- Submissions

Full Text

Research & Development in Material Science

Wear of Ultra High Molecular Weight Polyethylene against Synthetic Sapphire as Bearing Coating for Total Joint Replacements

Kevin D Gemmell and DML Meyer*

Mechanical Engineering, The University of Rhode Island, USA

*Corresponding author: DML Meyer, Thermomechanics Laboratory, The University of Rhode Island, Kingston, RI 02881, USA

Submission: April 27, 2018;Published: May 14, 2018

ISSN: 2576-8840

Volume6 Issue2

Abstract

Materials commonly found in hip replacements are a polymer paired with metals or alloys. Tribological behavior of polyethylene bearing surfaces against synthetic sapphire are compared against other bearing combinations to evaluate sapphire as a viable means to lower the incidence of revision surgery by mitigating production of wear debris. Sapphire disks against polyethylene plates were tested utilizing a tribometer. The polyethylene wear rate was found to be 22.6mm3 per year, less than the 40-80mm3 per year typically found in traditional hip replacements. A power law function is presented correlating a decreasing friction coefficient as polyethylene volume loss increases as V0.88. These results show potential for synthetic sapphire as an alternative bearing surface in joint replacements

Keywords: Polymer; Wear; Abrasive

Introduction

Synthetic sapphires have a common use in jewel bearings such as those found in some mechanical watches and sensitive measuring instruments due to low friction and also for improving bearing life [1,2]. Sapphire has mechanical properties, specifically its hardness of 9Mohs scale, making it the third hardest known natural substance [3]. Due to its hardness, it has a high resistance to scratching and abrasion, making it applicable to other bearing surfaces. To test if synthetic sapphire is a feasible option in other bearing surfaces, wear experiment were conducted to analyze volumetric wear rates and coefficients of friction of the polymer ultra-high-molecular-weight polyethylene (UHMWPE) against synthetic sapphire.

The inspiration for this research came from the total hip replacement. The majority of total hip (and knee) replacements are performed on adults when patients are having some type of arthritis of the hip or deterioration due to trauma, and who are usually 40+ years old [4,5]. If a patient’s hip is deteriorated and other treatments have failed, a hip replacement is often an option. While a total hip replacement is generally a successful surgery, there is the potential of failure of the replacement over time.

The type of failure evaluated in this research was weargenerated UHMWPE debris which initiates the destructive process of periprosthetic osteolysis and loosening of the implant. The polymer wear debris is created in part by abrasion between the femoral head and the UHMWPE acetabular liner. The debris particles can then migrate into regions contiguous with the femoral stem and femur bone, and initiate a bodily rejection [6,7]. However, these wear particles are resistant to the cellular response, which results in prolonged duration of inflammation and leads to progressive osteolysis [8], eventually causing loosening of the implant due to bone adsorption, and the requirement of a revision surgery.

The acetabular insert of a total hip replacement wears through its thickness at an average rate of 0.1mm/year, and in the case of one of the surfaces being polymer, it is estimated that 51billion polymer particles are produced each year from its surface [9]. The hip replacement is one of the most well-known implants, and a lot of research has been performed to analyze the implant material combinations and its wear characteristics. Previous work to mitigate the production of wear debris can be found in many articles, but for the current work [10-13] were used for comparative analysis, which included data for ultra-high-molecular-weight polyethylene-on-cobalt chromium (UHMWPE-on-CoCr), metalon- metal (MoM), ceramic-on-metal (CoM), ceramic-on-ceramic (CoC), and combinations of cross-linked and highly cross-linked polyethylene-on-cobalt chromium (CXPE and HXPE-on-CoCr) as well as HXPE-on-ceramic (Al2O3). A study using a flat sapphire disk against a flat UHMWPE disk [14], obtained friction coefficients of this material combination for a total of one hour of sliding, or the equivalent of 0.77% of one year of sliding of a total hip replacement. The short time period is insufficient to be able to use or compare the friction coefficients between the mating pair with other material combinations that typically have periods of sliding on the equivalent of one year or more. The same research group produced friction coefficients over a one hour period for sapphire-sapphire mating pairs [15].

