August 20, 2019

ISSN 2578-0271 Volume5 Issue3

Abstract

Sizing is a procedure where the film forming polymer is used to offer temporary protection to the warp yarns from abrasive and other types of stresses generated on the weaving machine in order to bring down the warp breakages. Moringa oleifera seed kernel contains starch with other ingredient such as oil, protein etc. In this paper we are concerned in sizing warp yarn by starch extracted from Moringa oleifera seed kernel and blended with maize to produce effective sizing chemical. Morninga seed starch is extracted and characterized and yarn is sized using the starch extracted. The performance properties tested after sizing are yarn strength and elongation test, end breakage test on loom, size removal test, size take percentage, abrasion resistance test and finally cost comparison was done. Yarn tensile strength and elongation test has been done using single and double end yarn strength tester machine. From the test result we found strength regain 35.91%, size take up 7.11% and loss of elongation 31.53% respectively. The loom efficiency was calculated after having end breakage test and it was found to be 95.8%. Size removal test was done using iodine drop test after desizing fabric using enzymatic desizing and the result shows brown color which means starches are completely removed from the fabric and abrasion resistance test revealed the total number of abrasive cycles to be around 1400 which is similar to result obtained using cassava and potato starch in previous studies . From cost comparison with sizing chemical that kombolcha textile Share Company® is using currently, we found that the company can save around 4, 914,561.6 birr per year if it uses starch extracted from moringa oleifera seed kernel.

Keywords:Moringa oleifera; MLR; Loom efficiency; Tensile strength; Elongation; Abrasion resistance; Fabric; Yarn

Introduction

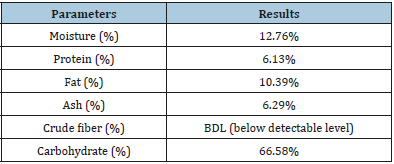

Sizing is an established method for improving the weave ability of textile yarns. Sizing is the process of coating or impregnating warp yarns with a polymer that improves the efficiency of the weaving. Moringa oleifera belongs to the genus Maringa ceae. Moringa oleifera is the most widely known and utilized of these species [1]. Moringa oleifera is esteemed as a versatile plant due to its multiple uses. Different parts of this plant contain a profile of important minerals, and are a good source of protein, vitamins, beta-carotene, amino acids and various phenols [2]. Moringa oleifera is a fast growing an aesthetically pleasing tree. The seeds of this plant are large and circular shaped and grow inside the lengthy pods of the Moringa oleifera tree and they are dark brown in color with three papery wings extending from the main kernel of the seeds [2]. Maize is one of the major cereals to have become staple food and contribute to constituent of our daily diet in Ethiopia. It is mainly rich in carbohydrate (starch). The maize contains starch by a percentage of 66, which can be extracted from the maize from various means. Steeping, grinding, drying and purifying are the essential processes that are being used for the extraction of starch from maize. The maize starch is also known to have the best usages in various other industries. Paper industry, textile industry, pharmaceutical industries are some of the common places where the maize starch has high usages. In textile industry, the starch can be used for the purpose of sizing so that the strength of the warp yarn can easily be increased [3]. (Figures 1 & 2) Historically, starches and flours have been the film-formers of choice for textile sizing. Flour is much less popular today than in the past, but starch remains of major importance. Starch is especially effective for cotton sizing because the film has a natural ability to stretch before rupture to a degree that closely parallels the natural stretch of cotton yarn [3]. The reason behind the popularity of starch can be attributed to the following factors.

a) Starch is chemically same with cotton thus the adhesion is very good.

b) Desizing is easy

c) Relatively cheap

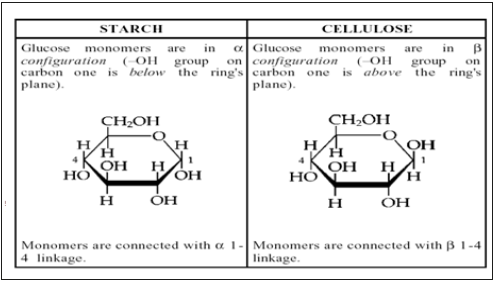

Properties can be tuned to cope with the need (Table 1).

Figure 1:Shows Moringa seed kernel and maize.

Figure 2:Chemical structure of starch and cotton.

Table 1:Proximate analysis of moringa is shown on the following table [7].

