- Submissions

Full Text

Significances of Bioengineering & Biosciences

New Powered Air Respirator

Cheberyachko S1*, Deryugin O2, Klimov D1, Tretyak O2 and Pustovoi D3

1The Department of Labor Protection and Civil Safety, Dnipro University of Technology, Ukraine

2The Department of Transport Management, Dnipro University of Technology, Ukraine

3The Department of Engineering, Technical Aesthetics and Design Arts, Dnipro University of Technology, Ukraine

*Corresponding author: Cheberyachko Serhiy, Doctor of Technical Sciences, The Department of Labor Protection and Civil Safety, Dnipro University of Technology, Ukraine

Submission: January 22, 2021 Published: March 05, 2021

ISSN 2637-8078Volume4 Issue4

Abstract

The analysis of respiratory protective device use efficiency has shown the substantial limitations of quality assessment for respirators. This results in potential hazard of excessive influence of harmful particulate pollutants on employees. To prevent occupational diseases development it is extremely important that employers are motivated to improve labour conditions. Not least important is development of requirements to the biomonitoring procedure and conditions, as well as selection, testing and users training for individual respiratory protective devices use as based on the modern science development. The elimination of hazard class based only in providing the employees with individual respiratory protective devices is not scientifically substantiated and inadmissible way.

Keywords: Dust mask; Protection factor; Dust load; Pneumoconiosis

Introduction

The filtering respirator with forced air supply is an effective means of individual protection of respiratory organs (RPD) of users in especially dangerous conditions saturated with harmful substances in which it is impossible to use other types of protective equipment [1-3]. The main disadvantages of the known designs of filtering respirators with forced air supply include inefficient operation of the fan due to the significant resistance of the air flow inhaled by the user. This is due to the shortcomings of the existing fan speed control system in the event of a sharp increase in air flow due to increased physical activity of the user or contamination of the filter elements [4,5]. This leads to the suction of polluted air along the obturation strip into the submask space, which can cause poisoning or death of the user [6].

Description of the Design and Operating Modes of the Filtering Respirator with Forced Air Supply

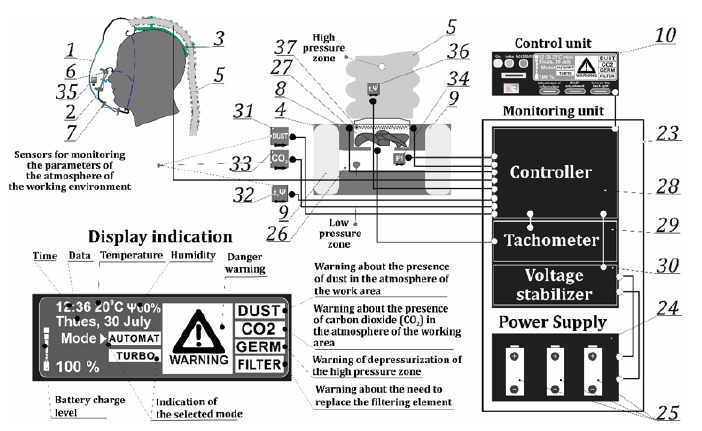

This problem is solved by equipping a filtering respirator with forced air supply by the air

flow control unit, which provides the relationship between air flow and the intensity of

physical activity of the user, considering the air flow passing through the filter elements

while maintaining the appropriate level of protective properties (Figure 1). The filtering

respirator with forced air supply has several operating modes (Table 1):

a. Automatic, based on the output signals of sensors for monitoring air parameters,

the information from which comes to the controller, where they are processed and

controlled: fan speed, purified air heater, indication and alarm, which is illuminated on

the display of the air purification unit.

b. Turbo mode, which is activated in case of heavy contamination of the filtering

elements to increase the speed of the fan, which is regulated by the controller in case of

receipt of the corresponding signals from the control sensors.

c. Emergency mode, which is activated when the battery is minimally charged, or

when the critical value of the pressure drop across the contaminated filter elements is

reached, for the user to quickly leave the danger zone.

Table 1: Operating modes of the filtering respirator with forced air supply.

