- Submissions

Full Text

Research & Development in Material Science

Review about Development from Nanotechnology to Nano-Engineering

Said S E H Elnashaie1*, Firoozeh Danafar2 and Hassan Hashemipour Rafsanjani2

1Department of Chemical and Biological Engineering, University of British Columbia, Canada

2Department of Chemical Engineering, ShahidBahonar University of Kerman, Iran

*Corresponding author: Said S E H Elnashaie, Department of Chemical and Biological Engineering, University of British Columbia, Vancouver, Canada

Submission: April 23, 2018;Published: May 15, 2018

ISSN: 2576-8840

Volume6 Issue3

Abstract

The world is presently witnessing the advancement and development of a new multidisciplinary technology, “Nanotechnology”. The concepts that seeded nanotechnology was first discussed in 1959 by renowned physicist Feynman [1] in his talk.

Introduction to Nanotechnology

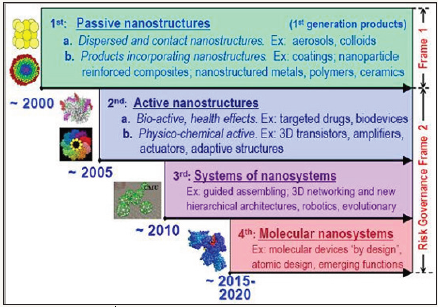

Figure 1: Generations of nanotechnology development Roco [3].

Accordingly, a comprehensive definition for Nanotechnology is: “Nanotechnology is art and science of manipulating atoms and molecules to create systems, materials, and devices at nano scale as well as their application in various fields.”

Nanotechnology can be referred to as a general-purpose technology, as it has significant impacts on almost all industries and all areas of society. Nanotechnology is expected to offer better built, longer lasting, cleaner, safer, and smarter products for the home, for communications, for medicine, for transportation, for agriculture, and for industry in general. Chemistry and materials science and in some cases biology are integrated to create new properties of materials in nanoscale. However, engineering principles must be exploited to gain market opportunities.

Application of nanotechnology in different fields

The expectations from nanotechnology as a key technology of the current century for innovative products and new market potentials are high. Some of these potential applications of nanotechnology-based products are presented in this section.

Nanotechnology in biotechnology

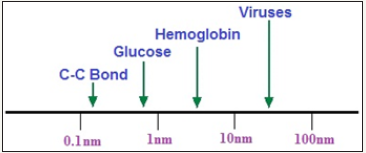

The size of nanometer is of central importance in the nature and biological systems. Cells are the main element of the living organisms that can be much smaller than the sub-micron size domain. A wide range of biomolecules, like proteins and viruses, are in the nano-scale range (Figure 2). Accordingly, nanotechnology has become a part of the world of biotechnology for understanding the biological systems and their phenomena [4]. Unexpected growth in the field of nanotechnology and biotechnology has brought novel technologies that make it possible to:

Figure 2: Various nano-sized biological systems.

a. Design new nanostructures by mimicking the structure and function of living systems

b. Control and alter the biosystems including cellular and sub-cellular organelles, protein molecules, receptors, and cytokines.

Proteins, with a typical size of 5nm, are comparable to the smallest nanoparticles that have been made by researchers. This circumstance has led to the improvement of the health care and medical research through the development of nano-based products, as a result of research efforts. These products have extensively found bio-applications in the fields of cosmetics, drug delivery, imaging and medical diagnosis, tissue engineering, etc. for example, biomolecules can be attached to nanoparticles by electrostatic forces including hydrogen bonding, hydrophobic forces and Vander Waals forces. New approaches of using nanostructures for biomolecule immobilization assist potential applications in biosensors (glucose sensor, DNA sensors), targeted drug delivery and other biocatalytic processes [5-7]. The optical properties of nanoparticles could be also implemented in imaging and characterization of bio-molecules, for example as a marker in TEM, as well as surface enhancement of fluorescent emission and Raman scattering [8,9].

The revolutionary advancements in bio-nanotechnology and biomedical research place a strong foundation for a customized, personalized, and quantitative medicine in the future. The vital role of nano-biotechnology in medicine is improvement of diagnostic technologies. Diagnosis is a key stage in health care; the earlier diagnose of a disease the more effective is the therapy, both from outcomes as well as from a total cost perspective. The integration of nanotechnology with medicine has given birth to a new field of science called “Nanomedicine.” The ultimate goal of nanomedicine is to develop well-engineered products (tools and materials) that could efficiently be used for the prevention, diagnosis, and treatment of different diseases. These products include drug delivery platforms, imaging systems, bio-chips and probes, needles for painless drug infusion or intracellular injections, etc. [4].

