- Submissions

Full Text

Strategies in Accounting and Management

Sustainable Manufacturing: Building the Framework for the Lombardy Region’s Manufacturers

Maria Garbelli

University of Milano Bicocca, Italy

*Corresponding author: Maria Garbelli, University of Milano Bicocca, Piazza Ateneo Nuovo 1, 20126 Milano, Ital

Submission:August 25, 2022Published: September 09, 2022

ISSN:2770-6648Volume3 Issue4

Abstract

Sustainable Manufacturing entails a transition from traditional processes - namely production, delivery and marketing, to new business models based on a commitment toward a reduction on the social and environmental business impact, while engaged in rising competitiveness and eco-nomic value for the company. A global, rising, commitment comes from governments and individuals, while Industry 4.0 technologies seem to support best this transition. In Italy, during the first half of the 2020, the perspective on the future suddenly changed forcing individuals, busi-nesses and governments to rethink their lives on a completely different schema due to the emergency of the Pandemic. Since the second semester, the global economy started to recover from the huge fall during the rough days of the Covid-19 and businesses ran to fill the gap of the first se-mester, facing unexpected rise in raw materials €™ prices and new pressures to curb global warm-ing, stressing the more and more individuals, businesses and global economies to adopt a re-sponsible attitude. This work offers an overview of the state-of-the-art on a huge business area, the Lombardy region –one of the leading in the European Union and proactively devoted to Sus-tainable manufacturing transition.

Introduction

During the first half of the 2020 the emergency of the global Pandemic forced the perspective on the future change for individuals, businesses and governments-pushed to rethink their lives on a completely different schema. Since the second semester of the same year, the global economy started to recover from the huge fall during the rough days of the Covid-19, and businesses ran to fill the gap of the first semester, while raw materials’ prices rose and new pressures emerged in order to curb global warming-and to force both individuals and global economies to adopt a responsible attitude. Along with urgent production priorities, a sustainable development of the company seems the more and more essential, boosting the most relevant Authorities of the world to attend meeting on topic and show their progress, national Governments are requested to be active, effective and fast stimulating the conversion process toward a sustainable development. Individuals plays a fundamentals role and seems to be the more and more conscious and responsible, while businesses are recognized with a pivotal role. Particularly due to its environmental impact, manufacturing urgently calls for adopting solutions to ensure environment preservation and social responsibility more than economic growth [1]: for this reason, in March 2020 the European Commission (EC) released the “Green Deal”, a 1,000-billion-euro green investment plan for the next ten years, underlining the circular economy opportunities for activities and jobs. Along with the Green Deal, EC also launched “A new Circular Economy Action Plan for a cleaner and more competitive Europe”: the communication recognizes the need to accelerate the process toward climate neutrality and a regenerative growth through the model of circular economy, defined as an essential part of a wider transformation of industry also comprising long-term competitiveness along value chains and production processes. Boosting the transition, to cope with the goals defined by the 2030 Agenda, matches with the urgency to face the economic crisis generated by the Covid-19. With this aim, the European Union (EU) has recently published the Next Generation EU program (NG-EU), a huge measure to stimulate the EU recovery. Its main tool, the Recovery and Resilience Facility, free 672,5 billion for the European Union nations till 2026. Founds are given upon provision of a national Recovery and Resilience Plan detailing the actions to take in place to face the socio-economic and environmental crisis and to promote ecological and digital transition, along with social and environmental sustainability. In this work we consider the situation of the Lombardy region which is the most industrialized area of Italy, and one of the richest of the whole European Union (EU): although severely touched by the economic crisis, as the whole country did, its 2020’ GDP per capita still remained above the national and EU average, and among the highest (Eurostat, 2020). The region’s production system is one of the most developed in EU (one of the highest rates of entrepreneurship in Europe, with about 815,956 registered enterprises, grouped in networks and industrial districts. The productive sector is dominated by micro and small enterprises. On the other hand, such an impressive economic development cope with several health and environmental issues. The Lombardy region ranks among the most air polluted areas of Europe due to the high industrialization rate that copes with the geographical features of the area (closed between mountain, the region has quite a lack of wind so air pollution remains) a severe problem in Lombardy and northern Italy. The latest report of the Lancet (available online at www.thelancet.com) released on January 2021 shows that region suffers the most serious impact at European level due to poor air quality, generating several health issues and a negative impact on life expectations. To face this huge situation, the regional Government actively participates to national level negotiations, and follows the path of sustainable renovation through a regionallevel legislative framework, underlining Smart specialization and Circular Economy strategy among the main drivers to foster the industrial development of the Region.

