- Submissions

Full Text

Research & Development in Material Science

Assessment of the Influence of Biofield Energy Treatment on the Physicochemical and Thermal Properties of Lead Using PXRD, PSA, and DSC

Alice Branton1, Mahendra Kumar Trivedi1, Dahryn Trivedi1, Gopal Nayak1 and Snehasis Jana2*

1 Trivedi Global, USA

2 Trivedi Science Research Laboratory Pvt Ltd, India

*Corresponding author: Snehasis Jana, Trivedi Science Research Laboratory Pvt Ltd, India

Submission: October 17, 2018Published: October 31, 2018

ISSN: 2576-8840 Volume8 Issue5

Abstract

The lead metal is used for different purposes, i.e. contraceptive, cosmetics, ornaments, glasses, glazes, enamels, writing material, currency, construction, lead-acid battery, etc. The objective of this study was to evaluate the impact of the Trivedi Effect® on the physicochemical and thermal properties of lead using PXRD, PSA, and DSC analysis. The lead sample was divided into control and treated parts. The control sample did not receive the Biofield Energy Treatment, whereas the treated sample received the Trivedi Effect®-Consciousness Energy Healing Treatment remotely by a famous Biofield Energy Healer, Alice Branton. The PXRD peak intensities and crystallite sizes were significantly altered ranging from -60.54% to -37.5% and -17.86% to 177.74%, respectively; whereas the average crystallite size was significantly increased by 138.96% in the treated sample compared with the control sample. The particle size values were significantly increased by 59.62% (d10), 118.05% (d50), 1976.76% (d90) and 1045.85% {D(4,3)}; thus, the specific surface area was significantly decreased by 51.15% in the biofield treated lead sample compared with the control sample. The latent heat of fusion was significantly increased by 15.53% in the treated sample compared with the control sample. The Trivedi Effect®-Consciousness Energy Healing Treatment might have generated a new polymorphic form of lead which could have better powder flowability and more thermal stability compared with the untreated sample. Therefore, the Biofield Energy Treated lead might minimize the lead poisoning/toxicity of the people continuosly associated with the pipe, paint, food, mining, plastic, glass, chemical, and alloys manufacturing industry.

Keywords: Lead, Consciousness energy healing treatment; The trivedi effect®; PXRD; Particle size; Surface area; DSC

Introduction

Lead (Pb) is a heavy metal used by humans since from ancient age. Naturally, lead consists of four stable isotopes along with traces of five short-lived radioisotopes [1]. The Ancient Egyptians used lead for the first time in cosmetics, sinkers in fishing nets, glazes, glasses, enamels, and for ornaments. Many other civilizations of the Fertile Crescent also used lead as a writing material, currency, and for construction; Ancient Chinese royal court as a stimulant, currency, and contraceptive; the Indus Valley civilization and the Mesoamericans used it for making amulets; and the eastern and southern African people used in wire drawing [2]. Lead resources all over world exceed 2 billion tons; significantly deposits are in Australia, China, Ireland, Mexico, Portugal, Peru, Russia, and the United States [3]. It has several useful mechanical properties, including a low melting point, ductility, peak inertness, and high density. It is used in the shotgun pellets, ballast in sailboat keels, scuba diving weight belts, protective sheath for underwater cables, lead sheets are used as architectural metals in roofing material, cladding, flashing, gutters and gutter joints, and on roof parapets; statues and sculptures; used to balance the wheels of cars; leadacid batteries; solder for electronics [2,4-7]. It is added to copper alloys such as brass and bronze, to increase machinability and for its lubricating qualities. Lead is one of the metals used in the Oddy test, to detect the organic acids, aldehydes, and acidic gases in museum materials [8,9]. It is used as, or in, colouring agents, oxidants, glass, plastic, candles, semiconductors, polyvinyl chloride coating of electrical cords. Lead-based semiconductors, i.e., lead telluride and lead selenide are used in photovoltaic cells and infrared detectors [10].