The purpose of the current investigation was to determine the effectiveness of synthetic sapphire as a potential coating on the femoral head as a means to improve the durability of a total hip replacement, and potentially lower the incidence for revision surgery by mitigating the production of UHMWPE wear debris. The experiments utilized a pin-on-flat linear tribometer to simulate the sliding conditions of a hip replacement over the course of one year of use. The pin fixture in the experiment was replaced with an in-house fabricated one to hold a sapphire disk on its edge, and UHMWPE, a commonly used acetabular cup lining material, was used as the mating bearing surface against the sapphire in the form of a plate. Bovine serum was used as the lubricant to simulate synovial fluid found in human joints.

Due to some failures using UHMWPE inserts in hip replacements, the material combinations of ceramic-on-ceramic (CoC), ceramicon- metal (CoM), and metal-on-metal (MoM) hip replacements are now also being used in practice, each with their own complications involving wear. Metal implants can lead to conditions such as metallosis after wear debris is generated [16,17]. Ceramics have been shown to have lower wear rates. However, if they fail, the failure can be catastrophic [18]. To determine the effectiveness of synthetic sapphire against UHMWPE, volumetric wear rates of the materials used in current total hip replacements are compared to the UHMWPE volumetric wear rate for sapphire-on-UHMWPE.

Material and Methods

Dimensional analysis

With the inspiration of the hip replacement, the failure mode of this research is UHMWPE volumetric wear that exceeds that of conventional total hip replacement material combinations. The failure mode from a mechanics point of view is plastic deformation of the polyethylene surface due to abrasive plowing. Dimensional analysis allows for a description of which physical parameters to change during experiments based on the dependence of variables and guarantees that all of the variables are accounted for throughout experimentation, eliminating a “trial and error,” approach, and a tool to systematically design experiments.

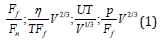

The experimental parameters are combined using the Buckingham Pi Theorem into dimensionless Pi groups [19]. This process resulted in the four dimensionless groups of Equation (1),

Where, is the absolute viscosity of the lubricant, bovine serum in this case; Ff is the frictional force between contacting surfaces; V is the UHMWPE volume loss during sliding; U is sliding velocity; T is time; L is sliding distance; Fn is normal load of the sapphire disk on the UHMWPE flat plate, and p is the contact pressure between the sapphire disk and UHMWPE plate. Note that the first pi group of Eq. (1), Ff/Fn=μ, is the friction coefficient between the sliding surfaces. Analysis of the experimental data using pi groups was considered and was found to reveal a correlation between and UHMWPE volume loss, as well as with time and friction force.

Tests were performed with a disk of synthetic sapphire-on- UHMWPE flat plate using bovine serum as the lubricant at room temperature. Sliding speeds were varied based on values found in the literature [10]. An average annual use of a hip joint correlates to 1million cycles, where a cycle is defined as the distance that the femoral head traverses the acetabular cup through a heelstrike, toe-off to the start of a heel-strike again. The average range for the annual distance varies between approximately 20E06mm to 50E06mm based on the radius of the femoral head. The total sliding distance of 23E06mm was used in the current work to simulate a year of hip motion [10-13]. For the first 9.99E06mm of sliding distance, the sliding velocity was 38.2mm/s, increasing to 67.2mm/s for the next 9.99E06mm of sliding distance, with a final sliding velocity of 93.4mm/s for the remainder of the test. A contact pressure of 6.5MPa is the typical average generated in hip replacements and was the average contact pressure for all of the literature comparisons. The contact area of the edge of the sapphire disk on the UHMWPE plate was measured using microscopy (Leica Model DMLB) and determined to be 0.45mm2. The lowest average contact pressure that was achievable with the linear tribometer and this contact area was 36.1MPa.

To make comparisons of the UHMWPE wear volume with wear volume values from the literature, the UHMWPE volume loss per distance traveled was normalized with the average contact pressure from the experiments. For instance, in the current work, the volume loss of UHMWPE at the first measurement was 12.9mm3 after traveling a distance of 3.33E06mm with an average contact pressure of 36.1MPa. Dividing the UHMWPE volume loss (12.9mm3) by the distance traveled (3.33E06mm) and dividing that value by the average contact pressure (36.1MPa), normalizes data for comparisons with literature values. The same process was repeated for volume loss per distance traveled using data from the literature and similarly normalized with the respective average contact pressure of 6.5MPa [10-13].