Literature Review

Sustainable manufacturing

Since its first official appearance in a document [2], the sustainability concept has deeply developed over the years, and tailored for different industries and situation. The sustainability concept emphasizes businesses’ social and environmental contributions to society [3] while maintaining financial profitability as well [4]. In manufacturing, more than one definition exists of the concept, basically entailing the integration of the best manufacturing practices with the principles of sustainability. A quite accurate definition of sustainable manufacturing is stated by the major economies: the US department of commerce refers to ‘the creation of products through the processes that minimize both negative environmental impacts and consumption of energy and natural resources, being also safe for employees, communities, consumers and economically viable [5] the European Union recognizes the need for economic growth to be searched while preserving environmental social issues, and devotes the Sustainable Development Strategy at this aim (www.ec.europa.eu): A huge boost to the European value chains competitiveness and development, through the promotion of cooperation among different regional specialization, ‘overcoming the barriers limiting innovation and transfer of research results to the European industry through the development of an European synergic network of pilot plants accessible to companies in a logic of Smart Specialization’.

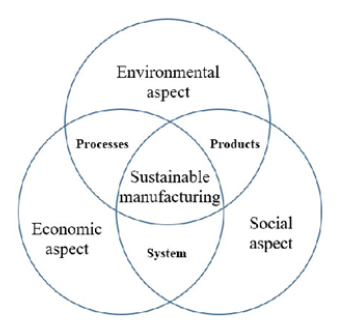

Due to several pressures, and driving the industrial modernization, sustainability in manufacturing has gained wide recognition in recent years with more calls for manufacturers to ensure preserving the environment and social alleviation besides economic growth [1] while creating manufactured products. Although the social responsibilities for a business are considered as a more challenging task to identify and measure [6], it is clearly considered a relevant dimension of SM: Zhang [7] define SM as the production of products in a way that minimizes environmental impacts and assumes the social responsibility of employees, the community and consumers throughout the life cycle of a product, while at the same time they achieve economic benefits. In 2017 Bonvoisin considers SM leading to create discrete manufactured products generating a manageable amount of impacts on the environment (nature and society) while offering economic and social value through their lifecycle. More recently, Garetti and Taisch’s definition of SM as the firm’s ability to maintain the intelligent use of natural resources to fulfill economic, social, and environmental aspects, which eventually leads to improving quality of life and preserving the environment. Hereafter, since the Jawahir et al. [8] work considering a three levels analysis in SM (“Sustainable manufacturing at product, process and system levels must: demonstrate reduced negative environmental impacts, offer improved energy and resource efficiency, generate minimum quantity of waste, provide operational personnel health while maintaining and/or improving the product and process quality with the overall life-cycle cost benefits), we borrow the Ojstersek et al. [4] representation of SM also comprising the three dimensions for sustainability (Figure 1).

Figure 1: Ojstersek R et al. [3].

