- Submissions

Full Text

Research & Development in Material Science

Toward the Creation of the Asian xEV Battery Recycling Zone

So Sasaki1*, Yoshiaki Ishimoto2 and Hiromitsu Takagi3

1Faculty of Economics, Chuo University, Japan and Faculty of Economics, Chulalongkorn University, Thailand

2Toyota Daihatsu Engineering & Manufacturing Co., Ltd., Thailand

3Waste Management Siam Ltd., Thailand

*Corresponding author: So Sasaki, Faculty of Economics, Chuo University, Japan

Submission: February 21, 2022;Published: March 08, 2022

ISSN: 2576-8840 Volume 16 Issue 5

Abstract

There are many research papers on xEV battery recycling, but few on practice-based approaches. The practice case of recycling in Thailand showed that manufacturers could evaluate the quality of used batteries and sort them into rebuild, reuse, and recycle for efficient resource use. In particular, recycling xEV batteries has shown that CO2 emissions can be reduced to one-third by the current cases of pretreatment in Thailand and posttreatment in Japan. Furthermore, if it becomes possible to collect used batteries from neighboring countries and carry out smelting in Thailand in the future, it can be estimated that the current cases can be reduced to one-third. Finally, based on these results, policy implications are recommended.

Keywords: Nickel-Metal Hydride (NiMH) batteries; Lithium-Ion Battery (LIB); CO2 emissions; Life cycle management

Introduction

Under the green recovery program for post-pandemic, it has been announced that new vehicles with an internal combustion engine will be banned from sales in addition to other measures to promote the Electric Motor Vehicle (EMV) in many countries. The EMV is commonly referred to as a Hybrid Electric Vehicle (HEV), a Plug-In Hybrid Electric Vehicle (PHEV), an Electric Vehicle (EV), and a Fuel Cell Electric Vehicle (FCEV). In this study, they are referred to as the xEV. The core technologies of xEV are “batteries,” especially Nickel-Metal Hydride (NiMH) batteries and Lithium-Ion Battery (LIB).

Recently, there are many research papers on xEV battery recycling [1-8]. Brückner et al. [1] and Werner et al. [2] discussed the supply chain and technical over-view of recycling after collection. However, rare and expensive metals (e.g., Co, Li, and Ni) are being recovered with great interest; nonetheless, there still exist insufficient studies regarding electrolyte and anode materials (graphite) in end-of-life LIBs [3,4]. Kim et al. [5] focused exclusively on the pretreatment process for the first time. The pretreatment process enhances recovery efficiency and reduces energy consumption. There are also some studies on the possibility of recovery. Mo [6] also analyzed the impact of LIB recycling policy on material prices, which is economically beneficial because valuable battery materials can be collected in the process of recycling. By substituting virgin materials with recycled materials, the total pack cost can be reduced by up to 30% [7]. In another study, it was estimated that approximately 65% of the cobalt necessary to satisfy vehicle demand in the United States could be achieved by LIB re-cycling [8]. The important point here is that they assumed that the collection would be carried out. Therefore, several papers have highlighted the challenges and the importance of collection.

Xu et al. [9] mentioned that Closed-loop recycling will play a minor but increasingly important role for reducing primary material demand until 2050; however, advances in recycling are necessary to economically recover battery-grade materials from end-of-life batteries. Qiao et al. [10] also concluded that the recovered lithium could meet 60% of the lithium demand for LIBs produced by 2050, and it is necessary to develop the closed-loop recycling of lithium vigorously in China.

As pointed out in Chinese papers, the Chinese government has announced policies and regulations on battery recycling. In particular, in February 2018, the “Tentative Law for the Recycling Management of NEV Drive Batteries” was announced, and it became obligatory to inform the authorities of the distribution route information of drive batteries to each business operator such as battery manufacturers and automobile manufacturers [11]. Furthermore, in November 2019, guidelines for the establishment and operation of bases for the collection of end-of-life NEV batteries were published [12]. In addition to some policies and regulations on battery recycling, the Ministry of Commerce, the Ministry of Public Security, and the State Administration of Taxation issued a notice that accelerated and promoted the registration of small and ultra-small non-commercial used cars across provinces, and also accelerated the formation of a unified nationwide market by improving the convenience of used car transactions [13].

Of course, reports other than those from China also point out the issue of collection. Yun et al. [14] estimated that in 2020, there were 250,000 tons of LIB waste and no infrastructure to match up its collection and recycling. Harper et al. [15] reported the environmental and economic advantages of second use and concluded that the low volume of electric-vehicle batteries currently available for recycling could stifle the development of a recycling industry in some places. The report by Beaudet et al. [16] is a good review paper that sorts out issues by recycling the supply chain and pointing out issues in particular about collection.