Experimental setup

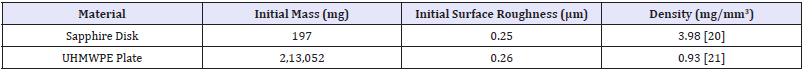

A linear tribometer, as shown in Figure 1, was used for the wear and friction tests to simulate a year of hip replacement UHMWPE wear against a sapphire disk. A fixture specifically designed and fabricated to hold the sapphire disk motionless on its edge, was used with a flat plate of UHMWPE as the articulating surface. The disk had a diameter of 6.27mm and a thickness of 1.63mm, while the rectangular sheet of UHMWPE had dimensions of 102mm x 305mm x 6.35mm. Prior to experimentation the mass and surface roughness of each material component were measured and are listed in Table 1.

Figure 1: Tribometer and experimental setup.

1a: Sketch of sapphire disk and UHMWPE plate, where Fn is the normal load, r is the sapphire disk radius, and t is the sapphire disk thickness.

1b: The tribometer and its components.

1c: The sapphire disk in the tribometer fixture.

1d: The fixture and sapphire disk in the tribometer with the UHMWPE plate mounted below the lubricant tray.

Table 1: Initial material properties of sapphire and UHMWPE.

In the tribometer experiments, the sapphire disk remained stationary while the UHMWPE plate track oscillated along the “x” axis shown in Figure 1a. Force and moment data were collected. One cycle on this tribometer was set to be 457mm (229 mm in each direction). Approximately 50mL of 50% bovine serum combined with distilled water, resulting in a 25% bovine serum mixture was used as the lubricant. The absolute viscosity of bovine serum at 25% is approximately 0.9mPa•s [22] (Figure 1a-1d).

To compare the current results to those found in the literature [10-13] and other hip simulator experiments, normalizing the experimental variables was performed. In [10], one cycle was a total sliding distance of 30mm and ran at a frequency of 2Hz, yielding a velocity of 60mm/s. Hip simulators are often used in testing and results of such experiments are found in the literature. The average sliding distance for one cycle in a hip simulator running at a frequency of 1Hz is 1.045D, where D is the diameter of the femoral head [23]. In [11], a hip simulator was used with femoral head diameters of 32mm and 44mm. This yields a sliding distance for the 32mm head of 33.44mm and speed of 33.44mm/s in one cycle, and the 44mm head had a sliding distance of 45.98mm and speed of 45.98mm/s in one cycle. In [12], a hip simulator was used with a femoral head diameter of 36mm. This yields a sliding distance of 37.62mm and speed of 37.62mm/s in one cycle. In [13], a hip simulator was used with a femoral head diameter of 28mm. This yields a sliding distance of 29.26mm and speed of 29.26mm/s in one cycle. In [11-13], the frequency and contact pressure were not explicitly stated. To extrapolate the normalization variables, a frequency of 1Hz and contact pressure of 6.5MPa were used to compare data. In the current experiment, to simulate the average hip movement in about one year, a distance of 23 × 106mm was traveled. The experimental parameters and those found in the literature are summarized in Table 2.

The experiment was interrupted every 3.33E06mm of distance that the sapphire disk traveled against the UHMWPE plate, to obtain the mass of the sapphire disk and UHMWPE plate (Mettler Toledo xs403s digital scale), as well as each material’s surface roughness (Mahr Federal profilometer). The UHMWPE volumetric wear, coefficients of friction and resultant forces were calculated from the experimental data.

Calculation

UHMWPE wear rate and friction

Prior to experimentation the initial mass, mi, of the UHMWPE plate was measured and recorded, and again at each 3.33E06mm traveled until the final measurement, mf, resulting in the mass loss as in Equation (2),

Δm = mi − m f(2)

The UHMWPE wear volume range for a traditional metal-on- UHMWPE hip replacement is between 40 and 80mm3 per year [13,24]. A volumetric wear rate that exceeds these bounds is considered a failure mode for the current experiments. To calculate UHMWPE volumetric wear, V, the change in mass of the UHMWPE, Δm, was used with its known density, ρ, as in Equation (3),

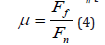

The instantaneous coefficients of friction, μ , were calculated using the ratio of the measured friction forces, Ff, to the measured normal forces, Fn [25].

Results

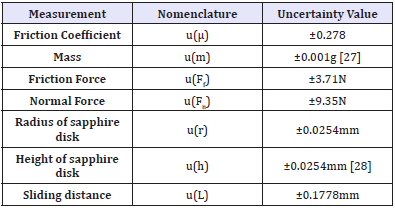

Table 3: Uncertainty values.

