- Submissions

Full Text

Techniques in Neurosurgery & Neurology

Physical Properties of Seven Different Brands of Standardized Endodontic Paper Cones

Jorge Paredes Vieyra1*, Francisco Javier Jiménez Enriquez2 and Fabian Ocampo Acosta3

1Universidad Autónoma de Baja California, México

2Oral Surgery, Universidad Autónoma de Baja California, México

3Histopathology Department, Universidad Autónoma de Baja California, México

*Corresponding author:Dr. Jorge Paredes Vieyra DDS, MSc, PhD, 710E San Ysidro Blvd. suite “A” #1513, San Ysidro California 92173, USA

Submission: August 05, 2019;Published: August 22, 2019

ISSN 2637-7748

Volume2 Issue3

Abstract

Aim: To evaluate the physical properties of 7 brands of standardized endodontic paper cones.

Methodology: Standardized endodontic absorbent paper points, size 30, from 7 different brands of 7 manufacturers were used for this study. Forty absorbent paper cones from each brand were selected at random from packages with assorted cones. A total of 280 cones were tested, all tests were conducted at a temperature of 23 °C.

Results: Three brands of standardized endodontic paper points (Diadent, Kerr, and Pearson) showed significantly higher absorbencies than the remaining 7 brands tasted (p<0.05).

Conclusión: Absorbent paper points, even inside packs sterilized by the manufacturer, may be contaminated. The most reliable method to maintain the aseptic chain during endodontic treatment is the sterilization of paper points before their use, regardless of the commercial type.

Keywords: Paper cones; Paper points; Pain; Apical healing

Introduction

Endodontic treatment attempts to remove bacteria from the root canal system to stimulate periapical healing. For that purpose, clinicians must consider elements as preoperative diagnosis, the ability to obtain infection control, root canal anatomy, procedural complications, and factors like patients’ signs and symptoms [1]. All the involved processes are aimed at creating and maintaining aseptic conditions and then obturation of the clean root canal system [2]. The presence of bacteria is totally linked to situations of failure in endodontic treatment, and many times this is due to failure in manage of root canals, as well as microbial permeation through saliva or the use of contaminated instruments and/or materials [3]. Infection persisting in the root canal and/or peri-apex is considered to be the most significant factor that affects the outcome of endodontic treatment.

Absorbent paper cones are used extensively in endodontics for several purposes, in endodontic treatment, the absorbent property, tapered and standardized size have been developed to aid in the cleansing and drying of the canal and to carry antiseptic or disinfecting coverings [4]. Paper points or paper cones were introduced for canal drying and applying intracanal medicaments [5]. Initially manufactured from bibulous paper, they exhibited low tensile strength and tended to disintegrate within the canal. They are now manufactured from long-fibre papers such as cotton, mitsumata or silk by rolling a triangular blank with longitudinally orien- tated fibres thus optimizing tensile strength and wicking properties [6]. Paper points consist of plant cellulose, an unbranched polymer of b-D-glucose. Darvell pointed that he abundant hydroxyl groups of cellulose form hydrogen bonds between polymer chains and render the polymer hydrophilic, allowing significant absorption of water within its structure and adsorption onto its surface [7]. The addition of organic resin binders improves the point’s integrity and stiff- ness, albeit at the expense of absorbency [7]. As manufacturers use different papers and bin- ders, absorbency and integrity vary significantly between brands of paper point [8].

There is a risk of cellulose fibres being deposited periapically when inserting a point beyond the apical foramen (direct shedding) [9]. Paper points may also shed fibres within the canal that may subse- quently be pushed through the apical foramen by another paper point, gutta-percha point or endodontic instrument (indirect shedding) [10,11].

As the paper cones are the last material inserted into the prepared canal before root filling, they play an important role and must be considered important to the outcome therapy. Desirable properties and characteristics of the absorbent paper cones:

A. Paper cones should have the property to absorb water, blood, and some other fluid like serous fluid,

B. Paper cones should have sufficient wet strength when it has been saturated with fluids and rigidity to be inserted and withdrawn from a root canal without collapsing under their own weight,

C. When dry, absorbent paper cones should be straight and have a uniform length, taper and size,

D. According with ISO draft specifications paper cones should have sufficient integrity [12] and

E. Absorbent paper cones should be clean and capable to be disinfected.

The aim of this study was to evaluate physical properties of 7 brands of standardized endodontic paper cones.

