- Submissions

Full Text

Research & Development in Material Science

Effect of Heat Treatment on Microstructural Evolution and Mechanical Properties of a Welded Pipeline A970 Duplex Stainless Steel

Zakaria Boumerzoug1*, Younes Gheriani1 and Fabienne Delaunois2

1LMSM, University of Biskra, Algeria

2Metallurgy Department, University of Mons, Belgium

*Corresponding author: Zakaria Boumerzoug, LMSM, University of Biskra, B.P. 145, Biskra, 07000, Algeria

Submission: August 12, 2022;Published: August 25, 2022

ISSN: 2576-8840 Volume 17 Issue 4

Abstract

In this investigation, the effect of an isothermal heat treatments at 300 °C on microstructure evolution and mechanical properties of the welded pipeline A970 duplex stainless steel have been studied by optical microscopy, scanning electron microscopy, energy dispersive spectroscopy analysis, X-ray diffraction, and hardness measurements. It was found that the fuzion zone is different from the heat affected zone and also from the base metal. The quantity of the ferritic phase decreased in the melting zone and was partially restored after the heat treatment, which has an influence on the hardness of the melting zone.

Keywords: Welding; Duplex stainless steel; Microstructures; Phases

Introduction

Duplex Stainless Steels (DSS) are stainless steels formed from two phases: austenite and ferrite [1]. The wide use of these steels is linked to their excellent resistance to corrosion, as well as high strength and toughness [2,3]. The good mechanical properties and corrosion resistance of DSS are due to the balanced content between ferrite (δ) and austenite (γ) [4]. The ferrite is responsible for the strength, and the austenite provides the toughness of the material [5]. The new generation of DSS has excellent weldability by conventional arc welding methods as long as heat input is controlled and inter-pass temperatures are limited to ensure proper γ to δ ratio in the weld metal and the heat-affected zone, HAZ [6,7]. It should be pointed out that welding duplex stainless steel is easy, but its welding is different from other steels. Indeed, the weldability and welding characteristics of duplex stainless steels are better than those of ferritic steels, although generally worse than austenitic steels [8]. However, the welding of duplex steels requires special attention due to the formation of many possible out-of-equilibrium transformations [9,10]. In addition, it is necessary to maintain an equality in the quantity of the two phases (austenitic phase (γ): ferrite (δ)) and the content of suitable alloys. It is therefore advisable to use a filler material generally over alloyed with nickel and a shielding gas containing nitrogen [11-13].

Generally, the welded process causes drastic microstructures changes in the heat affected zone [14,15]. Consequently, an annealing heat treatment subsequent to the welding operation can reduce these negatives effects. In this contexy, some investigations focussed on the effect of post heat treatment on the welding of DSS. Ferenc and Varbai [13] investigated the effect of heat treatment on the microstructure of duplex stainless-steel welds. Chromium nitride precipitates were observed in the heat affected zone, and after heat treatment, secondary austenite particles formed at the site of the nitride precipitates, resulting in an increase in the amount of austenite in the molten zone. Luo et al. [16] investigated Submerged Arc Welded (SAW) joints with and without Post-Weld Heat Treatment (PWHT) of 2205 Duplex Stainless Steel (DSS). They found that the σ phase disappears in the fuzion edge zone near the HAZ and an increase in the fuzion zone during the tracking PWHT, while the amount of γ phase is decreased in the central area welded with PWHT. However, one the highest microhardness value is measured at the fusion edge area near HAZ has disappeared and the other is still maintained at the central welded area during PWHT. This can be attributed to changes in second phases, element diffusions, and particle segregation during PWHT. Zhang et al. [17] investigated the effect of tungsten inert gas welding and subsequent postweld heat treatment on the microstructure evolution and pitting corrosion behavior of UNS S31803 duplex stainless steel. They found that in the fusion zone, the amount of ferrite is higher, which facilitates pitting corrosion attack than austenite. But the volume fraction of austenite in the heat affected zone and the weld metal is significantly high after the post-weld heat treatment.