The biological role of lead is not confirmed [11]. Lead is one of the metals that have the most damaging effects on human being. It can enter the human body through consumption of food (65%), water (20%) and air (15%). Continuous exposure to lead may result in the bioaccumulation of lead [12]. The main cause of toxicity is its interference with the proper functioning of enzymes, i.e., binding to the sulfhydryl groups found on many enzymes or mimicking and relocating other metals which act as cofactors in many enzymatic reactions [2]. Symptoms of lead poisoning include nephropathy, degrades the myelin sheaths and numbers, interferes with neurotransmission routes, decreases neuronal growth, colic-like abdominal pains, weakness in the fingers, wrists, and ankles, increases blood pressure, may cause anaemia, may cause miscarriage in pregnant women, reduce fertility in males, etc. [2,13]. Lead poisoning or lead intoxication is a life-threatening health hazard and a major concern all over the world. Therefore, lead content in food, nutraceuticals, pharmaceuticals, water, air, soil of the cultivated land needs to reduce. In this scenario, it was observed that the Biofield Energy Healing Treatment (the Trivedi Effect®) has the considerable impact on various properties such as crystallite and particle size, surface area, and other chemical and thermal behaviour of metals [14,15]. The Trivedi Effect® (Consciousness Energy Healing Treatment) is a natural and only scientifically proven phenomenon in which a person can harness this inherently intelligent energy from the Universe and transmit it anywhere on the planet through the possible mediation of neutrinos [16].

Every living organism possesses a unique, infinite, paradimensional electromagnetic field around the body known as “Biofield”. Biofield (Putative Energy Fields) based Energy Healing Therapies have been reported to have significant outcomes against various disease conditions [17]. National Institute of Health/ National Center for Complementary and Alternative Medicine (NIH/NCCAM) recommend and included the Energy therapy under Complementary and Alternative Medicine (CAM) category that has been accepted by the most of the U.S. population with several advantages [18,19]. With this the Trivedi Effect®-Consciousness Energy Healing Treatment has been extensively reported with surprising ability to alter the characteristic properties of the several living and non-living object(s), i.e. crops [20,21], microbes [22,23], cancer cell line [24,25], metals and ceramic [26,27], organic compounds [28,29], and nutraceuticals/pharmaceuticals [30, 31]. The Consciousness Energy Healing Treatment also found to alter the bioavailability of pharmaceutical/nutraceutical compounds [32-34]. Thus, this study was designed to determine the impact of the Trivedi Effect®-Consciousness Energy Healing Treatment on the physicochemical, and thermal properties of lead using powder X-ray diffraction (PXRD), particle size analysis (PSA), and differential scanning calorimetry (DSC).

Materials and Methods

Chemicals and reagents

The lead powder was purchased from Alpha Aeser, India. All other chemicals used during the experiments were of analytical grade available in India.

Consciousness energy healing treatment strategies

The test sample (lead powder) was divided into two parts. One part of the test sample was considered as a control/untreated sample (no Biofield Energy Treatment was provided). But, the second part of the test sample was received the Trivedi Effect®- Consciousness Energy Healing Treatment remotely under standard laboratory conditions for 3 minutes and known as the Biofield Energy Treated sample. This Biofield Energy Treatment was provided through the healer’s unique energy transmission process by the famous Biofield Energy Healer, Alice Branton, USA, to the test sample. Further, the control sample was treated with a “sham” healer. The “sham” healer did not have any knowledge about the Biofield Energy Treatment. After the treatment, the Biofield Energy Treated and untreated samples were kept in sealed conditions and characterized using PXRD, PSA, and DSC techniques.

Characterization

Powder x-ray diffraction (PXRD) analysis: The PXRD analysis of lead powder was performed with the help of Rigaku Mini Flex-II Desktop X-ray diffractometer (Japan) [35,36]. The CuKα radiation source tube output voltage used was 30kV, and tube output current was 15mA. Scans were performed at room temperature. The average size of individual crystallites was calculated from PXRD data using the Scherrer’s formula (1)

G = kλ/βcosθ (1)

Where k is the equipment constant (0.94), G is the crystallite size in nm, λ is the radiation wavelength (0.154056 nm for Kα1 emission), β is the full-width at half maximum (FWHM), and θ is the Bragg angle [37].