Materials and Methods

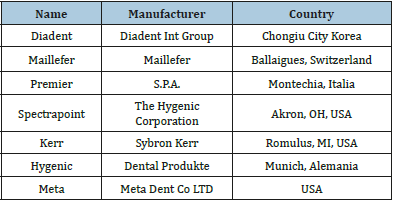

Standardized endodontic absorbent paper points, size 30, from 7 different brands of 7 manufacturers were used for this study (Table 1). Forty absorbent paper cones from each brand were selected at random from packages with assorted cones. A total of 280 cones were tested, all tests were conducted at a temperature of 23 °C.

Table 1:Brands and manufacturers of standardized absorbent paper points used in the study.

Each dry absorbent paper cone was weighted using an electronic laboratory balance (Sartorius, model 1712 MP8: Göttingen, Germany). Physical properties of paper cones include: dimension, length, taper, absorbency, fiber shedding and stiffness. The dimensions of each paper cone were measured by using a Mitutoyo Projection microscope at 20X magnification. The length was measured as the distance between the two ends of the paper cone (head and point).

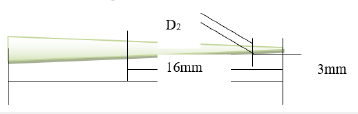

Taper were measured at distances of 3mm and 16mm from the tip or narrow end using a digital caliper (Figure 1). The difference of these two diameters divided by 13mm gave the value of taper of each paper cone. Taper = D1-D2/13, where D1 is the diameter at the 16mm from tip, and D2 is the diameter at 3mm from the tip.

figure 1:Determination of Taper.

For absorbency test, every paper cone was gripped in a pin vise, which was suspended vertically from a hanger with the tip pointing downwards. A length of 5mm from the tip was lowered into a 2% aqueous solution of mercurochrome. The rise in height of solution, by capillary action in 60 seconds were recorded.

For the fiber shedding test, 7 cones were placed in a particle free sterile test crystal cylinder containing 10ml of distilled water. The crystal cylinder and its content were gently agitated for 60 seconds, and then filtered through a 1μm gridded particle monitor filter paper (Millipore AABG 047). The filter paper allowed to dry and was then examined under 50X magnification for the number of fibers or particles having a dimension exceeding 200 -250μm.

All procedures were carried out in a similar condition of laminar flow cabinet conforming to AS 1386-1976 [15] as a controlled environment to prevent airborne particulate contamination of the particle monitor and the paper cones under examination. A length of 16mm from the tip was then lowered in distilled water for 5 seconds, paper cone was weighted again, and the difference between both measurements was taken as the value of the fluid absorbed (Figure 1).

For the Stiffness test, the paper cones were immersed in water at 40 °C for 20 minutes, the lifted out horizontally by their ends. All paper cones were inspected visually without magnification to note any indication of unrolling, disintegration or sagging after 30 seconds. To determine which brand presented the highest absorbency, a statistical analysis of the results obtained was conducted using the Kruskal-Wallis test and the Mann-Whitney U test. Dissimilarities in relation to the standard deviation were assessed by means of the F test (Fisher-Snedecor). The relationship between the variables dry weight and fluid absorbed was analyzed with the Pearson’s product-moment correlation coefficient (r).

Results

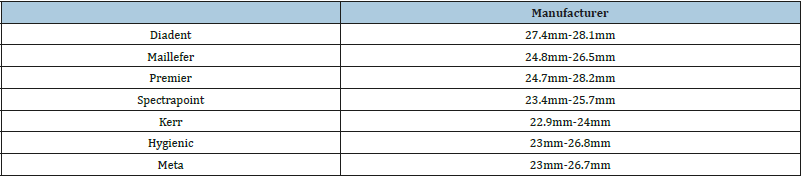

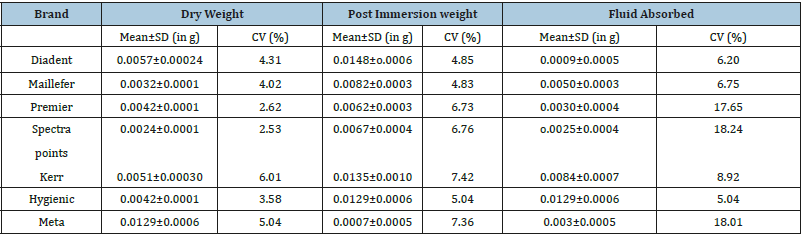

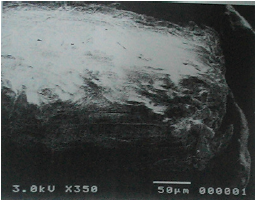

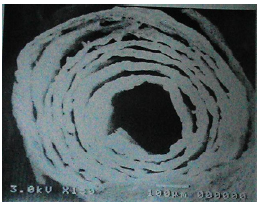

Three brands of standardized endodontic paper points (Diadent, Kerr, and Pearson) showed significantly higher absorbencies than the remaining 7 brands tasted (p<0.05) (Table 2 & 3). Figures 2 and 3 show some irregularities under SEM in cross section and longitudinal view.

