- Submissions

Full Text

Research & Development in Material Science

Deformation Behaviour and in Microstructural Analysis of Titanium alloy

Boopathi R1*, Senthur R2, Raajkumar M2, Shabharrish S2 and Saravanan S2

1Professor, Department of Mechanical Engineering, Mahendra Engineering College, India

2UG Students, Department of Mechanical Engineering, Mahendra Engineering College, India

*Corresponding author: Boopathi R, Professor, Department of Mechanical Engineering, Mahendra Engineering College, India

Submission: June 10, 2022;Published: June 28, 2022

ISSN: 2576-8840 Volume 17 Issue 2

Abstract

The present study deals with the warm temperature deformation behavior of the titanium (Ti-6Al-4V) alloy throughout investigating the flow behavior and the correlated microstructure evolutions. Toward this end, the hot compression tests were conducted at different temperatures and strain rate. Titanium is a low-density element that can be highly strengthened by alloying and deformation processing. Titanium is nonmagnetic and has good heat transfer properties. Its co-efficient of thermal expansion is somewhat lower than half that of aluminum. The titanium materials, in a relatively short time, have become backbone materials for the aerospace, energy, and chemical industries. The combination of high strength-to-weight ratio, excellent mechanical properties, and corrosion resistance makes titanium the best material choice for many critical applications. Hot compression test can be conveniently used to study the plastic deformation of a material under different conditions of temperature and strain rate. The effect of micro structural characteristics of the deformed specimen were studied and correlated with the test temperature, total strain and strain rate to develop a constitutive equation for the flow stress dependence on strain rate, and temperature. Micro-structural examinations were carried out, on the specimen and results were analyzed and reported.

Keywords: Titanium; Hot compression; Temperature; Strain rate

Introduction

Titanium is a low-density element (approx.60% of the density of iron) that can be highly strengthened by alloying and deformation processing. Titanium is nonmagnetic and has good heat transfer properties. Its co-efficient of thermal expansion is somewhat lower than half that of aluminum. Titanium is nontoxic and generally biologically compatible with human tissues and bones. The combination of high strength-to-weight ratio, excellent mechanical properties, and corrosion resistance makes titanium the best material choice for many critical applications. Today, titanium alloys are used for demanding applications such as static and rotating gas turbine engine components. Some of the most critical and highly stressed civilian and military airframe parts are made of these alloys. The use of titanium has expanded in recent years to include applications in nuclear power plants, food processing plants, oil refinery heat exchangers, marine components and medical prostheses. The high cost of titanium alloy components may limit their use to applications for which lower-cost alloys, such as aluminium and stainless steels. The relatively high cost is often the result of the inartistic raw material cost of metal, fabricating costs and the metal removal costs incurred in obtaining the desired final shape

Literature Review

SP700 titanium alloy is a super plastic titanium alloy developed by better formability and workability than TC4 titanium alloy and its good formability and mechanical processing properties make the alloy widely used in military and civilian fields such as aerospace, medical equipment [1]. Similar to other high temperature titanium alloys, such as Ti-1100 and IMI834, this alloy is quite difficult to be formed into a complex shape because of its poor workability and high strength. Moreover, the accurate control of microstructure morphologies and properties of final components is very difficult for those high temperature titanium alloys with high alloying elements in forming process. In order to develop plastic forming methods of high temperature titanium alloys, such as forging, extrusion and sheet hot forming, it is necessary to characterize the deformation behavior, including the flow stress behavior, deformation mechanism and microstructure evolution of the materials. Currently, quite a few investigations have been conducted to analyze the hot deformation behavior of high temperature titanium alloys [2].

