- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Detecting the Physical Properties of Thermal Bonded Nonwoven Fabrics

Shariful Islam*, Nasif Chowdhury, Jarin Yasmin, Arifuzzaman, Faridul Islama and Mehedi Hasan

Department of Textile Engineering, Faculty of Science and Engineering, India

*Corresponding author:Shariful Islam, Department of Textile Engineering, Faculty of Science and Engineering, India

Submission: July 16, 2019; Published: July 25, 2019

ISSN 2578-0271 Volume5 Issue3

Abstract

The purpose of this study turned into to apprehend the bonding conduct of different polymers in thermal bonding. Unique attention was given to the interplay of the materials variables with processing traits of the polymers. First of all, thermal bonding research were performed the use of films from one-of-a-kind polymers. Polymer films of different morphology had been made out of unique grades of Polypropylene. Thermal bonding of those movies become accomplished the usage of the hot press. Effect of movie structure, homes and bonding situations on the bonding performance becomes studied. A range of bond temperatures covering negative, optimal and over bonding had been studied to understand the modifications taking area. Bonded tensile strength become analyzed the use of tensile trying out. Change taking vicinity to polymer in bond point and unique surface have been analyzed using SEM. Significance was given to material variables of bonding and their impact on the bond electricity are scrutinized in this research. Polypropylene fibers Manufactured with special processing conditions and with exclusive cross-section, denier, and polymer soften-waft rate had been bonded with distinctive heat sealers. Bonding Studies have been also executed with several sheath-middle bi- thing fibers. Fiber bond strength outcomes were similar to effects determined in case of films with Respect to bonding temperatures studied. Carded webs had been prepared from polypropylene and other bi-component fibers. Impact of bonding temperature on belongings of Calendared web turned into determined the use of tensile, tear and stiffness trying out. Fiber web Mechanical houses multiplied with the calendaring temperature. At better calendaring Temperature energy improved together with the stiffness. After positive most useful Temperature, homes of the webs deteriorated.

Introduction

Nonwovens have emerged as component and parcel of human life. wide tiers of merchandise from nonwovens represent one of the most critical commodities of enterprise all through the world. Packages and demand are constantly growing and expected to grow in destiny. Thermal bonding constitutes one of the predominantly used manufacturing strategies and has big blessings. Exceptional of final products depends on deciding on right fabric and process variables. Fibers with lower orientation and lower crystallinity shape stronger thermal factor bonded nonwovens, possibly due to the fact the fibers can deform greater earlier than rupturing on the bond area, accordingly, sharing the weight higher. In order to apprehend thermal bonding, the consequences of the processing conditions and the molecular residences of the polymer should be understood. In particular, the molecular weight and molecular weight distribution may be exclusive on the surface than inside the bulk fiber. The crystallinity is almost sincerely specific in addition to the fee of melting and of crystallization on the surface. Likewise, the presence of finish and whether or not it's miles a plasticizing, nucleating or inert end will have an effect on melting and recrystallization as well as the inter diffusion price. The houses of soften spun IPP fibers had been notably studied [1]. The primary materials variables of iPP resins consist of the following: (a) molecular weight and molecular weight distribution, (b) stereo regularity (ataxic content and range, kind and distribution of defects), (c) presence, content material and distribution of co-monomer (e.g. ethylene), and (d) presence of nucleating agents inside the resin (deliberately brought or in any other case). These number one variables control other measurable functions of the resins which includes the soften go with the flow price (MFR), rheology, melting temperature and crystallization kinetics [2]. Research has also protected contrast of the morphology and houses of fibers and spun bond nonwovens constructed from Ziegler-Natta catalyzed resins to the ones of fibers made from metallocene-catalyzed resins with the same MFR [3]. Those outcomes in addition illustrate the results of most of the above-noted variables. As the opposite polymers are getting vital, it's miles essential to study and recognize the thermal bonding behavior of these new structures as nicely.