Melin [17] analyzed the areas in which peer-reviewed papers were concentrated and indicated that it takes a longer time for the batteries to reach recycling and that they are exported to a greater extent than other batteries for reuse purposes, and only a few studies in China, Japan, and the United States have focused on how batteries reach re-cycling. The imminent arrival of EVs into the waste stream requires planning for their disposal and the associated infrastructure [18].

The report by Malinauskaite et al. [19] is one of the few good papers in this field that summarizes the relationship between technology and the legal system. The authors pointed out that vehicle manufacturers and importers, among other things, are required to establish collection networks to take back their vehicles free of charge at end-of-life. Neubauer [20] also presented a cost analysis to evaluate the potential im-pact of the EOL battery value on the price of EVs, resulting in an 11% maximum potential reduction in the initial battery price when a considerable secondhand market demand exists at the time of retirement.

However, few previous studies have mentioned the distribution of used cars. Wang and Yu’s research is very valuable for exporting or trading used xEVs in Japan, Mongolia, and China. Wang et al. [21] estimated that there will be a huge amount of end-of-life HEVs as well as NiMH batteries generated in Mongolia, even more than in Japan, which has the largest HEV market. Wang [22] said that because of the flow of second-hand vehicles from economically developed cities to less economically developed cities, only 400,000 EoL EVs and 3.4 million waste LiBs will be recycled through the formal recycling route in China. Moreover, Wang [23] pointed out that it was essential to improve the collection rate of waste LiBs to establish an efficient waste LiB industry in China. Wang et al. [24], by using scenario analysis on the secondhand HEV exportation and components’ flow was further performed, and the effect of secondhand HEV and components’ exportation was discussed. The result shows that only 0.11 mil-lion waste HEVs will be recycled in Japan in 2030.

Regarding used car distribution in the EU, Bhari et al. [25] also found that vehicles with unknown whereabouts were significantly higher in the EU, while the used vehicle export fraction was significantly higher in Japan. Unknown whereabouts refer to deregistered vehicles without any proof of destruction or export [26]. Fallah et al. [27] published a rare paper that incorporates the distribution volume of the used car market imported into Ireland into an estimation model of end-of-life xEVs Battery Stock Esti-mation. Their results confirmed the significant influence of government policies on the EV adoption profile.

As revealed in the literature review, in order to consider a realistic xEV battery recycling model with practice-based approaches, used car distribution and its collection must be considered.

Case Presentation

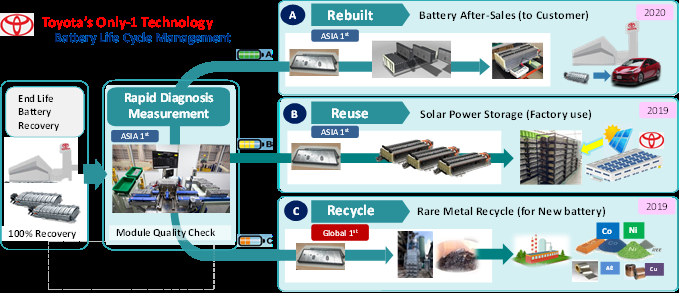

Here, we introduce an outline of advanced re-cycling cases in Thailand from the perspective of practice-based approaches and verify their effects. Toyota Motor Thailand (TMT) has established a battery lifecycle management system, which is the first outside of Japan. In Thailand, approximately 8,000 HEV batteries are replaced annually at their dealer shops. These batteries are then collected and transported to the warehouse and checked for quality using rapid diagnosis systems. These systems can be classified into three grades within five minutes. Grade A has become a rebuilt battery operated by Denso since 2020, Grade B is reused as a storage battery that is used by TMT, and Grade C is recycled by Toyota Tsusho since 2019 as shown in Figure 1.

Figure 1: Battery life cycle management system by Toyota motor Thailand.

The recycling process is pretreated at Waste Management Siam (WMS). WMS has owned and operated an incinerator for industrial waste since 2006 and added a fixed-bed furnace for xEV battery recycling. Their fixed bed furnace has a capacity of 4.2 ton/day. The reason for selecting the incineration process is that other processes have some risk of electric shock or fire in discharging/dismantling. The incineration process can resolve these problems in the postprocess, fewer processes that mean more efficient recycling, and prevent unauthorized resale or reuse, which can protect confidentiality. The disadvantages of the incineration process include the requirements for air pollution control equipment and ash treatment, which are costly. The cost of the air pollution prevention equipment has not increased because the existing equipment is shared.

