- Submissions

Full Text

Research & Development in Material Science

Impact of Shock Waves on Nano Crystalline Materials for Aerospace Applications

Sivakumr A and Martin Britto Dhas SA*

Department of Physics, Abraham Panampara Research Center, India

*Corresponding author: Martin Britto Dhas SA, Department of Physics, Abraham Panampara Research Center, India

Submission: June 13, 2018;Published: July 10, 2018

ISSN: 2576-8840 Volume7 Issue1

Abstract

Shock wave impact studies on crystalline materials provide the direct correlation to the structural stability and mechanical stability of the materials under critical condition such as high pressure, temperature, radiation impact and vibration. In this short review authors consolidated the highlights of the shock wave impact studies on nano materials.

Introduction

Impact of shock waves on materials whether they are in bulk or nano sized particles is a fertile research area in material science and it gives the direct relation to the structural and mechanical stability of the materials for aerospace and military applications. The demand for advanced materials such as piezoelectric, nonlinear optical (NLO) and ferroelectric crystals and metal oxide nano materials with multifunctional capabilities and high shock wave impact resistance are of great interest for the designers of aerospace and military devices applications [1,2]. Shock waves can produce extreme pressures and temperature on the materials, causing stresses that are much larger than their strength and it is one of the crucial factors to be considered in the design of aerospace structure, satellites, damping and armor design, high strength fibers, high-strength composites, automobile and nanometersized semiconductor devices [3-6]. Also, shock waves provide a uniaxial stress in the lattice planes during the propagation through the materials and it can influence various factors such as plastic and elastic deformation, lattice defects, grain boundaries, grain size, particle size, particle shape and phase transformation in the same material [7]. These changes can significantly affect the physical properties viz., structural, optical, morphological, thermophysical, vibrational, electrical properties etc. To prevent aerospace vehicles and aerospace devices from the shock damage, the designing engineers should be aware of the response of various components and structural elements under different shock wave recovery experiments. Though a number of materials including metals, metal oxide and composites have been used for aerospace applications, shock impact profile is available only for very few materials [8]. There is an impending need for next generation aerospace materials that have unique combination of properties such as ultra light-weight, flexible, radiation resistant, high thermal emissivity, non- corrosive, low thermal conductivity, low thermal diffusivity, low thermal expansion and high tear resistance as well as better shock resistant property.Hence, it is necessary to identify the shock resistance of a material in the laboratory before using it in the aerospace vehicles. It can be done by shock wave loading technique.

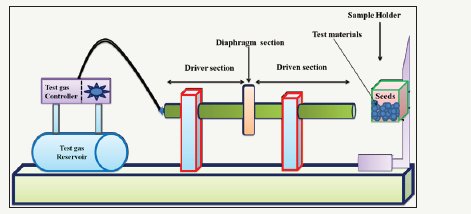

Figure 1: Schematic diagram of the experimental set-up of shock wave loading on samples.

Shock Wave Loading Technique

Many methods are available to find the stability of the materials, but shock wave loading technique is one of the most proficient methods to unearth the stable materials under critical conditions [7].Shock tube is an efficient device for producing controlled shock waves in laboratory conditions. It consists of three sections namely, driver section (higher-pressure section), driven section (lowerpressure section) and a diaphragm section which couples the other two sections. Using pressure reservoir, the test gas is compressed in the driver section till the diaphragm raptures. After the diaphragm rapture, it leads to create shock wave which propagates through the driven section. The test sample is rigidly fixed in the sampleholder which is placed 1cm away from the open end of the driven section. The schematic diagram of the experimental setup is shown in Figure 1.

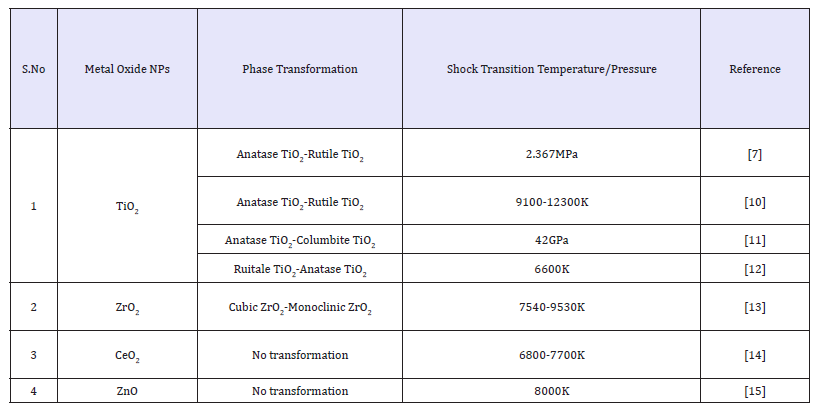

Table 1:Phase transformation studies on few metal oxide nanoparticles (NPs) by shock waves.