Table 2:Range of length of paper points.

Table 3:Mean value, standard deviation (SD), and coefficient of variation (CV) of dry and post immersion standardized endodontic paper points and for fluid absorbed

figure 2:Irregularities of a paper cone, longitudinal view (SEM 350X).

figure 3:SEM view of cross section of a Size 30 paper cone.

Discussion

Discussion In each of the properties measured, the study demonstrated wide variations. Tip diameters of products marked with standardized size designation did not correspond to the tip size defined by ISO size designation [13-15]. No correlation was observed between size and absorbency in any product range. The results suggest that better quality control is needed during the manufacture of this product [16]. A better paper cone will have adequate and closely controlled dimensions, good absorbency, no one brand can fulfill all these requirements completely. Paper cones with the highest absorbing capacity (Diadent, Kerr, and Hygienic) showed high SD values.

Conclusion

Absorbent paper points, even inside packs sterilized by the manufacturer, may be contaminated. All brands of endodontic have a variation in the number of fibers and it can be shed directly when inserted through the apical foramen. The most reliable method to maintain the aseptic chain during endodontic treatment is the sterilization of paper points before their use, regardless of the commercial type.

References

- Paredes-Vieyra J, Jiménez EFJ (2012) Success rate of single- versus two-visit root canal treatment of teeth with apical periodontitis: a randomized controlled trial. J Endod 38(9): 1164-1169.

- Rodriguez PE, Keiti NC, Machado LME (2011) Analysis of contamination of endodontic absorbent paper points. Rev Odonto Cienc 26(1): 56-60.

- Siqueira JF, Roças IN, Favieri A, Machado AG, Gahyva SM, et al. (2002) Incidence of postoperative pain after intracanal procedures based on an antimicrobial strategy. J Endod 28(6): 457-460.

- Möller B, Hensten-Pettersen (1985) A Biological evaluation of absorbent paper points Int Endod J 18(3): 183-186.

- Edwards RO, Bandyopahyay S (1981) Physical and mechanical properties of endodontic absorbent paper points. J Endod 7(3): 123-127.

- Morse DR (1970) Endodontic microbiology in the 1970s. International Endodontic Journal 14: 69-79.

- Darvell BW (2009) Materials Science for Dentistry. Cambridge, Woodhead Publishing, UK, pp. 604-605.

- Gloub LM, Kleinberg I (1976) Gingival crevicular fluid: a new diagnostic aid in managing the periodontal patient. Oral Sci Rev (8): 49-61.

- Edwards RO, Bandyopadhyay S (1981) Physical and mechanical properties of endodontic absorbent paper points. J Endod 7(3): 123-127.

- Koppang HS, Koppang R, Solheim T, Aarnes H, Stølen SO (1989) Cellulose fibers from endodontic paper points as an etiological factor in postendodontic periapical granulomas and cysts. J Endodo 15(8): 368-372

- Paredes Vieyra J, Acosta Guardado J, Gradilla I (1996) Comparación In Vitro de cinco materiales lubricantes en la fase de impresión de un poste. Práctica Odontológica 8: 4-7.

- Holland R, Bernabé P, Gonçalves JC, Gonçalves AP, Oda, LS (1991) Resposta do coto pulpar e tecidos periapicais de dentes de cães a cones de papel esterilizados em estufa ou vapores de formaldeído. Revista Brasileħa O. XVLVIII, No.5 Set/out, pp. 2-8

- R Core Team R: A language and environment for statistical computing [Computer Software] (2014) Vienna, Austria: R Foundation For Statistical Computing.

- Simon S, Machtou P, Adams N, Tomson P, Lumley P (2009) Apical limit and working length in endodontics. Dent Update 36(3): 146-150.

- Stock CJ, Gulabivala K, Walker RT (2004) Endodontics, 3rd edn, Maryland Heights, MO: Elsevier/Mosby, USA.

- ANSI/ADA Standard No. 73-Dental Absorbent Points (2008) American Dental Association, Chicago, IL, USA.

© 2018 Jorge Paredes Vieyra. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)