Materials and Experimental Methods

Materials used

In this study 34Nm count yarn was sized using starch extracted from moringa seed kernel and blended with maize. Karl mayer sizing machine available in Kombolcha® textile share company was used for warp sizing and fabric is constructed on rapier loom. Single and double end yarn strength tester machine was used for yarn property testing and enzyme was used for desizing fabric to test for size removal. Martindale Abrasion resistance tester was used to test abrasion resistance of fabric constructed using yarn size with moringa oleifera starch.

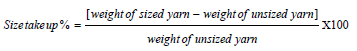

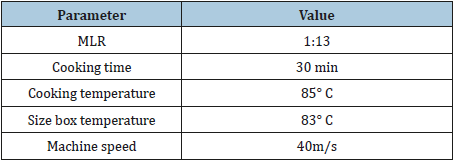

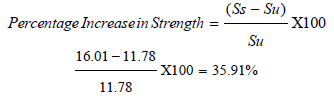

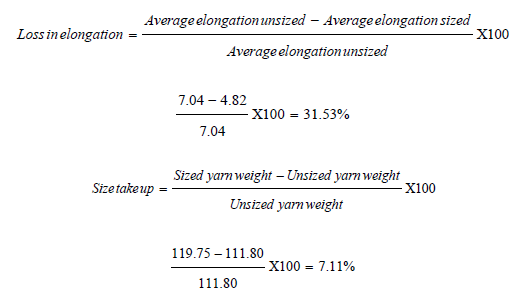

Sizing process: The warp yarns were sized in a conventional cylinder sizing machine with 9 drying cylinders. During sizing, all the parameters including the machine used, its speed (30-40m/ min), yarn tension, squeezing roller pressure (2kg/cm2), yarn stretch percentage (1-1.2%), total number of ends (3986) were kept constant. Equal amount of moringa and maize are used for solution preparation. Solution was prepared and cooked as given in Table 2. Viscosity (flows per second) of the prepared solution was measured using the zahn cup and converted to ASTM standard unit of centistokes. The viscosity result indicated that moringa starch solution achieved a viscosity of 15 flows/sec. Size take up percentage was calculated using equation (i).

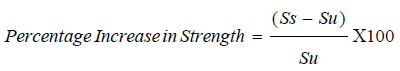

Percentage increase in strength is given as

Where, Ss: Sized yarn strength; Su: Unsized yarn Strength (Table 2).

Table 2:Size solution preparation and cooking parameters.

Experimental Tests

Unsized and sized yarn tests: The tensile strength and elongation test of both the unsized and sized yarn was tested. This was to compare the strength imparted by the starch. The tensile strength of unsized yarns was tested on Autodyne 300 single yarn strength tester as shown in Figure 3. It was done according to ASTM D2256 standards with a clamp speed of 1000mm/min and pretension force of 450N.

Figure 3:Autodyne yarn strength tester.

Sized yarn test result

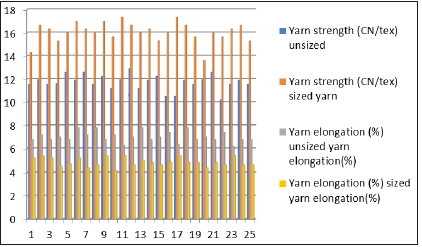

Tensile strength and elongation test result: The integral yarn strength is a major contributing factor to both tensile strength and tear strength of fabrics [1]. According to Ping and Greenwood, tensile strength of a fabric in either the warp or weft direction is the function of yarn strength. The breaking load and elongation test for sized yarn has been done using single and double end thread strength tester.

Size removal percentage test for sized yarn by desizing: Size removal percentage was calculated after desizing the samples. Enzymatic desizing was done at mass liquor ratio of 1:20, using 6%w/w biolase enzyme and 5%w/w NaCl at a temperature of 60° C for 1 hour with 1.5g/l wetting agent. Desizing is the process of removing the size material from the warp yarns in woven fabrics. Easy desizing ability is one of the greatest requirements of sizing agent. The higher the water solubility of sizing agents, the lesser will be the energy consumption. This leads to more economic process [4]. Desizing ability of sizing agents depends on factors like viscosity of size paste, moisture regain of size film, and solubility of size film in water. All these factors are directly or indirectly dependent on the chemical structure of the size material [1,5].

End break test: Plain fabric was constructed on rapier loom using 34Nm count of cotton weft yarn. The fabric width was 150cm with warp and weft crimp of 5% and 4%, respectively. All machine parameters were kept constant and end break rate was recorded for duration of 2 hours. The breaks/105 ends/104 picks were calculated and compared against Bombay Textile Research Association (BITRA) standard.

Result and Discussion

Yarn test results

Tensile strength: The tensile strength of yarn sized with moringa oleifera starch and unsized yarns were measured and the result is shown comparatively in Figure 4.