Due to the importance and necessity of the shock impact study, many researchers are working around the globe on nano crystalline materials.Vasu et al. [9] demonstrated that hightemperature shock waves causes morphological changes and a significant decrease in the interlayer separation between the (002) planes on MoS2, WS2 and MoSe2nanoparticles due to the lattice instability and structural instability of the nanoparticles under shock wave loading conditions. Recently, we have demonstrated the phase transformation of TiO2from Anatase to Rutile [7]. Also many research groups have reported the phase transformation of the metal oxides nanoparticles such as TiO2, ZrO2, CeO2, and ZnO [7,10-14]. Among these four transition materials CeO2and ZnO nanoparticles exhibit excellent structural, electrical and morphological properties under shock wave impact conditions and hence proved the applicability of these materials for aerospace applications. Table 1 gives the details of the phase transformation studies done by several groups [15].

Conclusion

From the above discussion, it is clear that during the propagation of shock waves on crystalline materials, micro or macro level changes may occur. It leads to structural, optical, electrical and morphological modifications in the material and it depends on the shock strength and the repetition of the shock pulses. Hence the properties of the materials could be tailored as per the requirements. Thus the research in the field of impact of shock waves on crystalline materials will play a vital role in future technology especially aerospace and nuclear power plants.

References

- Koteeswara VNR, Jayaram V, Arunan E, Kwon YB, Moon WJ, et al. (2013) Investigations on high enthalpy shock wave exposed graphitic carbon nanoparticles. Diamond & Related Materials 35: 53-57.

- Sivakumar A, Suresh S, Predeep JA, Balachandar S, Dhas SM (2018) Effect of shock waves on KDP crystal. J Eletronic Mater 47(8): 4831-4839.

- Ashuach Y, Rosenberg Z, Dekel E (2005) A shock compression condensed matter, more on the strength of materials under high shock pressures, pp. 1241-1244.

- Brontvein O, Jayaram V, Reddy KPJ, Gordon JM, Tenne R (2014) Two-step synthesis of MoS2 Nanotubes using shock waves with lead as growth promoter. Z Anorg Allg Chem 640(6): 1152-1158.

- Wang J, Yu H, Wu Y, Boughton R (2015) Recent developments in functional crystals in china. Engineering 1(2): 192-210.

- Jayaram V, Singh P, Reddy KPJ (2011) Experimental investigation of nano ceramic material interaction with high enthalpy argon under shock dynamic loading. Appl Mech and Mater 83: 66-72.

- Kalaiarasi S, Sivakumar A, Dhas SM, Jose M (2018) Shock wave induced anatase to rutile TiO2 phase transition using pressure driven shock tube. Mater Lett 219: 72-75.

- Koller DD (2009) Shock response of transition metallic oxide materials (LA-14777). Proceedings of the SEM Annual Conference 1: 1-4.

- Vasu K, Matte HSSR, Sharmila N, Shirodkar V, Jayaram V, et al. (2013) Effect of high-temperature shock-wave compression on few-layer MoS2, WS2 and MoSe2. Chem Phys Lett 582: 105-109.

- Jayaram V, Singh P, Reddy KPJ (2013) Study of anatase TiO2 in the presence of N2 under shock dynamic loading in a free piston driven shock tube. Advanc Ceram Sci and Engg 2: 40-46.

- Shul’ga YM, Matyushenko DV, Golyshev AA, Shakhrai DV, Molodets AM, et al. (2010) Phase Transformations in nanostructural anatase TiO2 under shock compression conditions studied by raman spectroscopy. Technical Physics Letters 36: 841-843.

- Jayaram V (2016) Shock-induced reversible phase transformation from rutile to anatase in TiO2 powders. SAMPE proceedings LB15-0212, pp. 1-14

- Jayaram V, Reddy KPJ (2016) Experimental study of the effect of strong shock heated test gases with cubic zirconia. Adv Mater Lett 8(2): 150- 152.

- Jayarama V, Guptab A, Reddy KPJ (2014) Investigation of strong shock wave interactions with CeO2 ceramic. J Adv Ceramic 3(4): 297-305.

- Devika M, Reddy NK, Jayaram V, Reddy KPJ (2017) Sustainability of aligned ZnO nanorods under dynamic shock-waves. Adv Mater Lett 8: 398-403.

© 2018 Martin Britto Dhas SA . This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)