- Submissions

Full Text

Research & Development in Material Science

Structural Diagram of Electro Magneto Elastic Actuator Nano Displacement for Material Science

Afonin SM*

National Research University of Electronic Technology MIET, Moscow, Russia

*Corresponding author:Afonin SM, National Research University of Electronic Technology MIET, Moscow, Russia

Submission: June 24, 2019;Published: July 02, 2019

ISSN: 2576-8840 Volume11 Issue2

Abstract

For control system in the scanning tunneling microscope and the adaptive optics for nanotechnology and material science we drew structural-parametric model, the structural diagram and the matrix transfer function, the characteristics of the electro magneto elastic actuator for nano displacement. In this work, we have the generalized structural diagram, the generalized matrix transfer function of the electro magneto elastic actuator.

Keywords: Structural diagram; Structural-parametric model; Electro magneto elastic actuator; Piezo actuator; Matrix transfer function

Introduction

For nanotechnology and material science is promising for use mechatronics systems with electromechanical actuators based on electro magneto elasticity. The electro magneto elastic actuator nano displacement with the piezoelectric, piezomagnetic, electrostriction, magnetostriction effects is used in the control system in the scanning tunneling microscope, the atomic force microscope and the adaptive optics [1-30].

For control system of nanotechnology and material science we receive structural-parametric model, the structural diagram, the matrix transfer function and the characteristics of the electro magneto elastic actuator [9-29].

Structural diagram and matrix transfer function<

The method of the mathematical physics with Laplace transform we have to build the structural diagram of the electro magneto elastic actuator for nanotechnology and material science. The structural diagram of the electro magneto elastic actuator nano displacement for material science is difference from Cady and Mason electrical equivalent circuits [1-18].

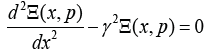

In the foundation the structural diagram actuator is used decision with Laplace transform the wave equation for the wave propagation in the long line with damping but without distortions. With Laplace transform the original problem for the partial differential equation of hyperbolic type using the Laplace transform is reduced to the simpler problem [8,13,14,18] for the linear ordinary differential equation

where Ξ(x, p) is the Laplace transform of the displacement of section of the actuator, γ = p/cΨ + α is the propagation coefficient, p is the parameter, cΨ is the sound speed for the control parameter Ψ = const, α is the damping coefficient.

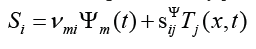

In general, the equation of the electro magneto elasticity [8,11] has the following form

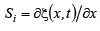

where  is the relative displacement along axis i of the cross-section of the actuator, t is the time, x is the coordinate,

is the relative displacement along axis i of the cross-section of the actuator, t is the time, x is the coordinate, is the control parameter, Em is the electric field strength for the voltage control along axis m, Dm is the electric induction for the current control along axis m, Hm for magnetic field strength control along axis m, Tj is the mechanical stress along axis j, Vmi is the electro magneto elastic coefficient, sijΨ is the elastic compliance for the control parameter, Ψ = const, i, j, m are the indexes.

is the control parameter, Em is the electric field strength for the voltage control along axis m, Dm is the electric induction for the current control along axis m, Hm for magnetic field strength control along axis m, Tj is the mechanical stress along axis j, Vmi is the electro magneto elastic coefficient, sijΨ is the elastic compliance for the control parameter, Ψ = const, i, j, m are the indexes.

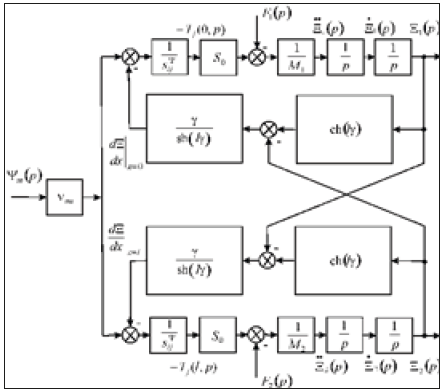

Figure 1:Generalized structural diagram of electro magneto elastic actuator.