Based on the previous works, it is interesting to study the microstructure of the welded joint and its evolution after heat treatment, because many questions remain unanswered. In this context, the purpose of this present work was to study the effect of an isothermal heat treatments at 300 °C on microstructure evolution and mechanical properties of the welded pipeline A970 duplex stainless steel.

Experimental Procedure

In this study, the Base Metal (BM) was a 790A duplex stainless steel used for transport gas pipeline applications. Figure 1 presents the chemical composition of the duplex stainless steel 790A which has been determined by the EDS technique.

Figure 1:Spectrum of analysis by EDS and chemical composition of pipeline A970 duplex stainless steel.

To produce good quality welds, welded tube was prepared with making of single V- butt joint with angle of 30°. Two consecutive passes were applied. The first pass made by a Gas Tungsten Arc Welding (GTAW) process with use of ER2209 as electrode, followed by a second pass by using a Shielded Metal Arc Welding (SMAW) process with E2209-15 as an electrode. The welding parameters are presented in Table 1.

Table 1: Welding parameters of pipeline A970 duplex stainless steel.

The input heat quantity is calculated by the following equation

[1]:

Heat Input =(I x V x 60) /S ……………… (1)

Where:

I = welding current(Ampere)

V = welding voltage (volt)

S = welding speed (m/min)

The average calculated value of the heat input is: 2400 kJ.

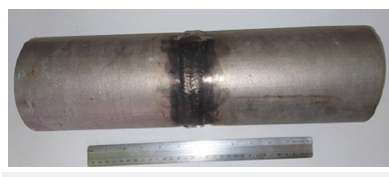

Figure 2 shows a macrographic view of the welded pipeline A970 duplex stainless steel, which has been well made without any visual defects.

Figure 2:Macrographic view of the welded welded pipeline A970 duplex stainless steel.

In order to study the heat treatment effect on welded samples, an isothermal annealing was performed in electrical furnace at 300 °C during 30min. Duplex steels are recommended to be used only at temperatures between -40 and 325 °C as they can become brittle outside of this temperature range [8].

Microhardness measurements along the welded joint were carried out using an INNOVATEST hardness tester with a load of 1000g and a dwell time of 15s. For the microstructural observations, the samples were polished by different abrasive papers and finally by a cloth containing a diamond pad. The chemical attack is carried out on the surface of the sample using a solution containing 30ml of hydrochloric acid (HCl) and 10ml of nitric acid (HNO3) and for 1m30s. The samples were analyzed by an optical microscope (HIROX Kh-8700) and a scanning electron microscope (HITACHI SU8020) equipped with an Energy Dispersive Spectroscopy (EDS) detector. Therefore, the base, fuzion zone, and heat affected zone microstructures were defined. An analytical X-ray diffractometer (BRUKER D-5000) was used to analyze the welded material with cobalt radiation. (λ=1.79Å).

Results and Discussion

Base metal

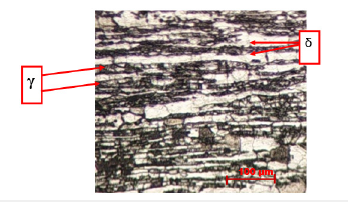

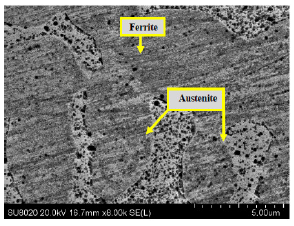

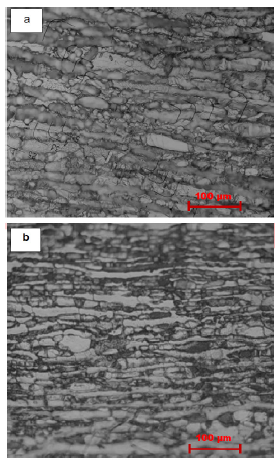

The Figure 3 shows the microstructure of 790A duplex stainless steel which consists of two phases: the phase that appears clear is ferrite (δ), while the phase that appears dark is austenite (γ). The microstructural characteristics of the observed duplex stainless steels are strongly influenced by the prior effect of thermomechanical treatment, since both phases have an elongated morphology. However, the SEM observation reveals the difference between the two phases as shown in Figure 4. The austenite phase is more eteched than the ferrite phase.