Nanostructures are an important component of biosensing platforms [10,11]. The extraordinary properties of nanostructures (specially electrical and optical properties) of nanostructures in the presence of biomolecules make them possible to be used in biosensors fabrication [12-14]. Biosensors, which act in the aqueous phase, are analytical devices incorporating biomolecule (e.g., DNA, enzymes, antibodies, microorganisms, etc.) associated with or integrated within a physico-chemical transducer [12]. Biosensors are now employed in a wide range of applications:

a. Detecting of diseases, particularly in cancer diagnostics [15,16]

b. These sensors capable of monitoring in vivo processes within living cells, leading to achieving new information on the inner workings of the entire cell and understanding the cellular function, thus revolutionizing cell biology and to differentiate normal and abnormal cells [12]

c. Organophosphorus pesticides and nerve gases [17,18]

d. Pathogens and toxins, or total cholesterol and glucose etc. in blood [19,20]

e. Low concentration of toxic gases [21,22]

Nanostructures have been also considered in the controlled release of active compounds in the application of pharmaceuticals [23] and food additives [24]. Drug delivery using nanostructures has demonstrated high and versatile loading capacity for therapeutic agents, some selective cargo unloading, and better cell penetration than many other delivery materials [25,26]. To achieve the efficient performance, a suitable scheme to conjugate the drug and the nanostructure is required to make nanostructures into viable delivery vehicles [21]. Another critical step is to conjugate the nanostructures in such a way that the functionality of the biomolecules is maintained.

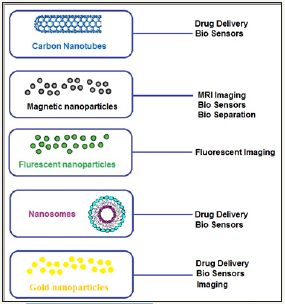

The present day nano-medicine initiatives include a range of successful and evolving technologies encompassing targeted drug delivery aimed at minimizing side effects, creation of implantable materials as scaffolds for tissue engineering, development of implantable devices, surface modification and designing optimal topology for biomaterial implants, surgical aids, nanorobotics, as well as high throughput drug screening and medical diagnostic imaging [4,27]. Medical applications of the most used nanostructures are presented in Figure 3. As presented in the previous paragraph and indicated in the Figure 3, medical applications of nanostructures commonly include imaging, sensing and delivery. However, magnetic nanoparticles (Fe3O4 and γ-Fe2O3) due to their unique behavior have a specific application for biomolecule separation selection. This application is especially well suited to the separation of rare tumor cells from blood, and low numbers of target cells [27,28].

Figure 3: Medical applications.

Nanostructures have also attracted great attention in tissue engineering for design of medical prostheses or implants [29]. Designing medical implants or scaffolds similar to natural tissue or organs with respect to their performance is a challenging task facing materials scientists and engineers. Novel innovative technology for the fabrication of nanostructural biomaterials increase the possibility to use nanostructure in designing and producing implants or prostheses with all ideal characteristic features in order to function in a natural way in the body environment [30]. Nano-composites of different types of ceramics are mostly used as orthopaedic implants and in dental applications to repair and replace diseased and damaged parts of the musculoskeletal system [31]. Metallic-based materials that present sufficient fatigue strength to endure the rigors of daily activity, such as walking, chewing, etc. are normally used as pins and plates and femoral stems, orthopedic implants, etc.). Coating materials in which nanostructures are used can modify the surface properties of materials used in medical activities (for example, surgery) by their improvements in performance, reliability and biocompatibility [32].

Nanostructures are also considered for the food packaging sector and nano-composites have shown impressive characteristic for this purpose [14,33,34]. According to these reviews, the majority of the researches used clay nano-particles; nevertheless, other types of reinforcing elements like carbon nanotubes, metals nano-particles and bio-based nano-fillers such as starch nanoparticles and biodegradable cellulose nano-whiskers have been applied. The latter bio-based nanofillers offer more advantageous like generating fully bio-based formulations and edibility since they can be made of food hydrocolloids.