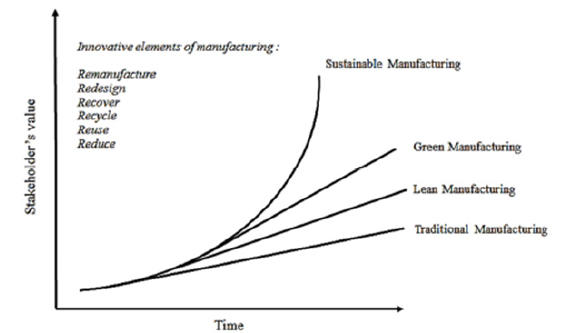

SM is considered a new economic model of production and consumption, for transforming resources into economically valuable goods by taking into account the environmental and social impact of that process -Sartal et al. [6]; its main goal is to create sustainable development through entrepreneurial corporate activities [9]. A very interesting perspective considers SM as the last, dynamic step of a process entailing 5 stages: developing work practice and maintenance; process optimization, raw materials substitution; new technologies; new product design [10]; this process enables SM evolutions, from the traditional manufacturing to the lean’, the green’ and the last stage, the SM (Figure 2). Also, SM concept refers both to large businesses and SME [1,6]. Dedicating attention to process, Haapala et al. [11] considers Jawahir SM six major elements, distinguishing the deterministic ones-particularly fitting manufacturing (manufacturing cost, energy consumption, and waste management) versus the generics, that can be pursued by non-manufacturing systems too [11]. Going in dept, SM should not be confined to some or particular activities but enter in a different manner all the business’ areas-integrating sustainability principles at all levels of manufacturing-product, process and system, through pursuing the six ‘r’ [10], adding three dedicated ‘r’ (recover, redesign, remanufacturing) to the three traditional ones (reduce, reuse, recycle) (Figure 3).

Figure 2:sustainable management evolution, Krajnik et al. [28] adapted from Kishawy et al. [9].

Figure 3:Six elements of sustainable manufacturing processes, in Haapala et al. [10].

Although the concept of sustainable manufacturing should not be confined into the field of technological improvement, a few but rising part of literature recognizes several benefits through the technological innovation and renovation connected to the Industry 4.0-hereafter, I4.0 [6,12,13], easily relating to the impact on the social [14,15] and environmental dimension of sustainability entailing the long term, [9] but also impacting on the economic viability of the firm [6,16]. Four areas for economic sustainability of I4.0 are identified (sustainable value creation; reduction in operational costs; impact on market share, supply chain and security; new business model opportunities, turnover) [16]. If several definitions can be founded for SM, it still seems not easy to recognize the advantages a business can pursuit while transforming in a sustainable manufacturer, although some generics are quit commonly recognized and even formalized by the same US environmental protection agency (Lower Resource and Production Costs, Lower Regulatory Compliance Costs, Improved Sales and Brand Recognition, Greater Access to Financing and Capital, Easier Employee Hiring and Retention, www.epa.gov). According to Kishawy et al. [10], the expectations of SM can be listed as follows: energy consumption reduction; waste elimination/reduction; product durability improvement; health hazards and toxic dispersion elimination, higher quality of manufacturing; recycling, reuse, and remanufacturing enhancement.

Monitoring the path toward SM implies the need for a business of a system of metrics that can evaluate the SM performance, through the elements of a SM (process, product, system). Some literature suggests a system of performance indicators that borrows the Key performance indicators’ features [17-19] although some studies focus on specific aspects (it’s the case of Rusinko, reviewing environmentally sustainable manufacturing practices) [20], a more comprehensive framework should at least identify the features of the metrics to use: Haapala et al [11] suggests the set of metrics for manufacturing processes proposed by Fiksel et al. [21] (comprehensiveness, controllability, cost-effectiveness, manageability, meaningfulness, robustness, and timeliness) and by Feng et al. [17] (measurable, relevant and comprehensive, understandable and meaningful, manageable, reliable, costeffective in data access and timely in manner). The house model of Huang offers the more exhaustive consideration of the SM levels takes on simultaneous account the Jawahir’ three along with the 6r and the TBL, to build the SM philosophy, and generating a complex performance measurement framework for SM at different levels (line, plant, enterprise, supply chain) [22].