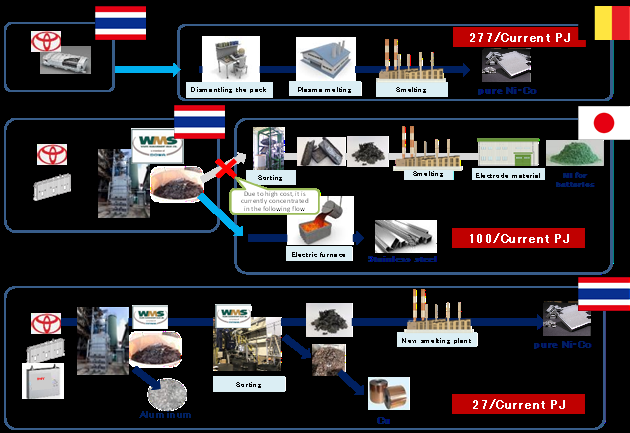

Figure 2: The current, past, and future recycling flows from the perspective of Life Cycle CO2 (LCCO2).

WMS has primarily processed NiMH batteries in Thailand, and then exported to Japan for smelting and using as recycled materials for new batteries. This post-process in Japan is expensive. Therefore, these are currently being changed to the process of making stainless steel using an electric furnace. We evaluated the current, past, and future recycling flows from the perspective of life cycle CO2, if the amount of CO2 emissions generated in the current project is 100, the past project that collected NiMH batteries in Thailand and exported to Belgium for recycling generated approximately 277 more CO2 emissions. It is estimated that CO2 emissions can be suppressed to up to 27, if batteries are collected from neighboring countries making integrated recycling, including the process of smelting in Thailand, which is a possibility in the future, as shown in Figure 2.

There are two reasons for collecting data from neighboring countries such as Cambodia, Laos, and Myanmar. The first is that Thailand alone lacks recycled materials that will be exported as used xEVs to be neighboring countries. Second, neighboring countries have already imported used xEVs from the USA, Japan, and so on; however, they do not have recycling facilities for batteries. It should be emphasized here that this future recycling flow will have the lowest estimated CO2 emissions and will also be an important strategy in the raw material procurement of the xEV strategy aimed by the Thai government.

Discussion

The practice case of recycling in Thailand showed that manufacturers could evaluate the quality of used batteries and sort them into rebuild, reuse, and recycle for efficient resource use. In particular, recycling xEV batteries showed that CO2 emissions can be reduced to one-third by making the past cases exported to Belgium into the current cases of pretreatment in Thailand and posttreatment in Japan. Furthermore, if it becomes possible to collect used batteries from neighboring countries and carry out smelting in Thailand in the future, it can be estimated that the current cases can be reduced to one-third. To achieve this, the statistics on scrapped cars have not yet been developed in many Asian countries, and it is necessary to estimate the material flow analysis that includes used car trade. And also, there are some policy challenges regarding the handling of used and waste xEV batteries due to the banning of E-waste imports by the Thai government, which has resulted in the loss of business opportunities for companies with legal import permits [28]. The Thai government should reconsider the ban and allow imports of used and waste xEV batteries under the Basel Convention procedure to promote resource security in Thailand and efficient resource circulation in Southeast Asia.

In the material flow survey, which points out the issues of collection End-of-life vehicles and end-of-life LIB [9-27], it is indispensable to grasp the trade of used cars, and it is the most effective response to promote the introduction of the Harmonized System code of used cars of xEVs in Asian countries as well as Japan and Europe, and it should be considered immediately. In the near future, battery resource circulation will be the main issue in the promotion of xEVs due to critical materials such as cobalt, nickel, and lithium. In Asian countries where there is no strategic resource circulation between nations, the establishment of an Asian Battery Alliance similar to the European Battery Alliance, measures to mitigate cross-border movement of battery recycling resources, and manufacturerled cross-border extended producer responsibility to collect batteries from exported used xEVs will be crucial steps in achieving the xEV strategy. Currently, there are xEV strategies and measures to attract foreign-affiliated companies in each Asian country. Instead, Asian Battery Alliance will be required to coordinate interests across Asian countries and support xEV battery recycling facilities.

Acknowledgement

This research was supported by JSPS KAKENHI Grant Numbers 19H01385 and 20KK0299

Conflicts of Interest

The views and opinions expressed herein are those of the author and do not necessarily reflect the views of their institution. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Brückner L, Frank J, Elwert T (2020) Industrial recycling of lithium-ion batteries-A critical review of metallurgical process routes. Metals 10: 1107.

- Werner D, Peuker UA, Mütze T (2020) Recycling chain for spent lithium-ion batteries. Metals 10: 316.

- Faiza Arshad F, Li L, Amin K, Fan E, Manurkar N, et al. (2020) A comprehensive review of the advancement in recycling the anode and electrolyte from spent lithium-ion batteries. ACS Sustainable Chem Eng 8: 13527–13554.