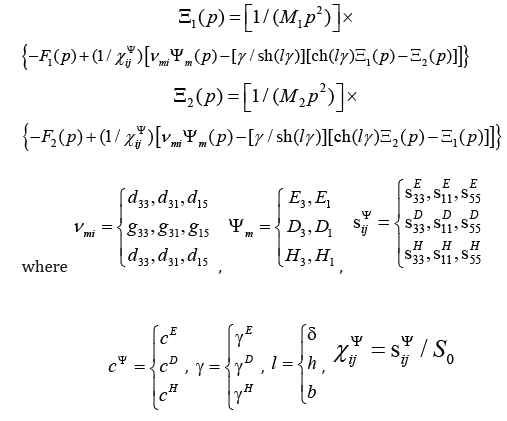

The generalized structural-parametric model and the generalized structural diagram [7,8,14] of the electro magneto elastic actuator for nano displacement on Figure 1 are obtained by the method of the mathematical physics with solution of the wave equation, the equation of the electro magneto elasticity, the boundary conditions in the form

Vmi is the electro magneto elastic coefficient, dmi is the piezo module at the voltage-controlled piezo actuator or the magnetostrictive coefficient for the magnetostrictive actuator, gmi is the piezo module at the current-controlled piezo actuator, sijΨ is the elastic compliance, S0 is the cross-section area, M1, M2 are the mass on two faces of the actuator, Ξ1(p), Ξ2 (p) and F1(p), F2(p)are the Laplace transforms of the displacements and the forces on two faces.

In this work, we have the working length l = δ, h, b for the piezo actuator in the form the thickness, the height and the width for the longitudinal, transverse and shift piezo effect.

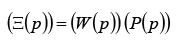

Let us consider the matrix transfer function of the electro magneto elastic actuator [8,18] obtained from the structural-parametric model in the form

where (Ξ(p)) is the matrix of the Laplace transforms of the displacements for the faces of the electro magneto elastic actuator, (W(p)) is the matrix transfer function,(P(p)) the matrix of the Laplace transforms of the control parameters.

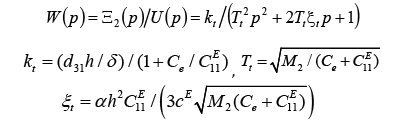

We receive the transfer function of the voltage-controlled transverse piezo actuator for the elastic-inertial load at  m<< M2, for the approximation the hyperbolic cotangent by two terms of the power series in the form

m<< M2, for the approximation the hyperbolic cotangent by two terms of the power series in the form

where U(p) is the Laplace transform of the voltage on the piezo actuator, are the transfer coefficient, the time constant and the damping coefficient of the piezo actuator.

are the transfer coefficient, the time constant and the damping coefficient of the piezo actuator.

For the transverse piezo actuator from piezo ceramics PZT with one fixed face and the elastic-inertial load at  m<< M2, for d31 = 2.5∙10-10m/V, h/δ =20, U=60 V, M2=1kg, C11E=2∙107N/m, Ce=0.5∙107N/m we obtain the steady-state value of displacement

m<< M2, for d31 = 2.5∙10-10m/V, h/δ =20, U=60 V, M2=1kg, C11E=2∙107N/m, Ce=0.5∙107N/m we obtain the steady-state value of displacement  =240nm, values the transfer coefficient kt=4 nm/V and the time constant of the piezo actuator Tt=0.2∙10-3s. The discrepancy between the experimental data and calculation results is 5%.

=240nm, values the transfer coefficient kt=4 nm/V and the time constant of the piezo actuator Tt=0.2∙10-3s. The discrepancy between the experimental data and calculation results is 5%.

The matrix transfer function of the electro magneto elastic actuator is calculated for control system of the deformation the electro magneto elastic actuator.

