- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Textile Analysis and Interpretation for Decision Making

Usha Chowdhary* and Stanley Mathews

*Corresponding author: Usha Chowdhary, Professor, Human Environmental Studies, Central Michigan University, Mount Pleasant, MI 48859, USA

Submission: October 11, 2018;Published: October 26, 2018

ISSN 2578-0271 Volume4 Issue4

Mini Review

Textile industry is actively involved in promoting quality products for textile and apparel. Despite society’s move to the casual lifestyle, need for lined garments has not disappeared. When selecting lined garments, it is of critical importance that apparel manufacturers test the appropriateness of each layer for the intended end-use and compatibility of all layers together. It is important to consider both structural and performance attributes while making such decisions from the available choices. Chowdhary [1] reported that crimp in yarn makes the synthetic filaments more resilient than the uncrimped yarns. Likewise, twist adds strength for the staple fibers when twisted to make yarns. Higher fabric count is associated with better quality that the lower count. Quality fabrics also intend to use defect free textiles. Breaking strength was higher for twill weave as opposed to plain and sateen weave [2]. Uttam [3] found that cotton became heavier and thicker with increased cover factor after repeated washing.

Chowdhary [4] asserted that dimensional stability can be used to determine fabric shrinkage and /or growth after care. This statement has merit because using two different fiber contents (cotton and lining) for a lined garment may change differentially and allow decision-makers either to change the care procedure or choose different fabric. Horizontal wicking is also an important performance attribute because it helps with moisture management for the wearer. In any garment appearance, comfort, ease of care and durability are important considerations. Compatibility should also be considered for lined garments [1].

For the reported study, five structural and five performance attributes were chosen to make decision for a lined dress. Structural textile attributes included fiber content (AATCC 20, 2013), yarn type, fabric construction (ASTM D579-01), fabric count (ASTM D3775-12), and fabric weight (ASTM D3776-2013) were selected as structural attributes. Performance attributes represented appearance retention (AATCC 124-2001), dimensional stability (AATCC 96, 2001), horizontal wicking (AATCC 198 2013), pilling resistance (ASTM D 3512-02), and tearing strength ASTM D 2261-96). All tests were performed following instructions from Wroblewski SM [5]. It is important to mention that lining should be slippery to allow easy donning and doffing of the garment. Acetate has been used extensively for lining in the industry. Therefore, acetate was chosen [6].

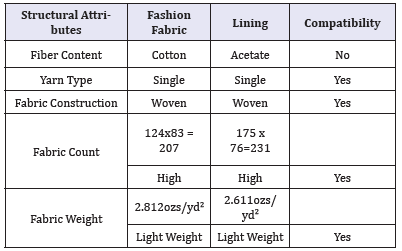

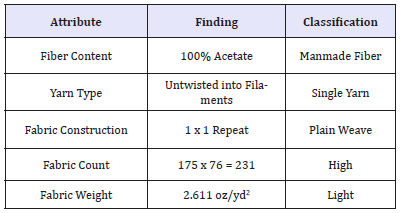

Findings revealed that fashion fabric was made from 100% cotton, single yarns, light weight, high count, and plain weave. Lining was made from 100% acetate, single yarns, light weight, high count, and plain weave. Except for fiber content, two fabrics were similar for structural attributes Table 1. Results from five structural attributes are provided in Table1. Based on structural attributes and role of lining two fabrics were found to be appropriate and compatible with each other.

Table 1:Structural textile attributes for cotton fashion fabric and acetate lining.

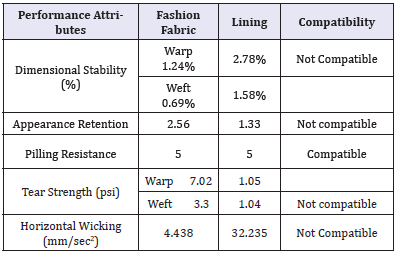

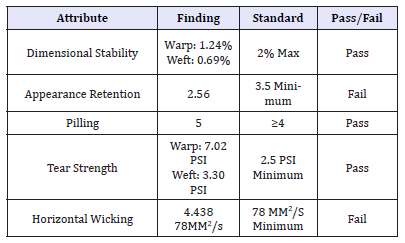

Table 2:Performance textile attributes for cotton fashion fabric and acetate lining.

