- Submissions

Full Text

Research & Development in Material Science

Development of Innovative Materials and Measurement Systems used for Radiation Environment

Eiichi Wakai1*, Yosuke Iwamoto1, Tamaki Shibayama2, Koichi Sato3, Kodai Toyota1, Takashi Onizawa1, Takashi Wakui1, Taku Ishida4, Shunsuke Makimura4, Yuki Nakagawa2 and Hiroyuki Noto5

1J-PARC Center, Japan Atomic Energy Agency, Japan

2Hokkaido University, Japan

3Kagoshima University, Japan

4J-PARC Center, KEK, Japan

5NIFS, Japan

*Corresponding author: Eiichi Wakai, Division of Materials and Life Science Experimental Facility, Japan Proton Accelerator Research Complex (J-PARC) center, Japan Atomic Energy Agency (JAEA), Tokai-mura, Naka-gun, Ibaraki 319-1195, Japan

Submission: February 09, 2022;Published: February 15, 2022

ISSN: 2576-8840 Volume 16 Issue 4

Abstract

In fields such as energy, nuclear power, space environment, radiation medicine, and nuclear fusion, radiation degrades materials and devices, so it is expected to develop materials with high durability and excellent functionality. In this study materials developing and the designing are mainly reviewed. It has been found that the number of defective clusters (nano-size) formed in materials by radiation above room temperature does not exceed an order of 1023m-3, and materials with high number density nanoclusters or with nano- or sub-nano- structures before irradiation are expected to exhibit high irradiation resistance. On the other hand, High-Entropy (HE) alloys, which have recently attracted much attention, have been found to have both high strength and excellent ductility, and high irradiation resistance has been reported in these alloys, presumably due to lattice distortions that can significantly affect the diffusion process of point defects. In order to gain a better understanding of the phenomena in such complex materials, it is important to develop various sophisticated measurement methods and theoretical analysis methods. In particular, it is important to improve measurement methods such as electrical resistance measurement and positron annihilation lifetime measurement, which use the fundamental properties of elementary particles, in order to measure changes at a level smaller than the nano range. In addition, it is important to develop a new measurement system that can measure changes in the nano- and micro-defect state inside such materials even under radiation, and we also introduce a challenging attempt

Keywords: Electrical resistance; Positron annihilation lifetime; Radiation; Nanocluster; High entropy alloy; Irradiation damage; Ti alloy; W; Strength; Ductility; Innovative materials

Introduction

Research and development of innovative materials is being promoted in various fields to counter global warming and energy. In the fields of energy, nuclear power, space environment, radiation medicine, nuclear fusion, and accelerator-related equipment, radiation degradation of materials and equipment occurs, and various methods such as processing heat treatment, impurity addition, alloying, micro-crystallization, nano-clusters, Oxide Dispersive Strength (ODS) steels, composites, and nano-fiber materials [1-23] have been used to improve mechanical properties, corrosion resistance and irradiation resistance, and these techniques have produced successful results. Historical rate of improvement in the maximum operating temperature for four generations of structural steels, based on results, is summarized by Viswanathan [23]. A key strategy for designing high-performance radiation-resistant materials in many cases is based on the introduction of a high, uniform density of nanoscale particles that simultaneously provide good high temperature strength and radiation damage resistance.

While, as an innovative material, high-entropy alloys (HEAs) are known for their high strength and ductility and are expected to be used in a variety of applications. HE alloys, which are currently being developed all over the world, are mixtures of five or more elements, and since there is no state diagram, alloy design is difficult. However, due to the difference in atomic size, the crystal lattice is expected to be distorted at the atomic level compared to the normal case. In addition, due to the complexity of the structure, the conventional mechanism of formation and damage of irradiation defects cannot be fully explained. As a challenging recent study, a group at Los Alamos National Laboratory in the U.S. found that a new type of material called high-entropy (HE) W alloy (composed of W, Ta, V, and Cr, which are low-activation elements) has high irradiation resistance by using a magnetic sputtering deposition method that can control the grain size to submicron and controlling the substrate temperature and it was found to have high irradiation resistance [24]. Not satisfied with the conventional materials developed so far, including iron-based alloys, challenging researches with even higher strength and ductility are being investigated by advanced institutions around the world, using the properties of high-entropy alloys and further improving them by introducing such as intermetallic compounds [25-29].