Figure 3:Optical observation of A790 duplex stainless steel.

Figure 4:SEM observation of duplex stainless steel 790A.

Welded joint

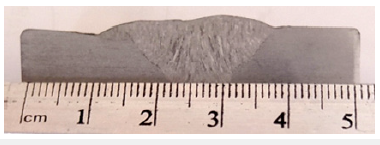

In this section, welded joint before and after heat treatment will be presented. Figure 5 shows a sample taken from the welded pipe, where a typical weld is observed.

Figure 5:Macrographic view of the welded A790 duplex stainless steel.

Microstructural observations

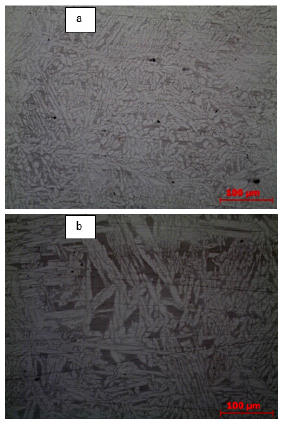

Figures 6-8 show the optical microstructures of the three zones of the welded joint of duplex stainless steel before and after heat treatment at 300 °C for 9h. The three zones are the base metal (Figure 6), the heat-affected zone (Figure 6) and the fusion zone (Figure 8). First of all, there is a microstructural difference between the three zones. The fuzion zone is characterized by a Widmanstätten and dendritic austenite with ferrite phase. It has been mentionned that during cooling after the welding process, austenite is again formed, mainly at ferrite grain boundaries with plate morphology (Widmanstätten austenite) [18].

Figure 6:Optical microstructure of the base metal (a): before and (b): after heat treatment at 300 °C for 9h of the welded pipeline A970 duplex stainless steel.

Figure 7:Optical microstructure of the heat affected zone (a): before and (b): after heat treatment at 300 °C for 9h of the welded pipeline A970 duplex stainless steel.

Figure 8:Optical microstructure of the fuzion zone (a): before and (b): after heat treatment at 300 °C for 9h of the welded pipeline A970 duplex stainless steel.

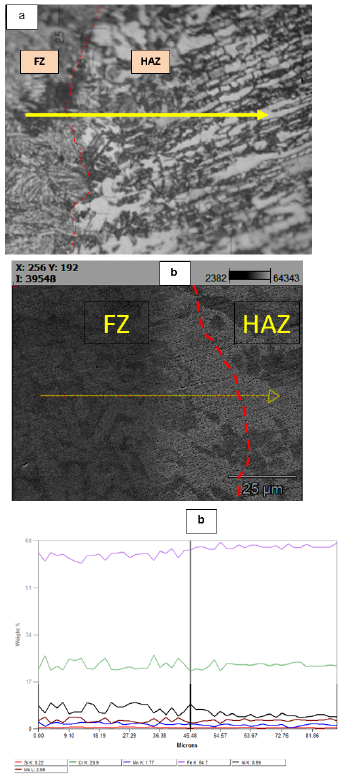

The distribution analysis of addition elements from the fusion zone to the heat-affected zone revealed fluctuations in chemical composition (Figure 9). Obviously, iron is the basic element of duplex steel (curve in viloet) varies slightly from one area to another. On the other hand, the addition elements (Cr, Ni, Mo, Mn, Si) have a slightly higher concentration in the fuzion zone than in the heat-affected zone. This distribution is due to the existing elements in the electrode.

Figure 9:EDS analysis from the fusion zone to the heat-affected zone in welded A790 duplex stainless steel. (a) SEM observation of the selected intermediate zone (FZ + HAZ). (b) Curves of the chemical composition variation in selected zone of Cr, Ni, Mo, Mn, and Si.