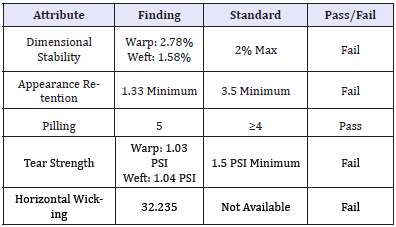

Table 2 displays results for performance attributes. Results revealed that fabrics were not found to be compatible for performance attributes. Fashion fabric passed for dimensional stability but lining failed (Table 2). Therefore, two could not be used together for a lined garment unless dry cleaned. Both failed appearance retention test. However, ironing could be recommended to overcome this difference. A special care is required because two fabrics do not withstand same temperature level. Acetate could melt at the temperature that cotton yields the best results. Both passes pilling test. Horizontal wicking was much higher for acetate than cotton. Acetate will be next to skin as lining and it is good to have higher wicking for effective moisture management than the fashion fabric. Finally, lining failed the tear strength test, but cotton passed it. Two fabrics may be appropriate choices but results show that lining is weaker than the fashion fabric and will result in compromised durability.

Preceding information reveals that even though two fabrics are structurally compatible, they did not perform well together based on various performance attribute. Another way to determine appropriateness and compatibility to compare findings against industry standards to assess if fabrics meet or exceed the standards. Therefore, technical data sheets were developed for both fashion fabric and lining fabrics. Comparison against the standards reveals that fashion fabric passed three out of five tests and lining passed only one out of five tests. Therefore, these two fabrics were not compatible based on both type of testing.

UCSM designs

Figure 1:100% cotton fabric, Price: $5.99/yd.

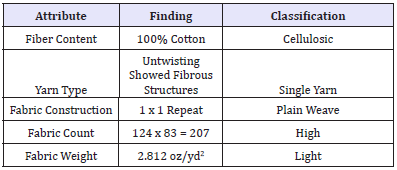

Table 3:Structural attributes.

Table 4:Performance attributes.

Figure 2:100% acetate lining, Price: $3.99/yd.

Table 5:Structural attributes.

Table 6:Performance attributes.

The research study can be duplicated in academic as well as industry settings. This methodology can be used for apparel product development process when making decisions to make final selection for a variety of fabrics and end uses. Using technical data sheets and same tests for all fabrics under consideration can enhance the efficiency of decision-making process. Communication between technical and executive team can be enhanced by using numbers simplistically and effectively [7]. The process can be further enhanced by using statistical testing to add objectivity in the selection process. For the reported study, t-values were computed to compare fashion fabric and lining for appearance retention and horizontal wicking. Results revealed that two fabrics differed significantly for these performance attributes and reinforced their non-compatibility. For the reported study, classification for fiber content was labeled as not applicable. If necessary, they could be labeled as cellulosic for the fashion fabric and regenerated for acetate. Depending on the end-uses, other structural and performance attributes could be chosen.

References

- Chowdhary U (2009) Textile analysis, quality control and innovative uses. Deer Park, Linus, New York, USA

- Elasher E, Dubrovski P (2008) The influence of the weave and the method of stitching on selected mechanical properties of woven double fabrics. AUTEX Research Journal 8(2): 41-43.

- Uttam D, Sethi R (2016) Impact of repeated washings on dimensional stability and fabric physical factors of woven cotton fabric. International Journal of Research in Engineering and Applied Sciences 6 (2): 126-135.

- Chowdhary U (2017) Comparing three brands of cotton t-shirts. AATCC Journal of Research 4(3): 22-33.

- Chwodhary U, Wroblewski SM (2016) Textile analysis: Laboratory manual. Ronkonkoma, Linus, New York, USA.

- Annual Book of ASTM Standards (2015) Conshohocken, ASTM, Pennsylvania, United States. Vol 1-2.

- Technical manual of the American Association of Textile Chemists and Colorists (2016) Research Triangle Park, American Association of Textile Chemists and Colorists, North Carolina, USA, pp.67-77

© 2018 Usha Chowdhary. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)