Investigated the high temperature behavior of a near-Ti-600 alloy and determined its optimized super plastic forming window. Although there is some research on the thermal stability and tensile formability of Ti-55 alloy. the hot compression behavior has been rarely reported, which limits the application of hot plastic forming processes, such as forging and extrusion, to this kind of titanium alloy. In this study, the isothermal compression of Ti-55 titanium alloy has been conducted at different strain rates and temperatures both regions. The flow stress behavior has been analyzed and the microstructure evolution has been observed. Subsequently, the processing map has been established to understand the deformation mechanism during hot compression, and the optimum hot working window has been determined for hot processing of Ti- 55 alloy [3].

Hot working is an important thermo mechanical process of b titanium alloys. It usually consists of primary ingot breakdown in the b phase field and secondary working either above or below the b transus temperature. As compared to aluminum or steel, titanium alloys generally exhibit limited hot workability at elevated temperatures. Hence, careful selection and control of the hot-working parameters, such as temperature and strain rate are critical for successful processing of the materials [4]. The SP-700 alloy with a nominal composition of Ti-4.5Al3V-2Mo-2Fe is the third most widely used two phase titanium alloy after Ti-6Al-4V and Ti- 6Al-6V-2Sn. This alloy is a beta rich two-phase alloy introduced in 1989 by the Japanese company NKK1 best known for its superior super plastic behavior. SP-700 alloy compared to Ti-6Al-4V shows superior mechanical properties such as fatigue and tensile strength, fracture toughness and lower super plastic deformation temperature. During the past two decades, in addition to the super plastic formability of the SP-700 alloy, many investigations have been carried out to improve its mechanical properties, fracture toughness and fatigue strength [5].

There are only a few papers on the hot deformation behavior of SP-700 such as hot compression and hot tension However, most of these studies significantly concentrated on the flow curves and mechanical formability, instead of the basic micro structural evolutions during hot deformation. Therefore, more experimental investigations are still needed for better understanding of the deformation mechanism and micro structural evolutions of SP-700 alloy during hot deformation. Hence, the other hot deformation processes of the alloy such as hot torsion, hot forging, hot rolling, multi-pass deformation processes and other hot deformation techniques need to be investigated. Additionally, dynamic/static restoration mechanisms, kinetics of static restoration, deformation limitations and the ways to reduce or remove these limitations for the alloy have not been studied so far. It is well known that deformation temperature, strain rate, amount of strain and many other factors could influence the deformation behavior of titanium alloy during hot working [6].

Hot compression of titanium (Ti-6Al-4V) alloy has been studied using finite element simulation and the results have been compared with those obtained experimentally. The constitutive behaviour of the material and friction at the extrusion temperature are established based on the results obtained through a ring compression test. The distribution of strain, temperature and effective stress have been simulated under different design and processing conditions. Simulation results show that heat generation due to deformation is significant in hot extrusion of titanium alloys, and it mainly occurs at the beginning of the extrusion process. This leads to reduction in flow stress which, in turn, leads to enlarged deformation zone. A fair agreement has been found between the experimental results and those obtained through simulation [7].

Similar to other high temperature titanium alloys, such as Ti- 1100 and IMI834, this alloy is quite difficult to be formed into a complex shape because of its poor workability and high strength. Moreover, the accurate control of microstructure morphologies and properties of final components is very difficult for those high temperature titanium alloys with high alloying elements in forming process. In order to develop plastic forming methods of high temperature titanium alloys, such as forging, extrusion and sheet hot forming, it is necessary to characterize the deformation behavior, including the flow stress behavior, deformation mechanism and microstructure evolution of the materials. Currently, quite a few investigations have been conducted to analyze the hot deformation behavior of high temperature titanium alloys. For instance, analyzed the deformation characteristics of IMI685 alloy and revealed its dynamic softening mechanism in β phase field, which was helpful for widening its forging temperature range. Explored the flow stress behavior and the microstructure evolution of near-α IMI834 alloy in β and α + β phase regions, respectively, through isothermal compression experiment [8].