The usefulness of using nanostructures in food industry as presented in [34-36] includes:

a. Controlled and/or burst release of substances in active and functional food packaging technologies and intelligent food packaging.

b. Formulation of active packaging technologies based on bio-plastics such as more efficient antioxidant, oxygen scavenging or antimicrobial bio-packaging, which has more direct implications in increasing packaged foods quality and safety.

c. Important issues associated to the use of bio-plastics, such as the non-intended migration of plastic components to foods, can also be potentially reduced by the use of nano-particles.

While significant progress has been made in the area of nanobiotechnology, there are still many issues left to resolve before clinical use of these materials can be realized. Before nanostructures can be utilized for human body, several important properties needs to achieved. The nanostructures must be nontoxic, nonimmunogenic, stable in blood, biodegradable, and applicable to various bio-molecules. From commercial and engineering points of view, the nanostructures also must possess scalable and inexpensive manufacturing process. Technical, regulatory, and legal challenges, however, exist along the road to implement nanotechnology in the fields of medical pharmaceutical and food industry. A great challenge is realizing the long-term impact of nanostructures on human health and their interactions [4]. The other issue is lack of knowledge about the stability of nanostructures during processing. However the use of natural additives like clay nano-particles and nano-cellulose may help to overcome this problem because of their biocompatibility

Nanotechnology in petroleum industries

Nanotechnology is offering new and improved methods in different areas of the oil and gas industries from exploration and well drilling to refining and distribution. Properties of nanostructures such as lightness, corrosion resistance and mechanical strength make them significant elements to be used in the oil industry machines, specially drilling machines [37]. Nanotechnology represents breakthrough elements, thanks to the development of innovative monitoring techniques and smarter nano-sensors. Conventional sensors and other measuring tools are unreliable in hostile high temperature and high pressure conditions. Improved performance sensors for imaging, measuring and controlling reservoirs and oilfields will improve all activities in the area of oil industry, from exploring oil-well and drilling to oil transporting and reserving [38].

Besides the potential applications enumerated for nanotechnology in oil and gas industry, nanostructures can provide extraordinary opportunities to develop more cost effective and environmentally friendly upgrading and recovery enhancement of heavy feed-stocks [39-41]. Nanostructures were used for reduction of the viscosity of heavy oil thus benefiting the oil exploitation and upgrading transportation: [42]. Using nanostructures in catalysts provide several advantageous that ultimately increase the economics of the upgrading process. The catalyst improved characteristics include [43]:

a. High surface area to volume ratio, which results in improved catalytic performance for processing purposes,

b. Increased probability of contacts between reactants because of their high mobilization inside the reactor

c. Long run times for conversion as there is no need of catalyst replacement because of nanocatalysts implementation inside the medium

d. Stable long-term high activity

Figure 4: In-situ heavy oil upgrading and recovery [40].

Another promising advantageous is possibility of in-situ preparation of catalyst. Figure 4 illustrates the in-situ preparation of nano-catalyst for upgrading and recovery of bitumen during the steam assisted gravity drainage (SAGD) process [40]. In this method, nanocatalysts are introduced into the porous media through a line to perform upgrading inside the reservoir to convert bitumen to lighter products. The ultra-dispersed nano-catalysts will aid the SAGD process and light oil is produced at the surface whereas heavy molecules, solids and minerals stay sub-surface. Successful in-situ processing will reduce the operating costs as well as environmental concerns; however, there is a long way and extensive works are needed to commercialize the proposed method [43].

Conclusion

Other emerging applications of nanotechnology in oil industry include development of:

a. New generation membranes for gas separation.

b. New types of smart fluids for water shut-off and improved/enhanced oil recovery [38].

c. Nano-catalyst [35]

d. Unconventional petroleum exploration and exploitation [44-51].

References

- Feynman RP (1961) There’s plenty of room at the bottom. Miniaturization. In: Gilbert HD (Ed.), Reinhold, New York, USA.

- Drexler KE, Minsky M (1990) Engines of creation, Fourth Estate, London, UK.

- Roco MC (2007) National nanotechnology initiative-past, present, future. Handbook on nanoscience, engineering and technology 2.

- Papazoglou ES, Parthasarathy A (2007) Bio-nanotechnology, synthesis lectures on biomedical engineering. Morgan & Claypool Publishers.

