- Submissions

Full Text

Research & Development in Material Science

Delayed Bleeding of High-Strength Steel Fiber Reinforced Concrete Mix

Dorf VA, Turkin VV*

JSC “Institute “Orgenergostroy, Moscow, Russia

*Corresponding author: Turkin VV, JSC “Institute “Orgenergostroy, Moscow, Russia

Submission: July 26, 2022;Published: August 05, 2022

ISSN: 2576-8840 Volume 17 Issue 3

Opinion

In the manufacture of samples from high-strength steel fiber reinforced concrete, we encountered the following phenomenon: on the upper surface of samples 30mm thick, made from a self-compacting steel fiber concrete mixture, there was practically no bleeding during 2 hours after molding, and after 3 hours water drops appeared. These droplets have grown larger over the next four hours, as can be seen in Figure 1.

Figure 1: Drops of water on the surface of concrete: a) after 3 hours, b) after 4 hours, c) after 6 hours.

The appearance of drops cannot be associated with the condensation of atmospheric moisture, because a similar effect was also observed on samples covered with polyethylene film immediately after molding. In the literature was described a decrease of bleeding with an increase of the content of cement and finely dispersed mineral additives in the concrete mixture (see, for example, [1]), however, there is no quantitative assessment of the slowdown in bleeding in these publications.

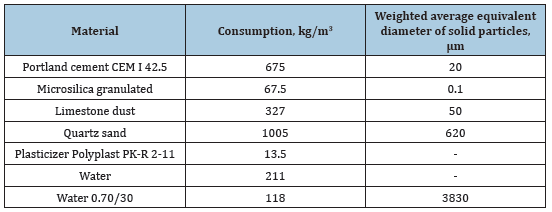

In our case, a self-compacting steel-fiber-reinforced concrete mixture was used with a high consumption of cement and mineral additives and a steel fiber content of 0.7*30mm of 1.5% by volume. The composition of the mixture is shown in Table 1. The weighted average equivalent diameter of solid particles was calculated from the particle size distribution of the materials. For fiber, the equivalent diameter was calculated for a sphere equal in volume to the fiber.

Table 1: Composition of mixture of self-compacting steel-fibre-reinforced concrete.

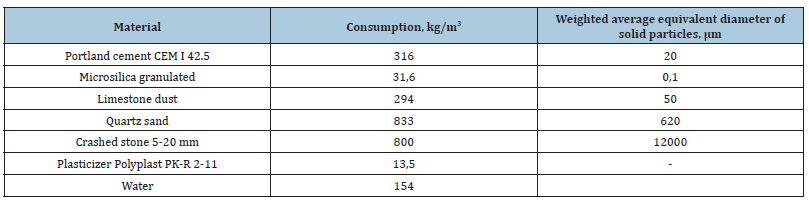

For comparison, self-compacting concrete of class B30 with crushed stone of 5-20mm with the same dose of plasticizer was tested. The composition of concrete is given in Table 2. The concrete mixture had a bleeding of 0.4% when tested according to GOST 10181-2014. Both in the steel-fiber-reinforced concrete and in the concrete mix, plasticizing additives with a prolonged duration of action were used. Therefore, the setting of the mixture occurred no earlier than after 6 hours. Consequently, the process of water separation proceeded during the same time. The process of water separation in the concrete mixture is associated with the settlement of heavier solid particles and squeezing water upwards. Therefore, it can be assumed that the rate of bleeding is related to the rate of water filtration in the structure of solid particles of cement, mineral additives and aggregates.

Table 2: Composition of mixture of self-compacting steel-fibre-reinforced concrete.

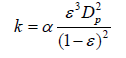

The rate of liquid filtration in a medium with small capillaries is well described by the Kozeny-Karman formula [5]

where: ε- porosity

D2p -Average particle diameter

𝛼- Coefficient of proportionality.

For self-compacting high-strength steel fiber reinforced concrete with a high content of cement and the presence of mineral additives ε=11.7%. For low-slump ordinary concrete of class B30 with the same additives ε=11.1%. Consequently, the porosity of concrete in this case does not have a significant effect on the rate of bleeding.

The weighted average particle diameter of cement, mineral additives, sand, coarse aggregate is 4.46mm for ordinary concrete, and 0.5mm for high-strength steel fiber concrete. The proportionality coefficient ∝ depends primarily on the tortuosity of the capillaries and, as a first approximation, it can be taken constant for different concretes.

Substituting the concrete structure parameters into the Kozeny- Karman formula, we obtain that for high-strength finely porous concrete, the duration of water separation will be several hours. This explains the effect of the slow appearance of water drops on the surface of high-strength steel fiber concrete and their absence for ordinary concrete.

References

© 2022 Turkin VV. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)