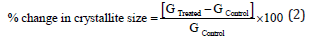

The percent change in crystallite size (G) of lead was calculated using the following equation 2:

Where GControl and GTreated are the crystallite size of the control and Biofield Energy Treated samples, respectively.

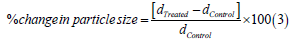

Particle size analysis (PSA): The particle size analysis of lead was performed on Malvern Mastersizer 2000, from the UK with a detection range between 0.01μm to 3000μm using wet method [38,39]. The percent change in particle size (d) for lead powder at below 10% level (d10), 50% level (d50), 90% level (d90), and D(4,3) was calculated using the following equation 3:

Where dControl and dTreated are the particle size (μm) at below 10% level (d10), 50% level (d50), and 90% level (d90) of the control and Biofield Energy Treated samples, respectively.

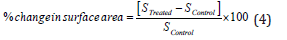

The percent change in surface area (S) was calculated using the following equation 4:

Where SControl and STreated are the surface area of the control and Biofield Energy Treated lead, respectively.

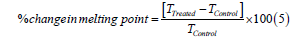

Differential scanning calorimetry (DSC): The DSC analysis of lead was performed with the help of DSC Q200, TA instruments. A sample of ~1-6 mg was loaded to the aluminium sample pan at a heating rate of 10 ºC/min from 30 °C to 350 °C [38,39]. The % change in melting point (T) was calculated using the following equation 5:

Where TControl and TTreated are the melting point of the control and treated samples, respectively.

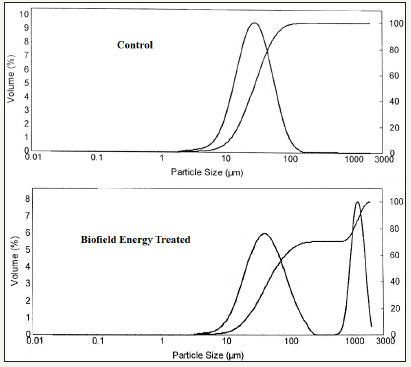

The percent change in the latent heat of fusion (ΔH) was calculated using the following equation 6:

Where ΔHControl and ΔHTreated are the latent heat of fusion of the control and treated lead, respectively.

Results and Discussion

Powder x-ray diffraction (PXRD) analysis

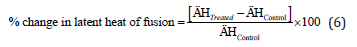

The PXRD diffractograms of the control and Biofield Energy Treated lead showed sharp and intense peaks (Figure 1) indicated that both the samples were crystalline. The control and Biofield Energy Treated samples showed the highest peak intensity at 2θ equal to 31.2° (Table 1). The peak intensities of the Biofield Energy Treated sample were decreased in the range from 37.5% to 60.54% compared with the control sample. Similarly, the crystallite sizes of the treated lead were significantly altered in the range from -17.86% to 177.74% compared to the control sample. Overall, the average crystallite size of the Biofield Energy Treated sample (762.29nm) was significantly increased by 138.96% compared with the control sample (319nm).

Figure 1:PXRD diffractograms of the control and Biofield Energy Treated lead powder.

Table 1:PXRD data for the control and Biofield Energy Treated lead powder.

adenotes the percentage change in the peak intensity of Biofield Energy Treated sample with respect to the control sample; bdenotes the percentage change in the crystallite size of Biofield Energy Treated sample with respect to the control sample

The experimental results indicated that there was a significant variation in the crystallite sizes and peak intensities of the Biofield Energy Treated sample compared to the control sample. According to the literature, the peak intensity of each diffraction face of the crystalline compound changes according to the crystal morphology [40], and alterations in the PXRD pattern provide the proof of polymorphic transitions [41,42]. The Alice’s Biofield Energy Healing Treatment probably produced the new polymorphic form of lead through the Consciousness Energy via neutrino [16]. Different polymorphic forms of pharmaceuticals have the significant effects on the drug performance, such as bioavailability, therapeutic efficacy, and toxicity, because of their physicochemical and thermodynamic properties like melting point, energy, stability, and especially solubility, are different from the original form [43,44]. Thus, it can be anticipated that the Trivedi Effect® Treated sample would be better for the industry using lead as a raw material for the manufacturing of pipe, paints, etc.