The legislative framework for sustainable manufacturing in Lombardy region

At national level, Italy dealt with a new industrial policy for rising awareness about doing business in a more sustainable and innovative way, and for sustaining competitiveness of “Made in Italy”. The national Government established a support system for innovative projects and investment through introducing some first measures for the “Green Deal”, and a huge fund (€ 4.24 billion for the period 2020-2023) devoted to support businesses and organizations in their sustainable transition. A National Technology Clusters was in charge of generating this impressive measure, in close cooperation with the Regional Technology Clusters [23-31].

Coping with the European guidelines, the Italian Recovery and

Resilience Plan (Piano Nazionale di Reprise Resilienza, PNRR),

considers three main areas of intervention to be supported by the

European founds:

a) digital transition and innovation

b) ecological transition

c) social inclusion.

40% of the total amount of resources displayed will be devoted

to the ecological transition, boosting the Country toward more

sustainable equilibrium: according to the latest Symbol report

(www.symbola.net), right now, Italy is heading the ranking list for

the waste management, achieving the best reduction in Europe:

79% of the total waste is recycled-compared to the second rank

France (56%) and Germany (43%). Much can be done, especially

in manufacturing. The national framework for driving the Country

to more competitive and sustainable business models, involves

the National and Regional Technology Clusters. The Lombardy

Technology Clusters is among the prominent ones offers support

to the regional governance, and it ‘is supposed to significantly

influence national policies, being Lombardy the first Region in terms

of contribution to Italian Manufacturing volume and performance’

(www.openinnovation.regione.lombardia.it): for its nature, the

platform calls for co-generation of new ideas through communities.

Collaboration, innovation, sharing and networking emerges from

dedicated work groups while the topics are several-innovative

solutions, blockchain tests, interregional Alp space cluster,

internationalization, cyber security and so on. For its relevance, the

European Sustainable Manufacturing- A plan aiming at promoting

cooperation and development among European regional

specialization, considers Lombardy region one of the three leading

the project and heading the following thematic areas:

a) De-and remanufacturing

b) Smart and adaptive manufacturing

c) Digital and virtual factory

As well recognized by the European Union, the path toward a circular economy will however require long-term involvement at all levels. To measure the state of the art in the industrial system of the region, next section details the Lombardy Roadmap for Research and Innovation on Circular Economy, with a focus on manufacturing. The action plan focusses on action at EU level with high added value. Making the circular economy a reality will however require long-term involvement at all levels, from Member States, regions and cities to businesses and citizens. With this statement, Member States are invited to play their full part in EU action, integrating and complementing it with national action. Lombardy is proactively moving toward an industrial modernization, aiming at transforming in a more sustainable direction its territory through a system of initiatives-in-between the European Union, but nationally and locally at the same time, with a strong focus on shared and coordinated effort. As a result of such a commitment over the combination of a shared efford toward innovation throguh different players and stakeholders, but following the priority areas identified by the regional Smart Specialization Strategy (S3), a Lombardy technology cluster is generated: AFIL, Associazione Fabbrica Intelligente Lombardia, aiming at driving and supporting the business transition toward innovation in manufacturing. It brings together both companies of any size and age, industrial association as Confindustria and public research centers-as local Universities. On a broader scale, in light of the Green Deal commitment of the Union, several initiatives emerge involving the Region: the Vanguard Initiative-the alliance 39 of the most advanced industrial regions in Europe, for encouraging innovation and the construction of a value-chain European system of complementary (www.s3vanguardinitiative.eu)-stimulated Lombardy to lead along with the French Auvergne Rhone-Alpes, and the Spanish Catalonia, the European Sustainable Manufacturing ESM- a plan aiming at promoting cooperation and development among European regional specialization,. The aim of the partnership, as well stated by the Eu, is ‘to create an integrated network of European demo-sites and pilot plants supporting the uptake of advanced technologies boosting manufacturing efficiency and sustainability’ (s3platform. jrc.ec.europa.eu), in order to support, help and improve European companies’ global competitiveness. Lombardy heads the following thematic areas within the ESM: de- and remanufacturing; smart and adaptive manufacturing; digital and virtual factory. As Circular Economy has been introduced as one of the main drivers to foster the industrial development of the Region - and relevant part of the Smart Specialization Strategy of the Lombardy Region 2021- 2027, we also introduce the Lombardy Roadmap for Research and Innovation on Circular Economy, a public and private framework for the development of a ‘sustainable, low carbon, resource efficient and competitive strategy for the transition to a more circular economy in the Lombardy Region, under a smart specialization perspective.(…) The elaboration of this roadmap started in 2019, seeking the challenge of the Lombardy’s Smart Specialization Strategy (in brief S3) to give answers and, where possible, anticipate market changes, to address new social and cultural needs’ (…) The Roadmapping Group was led and coordinated by DG Research, AFIL-Lombardy Intelligent Factory Association (the regional technology Cluster represented regional Advanced Manufacturing) and Finlombarda, the regional finance in-house company. Representatives of the 9 Lombardy Technological Cluster participated to the roadmapping process have represented the priorities of their specialization areas and invited also their key stakeholders (companies, universities and research bodies) to suggest new or confirm the identified priorities. Thus, the definition of the Regional Circular Economy Roadmap is based on relevant intercluster cooperation process.’ (www.clustercollaboration.eu). The implementation of cross-sectoral actions, in close cooperation with the Lombardy Technology Clusters, aims at reinforcing the European value chains’ inter-regional cooperation.