Despite the fact that many research was achieved to apprehend cloth and procedure variables affecting thermal bonding, have an effect on of fabric variables; polymer grade, fiber houses, procedure records of uncooked material on the properties of stop products isn't always clear. Not one of the previous experimental installations becomes proper representation of business procedure. On this research, an enterprise has been finished to recognize and decide the possibility of predicting the bonding behavior in material level via the fiber bonding research using specific form of heat sealers. Crucial process variables; time, temperature and strain had been intently decided on to match the commercial installation. Bonding temperature become essential manner variable on this investigation despite the fact that different parameters were studies to a restricted quantity. The surface traits are notably altered by way of the spin end that is used to decorate the process capacity by means of tackling the static and friction related troubles. It is recognized that the impact of finishes on thermal bonding efficiency is different based at the composition. These differences, in effects, can cause vast loss in energy of the nonwoven fabrics produced. The contemporary studies changed into to examine the effect of a number of the finishes on thermal bonded (PP) nonwovens and to apprehend the rea- sons, and mechanisms that is probably worried for those determined differences.

Materials and Method

Materials

Polypropylene fibers with different processing conditions, polymer houses, move- segment, soften waft price and denier, had been acquired from Sunoco chemical substances. Properties of these fibers are shown in Table 1. In addition, polypropylene fibers created from exceptional polymer composition and grades, under different conditions were also acquired from Sunoco (Table 1). Also, PP fibers with specific form of spin finish had been furnished by using Fiber visions. For spin end studies, finishes, one hydrophobic and some other hydrophilic were acquired from Goulston Tech.

Table 1:

Methods

Testing of the materials: Control fibers, fabrics, thermally bonded movies, fiber bundles and nonwoven webs were characterized through exceptional assessments. Nearly all the textile testing changed into carried out at popular atmosphere for fabric testing, with room temperature of 21±1˚C and relative humidity of 65±2%.

Weight test: Foundation weight of nonwoven webs became measured the usage of the ASTM D-3776-96 standard test approach. average weight in grams in keeping with rectangular meter of the internet is calculated [4].

Tensile test: Tensile strength of the fiber package, bonded fiber package deal, bonded films and material webs have been examined using the united tensile tester. Common power of five samples of 12 cm duration and a couple of fifty-four cm width had been used [5]. Fabric webs are examined according to ASTM D 3822-ninety-one (standard trying out techniques for Tensile trying out of Fiber/Filament) and D1117-eighty (well-known checking out strategies for Tensile testing of Nonwoven fabric) for nonwoven fabric. For fiber energy measurements, gauge lengths of one inch and move head velocity of 12meters per min have been used. Average of five readings is mentioned for every statistics factor. Graphs had been plotted with mistakes bar with ±1SD.

Bending Length: Bending duration of the webs turned into measured the usage of the ASTM D 1388-64 well-known take a look at method for stiffness of cloth. In this method stiffness of the material changed into calculated by the usage of the F.R.L cantilever bending of fabric underneath its personal weight. Bending period is the length of material at which it bends under its personal weight to exact quantity. This period turned into taken as a way to examine stiffness and the draping satisfactory. In this technique, rectangular cloth strips of 6in×1in are chosen in every case. Sample is placed at the horizontal platform with the engraved scale and slid at consistent charge at the side of template. Duration is mentioned down while the pattern bends underneath its personal weight and makes a perspective of 41.5˚ with the horizontal platform. each sample is tested 4 times on each sides (top, bottom) and by turning (proper, left).

Result and Discussion

Tear strength

Elmendorf tear power tester becomes used to test the tear energy of the webs. Tear strength was examined consistent with ASTM D-5734. Common of five measurements is suggested in every case.

