- Submissions

Full Text

Research & Development in Material Science

Study on Hydrodynamic Characteristics of Fluted Floating Garbage Collection Device

Zhou Ting1,2*, Nianqing Zhou1 and Simin Jiang1

1Department of Hydraulic Engineering, Tongji University, China

2Engineering, Nagoya Institute of Technology, Japan

*Corresponding author: Zhou Ting, Department of Hydraulic Engineering, Tongji University, China

Submission: February 25, 2020;Published: March 02, 2020

ISSN: 2576-8840 Volume 13 Issue 1

Abstract

Water environmental pollution caused by floating garbage in rivers is increasingly worse, and severely affects biodiversity, human health and ecosystems. According to the hydrodynamic characteristics, the riverbank structure can be set up reasonably, which can solve the problem of floating garbage with energy saving and high efficiency. Change the length of concave part and guide wall to explore the hydrodynamic characteristics. The microstructures generated in these hardened alloys have been assessed by proper techniques aiming at controlling and understanding the composition modification in the nanophasereinforced and nanophase-free hcp magnesium and hcp zirconium alloys. The experimental studies were employed to optimize the composition-processing-microstructure-strength property relationship of the nano-reinforced composite materials in terms of extended uniform strain concept. Under the data of internal friction to be carried out isothermally in the hcp Mg-Ba and hcp Be-Fe, C alloys the deviations from Cottrell-Bilby time law have been revealed due to the non-isothermal kinetics of nanoparticulate nucleation by a pre-precipitate (cluster-forming) mechanism. A series of hcp metal alloys in the Mg-Al- Ca and Zr-Nb-Sn systems discontinuously nano-reinforced by Zr3Al and ZrO2, respectively have been developed as crystalline nanophase materials with more excellent heat and creep resistance as well as higher long-term strength. The observations and findings suggest that the principles of nanophase strengthening should be considered as an effective means of obtaining desirable combinations of mechanical properties due to the nanoparticle-induced delaying of time-dependent shear localization.

Keywords: Hydrodynamic characteristics; Floating garbage; Collecting device; Simulation; Experiment

Introduction

In recent years, a large number of floating garbage carried by rivers have entered the ocean through estuaries, causing marine pollution as well as ecological and environmental problems. Many marine garbage is transported through waterbodies. Therefore, in order to reduce the amount of garbage entering the ocean, we need to pay attention to the collection and disposal of garbage into the sea channel, among which floating waste disposal is an urgent problem to be solved. The collection device designed in this paper can automatically collect garbage without adding external driving force [1]. The retaining plate in the device is used to change the flow state, and the flow is guided to drive the floating waste into the groove structure, so as to achieve the collection effect.

Experimental Procedure

The rectangular cross-section waterway with a length of 12m and a wide 60cm is used in the test model, and the gradient of the waterway is I = 1/1000. A PVC board with a width of 30cm and a height of 3cm is set on the left bank of the waterway, and the width of the main waterway is 30cm [2]. As shown in Figure 1, the recess is set at an upstream position of 3m. In addition, a capture metal mesh of length 30cm is also arranged downstream of the concave. The water depth is adjusted to 6cm at the downstream end.

Figure 1: Schematic diagram of floating garbage automatic collection device.

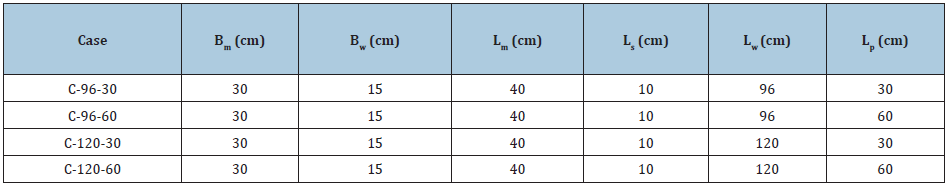

In order to show the change of surface flow direction more intuitively. Using talc powder as display agent, it is convenient to carry out visual flow velocity measurement by PIV (Particle Image Velocimetry) method. Take pictures with a digital camera at 1280×780 pixels and 30fps. The hydrodynamic conditions are described in Table 1. And the case setting as Table 2.

Table 1: Somatic diseases and concomitant OMD.

Table 2: Somatic diseases and concomitant OMD.

Results and Discussion

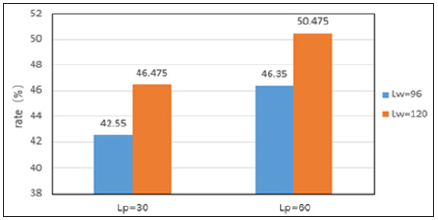

When setting up the test device, design with reference to the simulation results. In this laboratory test study, the two schemes of groove length of 0.96m and 1.2m were adopted. First, the length of the inner wall was controlled at 30cm for the experiment. The collection rates of 0.96m and 1.2m were 42.55% and 46.475%. Then, the length of the inner wall is controlled to the length of the 60cm for the same experiment [3]. The results show that the collection rate of 0.96m and 1.2m is 46.35% and 50.475% respectively. The comparison of garbage collection rates between the two scenarios is shown in Figure 2.

Figure 2: The garbage collection rate comparison chart.

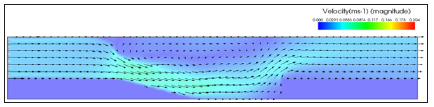

The model with the best collection rate is C-120-60, and its flow state is the focus of our attention. Figure 3 shows the flow chart obtained by processing the PIV experimental results. The velocity vector diagram of Figure 4 is obtained by numerical simulation with iric software, which is in good agreement with the experimental results.

Figure 3: Streamline chart of PIV case C-120-60.

Figure 4: Velocity vector simulation of case C-120- 60.

It can be seen that the collection structure has a great influence on the surface turbulence. At the entrance of the device, due to the small cross section, the flow velocity increases sharply [4], and is acted by the guiding wall, and most of the flow flows to the recess collecting tank. A small portion of the water flows out of the main channel.

Conclusion

In this study, in order to collect floating waste in the river, the appropriate size ratio of the test model is determined by numerical simulation method, and then the specific collection results are obtained according to the laboratory test research, and the test results are analyzed and compared. Through a series of experimental studies, the following main conclusions are drawn:

1) The flow direction can be adjusted by the river structure, and the floating garbage can be collected effectively by using the device designed by the riparian groove and baffle.

2) With the increase of the length of the inner wall of the device and the decrease of the angle of the inner wall, the capture rate shows an upward trend.

References

- Tominaga A, Horibe F, Sakaki T (2012) Restraining effects of sand deposition by shielding of entrance in an artificial embayment. Journal of Japan Society of Civil Engineers 67(4): 1057-1062.

- Jong J, Tominaga A (2012) Flow structure and sedimentation mechanism in the riverside embayment with various shape configuration. Journal of Japan Society of Civil Engineers 67(4): 1051-1056.

- Chi-Wai NG, Shu L, Xiaoxuan LU (2018) A plastic tide: mining floating plastic waste through landscape processes. Landscape Architecture Frontiers 6(4): 126-135.

- Vukić M, Institut KS, Beograd, Spruk U, Aluxom (2009) Vessels and floating boats waste water pollution monitoring system. Agricultural Engineering 2009(8): 62.

© 2020 Zhou Ting. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)