All uncertainty values from the experimental measurements were calculated using equations from [25,26], and are listed in Table 3. To evaluate an uncertainty, the law of propagation of uncertainty is utilized to determine the combined uncertainty, which is a function of the standard uncertainty of each input measurement and associated sensitivity coefficients. The standard uncertainty of each input variable was determined from the standard deviation of the force measurements, Ff and Fn, and from the tolerances given by the manufacturers of the sapphire disk and the mass scale, respectively.

The gravimetric data collected was converted into a volumetric wear of UHMWPE using the density of Table 1 with Equation (3). Note that all comparative data from the literature has been estimated by transcribing data from graphs or tables presented.

To compare the different material combinations found in total hip replacements, the normalized data as described earlier, of sapphire-on-UHMWPE from the current experiments are plotted against the normalized data of UHMWPE-on-CoCr, CXPE-on-CoCr, HXPE-on-CoCr, pre-worn HXPE-on-CoCr, HXPE-on-Al2O3, MoM, CoM, and CoC, as in [10-13]. This normalization takes into account the different contact pressures generated, different sliding distances, and frequencies at which the experiments were performed. By normalizing these factors, different experiments can be directly compared. The interpolated averaged data from [10-13] is within confidence intervals presented in [9-13,29-34].

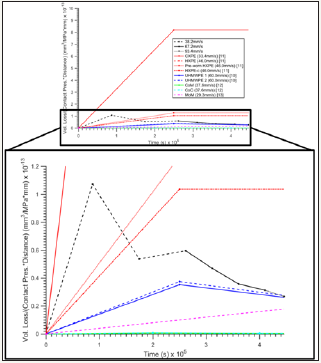

Figure 2: Ratio of UHMWPE volumetric wear to distancetraveled and contact pressure versus time of sapphire-on- UHMWPE, compared with material combinations found in the literature for UHMWPE-on-CoCr, CXPE-on-CoCr, HXPE-on-CoCr, pre-worn HXPE-on-CoCr, HXPE-on-Al2O3, MoM, CoM, and CoC [10-13].

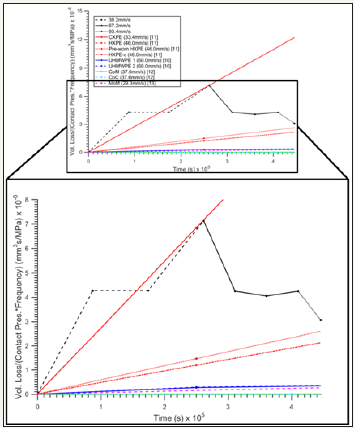

Figure 2 shows the ratio of the normalized UHMWPE volumetric wear to distance traveled and contact pressure versus time. Figure 3 shows the ratio of volumetric wear to frequency and contact pressure versus time. Note that the literature wear data used for comparisons with the UHMWPE wear against sapphire, of the current work, compare UHMWPE wear data from [10,11], while the wear data comparisons from [12,13] are that of metal and ceramic, specifically CoCr and zirconia toughened alumina ceramic (ZTA).

Figure 3: Ratio of UHMWPE volumetric wear to frequency and contact pressure versus time of sapphire-on-UHMWPE, compared with material combinations found in the literature for UHMWPE-on-CoCr, CXPE-on-CoCr, HXPE-on-CoCr, pre-worn HXPE-on- CoCr, HXPE-on-Al2O3, MoM, CoM, and CoC [10-13].

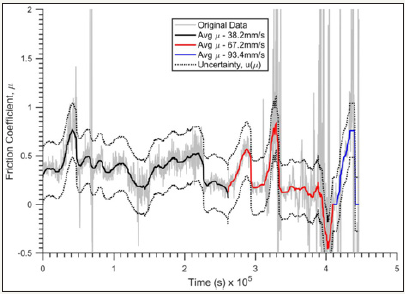

Figure 4: Friction coefficient versus time, plotted as a rolling average of the original data with the uncertainty.

Equation (4) was used to calculate the friction coefficients, which are plotted versus time, as shown in Figure 4. A rolling average was used to determine a best fit of the original data. Notice that when the velocity is set to the highest setting, the data becomes very noisy. This is due to the vibration of the stepper motor on the tribometer which affects the force transducers while collecting data.