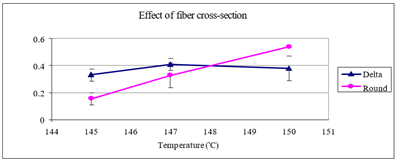

Fiber cross-section

Results for PP non-stop fiber filaments with exceptional cross-phase bonded at three different temperatures using consistent heat sealer are shown in Figure 1. Basic energy of the delta fiber was barely higher than that of the spherical fiber package. This will be due to expanded contact location. These outcomes are to be interpreted carefully due to the variations in the elongation of the 2 fibers. It has been proven in earlier research that fibers with higher breaking elongation, due to differences of their morphology are in all likelihood to show higher bonding with stepped forward bonded web structures [6]. Also, even small variations in denier are probably to con- tribute some of the variations seen in bond energy.

Figure 1:

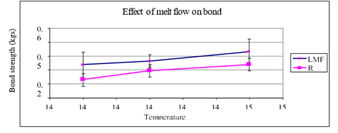

Impact of melt glide rate

Consequences for non-stop fiber filaments with different melt waft charge bonded at 3 extraordinary temperatures the use of consistent warmth sealer is proven in desk 10 and determine 36. There may be massive difference in version between elongation and bond strength. energy values are slightly better for fiber from low MFR. Excessive MFR fibers are weaker and bond energy from those fibers are lower in comparison to low MFR fibers. These can be just because of the molecular weight effect. One has to keep in mind that these temperature differences are small (Figure 2).

Figure 2:

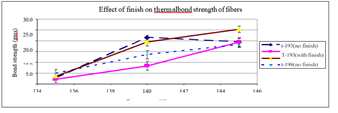

Effect of end on bond strength of fibers

Version of bond power of fibers at special temperatures is proven in Figure 3. Despite the fact that fiber mechanical properties are slightly affected by extraction, bond energy of end extracted fibers is better than that of fibers with end. At higher temperatures, bond electricity of fibers with end will increase and its miles equal to that of end extracted fibers. SEM image of fibers with end and end extracted are proven in parent sixty-six. It is evident that the fiber with the finish is smoother than the finish extracted fiber. those floor changes may additionally have a few roles in bond electricity changes as properly and the outcomes need to be interpreted carefully [7-10].

Figure 3:

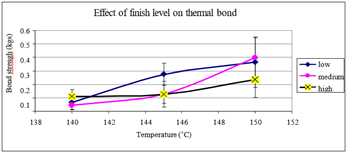

Thermal bonding of fibers with extraordinary levels of finish

Consequences for polypropylene fibers with three extraordinary degrees of finish are shown in determine sixty- seven. From the information it's miles clean that premiere bond temperature for fibers with high finish is slightly higher than fiber with less finish. Whilst the finish level is very excessive power values do no longer seem to attain that of fibers with lower or no end on them. These effects are constant with our in advance observations on film studies (Figure 4).

Figure 4:

Carding and calendaring of pp fibers with finish

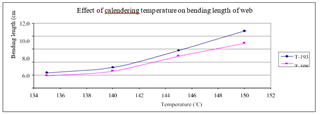

Fiber bond electricity results were taken as reference for selecting the calendaring temperature. Bond energy variant with temperatures is shown in discern 69 and bending duration at extraordinary temperatures is shown in determine 70. The best bond electricity observed turned into 145˚C, that is comparable to the fiber bonding studies. that is a demonstration that fiber bonding research can be used to are expecting the bonding of fiber web. Bending period values retain to increase indicating the trend of increasing stiffness with better bonding temperature (Figure 5).

Figure 5:

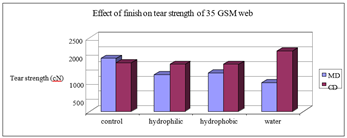

Impact of finish on bond strength on continuous PP WEBS

Material tensile power results are in comparison in Figure 6. Tensile strength barely decreases with both form of finish and water. Net tear energy in each machine and go course is shown in figure six. In this look at we did not examine any conspicuous tear strength trade in presence of finish or water. Electricity reduction is much like the consequences found in the course of film and fiber bonding research and might be because of reduction in powerful bonding temperature [11-13].