Conclusion

For nanotechnology and material science we obtain the generalized structural diagram of the electro magneto elastic actuator for nano displacement with the mechanical parameters the displacement and the force in the difference from Cady and Mason electrical equivalent circuits. From the structural diagram, the matrix transfer function of the electro magneto elastic actuator we have the dynamic and static characteristics of the actuator with regard to physical parameters and external load.

References

1. Schultz J, Ueda J, Asada H (2017) Cellular actuators. Butterworth-Heinemann Publisher, Oxford, UK, p. 382.

2. Afonin SM (2006) Absolute stability conditions for a system controlling the deformation of an elecromagnetoelastic transduser. Doklady mathematics 74(3): 943-948.

8. Afonin SM (2008) Structural parametric model of a piezoelectric nanodisplacement transduser. Doklady physics 53(3): 137-143.

10. Cady WG (1946) Piezoelectricity: An introduction to the theory and applications of electromechancial phenomena in crystals. McGraw-Hill Book Company, New York, London, UK, p. 806.

11. Mason W (1964) Physical acoustics: Principles and methods. Part A. Methods and devices. Academic Press, New York, USA, p. 515.

12. Zwillinger D (1989) Handbook of differential equations. Academic Press, Boston, USA, p. 673.

13. Afonin SM (2015) Structural-parametric model and transfer functions of electroelastic actuator for nano- and microdisplacement. Chapter 9 in Piezoelectrics and nanomaterials: Fundamentals, developments and applications. Parinov IA (Ed.), Nova Science, New York, USA, 1: 225-242.

14. Afonin SM (2017) A structural-parametric model of electroelastic actuator for nano- and microdisplacement of mechatronic system. Chapter 8 in Advances in nanotechnology. Bartul Z, Trenor J (Eds.), Nova Science, New York, USA, 19: 259-284.

15. Afonin SM (2012) Nano- and micro-scale piezomotors. Russian Engineering Research 32(7-8): 519-522.

16. Afonin SM (2007) Elastic compliances and mechanical and adjusting characteristics of composite piezoelectric transducers. Mechanics of solids 42(1): 43-49.

17. Afonin SM (2014) Stability of strain control systems of nano-and microdisplacement piezotransducers. Mechanics of solids 49(2): 196-207.

19. Afonin SM (2017) Structural-parametric model of piezoactuator nano- and microdisplacement for nanoscience. AASCIT journal of nanoscience 3(3): 12-18.

20. Afonin SM (2016) Solution wave equation and parametric structural schematic diagrams of electromagnetoelastic actuators nano- and microdisplacement. International Journal of Mathematical Analysis and Applications 3(4): 31-38.

21. Afonin SM (2018) Structural-parametric model of electromagnetoelastic actuator for nanomechanics. Actuators 7(1): 1-9.

23. Afonin SM (2017) Parametric block diagrams of a multi-layer piezoelectric transducer of nano- and microdisplacements under transverse piezoelectric effect. Mechanics of solids 52(1): 81-94.

24. Afonin SM (2018) Multilayer electromagnetoelastic actuator for robotics systems of nanotechnology. Proceedings of the 2018 IEEE Conference EIConRus, pp. 1698-1701.

25. Afonin SM (2018) Electromagnetoelastic nano- and microactuators for mechatronic systems. Russian Engineering Research 38(12): 938-944.

26. Afonin SM (2018) Structural-parametric model of electro elastic actuator for nanotechnology and biotechnology. Journal of Pharmacy and Pharmaceutics 5(1): 8-12.

29. Afonin SM (2018) Structural–parametric model electroelastic actuator nano– and microdisplacement of mechatronics systems for nanotechnology and ecology research. MOJ Ecology and Environmental Sciences 3(5): 306-309.

30. Bhushan B (2004) Springer Handbook of Nanotechnology. Springer, Berlin, New York, USA, p. 1222.

© 2019 Dayanand M Goudar . This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)