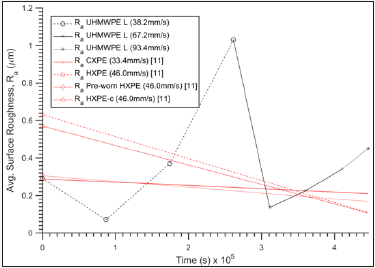

The UHMWPE surface roughness was measured along the wear track as well as across the wear track. The surface roughness of the sapphire disk was found to remain relatively constant, yielding an average roughness of 0.32μm. The surface roughness of the UHMWPE along the wear track is of interest. This surface roughness versus time is shown in Figure 5 and compared to surface roughness data shown in [11].

Figure 5: Comparative UHMWPE surface roughness versus time of sapphire-on-UHMWPE experiments and of surface roughness data of CXPE-on-CoCr, HXPE-on-CoCr, pre-worn HXPE-on-CoCr, and HXPE-on-Al2O3 [11].

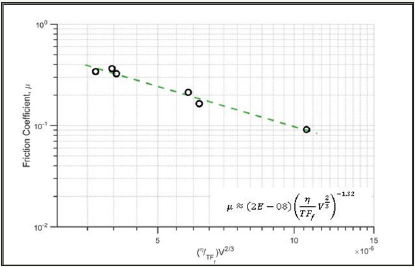

Figure 6: Power law correlation of friction coefficient between the sapphire disk against the UHMWPE plate with time, friction force and UHMWPE volume loss.

Using the first two pi groups of Eq. (1), namely

and

and

a

power law correlation is presented in Figure 6.

a

power law correlation is presented in Figure 6.

Discussion

UHMWPE is one of the most common materials found in a hip replacement paired with a metal. However, wear of UHMWPE may contribute to mechanical failure of the hip replacement. Many material combinations have been studied as a means to mitigate harmful sub-micron wear debris in a hip replacement. It is seen that MoM wear is very dependent on the type of metal, surface finish, and tribological design used [33]. These features create a large variation in wear for MoM implants and also a slight variation in CoM wear [33]. UHMWPE on metal also shows a large variation in wear due to the dependence on factors such as radiation and absorption of lubricant [10]. CoC demonstrates a very low variance along with its very low volumetric wear [12,13].

Reviewing the literature, it is seen that there are many different experimental setups as well as presentations of results, which create challenges in directly comparing wear experiments. Using the normalized plots provided in the current work allows for comparisons of different experiments. Interpolated averaged data within confidence intervals for the volumetric wear of UHMWPE against sapphire in the current work shows promise as a bearing combination in joint replacements. The average volumetric wear of CoM and CoC remains the lowest and most comparable to each other. MoM bearings show slightly higher volumetric wear compared to CoM and CoC bearing combinations, and also with greater variations than with CoM and CoC bearings [12,13,34].

The overall average coefficient of friction (COF) was determined using the average COF at each time step at which the experiments were halted to take mass measurements. When these average COFs are averaged, an overall average COF is found to be 0.28. This is an order of magnitude higher than expected for material combinations using UHMWPE, which have a COF range from 0.06 to 0.08, and is on the same order of magnitude when compared to metal-onmetal material combinations which have a COF range from 0.22 to 0.27 [35]. It may be explained by the very small contact area of 0.45mm2, producing a contact pressure of 36.1MPa. This contact pressure is also an order of magnitude greater than the typical contact pressures seen in total hip replacements, and thus explains, at least in part, the high overall average COF. Future experiments will need to be performed using the more realistic 6.5MPa contact pressure and contact area, where average COF values based on these typical values can be calculated and compared.

The power law function presented in Figure 6 demonstrates that the coefficient of friction continues to decrease over time as smaller increments of UHMWPE volume is removed through sliding contact. The fitted power law line displays the relationship between the logarithmic base ten (log10) of friction coefficient between sapphire and UHMWPE with log10 of time, friction force and volume loss of the UHMWPE, from the experimental data. The friction coefficient decreases the same with both time and friction force, both to the power 1.32, or T1.32 and Ff1.32., respectively. The friction coefficient has an inverse relation with the UHMWPE volume loss V, such that decreases with increasing UHMWPE volume loss as V0.88. For the power law equation of Figure 6, the correlation of these parameters follows a coefficient of determination R2=0.977, showing good correlation of the experimental data.

The surface roughness along the wear track of the UHMWPE against sapphire is of interest. The roughness initially decreases during the first 3.33E06mm of the first velocity, an indication that the sapphire disk abraded the UHMWPE surface. The roughness then increases for the next 6.66E06mm of the first velocity, indicating strain hardening of the polymer. After a total distance traveled of 9.99E06mm at the first velocity, the velocity was increased, and the surface roughness along the wear track of the UHMWPE drops significantly. The surface roughness begins to slowly, linearly increase for the remainder of the experiment.