Particle size analysis (PSA)

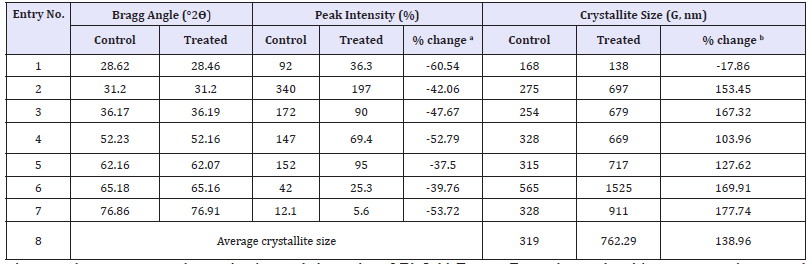

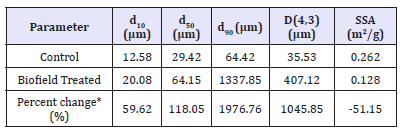

The particle size distribution analysis of both the control and Biofield Energy Treated lead were performed, and the distribution curves are presented in Figure 2. The particle size distribution curve of the Biofield Energy Treated lead was significantly different compared to the control sample. One extra peak was observed in the case of the Biofield Energy Treated sample compared to the control sample (Figure 2). The particle size values of the control sample at d10, d50, d90, and D(4,3) were 12.58μm, 29.42μm, 64.42μm, and 35.53μm, respectively. Similarly, the particle sizes of the Biofield Energy Treated lead at d10, d50, d90, and D(4,3) were 20.08μm, 64.15μm, 1337.85μm, and 407.12μm respectively. Hence, the particle size values in Alice’s Biofield Energy Treated lead were significantly increased at d10, d50, d90, and D(4,3) by 59.62%, 118.05%, 1976.76%, and 1045.85%, respectively compared to the control sample (Table 2). The specific surface area of the Biofield Energy Treated lead (0.128m2/g) was significantly decreased by 51.15% compared with the control sample (0.262m2/g). Hence, it can be hypothesised that the Trivedi Effect®-Consciousness Energy Healing Treatment might act as an external force for increasing the particle size of the lead sample. Moreover, the increased particle size of the compound may help in enhancing the appearance, shape, and flowability of the compound [45,46]. Thus, the Biofield Energy Treatment might be used as a measure to improve the powder flowability, lower solubility, and bioavailability of lead. Lower bioavailability of the Biofield Energy Treated lead might be helpful to minimise the lead poisoning of the people associated with the pipe, paint, food, etc. manufacturing industry.

Table 2:Particle size distribution of the control and Biofield Energy Treated lead.

d10, d50, and d90: particle diameter corresponding to 10%, 50%, and 90% of the cumulative distribution, D(4,3): the average mass-volume diameter, and SSA: the specific surface area. *denotes the percentage change in the Particle size distribution of the Biofield Energy Treated sample with respect to the control sample.

Figure 2:Particle size distribution curve of the control and Biofield Energy Treated lead.