- Natarajan S, Aravindan V (2020) An urgent call to spent lib recycling: Whys and wherefores for graphite recovery. Adv. Energy Mater 10(37).

- Kim S, Bang J, Yoo J, Shin Y, Bae J, et al. (2021) A comprehensive review on the pretreatment process in lithium-ion battery recycling. J Clean Prod 294.

- Mo JY, Jeon W (2018) The impact of electric vehicle demand and battery recycling on price dynamics of lithium-ion battery cathode materials: A Vector Error Correction Model (VECM) Analysis. Sustainability 10: 2870.

- Mayyas A, Steward D, Mann M (2019) The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain Mater Technol 19: e00087.

- Mann M (2019) Battery recycling supply chain analysis. In Proceedings of the DOE Vehicle Technologies Program 2019 Annual Merit Review and Peer Evaluation Meeting, Arlington, VA, USA, pp. 10-13.

- Xu C, Dai Q, Gaines L, Hu M, Tukker A, Steubing B (2020) Future material demand for automotive lithium-based batteries. Commun Mater 1.

- Qiao D, Wang G, Gao T, Wen B, Dai T (2021) Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010-2050. Sci Total Environ 764.

- Ministry of Industry and Information Technology, Ministry of Science and Technology, Ministry of Environmental Protection, Ministry of Transport, Ministry of Commerce, General Administration of Quality Supervision, Inspection and Quarantine, and Bureau of Energy, “Tentative Law for the Recycling Management of NEV Drive Batteries”.

- Ministry of Industry and Information Technology, “New energy vehicle waste power battery comprehensive utilization industry specification conditions (2019 this)”, and “New energy vehicle waste power battery comprehensive utilization industry standard announcement management interim measures (2019 this)”.

- Ministry of Commerce, Ministry of Public Security, and State Administration of Taxation, “Promotion of Registration of Transactions Between Used Car Provinces and Improvement of Convenience of Foreign Land Transactions for Used Vehicles".

- Yun L, Linh D, Shui L, Peng X, Garg A, et al. (2018) Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour Conserv Recycl 136: 198-208.

- Harper G, Sommerville R, Kendrick E, Driscoll L, Slater P, et al. (2019) Recycling lithium-ion batteries from electric vehicles. Nature 575: 75-86.

- Beaudet A, Larouche F, Amouzegar K, Bouchard P, Zaghib K (2020) Key challenges and opportunities for recycling electric vehicle battery materials. Sustainability

- Melin HE (2019) State-of-the-Art in reuse and recycling of lithium-ion batteries-A Research Review. Report Commissioned by The Swedish Energy Agency.

- Baars J, Domenech T, Bleischwitz R, Melin HE, Heidrich O (2021) Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat Sustain 4: 71-79.

- Malinauskaite J, Anguilano L, Rivera XS (2021) Circular waste management of electric vehicle batteries: Legal and technical perspectives from the EU and the UK post Brexit. Int J Thermofluids 10: 100078.

- Neubauer J, Pesaran A (2011) The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J Power Sources 196: 10351-10358.

- Wang S, Yu J, Okubo K (2019) Scenario analysis on the generation of end-of-life hybrid vehicle in developing countries—focusing on the exported secondhand hybrid vehicle from Japan to Mongolia. Recycling 4: 41.

- Wang S, Yu J (2020) Evaluating the electric vehicle popularization trend in China after 2020 and its challenges in the recycling industry. Waste Manag Res 39(6): 818-827.

- Wang S, Yu J (2020) A comparative life cycle assessment on lithium-ion battery: Case study on electric vehicle battery in China considering battery evolution. Waste Manag Res 39(1): 156-164.

- Wang S, Yu J, Okubo K (2020) Estimation of end-of-life hybrid vehicle number in Japan considering secondhand vehicle exportation. Waste Manage 104: 198-206.

- Bhari B, Yano J, Sakai S (2021) Comparison of end-of-life vehicle material flows for reuse, material recycling, and energy recovery between Japan and the European Union. J Mater Cycles Waste Manag 23: 644-663.

- Oeko-Institut eV (2017) Assessment of the implementation of Directive 2000/53/EU on end-of-life vehicles (the ELV Directive) with emphasis on the end-of-life vehicles of unknown whereabouts.

- Fallah N, Fitzpatrick C, Killian S, Johnson M (2021) End-of-life electric vehicle battery stock estimation in Ireland through integrated energy and circular economy modelling. Resour Conserv Recycl 174: 105753.

- Sasaki S (2021) The effects on Thailand of China's import restrictions on waste: measures and challenges related to the international recycling of waste plastic and e-waste. J Mater Cycles Waste Manag 23: 77-83.

© 2022 So Sasaki. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)