Recent Activities and Discussion

On the other hand, the defect clusters formed by irradiation have not been found to exceed the order of 1023m-3 above room temperature [30-34]. This suggests that high-density nanoclusters, or materials with properties similar to those of nanoclusters before irradiation, may exhibit high irradiation resistance. Materials such as titanium and zirconium alloys, in which high-density nanoclusters can be controlled by a simple heat treatment method, are expected to have high strength, high ductility, and high corrosion resistance, and are expected to be applied in various ways in the future. Recently, it has been shown that metastable β-Ti alloys with a body-centered cubic lattice structure have high-density nanoclusters before and after irradiation, which act as sink sites for interstitial atoms and vacancies bounced away from their lattice positions induced by collisions with high-energy particles and have high irradiation resistance [5]. Based on these two findings, we can expect to create new special materials that contain dispersive nano particles with very high number density or ultra-fine microstructure or nanocomposite structures with revolutionary irradiation resistance.

However, previous studies have shown that existing irradiation damage models cannot be applied to these materials with complex internal structures, and in order to identify very small (sub-nano to nm order) irradiation defects formed in the materials, new measurement systems beyond the three-dimensional atom probe (APT) method and high-resolution scanning electron microscopy (including High Z-contrast, atomic weight) have been found to be necessary to identify very small (sub-nano to nm order) irradiation defects in materials. Non-destructive measurement methods utilized with developed Surface Acoustic Wave (SAW) technique [35,36] and a magnetic flux density measurement system [37] were examined in the irradiated specimens and the relation between these measurement results and irradiation hardening. Nanoindentation techniques for examination of irradiation hardening behavior were also evaluated in ion irradiation experiment [38].

Figure 1: Features of the multi-type simultaneous measurement system to be developed in this research.

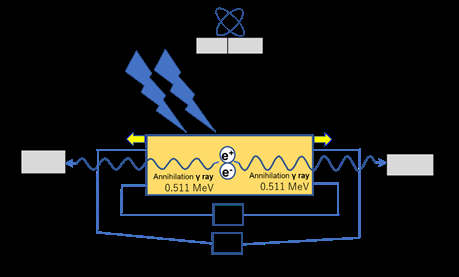

The positron annihilation method and the electrical resistance measurement method are uniquely useful measurement methods because they can nondestructively detect the type and amount of atomic-level lattice defects that cannot be seen even with a highresolution electron microscope. In the conventional positron apparatus (γ-γ coincidence measurement method) [39,40], simultaneous measurement with the electrical resistance method [41,42] was difficult. However, in recent years, the development of the simultaneous β+-γ measurement method using Avalanche Photodiode Detector (APD) has progressed [43,44], enabling a variety of applications, including in the nuclear and medical fields. In addition to that Thus, we are now developing a multi-type simultaneous measurement system that combines positron lifetime measurement, electrical resistance measurement, and stress load measurement as a new method to measure irradiation defects in advanced new materials with such complex structures (Figure 1 & 2). The PHITS code [45,46], which simulates the radiation behavior of all kinds of materials, can be used to advance the basic theory of irradiation damage by incorporating the defect formation rates of complex materials obtained by MD simulation [47-49]. The combination of the multi-type simultaneous measurement system and the PHITS analysis method is expected to rapidly advance the understanding and application of materials science and engineering in a wide range of fields related to the radiation environment.

Figure 2: Principle of the multi-type simultaneous measurement system being developed in this research.