Conclusion

As far as the theory on sustainable manufacturing develops, global markets-and society too-calls for a coordinated system of measures supporting the transition of the industrial system to more sustainable solutions. Even if the Covid-19 has viciously interrupted this transformation during the beginning of 2020, the need to push toward a more sustainable world seems the more and more urgent: in Europe in fact this transition is getting its way, as the European Union supports it with a clear strong attitude and relevant financial measures, but several issues are still under examination with noticeable local differences. The features of specific industrial tissues strongly requires direct intervention through national and local institutions. This is the case of the Lombardy region as the first industrial region in Italy - but on a top level in Europe too. The overview of the framework generated to support the manufacturing industry transition witnesses the common effort of both Institution and manufacturing stakeholders toward initiatives and programs of co-creation.

References

- Ali H, Chen T, Hao Y (2021) Sustainable manufacturing practices, competitive capabilities and sustainable performance: Moderating role of environmental regulations. Sustainability 13(18): 10051.

- WCED (1987) Our common future - Report of the world commission on environment and development. Oxford University Press, Oxford, New York, USA.

- Elkington J (1998) Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ Qual Manag 8(1): 37-51.

- Ojstersek R, Palcic I, Buchmeister B (2020) Simulation modelling of environmental and economic aspects in manufacturing systems. In: Katalinic B (Ed.), Proceedings of the 31st DAAAM International Symposium, Published by DAAAM International, Vienna, Austria, pp. 436-443.

- McElnea WK (2011) Sustainable manufacturing initiative: US department of commerce. In: Princet NJ (Ed.), Int J Powder Metall 47: 12-16.

- Sartal A, Bellas R, Mejías AM, García-Collado A (2020) The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Advances in Mechanical Engineering 12(5).

- Zhang H, Haapala KR (2015) Integrating sustainable manufacturing assessment into decision making for a production work cell. J Clean Prod 105: 52-63.

- Jawahir IS, Badurdeen F, Rouch K (2014) Innovation in sustainable manufacturing education. 11th Global Conference on Sustainable Manufacturing, University of Kentucky, USA, pp. 9-16.

- Carvalho N, Chaim O, Cazarini E, Gerolamo M (2018) Manufacturing in the fourth industrial revolution: A positive prospect in sustainable manufacturing. Procedia Manufacturing 21: 671-678.

- Kishawy HA, Hegab H, Saad E (2018) Design for sustainable manufacturing: Approach, implementation and assessment. Sustainability 10(10): 3604.