- Kim J, Grate JW (2003) Single-enzyme nanoparticles armoured by a nanometer-scale organic/inorganic network. Nano Letters 3: 1219- 1222.

- Kim J, Grate JW, Wang P (2006) Nanostructures for enzyme estabilization. Chemical Engineering Science 61: 1017-1026.

- Kim YA, Hayashi T, Endo M, Gotoh Y, Wada N, et al. (2006) Fabrication of aligned carbon nanotube-filled rubber composite. Scripta Materialia 54(1): 31-35.

- Wang ZL (2000) Characterization of nanophase materials. Wiley-VCH VerlagGmbH, USA.

- Wang ZL (2000) Transmission electron microscopy and spectroscopy of nanoparticles. In: Wang ZL (Ed.), Characterization of Nanophase Materials. Wiley-VCH VerlagGmbH, USA.

- Bianco A, Prato M (2003) Can carbon nanotubes be considered useful tools for biological applications? Adv Mater 15(20): 1765-1768.

- Davis JJ, Coleman KS, Azamian BR, Bagshaw CB, Green MLH (2003) Chemical and biochemical sensing with modified single walled carbon nanotubes. Chemical European Journal 9(16): 3733-3739.

- Vo-Dinh T (2004) Nanobiosensor. Encyclopedia of nanoscience and nanotechnology 6.

- Hong WJ, Bai H, Xu YX, Yao ZY, Gu ZZ, et al. (2010) Preparation of gold nanoparticle/graphene composites with controlled weight contents and their application in biosensors. Journal of Physical Chemistry C 114: 1822-1826.

- Duncan TV (2011) Applications of nanotechnology in food packaging and food safety: barrier materials, antimicrobials and sensors. Journal of colloid and interface science 363(1): 1-24.

- Fortina P, Kricka LJ, Graves DJ, Park J, Hyslop T, et al. (2007) Applications of nanoparticles to diagnostics and therapeutics in colorectal cancer. Trends in biotechnology 25(4): 145-152.

- Perfézou M, Turner A, Merkoçi A (2012) Cancer detection using nanoparticle-based sensors. Chemical Society Reviews 41(7): 2606- 2622.

- Gan N, Yang X, Xie D, Wu Y, Wen W (2010) A disposable organophosphorus pesticides enzyme biosensor based on magnetic composite nanoparticles modified screen printed carbon electrode. Sensors 10(1): 625- 638.

- Liang M, Fan K, Pan Y, Jiang H, Wang F, et al. (2012) Fe3O4 magnetic nanoparticle peroxidase mimetic-based colorimetric assay for the rapid detection of organophosphorus pesticide and nerve agent. Analytical chemistry 85(1): 308-312.

- Lahiff E, Lynam C, Gilmartin N, O’Kennedy R, Diamond D (2010) The increasing importance of carbon nanotubes and nanostructured conducting polymers in biosensors. Analytical and bioanalytical chemistry 398(4): 1575-1589.

- Kuila T, Bose S, Khanra P, Mishra AK, Kim NH, et al. (2011) Recent advances in graphene-based biosensors. Biosensors and Bioelectronics 26(12): 4637-4648.

- Endo M, Strano MS, Ajayan PM (2008) Potential applications of carbon nanotubes. Carbon nanotubes, pp. 13-61.

- Asefa T, Duncan CT, Sharma KK (2009) Recent advances in nanostructured chemosensors and biosensors. Analyst 134(10): 1980-1990

- Kumar MNVR (2000) Nano and microparticles as controlled drug delivery devices. J Pharm Pharm Sci 3(2): 234-258.

- Chaudhry Q, Scotter M, Blackburn J, Ross B, Boxall A, et al. (2008) Applications and implications of nanotechnologies for the food sector. Food additives and contaminants 25(3): 241-258.

- Farokhzad OC, Langer R (2009) Impact of nanotechnology on drug delivery. ACS nano 3(1): 16-20.

- Verma A, Stellacci F (2010) Effect of surface properties on nanoparticlescell interactions. Small 6(1): 12-21.

- Pankhurst QA, Connolly J, Jones SK, Dobson J (2003) Applications of magnetic nanoparticles in biomedicine. Journal of physics D: Applied physics 36(13): R167.

- McCarthy JR, Weissleder R (2008) Multifunctional magnetic nanoparticles for targeted imaging and therapy. Advanced drug delivery reviews 60(11): 1241-1251.