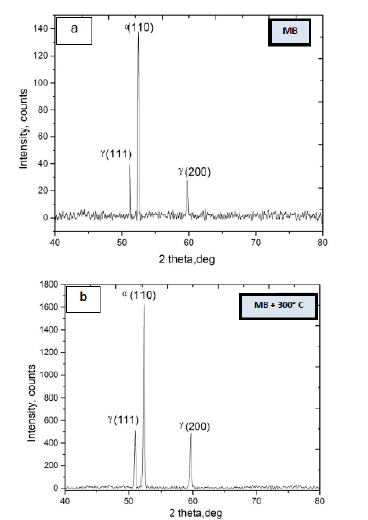

XRD analysis

The result of the X-ray diffraction analysis of the two zones of the welded joint (Base metal and fuzion zone) before and after the heat treatment at 300 C is shown in the Figure 10 & 11. The diffractogram of the base metal before (Figure 7a) and after heat treatment at 300 C (Figure 7b) reveals the main ferrite and austenite peaks without any significant change. The X-ray diffractogram of the fuzion zone before heat treatment (Figure 8a) reveals the main ferrite and austenite peaks but with a strong intensity of austenite peaks. The effect of heat treatment on the fusion zone increased the amount of ferrite phase (Figure 8a) which is beneficial for the mechanical properties of the welded joint. Generally, duplex steels solidify with a fully ferritic structure with austenite nucleation and growth upon cooling. Rapid cooling from high temperatures can still result in high levels of ferrite in the molten metal and adjacent base metal. Therefore, filler metals are specially designed with higher nickel contents to produce a phase balance similar to that of the base material [8]. Ferenc and Varbai [13] studied the effect of heat treatment on the microstructure of duplex stainlesssteel welds. chromium nitride precipitates were observed in the HAZ, and after heat treatment, secondary austenite particles were formed at the site of the nitride precipitates, which increased the amount of austenite in the FZ.

Figure 10:X-ray diffractograms of the base metal: (a) before and: (b) after heat treatment at 300 ℃ for 9h.

Figure 11:X-ray diffractograms of the fusion zone: (a) before and: (b) after heat treatment at 300 ℃ for 9h.

Hardness measurements

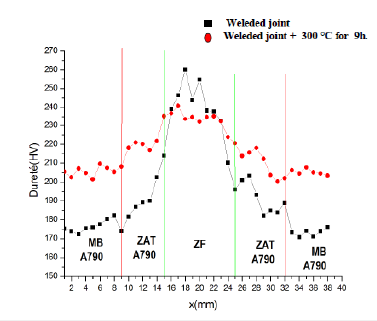

Figure 12:Vickers microhardness profile of the welded joint of duplex stainless steel before and after heat treatment at 300 ℃.

The best method of delineating the different zones in a welded joint is to make a Vickers microhardness profile through the welded joint. Figure 12 presents the hardness curves produced on the welded joint of duplex stainless steel before and after heat treatment at 300 C. The curve of the welded sample shows a high hardness in fuzion zone (~260Hv) followed by slight decrease of hardness in heat affected zone(~170-~200Hv). The mean hardness value of the base metal is 175Hv. Our hardness results are in good agreement with the literature, because Mohamed et al. [19], found in the weld joint of a 2205 duplex stainless steel, that the maximum hardness values are measured in the fuzion zone and the low value in base metal. The variation in harnesses across the weld can be attributed to several factors such as residual stresses just after welding, and the microstructural difference between the three zones.

However, after the isothermal heat treatment at 300 °C, the hardness in FZ decreases, on the other hand it increases in the base metal and in the HAZ. This is due to recrystallization reaction in the base metal and HAZ and phase transformation in FZ such as the increase in the amount of austenite. In addition, this heat treatment can decrease the residual stresses in the welded joint.