Figure 1:Schematic and structural scheme of the filtering respirator with forced air supply: helmet-mask (1), obturator (2), head straps (3), air purification device (4), flexible corrugated air duct (5), inhalation valve (6), exhalation valve (7), air cleaner housing (8), filter elements (9), control unit (10), on/off switch (11), button №1 (12), “Information correction” (time, day of the week, month, ambient temperature, humidity); button №2 (13), “Mode adjustment” (automatic mode, turbo mode, emergency mode); button №3 (14), “Display backlight”; indicator lights: - red indicator light (15), “Accident”, blue indicator light (16), “Turbo”, green indicator light (17), memory card (18), display (19), loudspeaker (20), connector for charging batteries (21), USB connector for connection to a PC for setting up and adjusting the software of the air cleaning device (22), monitoring unit (23), power supply unit (24), which includes three batteries (25), channel (26), power supply (27), controller (28), tachometer (29), voltage stabilizer (30), sensor for monitoring the presence of dust in the atmosphere of the working area (31), temperature and humidity control sensor in the working zone atmosphere (32), carbon dioxide concentration control sensor in the working zone atmosphere (33), low pressure zone pressure control sensor (34), high pressure zone pressure control sensors (35), control sensor temperature and humidity in the high pressure zone (36), purified air heater (37).

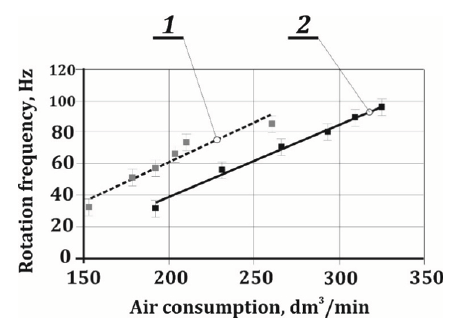

Laboratory studies have established a relationship between the volume of air flow that enters the submask space to the user’s respiratory system and the fan speed (Figure 2). The critical pressure drop on the filtering elements, which change the parameters of the air flow, is determined and the changes of the air flow modes from the intensity of the user ‘s physical activity are investigated. As a result of substantiation of design parameters and modes of operation of the fan on the basis of processing of input signals from sensors of control of technological parameters and comparison with existing analogues RPD of the corresponding class, efficiency of the offered design of the dust respirator with forced air supply inhaled taking into account the frequency and depth of breathing of the user during exercise.

Figure 2:Graphs of air flow dependences on fan speed “HA4010V4” unmodernized (1) and modernized with replacement of stator excitation windings by resistors (2).

Conclusion

The design of a filtering respirator with forced air supply in which a new element is introduced - the control unit of air flow parameters (volume, speed, temperature, humidity), which enters the submask space. This allows not only to provide the required volume of air in the submask space of the filtering respirator, by controlling the fan speed in a given range, taking into account the frequency and depth of breathing of the user depending on physical activity.

References

- Tannahill SN, Willey RJ, Jackson MH (1990) Workplace protection factors of HSE approved negative pressure full facepiece dust respirators during asbestos stripping: Preliminary findings. The Annals of Occupational Hygiene 34(6): 547-552.

- Wood GO, Snyder JL (2011) Estimating reusability of organic air-purifying respirator cartridges. Journal of Occupational and Environmental Hygiene 8(10): 609-617.

- Petrachkova NM (2013) Analysis of the effectiveness of personal protective equipment for miners in winter conditions. Scientific Research of Young Scientists 1: 106-109.

- Gudkov SV, Butler SI, Putin SB, Tarov VP (2008) Isolating breathing apparatus and the basics of their design. In: Mashinostroenie, Russia, p. 188.

- Mang C, Hui L, Shengnan S, Yu W, Quan Y (2017) Customized design and 3D printing of face seal for an N95 filtering facepiece respirator. Journal of Occupational and Environmental Hygiene 15(3): 226-234.

- Borovskiy E (2015) New gas sensors from figaro. Components and Technologies 1: 122-124.

© 2021 © Cheberyachko S. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)