Overall, sapphire against UHMWPE has been found to be a viable bearing surface for implant materials, potentially as a coating for the femoral head component of a total hip replacement. The results show a promising volumetric wear when compared with current material combinations of polyethylene-on-metal and even metal-on-metal. The wear rate of the UHMWPE in the sapphire experimentation was found to be 22.58mm3 per year, which is less than the 40-80mm3 per year that is typically found in a traditional metal-on-polyethylene hip replacement [13]. Further, these wear rate results do not account for serum absorption as discussed in [10,36]. Since the wear rate calculations are derived from gravimetric measurements, serum absorption by the UHMWPE can have a direct effect on the results. An in-vitro study of sapphire and other gem surfaces against currently-used implant materials, as well as accounting for serum absorption, would further explore this potential articulating surface combination. Further possibilities in bearing surfaces may also be determined as useful where longevity is a top priority.

Conclusion

In this study sapphire-on-UHMWPE showed a decrease in UHMWPE wear rate compared to UHMWPE-on-CoCr and the metal of MoM. However, in order to compare debris generation, debris morphology should be analyzed for size and shape differences to current wear debris found in hip replacements.

While this research focuses on sapphire as a coating material in current total joint replacements, another consideration is the use of sapphire as the femoral head material or as a coating in non-metallic joints, combinations of which can be used in CT scans and MRIs. While most metal implants are not magnetic, the metal can still cause distortions in imaging. Additionally, metal combination implants also require users to notify security officers prior to passing through any metal detectors. Utilizing gemstone as a bearing surface against non-metals can eliminate this burden from having metal implants, assuming the gemstone is not solely a coating on a metal surface.

Sapphire may be considered for further testing in tribometers and hip simulators against UHMWPE to more accurately measure the UHMWPE wear rate in-vitro, for 2 to 10million cycles. This will yield results including wear-in and steady-state periods, which can further be compared to those found in the literature. The overall average friction coefficient between sapphire and UHMWPE was found to be 0.28, an order of magnitude higher than expected. Future experiments will need to be performed using the more typical 6.5MPa contact pressures, where average COF values based on these contact pressures can be calculated. The power law function shows that decreases as the volume loss V of UHMWPE increases to the power 0.88, or V0.88.

The wear rate of the UHMWPE in the sapphire experimentation was found to be 22.58mm3 per year, which is less than the 40- 80mm3 per year that is typically found in a traditional metal-onpolyethylene hip replacement, or approximately 44-72% less, which provides justification to further pursue sapphire as an alternative bearing surface in polymer and metal-based total hip and knee replacements.

References

- (1993) Lubricants and bearings. Mach Des 65: 178.

- Dai X, Zhang K, Tang C (2013) Friction and wear of pivot jewel bearing in oil-bath lubrication for high rotational speed application. Wear 302(1- 2): 1506-1513.

- Schumann W (2009) Properties of gemstones. Gemstones of the world. Sterling: New York, USA, p. 20.

- Iorio R, Robb WJ, Healy WL, Berry DJ, Hozack WJ, et al. (2008) Orthopedic surgeon workforce and volume assessment for total hip and knee replacement in the United States-preparing for an epidemic. The Journal of Bone & Joint Surgery 90(7): 1598-1605.

- Frankel L, Sanmartin C, Spady BC, Marshall DA, Collins LF (2012) Osteoarthritis patients’ perceptions of “appropriateness” for total joint replacement surgery. Osteoarthritis and Cartilage 20(9): 967-973.

- Dattani R (2006) Femoral osteolysis following total hip replacement. Postgrad Med J 83(879): 312-316.

- Harris WH (1994) Osteolysis and particle disease in hip replacement: A review. Acta Orthopaedica 65(1): 113-123.

- Desai M, Bancroft L (2008) Periprosthetic osteolysis. Orthopedics 31.

- Lewis G (1997) Polyethylene wear in total hip and knee arthroplasties. J Biomed Mater Res 38(1): 55-75.

- Laraia K, Leone N, MacDonald R, Blanchet TA (2006) Effect of water and serum absorption on wear of unirradiated and crosslinked UHMWPE orthopedic bearing materials. Tribol Trans 49: 338-346.