Although there is some research on the thermal stability and tensile formability of Ti-55 alloy, the hot compression behavior has been rarely reported, which limits the application of hot plastic forming processes, such as forging and extrusion, to this kind of titanium alloy. In this study, the isothermal compression of Ti-55 titanium alloy has been conducted at different strain rates and temperatures both in the α + β and β regions. The flow stress behavior has been analyzed and the microstructure evolution has been observed. Subsequently, the processing map has been established to understand the deformation mechanism during hot compression, and the optimum hot working window has been determined for hot processing of Ti-55 alloy [9]. Basic machining method for the manufacturing industries of aerospace, nuclear engineering, micro nozzle fabrication, aerospace, heat resistance material, surgical components, and drilling of composites [10].

Experimental Procedure

Hot compression test specimens of 9mm height and 6mm diameter were machined for testing. A 0.2mm 45° chamfer was provided on the specimen edges to avoid fold-over of the material during the initial stages of compression. A small hole of 0.8mm diameter and 4mm depth was drilled at mid height of the specimen for inserting a thermocouple which was used to measure the actual temperature of the specimen as well as temperature rise, if any, during the testing. Hot compression tests were conducted using a servo controlled UTM testing machine shown in Figure 1. The test temperature ranges from room temperature to 500 °C at an interval of 100 °C and strain rates of 0.01, 0.05 and 0.1s1. The temperature of the specimen was monitored using an iron copper wire inserted in the specimen. After compression testing, the specimens were immediately quenched in water and the deformed specimens were prepared for micro-structural examination.

Data collection

The load and displacement values for a given strain rate and temperature were observed from the computer output and a sample data collected for a strain rate of 0.01s1 at a temperature of 100 °C. The load-displacement curve is constructed as taking the displacement value on x-axis and load value on y-axis.

