- Submissions

Full Text

Research & Development in Material Science

In-Situ Formation of WO3 Nanowires as Well as Tungsten Nanoparticles by Oxidation-Reduction Mechanism

Ahangarkani M*

Department of materials, Malek ashtar University of Technology, Tehran, Iran

*Corresponding author:Ahangarkani M, Department of materials, Malek ashtar University of Technology, Tehran, Iran

Submission: June 08, 2019;Published: June 11, 2019

ISSN: 2576-8840 Volume11 Issue1

Abstract

In this paper, an interesting approach for activating the solid-state sintering of tungsten powders was proposed. In this approach, WO3 nanowires were formed on tungsten particles by addition of sub-micron particles as required oxygen source in powder mixture. High oxygen content of sub-micron particles acts as required oxygen source in formation of WO3 nanowires. The microstructural studies exhibited that, reduction of WO3 nanowires in hydrogen atmosphere led to formation of tungsten nanoparticles during sintering which can activate solid state sintering of compact.

Keywords: Solid state sintering; WO3 nanowires; Tungsten nanoparticles

New Interesting Sintering Activation

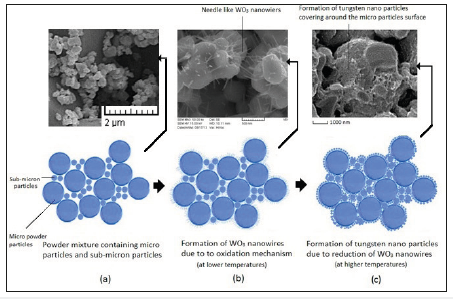

It is suggested in current paper that WO3 nanowires can be formed due to partial oxidation of tungsten particles and evaporation of resulted WO3 at high temperature during sintering. It led to formation of needle like WO3 nanowires with uniform distribution throughout compacts. These nanowires may be created based on nucleation and growth mechanism. By adequate controlling the thermal condition during sintering, linear growth of WO3 nucleus will be predominated and then, linear growth of nanowires occurred. Subsequently, by interaction between WO3 nanowires and hydrogen atmosphere, tungsten nanoparticles are formed on the micro-particles. Consequently, simple micro-particle powder mixture is replaced by a mixture containing uniformly distributed nanoparticles [1]. This in-situ formation of WO3 nanowires following by in-situ formation of tungsten nanoparticles is illustrated in Figure 1. In summary, current proposed mechanism can be separated into some subsequently stages.

Figure 1:Different stages during in-situ formation of tungsten nanoparticles during sintering (a) formation of WO3 nanowires due to nucleation of WO3 vapors and subsequently linear growth, (b) hydrogenreduction of needle like WO3 nanowires and continues formation of nanoparticles, (c) micro-particles are completely covered by nanoparticles that activate sintering of compact remarkably. .

On the other hand, when the sintering temperature continues to raise, reduction of WO3 nanowires take place. Due to nanostructure of WO3, reduction of nanowires resulted into formation of tungsten nanoparticles around the former particles (Figure 1b & 1c) It is well known that the hydrogen reduction process has a great effect on the morphology of the reduced tungsten particles, especially on the diameter [2]. It resulted into homogenous distribution of nanoparticles in the whole of system. Tungsten nanoparticles formation on the micro particles exhibits activating sintering at low temperature owing to the size effects. Accordingly, the sintering stress between nanoparticles and nanoparticle and micro-particle makes mass transport enhanced in the case of nanoparticle addition [3,4]. It led to enhanced densification in presence of nanoparticles.

References

- Ahangarkani M (2018) Int J Refract Metal Hard Mater 70: 93-100.

- Qin M (2017) Int J Refract Metal Hard Mater 68: 145-150.

- Hyesook J (2011) Rev Adv Mater Sci 28: 200-206.

- Tolochko OV (2009) Rev Adv Mater Sci 28: 192-197.

© 2019 Ahangarkani M . This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)