- Haapala KR, Zhao F, Camelio J, Sutherland JW, Skerlos SJ, et al. (2013) A review of engineering research in sustainable manufacturing. Journal of manufacturing science and engineering 135(4).

- Stock T, Seliger G (2016) Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 40: 536-541.

- Sharma R, Jabbour CJC, Jabbour ABLDS (2020) Sustainable manufacturing and industry 4.0: what we know and what we don't. Journal of Enterprise Information Management 34(1): 230-266.

- Romero D, Stahre J, Wuest T, Noran O, Bernus P, et al. (2016) Towards an operator 4.0 typology: A human-centric perspective on the fourth industrial revolution technologies. In proceedings of the international conference on computers and industrial engineering (CIE46), Tianjin, China, pp. 29-31.

- Morrar R, Arman H, Mousa S (2017) The fourth industrial revolution (Industry 4.0): A social innovation perspective. Technology Innovation Management Review 7(11): 12-20.

- Jamwal A, Agrawal R, Sharma M, Giallanza A (2021) Industry 4.0 technologies for manufacturing sustainability: A systematic review and future research directions. Applied Science 11(12): 5725.

- Feng SC, Joung CB (2010) Development overview of sustainable manufacturing metrics. Proceedings of the 17th CIRP international conference on life cycle engineering 6: 12.

- Lu T, Gupta A, Jayal AD, Badurdeen F, Feng SC, et al. (2011) A framework of product and process metrics for sustainable manufacturing. Advances in sustainable manufacturing, pp. 333-338.

- Joung CB, Carrell J, Sarkar P, Feng SC (2013) Categorization of indicators for sustainable manufacturing. Ecological indicators 24: 148-157.

- Rusinko C (2007) Green manufacturing: An evaluation of environmentally sustainable manufacturing practices and their impact on competitive outcomes. IEEE transactions on engineering management 54(3): 445-454.

- Fiksel J, McDaniel J, Mendenhall C (1999) Measuring progress towards sustainability principles, process, and best practices. Eighth International Conference of Greening of Industry Network Chapel Hill.

- Huang A, Badurdeen F (2017) Sustainable manufacturing performance evaluation: Integrating product and process metrics for systems level assessment. Procedia Manufacturing 8: 563-570.

- Bonvoisin J, Stark R, Seliger G (2017) Field of research in sustainable manufacturing. In: Jantzen P (Ed.), Sustainable production, life cycle engineering and management, Springer Nature, Germany, pp. 3-20.

- Garetti M, Taisch M (2012) Sustainable manufacturing: Trends and research challenges. Production planning & control 23(2-3): 83-104.

- Giret A, Trentesaux D, Prabhu V (2015) Sustainability in manufacturing operations scheduling: A state of the art review. Journal of Manufacturing Systems 37(1): 126-140.

- Jawahir IS, Dillon OW (2007) Sustainable manufacturing processes: new challenges for developing predictive models and optimization techniques. Sustainable Manufacturing Montreal, Canada, pp. 1-19.

- Khomenko S, Cirach M, Barboza EP, Mueller N, Gómez BJ, et al. (2021) Premature mortality due to air pollution in European cities: A health impact assessment. The Lancet Planetary Health 5(3): e121-e134.

- Kiel D, Müller JM, Arnold C, Voigt KI (2020) Sustainable industrial value creation: Benefits and challenges of industry 4.0. International Journal of Innovation Management 21(8): 231-270.

- Krajnik P, Pusavec F, Rashid A (2011) Nanofluids: Properties, applications and sustainability aspects in materials processing technologies. Sustainable Manufacturing, Germany, pp. 107-113.

- Lai WH, Lin C, Wang TC (2015) Exploring the interoperability of innovation capability and corporate sustainability. Journal of Business Research 68(4): 867-871.

- Seliger G, Kim HJ, Kernbaum S, Zettl M (2008) Approaches to sustainable manufacturing. International Journal of Sustainable Manufacturing 1(1-2): 58-77.

© 2022 Maria Garbelli. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)