Figure 6:

Conclusion

Based at the thermal bonding studies finished on the staple fibers using warmth sealers it may be concluded that

1. Bond electricity will increase with the boom in bonding temperature and a peak strength is observed in positive range of temperatures in the place of melting factor of the polymer, and power drops with further boom in temperature.

2. Fiber pass-phase, crimp and denier have an impact on the thermal bonding performance.

3. As compared to round fiber, delta go-segment fiber plays better and may be bonded at decrease bonding temperatures.

4. Decrease denier, low melt waft price polymer fibers carry out higher in thermal bonding.

5. Natural fibers like cotton can be bonded with some guy-made fibers. Raw cotton indicates higher bond energy in comparison to that of bleached cotton with PLA and Eastar-PP. Primarily based on the consequences of non-stop filament bonding, it turned into found that.

6. Fibers with distinctive polymer kind, blends have distinct melting conduct and therefore their top-quality bond strengths for these fibers are specific.

7. Filament bonding behavior is much like movie and staple polymer bonding.

8. There is a positive most useful bonding temperature range for each filament.

Studies with spin finish showed that the bond electricity is lower with finish either hydrophobic or hydrophilic. The results confirmed for staple fibers, continuous filaments, and for webs of both staple and continuous fibers. Presence of end possibly influences warmness switch and diffusion of molecules on the interface, as a result lowering the bond electricity. The findings from this venture will assist in figuring out how the fabric and technique variables may be used to control the formation of efficient thermal bonded fabrics from polymers. It is miles obvious that depending on polymer shape and homes, the processing parameters ought to be adjusted to get the high-quality possible overall performance. The outcomes from this research ought to help the enterprise in deciding on the proper fabric and method combinations to produce nonwovens with favored residences. Although the focus is on thermal point bonding, this information will be applicable to other similar tactics together with spun bonding and via-air bonding. This look at affords new and fuller know-how of the have an impact on of fabric variables on thermal bonding, and on the homes of the bonded webs. The primary system of interest is thermal point bonding. The consequences may also be relevant to thru-air or ultrasonic, bonding techniques. The thermal bonded nonwovens continue to grow and growing a good understanding of the procedure will become more vital beneath this condition [14,15].

References

1. Fraser LL, Gillette SM (2019) Multi-layered flame retardant and chemical resistant composites and methods of making and using the same. USA Patent Application 16/082,549.

3. Kim C, Cho EG, Suh SC, Seo IY, Amo Lifescience Co Ltd (2019) Composite membrane for western blotting containing a pvdf nanofiber web and manufacturing method thereof. USA Patent Application 16/208,968.

4. Guo CY, Wang QW, Liu JG, Qi L, Huangfu MG, et al. (2019) Electrospun polyimide ultrafine non-woven fabrics with high whiteness and good thermal stability from organo-soluble semi-alicyclic polyimides: preparation and properties. Express Polymer Letters 13(8).

5. Chou WT, Lai MY, Huang KS, Shao Hua CU, Hsu CY (2019) Method of preparing of natural graphene cellulose blended spunbond nonwoven fabric. USA Patent Application 10/190,242.

11. Kubley A, Chauhan D, Kanakaraj SN, Shanov V, Xu C, et al. (2019) Smart textiles and wearable technology innovation with carbon nanotube technology. In Nanotube Super Fiber Materials pp. 263-311.

13.

14. Ahmad Rasyid MF, Salim MS, Akil HM, Karger KJ (2019) Non-woven flax fibre reinforced acrylic based polyester composites: the effect of sodium silicate on mechanical, flammability and acoustic properties. Express Polymer Letters 13(6).

15. Nie S, Jin D, Yang JN, Dai G, Luo Y (2019) Fabrication of environmentally benign flame retardant cotton fabrics with hydrophobicity by a facile chemical modification. Cellulose 26(8): 5147-5158.

© 2019 Shariful Islam. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)