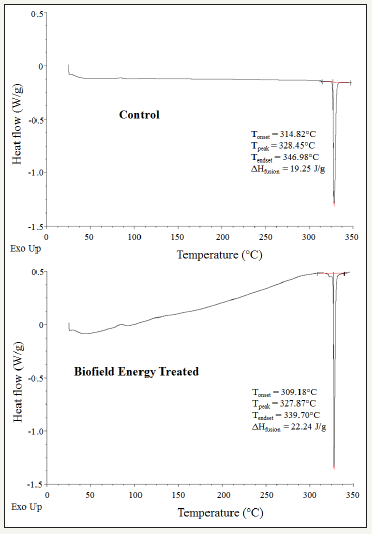

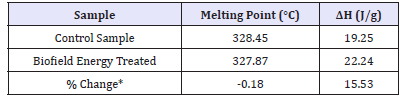

Differential scanning calorimetry (DSC) analysis

DSC analysis has been performed to characterize the thermal behavior of both controls, and Biofield Energy Treated lead (Figure 3). The DSC thermograms of the control and Biofield Energy Treated lead showed the sharp endothermic peak at 328.45 °C and 327.87 °C, respectively (Table 3). The melting point of the Biofield Energy Treated lead was slightly decreased by 0.18% compared with the control sample (Table 3). The latent heat of fusion (ΔHfusion) of the Biofield Energy Treated lead (22.24 J/g) was significantly increased by 15.53% compared with the control sample (19.25 J/g) (Table 3). The change in the latent heat of fusion can be attributed to the disrupted molecule chains and the crystal structure [47]. Thus, it can be assumed that Alice’s Biofield Energy Treatment may be responsible for the disruption the molecular chains and crystal structure of lead which improved the thermal stability of the treated sample compared with the control sample.

Figure 3:DSC thermograms of the control and Biofield Energy Treated lead

Table 3:DSC data for both control and Biofield Energy Treated samples of lead.

Conclusion

The Trivedi Effect®-Consciousness Energy Healing treatment showed a significant impact on the peak intensities, crystallite size, particle size, surface area, and thermal properties of lead. The PXRD diffractograms of the control and biofield energy treated lead showed sharp and intense peaks indicated that both the samples were crystalline in nature. The peak intensities of the Biofield Energy Treated lead were significantly decreased in the range from 37.5% to 60.54% compared with the control sample. Similarly, the crystallite sizes of the Biofield Energy Treated sample were significantly altered in the range from -17.86% to 177.74% compared to the control sample. Overall, the average crystallite size of the Biofield Energy Treated sample was significantly increased by 138.96% compared with the control sample. The particle size values of the Biofield Energy Treated lead were significantly increased at d50, d50, d90, and D(4,3) by 59.62%, 118.05%, 1976.76% and 1045.85%, respectively compared to the control sample. The specific surface area of the Biofield Energy Treated lead powder was significantly decreased by 51.15% compared with the control sample. The DSC analysis revealed that the melting point was slightly decreased, whereas the ΔHfusion was significantly increased by 15.53% in the Biofield Energy Treated sample compared with the control sample. The Trivedi Effect®-Consciousness Energy Healing Treatment might have generated a new polymorphic form of lead which could have better powder flowability and more thermal stable compared with the untreated sample. Therefore, the Trivedi Effect®-Consciousness Energy Healing Treated lead might minimize the lead poisoning/toxicity of the people continuosly associated with the pipe, paint, food, mining, plastic, glass, chemical, and alloys manufacturing industry.

Acknowledgement

The authors are grateful to Central Leather Research Institute, SIPRA Lab Ltd, Trivedi Science, Trivedi Global, Inc, Trivedi Testimonials, and Trivedi Master Wellness for their assistance and support during this work.

References

- IAEA- Nuclear Data Section (2017) Live chart-table of nuclides-nuclear structure and decay data. International Atomic Energy Agency.

- https://en.wikipedia.org/wiki/Lead. Retrieved 27-12-2017.

- United States Geological Survey (2017) Lead. Mineral commodities summaries.

- Parker RB (2005) The new cold-molded boatbuilding: from lofting to launching. Wooden Boat Books. ISBN 978-0-937822-89-0.

- Krestovnikoff M, Halls M (2006) Scuba diving. Dorling Kindersley. ISBN 978-0-7566-4063-4067.

- Weatherings to parapets and cornices. The lead sheet association. Retrieved 27-12-2017.

- Putnam B (2003) The sculptors way: a guide to modelling and sculpture. Dover publications. ISBN 978-0-486-42313-5.

- Gulbinska MK (2014) Lithium-ion battery materials and engineering: current topics and problems from the manufacturing perspective. Springer pp. 96.