Average Elongation unsized = 7.04%

Average Elongation sized = 4.82%

From the result we can see that the strength gain is found to be 35.91% which acceptable as per BITRA standard (25-40%) which ensures that Moringa oleifera seed kernel starch can give sufficient strength to the sized yarn and can be utilized for warp sizing. The loss in elongation is found to be about 36.01% which is higher as compared to company standard which is 27.84% and this may show improvement in the strength gain.

Figure 4:Graph showing tensile strength result of sized and unsized yarns.

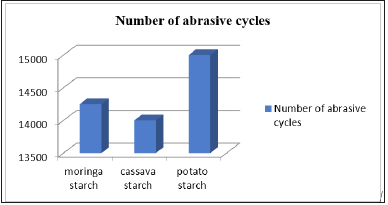

Abrasion resistance test: Abrasion is wearing a way of any part of material by rubbing against another surface [6]. Abrasion resistance is measured in terms of number of abrasive cycles. Complete movement of abrasion cycle depends on the action of abrasion machine and test methods used. As the number of abrasive cycles increase the performance of sized yarn on the loom will be high. Fabric abrasion resistance is directly related to yarn abrasion resistance. Abrasion resistance test result of moringa oleifera starch sized yarn is given in graph (Figure 5) in comparison with other commonly used warp sizing starch sized yarns which is measured from fabric abrasion resistance test. From the abrasion resistance test result, we can see that moringa oleifera starch sized yarn has comparable abrasion resistance to those of cassava and potato starch sized yarns [7] and this can ensure that moringa oleifera starch can give good abrasion resistance to sized yarns.

Figure 5:Abrasion resistance result for moringa seed starch sized yarn comparatively.

End breakage test result and loom efficiency: Using sizing chemical developed in this research work warp yarn is sized and plain fabric was constructed on loom to see performance of the yarns and end breakage rate was recorded for two hours. Here comparison of chemical developed in this research and chemical that company is using was done during fabric construction for loom efficiency and end breakage rate. The following table, Table 3 shows end breakage rate and efficiency of different looms used for fabric construction using yarn sized withmoringa oleifera starch and other conventional starches used in the company.

Table 3:End breakage test result and loom efficiency.

Desizability

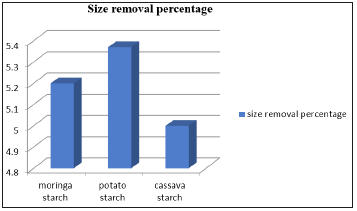

Desizability refers to easy removal of starch from yarn or fabric surface as it is not needed for next operation or processing of fabric. Desizability of sizing agents depends on factors like the viscosity of size paste, moisture regain of size film, and solubility of size film in water. All these factors are directly or indirectly dependent on the chemical structure of the size material [8-13]. Size removal percentage has been calculated by enzymatic desizing of the fabric samples and weight loss calculation to get idea about desizability or easy removal of starch. Amylase enzyme 6%owf, sodium chloride 5%owf and wetting agent 1.5g/l at an MLR ratio of 1:20 were used for desizing solution preparation. The size removal test result is shown in Figure 6 in comparison with result from yarns sized with potato and cassava starches. From the size removal test result, we can see that moringa oleifera starch sized yarns has comparable size removal percentage to those of cassava and potato starch sized yarns [7] and this ensures that moringa oleifera starch is easily removable from surface of yarns and this can make it suitable for warp sizing.

Figure 6:Size removal test result in comparison with potato and cassava starch sized yarns.