Conclusion

Research and development of innovative materials is being promoted in various fields to counter global warming and energy. In the fields of energy, nuclear power, space environment, radiation medicine, nuclear fusion, and accelerator-related equipment, radiation degradation of materials and equipment occurs, and various methods such as processing heat treatment, impurity addition, alloying, micro-crystallization, nano-clusters, Oxide Dispersive Strength (ODS) steels, composites, and nano-fiber materials have been used to improve mechanical properties, corrosion resistance and irradiation resistance, and these techniques have produced successful results. Recently, high-entropy alloys and their composites have been attracting attention as materials that have both excellent strength and ductility, and their research and development is progressing rapidly. In the development and prompt evaluation of such advanced materials, the role of new and better state-of-the-art analysis and analytical equipment is of primary importance. Thus, we are now developing a multi-type simultaneous measurement system that combines positron lifetime measurement, electrical resistance measurement, and stress load measurement as a new method to measure irradiation defects in advanced new materials with such complex structures.

The combination of the multi-type simultaneous measurement system and the PHITS analysis method is expected to rapidly advance the understanding and application of materials science and engineering in a wide range of fields related to the radiation environment.

Acknowledgment

This work was supported by JSPS Grants-in-Aid for Scientific Research 21H04668, 19H02652, and 21H04480, and a collaborative research program of National Institute for Fusion Science. A part of this work was also conducted at the Hokkaido University as a program of “Nanotechnology Platform” of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan, Grant Number JPMXP09A21HK0074.

Conflict of Interest

The authors declare no conflict of interest.

References

- Ozturk F, Bas O, Ates E (2021) Thermoplastic composite materials for the aerospace industry. Research & Development in Material Science 15: 1745-1748.

- Silva PM, Serna MM, Galego E, Faria RN (2021) The influence of the nanostructures on the dye adsorption in dye sensitized solar cell. Research & Development in Material science 15(2): 1680-1684.

- Wakai E, Taguchi T, Yamamoto T, Tomita H, Takada F, et al. (2005) Effects of helium production and heat treatment on neutron irradiation hardening of F82H steels irradiated with neutrons. Materials Transactions 46(3): 481-486.

- Ishida T, Wakai E, Makimura S, Hurh PG, Ammigan K, et al. (2020) Radiation Damage Studies on Titanium Alloys as High Intensity Proton Accelerator Beam Window Materials. JPS Conference Proceedings 28: 041001.

- Ishida T, Wakai E, Hagiwara M, Makimura S, Tada M, et al. (2018) Study of the radiation damage effect on Titanium metastable beta alloy by high intensity proton beam. Nuclear Materials and Energy 15: 169-174.

- Sato K, Wakai E, Makimura S, Saito S, Ishida T, et al. (2020) Introduction to the proceedings. Proceedings of 14th international workshop spallation materials technology. JPS Conference Proceedings 28: 021001.

- Wakai E, Hishinuma A, Usami K, Kato Y, Takaki S, et al. (2000) Damage structures and mechanical properties of high-purity Fe-9Cr alloys irradiated by neutrons. Materials Transactions, JIM 41(9): 1180-1183.

- Wakai E, Ando M, Okubo N (2015) Effects of heat treatments and addition of minor elements of boron and nitrogen on mechanical properties and microstructures of reduced-activation ferritic/martensitic steel. Journal of Plasma and Fusion Research SERIES 11: 104-112.

- Okubo N, Wakai E, Matsukawa S, Sawai T, Kitazawa S, et al. (2007) Effects of heat treatment and irradiation on mechanical properties in F82H steel doped with boron and nitrogen. Journal of Nuclear Materials 367-370: 107-111.

- Chauhan A, Litvinov D, Carlan, Y, Aktaa J (2016) Study of the deformation and damage mechanisms of a 9Cr-ODS steel: Microstructure evolution and fracture characteristics. Materials Science and Engineering 658: 123-134.

- Brocq ML, Legendre FL, Mathon MH, Mascaro A, Poissonnet S, et al. (2012) Influence of ball-milling and annealing conditions on nanocluster characteristics in oxide dispersion strengthened steels. Acta Materialia 60(20): 7150-7159.

- Klueh RL, Shingledecker JP, Swindeman RW, Hoelzer DT (2005) Oxide dispersion-strengthened steels: A comparison of some commercial and experimental alloys. Journal of Nuclear Materials 341(2-3): 103-114.

- Zinkle SJ, Busby JT (2009) Structural materials for fission & fusion energy. Materialstoday 12(11): 12-19.