- Beiner GG, Lavi M, Seri H, Rossin A, Lev O, et al. (2015) Oddy tests: adding the analytical dimension. Collection forum 29(1): 22-36.

- Rogalski A (2010) Infrared detectors (2nd edn), CRC Press. US, ISBN 978- 1-4200-7671-4. pp. 898.

- Emsley J (2011) Natures building blocks: An A-Z guide to the elements. Oxford University Press, UK.

- Agency for toxic substances and disease registry (ATSDR).

- Ana NA (2007) Lead exposure and cardiovascular disease-a systematic review. Environ Health Perspect 115(3): 472-482.

- Trivedi MK, Tallapragada RM (2008) A transcendental to changing metal powder characteristics. Metal Powder Report 63(9): 22-28.

- Dabhade VV, Tallapragada RMR, Trivedi MK (2009) Effect of external energy on the atomic, crystalline, and powder characteristics of antimony and bismuth powders. Bulletin of Materials Science 32(5): 471-479.

- Trivedi MK, Mohan TRR (2016) Biofield energy signals, energy transmission and neutrinos. American Journal of Modern Physics 5(6): 172-176.

- Rubik B, Muehsam D, Hammerschlag R, Jain S (2015) Biofield science and healing: history, terminology, and concepts. Glob Adv Health Med 4: 8-14.

- Barnes PM, Bloom B, Nahin RL (2008) Complementary and alternative medicine use among adults and children: United States, 2007. Natl Health Stat Report 10(12): 1-23.

- Koithan M (2009) Introducing complementary and alternative therapies. J Nurse Pract 5(1): 18-20.

- Trivedi MK, Branton A, Trivedi D, Nayak G, Mondal SC (2015) Evaluation of plant growth, yield and yield attributes of biofield energy treated Mustard (Brassica juncea) and Chick pea (Cicer arietinum) Seeds. Agriculture, Forestry and Fisheries 4(6): 291-295.

- Trivedi MK, Branton A, Trivedi D, Nayak G, Gangwar M, et al. (2015) Evaluation of Vegetative Growth Parameters in Biofield Treated Bottle Gourd (Lagenaria siceraria) and Okra (Abelmoschus esculentus). International Journal of Nutrition and Food Sciences. 4(6): 688-694.

- Trivedi MK, Branton A, Trivedi D, Shettigar H, Nayak G, et al. (2015) Antibiogram typing of biofield treated multidrug resistant strains of Staphylococcus species. American Journal of Life Sciences 3(5): 369- 374.

- Trivedi MK, Branton A, Trivedi D, Shettigar H, Nayak G, et al. (2015) Antibiogram, biochemical reactions and genotyping characterization of biofield treated staphylococcus aureus. American Journal of BioScience 3(6): 212-220.

- Trivedi MK, Patil S, Shettigar H, Mondal SC, Jana S (2015) The potential impact of biofield treatment on human brain tumor cells: A time-lapse video microscopy. J Integr Oncol 4: 141.

- Trivedi MK, Patil S, Shettigar H, Gangwar M, Jana S (2015) In vitro evaluation of biofield treatment on cancer biomarkers involved in endometrial and prostate cancer cell lines. J Cancer Sci Ther 7: 253-257.

- Trivedi MK, Tallapragada RM, Branton A, Trivedi D, Nayak G, et al. (2015) Characterization of physical and structural properties of aluminum carbide powder: Impact of biofield treatment. J Aeronaut Aerospace Eng 4: 142.

- Trivedi MK, Patil S, Tallapragada RM (2013) Effect of biofield treatment on the physical and thermal characteristics of vanadium pentoxide powders. J Material Sci Eng S11: 001.

- Trivedi MK, Branton A, Trivedi D, Nayak G, Sethi KK, et al. (2016) Isotopic abundance ratio analysis of biofield energy treated indole using gas chromatography-mass spectrometry. Science Journal of Chemistry 4(4): 41-48.

- Trivedi MK, Branton A, Trivedi D, Nayak G, Panda P, et al. (2016) Evaluation of the isotopic abundance ratio in biofield energy treated resorcinol using gas chromatography-mass spectrometry technique. Pharm Anal Acta 7: 481.