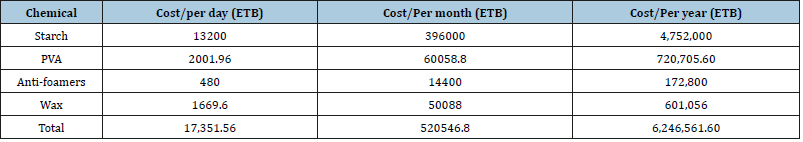

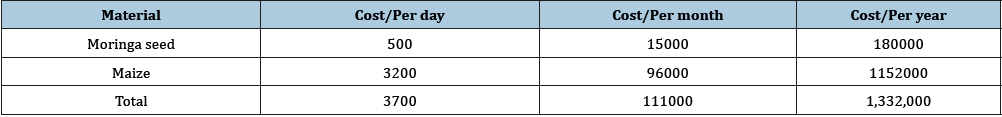

Cost analysis

Cost analysis was done for sizing chemical developed in this research to see its feasibility in terms of cost .Here daily need of company for sizing chemical in terms of cost for equal amount of production was used as means of comparison for sizing chemical developed in this research and chemical that the company is using currently from different manufacturers [14-17]. The daily and yearly expenditure of company for sizing chemical that it is using currently and estimated expenditure of company for the newly developed sizing chemical is given in comparison in the following tables. The cost of sizing material which kombolcha® textile share company is using currently is given as shown in the following table. As we can see from the above table the company is spending around six million birr per year for warp sizing. The cost of sizing using sizing chemical developed in this research is given as shown in Tables 4 & 5. As we can see from the above table the company can spend around one million birr per year for warp sizing if it uses sizing chemical developed in this research. So, we can see from the above two tables that the company can save up to 4,914,561.6ETB per year if it uses the sizing chemical developed in this research which is moringa seed and maize blend. So, this shows that moringa seed kernel is cost effective and good performing warp sizing chemical.

Table 4:Shows cost of sizing recipe being used currently at kombolcha® textile share company.

Table 5:Shows the cost of sizing recipe developed in this research work.

Conclusion

From this research experimental result, we have seen moringa oleifera starch sized yarn is showing good performance properties and it is also cost effective as compared to the conventional sizing starches. So, from the research work we can conclude that moringa oleifera seed kernel starch can be used in textile industry for warp yarn sizing as optional or substitute for other starches.

References

- Abdul DAS (2007) Economic importance of moringa oleifera in tafa local government area of niger state, Nigeria, p. 34.

- Adejumo A, Aderibigbe AF, Layokun SK (2011) Cassava starch: production, physicochemical properties and hydroxylation-a review. Advances in Food and Energy Security 2: 8-17.

- Afolayan, Michael O, Omojola, Moses O, Orijajogun, et al. (2012) Further physicochemical characterization of anchomanes deforms starch. Agriculture and Biology Journal of North America 3(1): 31-38

- Ajayi GO, Kabele TBB, Wodi MO, Williams AO (1996) Physico-chemical properties of starch obtained from two Nigerian plants ipomoea batatas and anchomanes difformis. West Afr J Biol Sci 5(1): 77-83.

- Lata K (2012) Experimental study on application of different sizing agents and its impact of fabric properties. Int J Multidisc Edu Res 1(4).

- Malik ZA (2015) Relationship between tensile strength of yarn and woven fabric, Mehran University of Engineering & Technology, Jamshoro, Pakistan.

- Temesgen S, Murugesan B, Gideon RK (2019) Performance evaluation of cotton yarn sized with natural starches produced from native corn, cassava and potato starches. J Textile Sci Eng 9(1): 389.

- Aberra Melesse, Kefyalew Berihun (2013) Chemical and mineral compositions of pods of moringa stenopetala and moringa oleifera cultivated in the lowland of Gamogofa Zone. J Environ Occup Sci 2(1): 33-38.

- Adi Adumitroaie, Barbero EJ (2012) Stiffness and strength prediction for plain weave textile reinforced composites. Mech Adv Mater Struc 19(1-3).

- Aberra Melesse (2011) Comparative assessment on chemical compositions and feeding values of leaves of moringa stenopetala and moringa oleifera using in vitro gas production method. Ethiop J Appl Sci Technol 2(2): 31-41.

- Behera BK, Joshi VK (2006) Effect of sizing on weavability of DREF yarns. Autex Res J 6(3): 142-147.

- Agbo IU, Odo GE (2010) The effect of hypochlorite oxidation and acetylation on some of the physicochemical properties of icacinatrichantha starch. Bio-Research 8(1): 593-597.

- AOAC (1990) Official methods of Analysis. (15th edn), Association of official analytical chemists. Washington, DC, USA, pp: 831-835.

- Attama AA, Nnamani PO, Mbonu IK, Adiku MU (2003) Effect of hypochlorite oxidation on the physicochemical properties of gladiolus starch. Journal of Pharm and Allied Science 1(1): 28-35.

- Bandhari PN, Singhal RS (2002) Studies on the optimization of preparation of succinate derivatives from corn and amaranth starches. Carbohydrate Polymers 47(3): 277-283.

- Builders PE, Emeje M, Kunle OO (2001) Some physico-chemical properties of cyperus starch-A potential pharmaceutical excipient. Journal of Pharmaceutical and Allied Sciences 2(1): 138-144.

- Charles A, Chang Y, Ko W, Sriroth K, Huang T (2004) Some physical and chemical properties of starch isolates of cassava genotypes. Starch 56(9): 413-418.

© 2019 Selamu Temesgen. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)