- Moriyama T, Yoshimi K, Zhao M, Masnou T, Yokoyama T, et al. (2017) Room-temperature fracture toughness of MoSiBTiC alloys. Intermetallics 84: 92-102.

- Taguchi T, Igawa N, Miwa S, Wakai E, Jitsukawa S, et al. (2004) Synergistic effects of implanted helium and hydrogen and the effect of irradiation temperature on the microstructure of SiC/SiC composites. Journal of Nuclear Materials 335(3): 508-514.

- Snead LL, Nozawa T, Katoh Y, Byun TS, Kondo S, et al. (2007) Handbook of SiC properties for fuel performance modeling. Journal of Nuclear Materials 371(1-3): 329-377.

- El-Atwani O, Nathaniel JE, Leff AC, Hattar K, Taheri ML (2017) Direct observation of sink-dependent defect evolution in nanocrystalline ion under irradiation. Scientific Reports 7: 1836.

- Makimura S, Kurishita H, Niikura K, Jung H, Onoi M, et al. (2020) Tungsten alloy development as advanced target material for high-power proton accelerator. JPS Conference Proceedings 28: 031002.

- Noto H, Hishinuma Y, Muroga T, Benoki H (2020) Microstructure and mechanical properties of dispersion strengthened tungsten by HIP treatment followed by thermal annealing. Results in Materials 7: 100116.

- Nogami S, Hasegawa A, Fukada M, Rieth M, Reiser J, et al. (2021) Mechanical properties of tungsten: recent research on modified tungsten materials in Japan. Journal of Nuclear Materials 543: 152506.

- Teru T, Wakeda M, Suzudo T, Itakura M, Ogata S (2020) Anomalous solution softening by unique energy balance mediated by kink mechanism in tungsten-rhenium alloys. Journal of Applied Physics 127: 025101.

- Cui S, Cui C, Xie J, Liu S, Shi J (2018) Carbon fibers coated with graphene reinforced TiAl alloy composite with high strength and toughness. Scientific Reports 8: 2364.

- Viswanathan R (2004) Materials technology for coal fired power plants. Advanced Materials and Processes 162(8): 73-76.

- Atwani O, Li N, Li M, Devaraj A, Baldwin JKS, et al. (2019) Outstanding radiation resistance of tungsten-based high-entropy alloys. Sci Adv 5(3): eaav2002.

- Lu ZP, Wang H, Chen MW, Baker I, Yeh JW, et al. (2015) An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics 66: 67-76.

- Wang Z, Lu W, Zhao H, Liebscher CH, He J, et al. (2020) Ultrastrong lightweight compositionally complex steels via dual-precipitation. Science Advances 6(46): 9543.

- Yang MX, Yuan FP, Xie QG, Wang YD, Ma E, et al. (2016) Strain hardening in Fe-16Mn-10Al-0.86C-5Ni high specific strength steel. Acta Materialia 109: 213-222.

- Liu L, Yu Q, Wang Z, Ell J, Huang MX, et al. (2020) Making ultrastrong steel tough by grain-boundary delamination. Science 368(6497): 1347-1352.

- Fang Q, Peng J, Chen Y, Li L, Feng H, et al. (2021) Hardening behavior in the irradiated high entropy alloy. Mechanics of Materials 155: 103744.

- Kiritani M (1991) History, present states and future of the contribution of high-voltage electron microscopy to the study of radiation damage and defects in solids. Ultramicroscopy 39(1-4): 135-159.

- Wakai E, Miwa Y, Hashimoto N, Robertson JP, Klueh RL, et al. (2002) Microstructural study of irradiated isotopically tailored F82H steel. Journal of Nuclear. Materials 307-311: 203-211.

- Zhang W, Guo L, Shen Z, Xin J, Huang Q, et al. (2018) Evolution of dislocation loops induced by different hydrogen irradiation conditions in reduced-activation martensitic steel. Materials (Basel) 11(11): 2276.

- Hashimoto N , Wakai E , Robertson JP (1999) Damage structure in austenitic stainless steel 316LN irradiated at low temperature in the HFIR. Journal of Electron Microscopy 48(5): 575-580.