- Trivedi MK, Patil S, Shettigar H, Bairwa K, Jana S (2015) Spectroscopic characterization of chloramphenicol and tetracycline: An impact of biofield. Pharm Anal Acta 6: 395.

- Jana S, Trivedi MK, Tallapragada RM, Branton A, Trivedi D, et al. (2015) Characterization of physicochemical and thermal properties of chitosan and sodium alginate after biofield treatment. Pharm Anal Acta 6: 430.

- Branton A, Jana S (2017) Effect of the biofield energy healing treatment on the pharmacokinetics of 25-hydroxyvitamin D3 [25(OH)D3] in rats after a single oral dose of vitamin D3. American Journal of Pharmacology and Phytotherapy 2(1): 11-18.

- Branton A, Jana S (2017) The influence of energy of consciousness healing treatment on low bioavailable resveratrol in male sprague dawley rats. International Journal of Clinical and Developmental Anatomy 3(3): 9-15.

- Branton A, Jana S (2017) The use of novel and unique biofield energy healing treatment for the improvement of poorly bioavailable compound, berberine in male sprague dawley rats. American Journal of Clinical and Experimental Medicine 5(4): 138-144.

- (1997) Desktop X-ray diffractometer miniFlex+. The Rigaku Journal 14: 29-36.

- Zhang T, Paluch K, Scalabrino G, Frankish N, Healy AM, et al. (2015) Molecular structure studies of (1S,2S)-2-benzyl-2,3-dihydro-2- (1Hinden-2-yl)-1H-inden-1-ol. J Mol Struct 1083: 286-299.

- Langford JI, Wilson AJC (1978) Scherrer after sixty years: A survey and some new results in the determination of crystallite size. J Appl Cryst 11: 102-113.

- Trivedi MK, Sethi KK, Panda P, Jana S (2017) A comprehensive physicochemical, thermal, and spectroscopic characterization of zinc (II) chloride using X‑ray diffraction, particle size distribution, differential scanning calorimetry, thermogravimetric analysis/ differential thermogravimetric analysis, ultraviolet‑visible, and Fourier transform‑infrared spectroscopy. International Journal of Pharmaceutical Investigation 7(1): 33-40.

- Trivedi MK, Sethi KK, Panda P, Jana S (2017) Physicochemical, thermal and spectroscopic characterization of sodium selenate using XRD, PSD, DSC, TGA/DTG, UV-vis, and FT-IR. Marmara Pharmaceutical Journal 21(2): 311-318.

- Inoue M, Hirasawa I (2013) The relationship between crystal morphology and XRD peak intensity on CaSO4.2H2O. J Crystal Growth 380: 169-175.

- Raza K, Kumar P, Ratan S, Malik R, Arora S (2014) Polymorphism: the phenomenon affecting the performance of drugs. SOJ Pharm Pharm Sci 1: 10.

- Brittain HG (2009) Polymorphism in pharmaceutical solids in drugs and pharmaceutical sciences. (2nd edn), Informa Healthcare, New York, USA.

- Censi R, Martino PD (2015) Polymorph impact on the bioavailability and stability of poorly soluble drugs. Molecules 20(10): 18759-18776.

- Blagden N, de Matas M, Gavan PT, York P (2007) Crystal engineering of active pharmaceutical ingredients to improve solubility and dissolution rates. Adv Drug Deliv Rev 59(7): 617-630.

- Mosharrof M, Nystrom C (1995) The effect of particle size and shape on the surface specific dissolution rate of microsized practically insoluble drugs. Int J Pharm 122(1-2): 35-47.

- Buckton G, Beezer AE (1992) The relationship between particle size and solubility. Int J Pharmaceutics 82(3): R7-R10.

- Zhao Z, Xie M, Li Y, Chen A, Li G, et al. (2015) Formation of curcumin nanoparticles via solution-enhanced dispersion by supercritical CO2. Int J Nanomedicine 10: 3171-3181.

© 2018 Snehasis Jana . This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)