Results and Discussion

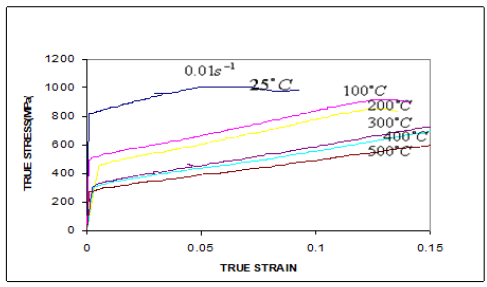

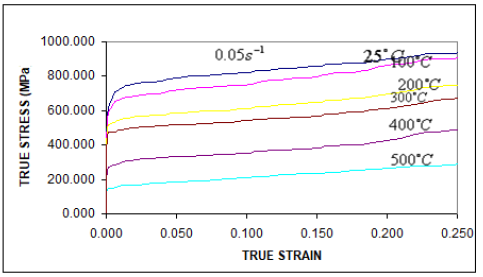

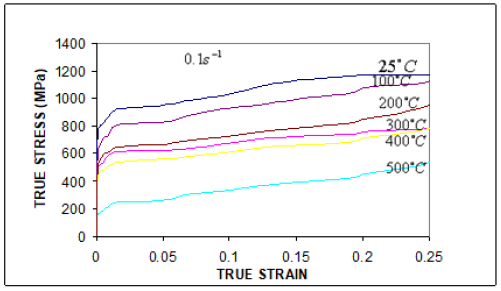

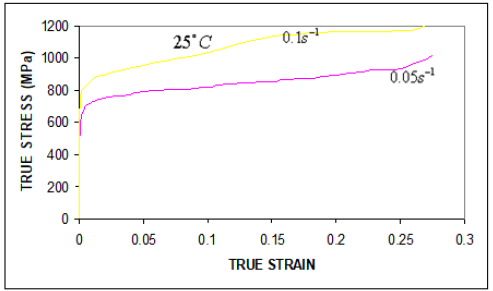

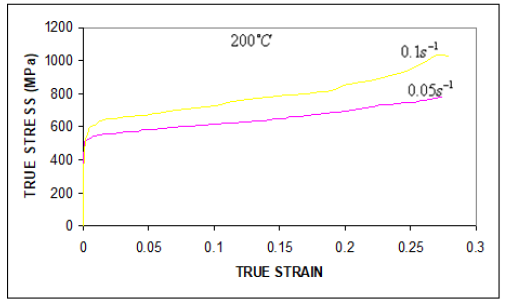

The flow curves obtained for Ti-6Al-4V alloy deformed in compression at 25 ℃ to 500 ℃ and at strain rates ranging of 0.01s- 1, 0.05s-1 and 1.0s-1 are presented in Figures 1-6 it is observed that the flow stress rises to peak value of 1010MPa and then decreases, indicating that flow softening has occurred. From these figures it is found that irrespective of strain rates, as temperature increases, the flow stress values decrease corresponding to a given strain. It is also observed that the flow stress value increases with respect to strain. Further it noted that at low temperature the strain hardening is more, and as the temperature increases strain hardening decreases.

Figure 1: Flow curves different temperatures at a constant strain rate 0.01s-1.

Figure 2: Flow curves different temperatures at a constant strain rate 0.05s-1.

Figure 3: Flow curves different temperatures at a constant strain rate 0.1s-1.

Figure 4: Flow curves different strain rates at a constant temperature of 25OC

Figure 5:Flow curves different strain rates at a constant temperature of 200OC.

Figure 6:Flow curves for different strain rates at a constant temperature of 500OC.

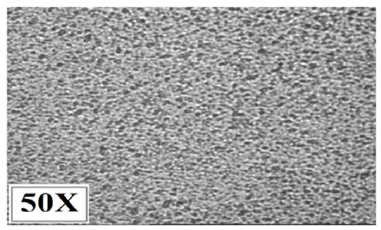

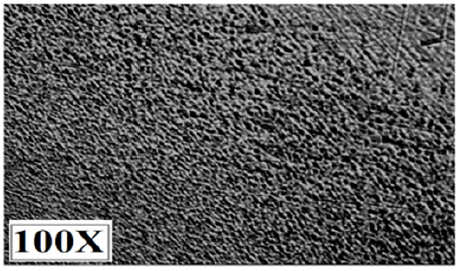

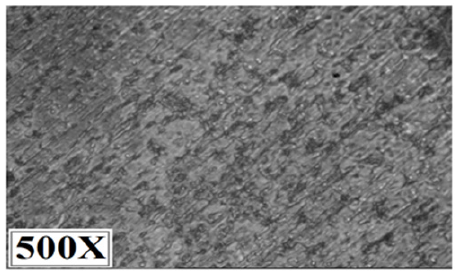

The micrographs of specimens deformed at a temperature of 100 ℃ and strain rate 0.05s-1 and a temperature of 100 ℃ and strain rate 0.1s-1 shown in Figure 7 & 8, which exhibit crystal microstructure and globularization of the colony structure. The machined surface exhibits discharge craters of various diameters generated [11]. These micrographs clearly reveal the primary 𝛼 grain size produced after globularization and it is observed that the amount of the globularization increases with increasing strain rate. The micrographs of specimens deformed at a temperature of 500 ℃ and strain rate 0.05s-1, temperature of 500 ℃ and strain rate 0.1s-1 is shown in Figure 9 & 10, which exhibits flow dynamic recovery microstructure and localization bands. The intensity of these bands is found to decrease with increasing temperature and decreasing strain rate. Their formation may be attributed to the adiabatic condition created during deformation and low thermal conductivity of Ti-6Al-4V.

Figure 7:Crystal micro structure. deformed at 100OC and strain rate 0.05s-1

Figure 8:Globularization microstructure deformed at 100OC and strain rate 0.1s-1.

Figure 9:Dynamic recovery microstructure deformed at 500OC and strain rate 0.05s-1.

Figure 10:Flow localization microstructure deformed at 500OC and strain rate 0.1s-1.