- Wakai E, Ezawa T, Imamura J, Takenaka T, Tanabe T, et al. (2002) Effect of solute atoms on swelling in Ni alloys and pure Ni under He+ ion irradiation. Journal of Nuclear Materials 307-311: 367-373.

- Kitazawa S, Wakai E, Aoto K (2016) Evaluation of annealing and double ion beam irradiation by a laser induced and laser-detected surface acoustic wave diagnostic system. Radiation Physics and Chemistry 127: 264-268.

- Kitazawa S, Chiba A, Wakai E (2015) Laser-induced surface acoustic waves and their detection via diagnostic systems for detecting radiation damage on steel materials. Nuclear Instrument and Methods in Physics Research A 786: 47-50.

- Takaya S, Nagae Y, Aoto K, Yamagata I, Ichikawa S, et al. (2009) Nondestructive evaluation of neutron irradiation damage on austenitic stainless steels by measurement of magnetic flux density. Proceedings of the 17th International Conference on Nuclear Engineering ICONE 17-75215: 371-374.

- Wakai E, Kitazawa S, Takaya S, Okubo N, Nagae Y, et al. (2018) Effects of helium production, displacement damage on mechanical properties and surface acoustic wave in austenitic stainless steels and martensitic steel. Nuclear Materials and Energy 17: 34-39.

- Wakai E, Nogami S, Hasegawa A, Okubo N, Takaya S, et al. (2021) Effects of helium production and displacement damage on microstructural evolution in helium-implanted austenitic stainless steel and martensitic steel examined mainly by TEM and positron annihilation lifetime measurement. Materials Science Forum 1024: 53-69.

- Sato K, Yoshiie T, Xu Q, Satoh Y, Wakai E, et al. (2005) Point Defect Formation in V-4Cr-4Ti and F82H Irradiated with Fission and Fusion Neutrons. Materials Transactions 46(3): 445-449.

- Iwamoto Y, Iwamoto H, Harada H, Niita K (2014) Calculation of displacement cross-section for structural materials in accelerators using PHITS event generator and its applications to radiation damage. Journal of Nuclear Science and Technology 51(1): 98-107.

- Iwamoto Y, Meigo S, Hashimoto S (2020) Estimation of reliable displacements-per-atom based on athermal-recombination-corrected model in radiation environments at nuclear fission, fusion, and accelerator facilities. Journal of Nuclear Materials Volume 538.

- Kawaguchi Y, Shirai Y (2002) Fatigue evaluation of type 316 stainless steel using positron annihilation lineshape analysis and β^+-γ coincidence positron lifetime measurement. Journal of Nuclear Science and Technology 39(10): 1033-1040.

- Osborne MD, Hobson PR, Watts SJ (2000) Numerical simulation of neutron radiation effects in avalanche photodiodes. IEEE Transactions on Electron Devices 47(3): 529-536.

- Sato T, Iwamoto Y, Hashimoto S, Ogawa T, Furuta T, et al. (2018) Features of Particle and Heavy Ion Transport code System (PHITS) version 3.02. Journal of Nuclear Science and Technology 55(6): 684-690.

- Iwamoto Y, Sato T, Hashimoto S, Ogawa T, Furuta T, et al. (2017) Benchmark study of the recent version of the PHITS code. Journal of Nuclear Science and Technology 54(5): 617-635.

- Wu J, Xu Z, Zhao J, Rommel M, Nordlund K, et al. (2021) MD simulation of two-temperature model in ion irradiation of 3C-SiC: Effects of electronic and nuclear stopping coupling, ion energy and crystal orientation. Journal of Nuclear Materials.

- Chu G, Li Y, Zhao R, Ren S, Yang W, et al. (2021) MD simulation of hundred-billion-metal-atom cascade collision in Sunway Taihuligh. Computer Physics Communications.

- Wakai E, Takaya S, Matsui Y, Nagae Y, Kato S, et al. (2021) Irradiation damages of structural materials under different irradiation environments. Journal of Nuclear Materials.

© 2022 Eiichi Wakai. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)