- Scholz MS, Blanchfield JP, Bloom LD, Coburn BH, Elkington M, et al. (2011) Composites Science and Technology 71(16): 1791-1803.

- Dastjerdi R, Montazer M (2010) A review on the application of inorganic nano-structured materials in the modification of textiles: focus on antimicrobial properties. Colloids and Surfaces B: Biointerfaces 79(1): 5-18.

- Chevalier J, Gremillard L (2009) Ceramics for medical applications: A picture for the next 20 years. Journal of the European Ceramic Society 29(7): 1245-1255.

- Ben-Nissan B, Choi AH (2006) Sol-gel production of bioactive nanocoatings for medical applications. Part 1: an introduction. Nanomedicine (Lond) 1(3): 311-319.

- Garcia SMD, Rubio LA, Lagaron JM (2010) Natural micro and nanobiocomposites with enhanced barrier properties and novel functionalities for food biopackaging applications. Trends in Food Science & Technology 21(11): 528-536.

- Lagaron JM, Rubio LA (2011) Nanotechnology for bioplastics: opportunities, challenges and strategies. Trends in food science & technology 22(11): 611-617.

- Gharibi M, Zangeneh FT, Yaripour F, Sahebdelfar S (2012) Nanocatalysts for conversion of natural gas to liquid fuels and petrochemical feedstocks. Applied Catalysis A: General 443-444: 8-26.

- Mastromatteo M, Mastromatteo M, Conte A, Nobile D (2010) Advances in controlled release devices for food packaging applications. Trends in Food Science & Technology 21(12): 591-598.

- Singh SK, Ahmed RM, Growcock F (2010) Vital role of nanopolymers in drilling and stimulations fluid applications. In SPE Annual Technical Conference and Exhibition.

- Matteo C, Candido P, Francesca VR (2012) Current and future nanotech applications in the oil industry. American journal of applied sciences 9(6): 784-793.

- Krishnamoorti R (2006) Extracting the benefits of nanotechnology for the oil industry. Journal of petroleum technology 58(11).

- Nassar NN, Husein MM, Almao PP (2011) In-situ prepared nanoparticles in support of oil sands industry meeting future environmental challenges. Exploration and Production: Oil and Gas Review 9(1): 46-48.

- Almao PP (2012) In-situ upgrading of bitumen and heavy oils via nanocatalysis. The Canadian Journal of Chemical Engineering 90(2): 320-329.

- Chen Y, Wang Y, Lu J, Wu C (2009) The viscosity reduction of nanokeggin- K3PMo12O40 in catalytic aquathermolysis of heavy oil. Fuel 88(8): 1426-1434.

- Hashemi R, Nassar NN, Almao PP (2014) Nanoparticle technology for heavy oil in-situ upgrading and recovery enhancement: Opportunities and challenges. Applied Energy 133: 374-387.

- Caineng Z, Shizhen T, Zhi Y, Xuanjun Y, Rukai Z, et al. (2012) New advance in unconventional petroleum exploration and research in China. Bulletin of Mineralogy and Geochemistry 31(4): 313-320.

- Filho AGS, Fagan SB (2011) Nanomaterials Properties. In: Bergmann CP, Andrade MJ (Eds.), Nanostructured Materials for Engineering Applications. Springer, Germany.

- Kim B, Chung H, Kim W (2012) High-performance supercapacitors based on vertically aligned carbon nanotubes and nonaqueous electrolytes. Nanotechnology 23(15): 155401.

- Panyala NR, Peña-Méndez EM, Havel J (2009) Gold and nano-gold in medicine: overview, toxicology and perspectives. J Appl Biomed 7(2): 75-91.

- Roco MC (2004) Nanoscale science and engineering: unifying and transforming tools. AIChE Journal 50(5): 890-897.

- Roco MC (2011) The long view of nanotechnology development: the National Nanotechnology Initiative at 10 years. Nanotechnology Research Directions for Societal Needs in 2020. Springer, Netherlands, pp. 1-28.

- Savage N, Diallo MS (2005) Nanomaterials and water purification: opportunities and challenges. J Nanopart Res 7(4-5): 331-342.

- Schlemmer D, Angélica RS, Sales MJA (2010) Morphological and thermomechanical characterization of thermoplastic starch/ montmorillonite nanocomposites. Composite Structures 92(9): 2066- 2070.

© 2018 Said S E H Elnashaie. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)