The heat generated during deformation is not conducted away due to insufficient time, which reduces the flow stress locally and causes flow localization. Machined surface produced irregular topography and defects including globules of debris and spherical particle [12]. Micrographs of specimens deformed at a temperature of 500 ℃ and strain rate 0.1s-1 is shown in Figure 9, which shows dynamic recovery. The process that occurs during dynamic recovery is the diffusion of the rate controlling atomic species. The dynamically recovered microstructure has well defined sub grains with relatively dislocation free interiors. Dynamic recovery causes work hardening of the material, the rate of which is lower than that obtained in cold working.

Conclusion

1. The hot deformation behavior of titanium (Ti-6Al-4V)

alloy has been studied through hot compression tests at different

temperatures and strain rates.

2. Low temperature the strain hardening is more, and as the

temperature increases strain hardening decreases.

3. Flow curves have been developed in the strain rate ranges

of 0.01s-1 to 1.0s-1 and a temperature range of 25oC to 500oC.

4. The micro structural analysis has also been carried out

and the results reported.

Acknowledgement

The authors are very grateful to the Department of Manufacturing Engineering, Annamalai University, Chidambaram, India for providing permission to carry out the experiments and to the Department of Mechanical Engineering, Mahendra Engineering College, India for providing the facilities for smooth conduction of this research work.

References

- Gunawarman B, Niinomi M, Akahori T, Takeda J, Toda H (2005) Mechanical properties of Ti-4.5Al-3V-2Mo-2Fe and possibility for healthcare applications. Mat Sci Engg 25(3): 296-303.

- Wanjara P, Jahazi M, Monajati H, Yue S (2006) Influence of thermomechanical processing on microstructural evolution in near-α Mat Sci Engg 416(5): 300-311.

- Liu ZG, Li PJ, Xiong LT, Liu TY, He LJ (2017) High-temperature tensile deformation behavior and microstructure evolution of Ti-55 titanium alloy. Mat Sci Engg 680(8): 259-269.

- Jingqi Z, Hongshuang D, Hongtao W, Kun M, Tianjun M, et al. (2012) Hot deformation behavior of Ti-15-3 titanium alloy: A study using processing maps, activation energy map, and Zener-Hollomon parameter map. Mat Sci Engg 47: 4000-4011.

- Amir HS, Maryam M, Seyed MA (2018) Hot torsion behavior of SP-700 near beta titanium alloy in single and dual phase regions. Inter J Mat Res 109: 1136-1145.

- Lin YH, Wu SM, Kao FH, Wang SH, Yang JR, et al. (2011) Comparative study of the microstructure of Ti-6Al-4V titanium alloy. Mat Sci Engg 528: 2271-2276.

- Li LX, Rao KP, Lou Y, Peng DS (2002) A study on hot extrusion of Ti-6Al-4V using simulations and experiments. Inter J Mech Sci 44(12): 2415-2425.

- Fengyong W, Wenchen X, Xueze J, Xunmao Z, Xingjie W (2017) Study on hot deformation behavior and microstructure evolution of Ti55 high-temperature titanium alloy. Metals 7(8): 319-327.

- Fang B, Chen ZY, Chen ZQ, Liu JH, Wang QJ (2010) Continuous cooling transformation diagram and microstructure evolution of Ti-55 alloy. Chi J Nonferrous Met 20: 319-327.

- Boopathi R, Thanigaivelan R, Prabu M (2018) Effects of process parameters on MRR, EWR and Ra in nanoparticles mixed EDM. Res & Develop Mat Sci 4(3): 01-03.

- Boopathi R, Sundaram S, Senthilkumar C, Prabu M (2017) Effect of machining characteristics of nano-TiC mixed dielectric fluids on Inconel 718 in the EDM process. Mat Test 59(04): 402-408 .

- Boopathi R, Sundaram S, Senthilkumar C, Prabu M (2018) Investigation on electrode vibration behavior of machining characteristics in nano-TiC mixed an EDM machining performance. J Balkan Tribological Asso 24(03): 363-380.

© 2022 Boopathi R. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)