Conclusion

In summary, the effect of isothermal heat treatment on microstructure evolution and mechanical properties after welding of A790 pipeline duplex stainless steel have been studied by using optical microscopy, scanning electron microscopy, energy dispersive spectroscopy analysis, X-ray diffraction, and hardness measurements. Three distinct zones (Base Metal, Heat Affected Zone and Fuzion Zone) were observed. The fuzion zone has the highest hardness value in the welded joint which decreases after isothermal heat treatment at 300 °C. This decrease of hardness in FZ was due to the phase transformation during the heat treatment. The quantity of the ferritic phase decreased in the melting zone and was partially restored after the heat treatment.

References

- Rocha AC, Rocha Santos AP, Pereira GR (2018) Phase transformations in duplex stainless steel: An assessment by in situ x-ray diffraction. Stainless Steels and Alloys. Zoia Duriagina (Ed.), Intech Open.

- Gibson RG, Hayden HW, Brophy JH (1968) Properties of stainless steels with micro duplex structure. Trans ASM 61: 85.

- Hayden HW, Floreen S (1968) The deformation and fracture of stainless steels having micro duplex structures. 61: 474.

- Burcu T (2012) Microstructural and mechanical characterization of duplex stainless-steel grade 2205 joined by hybrid plasma and gas metal arc welding. Thesis, Middle East Technical University, Turkey, pp. 1-56.

- Floreen S, Hayden HW (1968) The influence of austenite and ferrite on the mechanical properties of two-phase stainless steels having micro duplex structures. 61: 489.

- Nilsson JO (1992) Super duplex stainless steels. Materials Science and Technology 8: 685-700.

- Kordatos JD, Fourlaris G, Papadimitriou G (2001) The effect of cooling rate on the mechanical and corrosion properties of SAF 2205 (UNS 31803) duplex stainless steel welds. Scripta Metallurgica 44(3): 401-408.

- https://www.outokumpu.com/en/expertise/2021/welding-metallurgy-of-duplex- stainless steel.

- Uzonyi S, Asztalos L, Dobránszky J (2015) Welding of duplex corrosion-resistant steel sheets. Technical Scientific Bulletins 3: 315-318.

- Pálfi N, Berecz T, Fazakas É, Fábián ER (2017) Microstructural changes in SAF 2507 type duplex corrosion-resistant steel heated at 900 °C and then formed. XXV. International Mechanical Engineering Conference. 25th International Conference on Mechanical Engineering. Cluj, Románia, pp. 303-306.

- Fábián ER, Dobránszky J, Csizmazia J (2016) Technical Scientific Publications 5: 141-144.

- Sándor T (2010) Jubilee Welding Conference. Budapest, Hungary, pp. 19-21.

- Tolnai F, Varbai B (2020) Acta Materialia Transylvanica 3/2.

- Easterling KE (1992) Introduction to the physical metallurgy of welding. Butterworth-Hermann Ltd., Oxford.

- Spanos G, Fonda RW, Vandermeer RA (1995) Changes occurring during laser beam welding of duplex steel sheets. In: Matuszeski A (Ed.), Metall Mater Trans 26A: 3277-3293.

- Luo J, Dong Y, Li L, Wang X (2014) Microstructure of 2205 duplex stainless steel joint in submerged arc welding by post weld heat treatment. Journal of Manufacturing Processes 16(1): 144-148.

- Zhang Z, Wang Z, Jiang Y, Tan H, Han D, et al. (2012) Effect of post-weld heat treatment on microstructure evolution and pitting corrosion behavior of UNS S31803 duplex stainless steel welds. Corrosion Science 62: 42-50.

- Aguiar I, Perez ED, Santos ADB, Modenesi PJ (2015) Microstructure characterization of a duplex stainless-steel weld by electron backscattering diffraction and orientation imaging microscopy techniques. Revista Matéria 20(1): 212-226.

- Mohammed R, Madhusudhan RG, Srinivasa RK (2018) Effect of welding process on microstructure, mechanical and pitting corrosion behaviour of 2205 duplex stainless steel welds. IOP Conf Series: Materials Science and Engineering.

© 2022 Zakaria Boumerzoug. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)