- Kubo K, Clarke IC, Sorimachi T, Williams PA, Donaldson TK, et al. (2009) Aggressive 3rd body wear challenge to highly crosslinked polyethylene: A hip simulator model. Wear 267: 734-742.

- Reinders J, Sonntag R, Heisel C, Reiner T, Vot L, et al. (2013) Wear performance of ceramic-on-metal hip bearings. PLoS One 8(8): e73252.

- Firkins PJ, Tipper JL, Ingham E, Stone MH, Farrar R, et al. (2001) A novel low wearing differential hardness, ceramic-on-metal hip joint prosthesis. J Biomech 34(10): 1291-1298.

- Mamalis AG, Ramsden JJ, Grabchenko AI, Lytvynov LA, Filipenko VA, et al. (2006) A novel concept for the manufacture of individual sapphiremetallic hip joint endoprostheses. Journal of Biological Physics and Chemistry 6: 113-117.

- Mamalis AG, Lytvynov LA, Filipenko VA, Lavrynenko SN, Ramsden JJ, et al. (2007) Perfection of contemporary hip joint endoprostheses by using a sapphire-sapphire friction pair. Journal of Biological Physics and Chemistry 7: 3-5.

- Browne J, Bechtold CD, Berry D, Hanssen A, Lewallen D (2010) Failed metal-on-metal hip arthroplasties: a spectrum of clinical presentations and operative findings. Clin Orthop Relat Res 468(9): 2313-2320.

- Korovessis P, Petsinis G, Repanti M, Repantis T (2006) Metallosis after contemporary metal-on-metal total hip arthroplasty. The Journal of Bone & Joint Surgery 88(6): 1183-1191.

- Park Y, Hwang S, Choy W, Kim Y, Moon Y, et al. (2006) Ceramic failure after total hip arthroplasty with an alumina-on-alumina bearing. The Journal of Bone & Joint Surgery 88(4): 780-787.

- Buckingham E (1916) Model experiments and the forms of empirical equations. ASME 37: 263-296.

- Bird Precision I (2014) Properties of synthetic sapphire and ruby.

- Plastic Products I (2014) Technical product data sheets-UHMWPE, USA.

- Mattei L, Puccio FD, Piccigallo B, Ciulli E (2011) Lubrication and wear modelling of artificial hip joints: A review. Tribol Int 44: 532-549.

- Wang A, Sun DC, Yau S, Edwards B, Sokol M, et al. (1997) Orientation softening in the deformation and wear of ultra-high molecular weight polyethylene. Wear 203-204: 230-241.

- McKellop HA, Campbell P, Park SH, Schmalzried TP, Grigoris P, et al. (1995) The origin of submicron polyethylene wear debris in total hip arthroplasty. Clin Orthop Relat Res (311): 3-20.

- Schmitz TL, Action JE, Ziegert JC, Sawyer WG (2005) The difficulty of measuring low friction: uncertainty analysis for friction coefficient measurements. Journal of Tribology 127(3): 673-678.

- Schmitz TL, Action JE, Burris DL, Ziegert JC, Sawyer WG (2004) Wearrate uncertainty analysis. Journal of Tribology. 126(4): 802-808.

- Toledo M (2014) Specifications-Balance XS403S.

- Bird Precision I (2014) Ring jewel bearings information catalogue.

- Affatato S, Spinelli M, Squarzoni S, Traina F, Toni A (2009) Mixing and matching in ceramic-on-metal hip arthroplasty: an in-vitro hip simulator study. J Biomech 42: 2439-2446.

- Affatato S, Zavalloni M, Taddei P, Foggia Di M, Fagnano C, et al. (2008) Comparative study on the wear behaviour of different conventional and cross-linked polyethylenes for total hip replacement. Tribol Int 41: 813- 822.

- Affatato S, Spinelli M, Zavalloni M, Traina F, Carmignato S, et al. (2010) Ceramic-on-metal for total hip replacement: mixing and matching can lead to high wear. Artif Organs 34: 319-323.

- Barnes CL, DeBoer D, Corpe RS, Nambu S, Carroll M, et al. (2008) Wear performance of large-diameter differential-hardness hip bearings. J Arthroplasty 23(6 Suppl 1): 56-60.

- Firkins PJ, Tipper JL, Saadatzadeh MR, Ingham E, Stone MH, et al. (2001) Quantitative analysis of wear and wear debris from metal-on-metal hip prostheses tested in a physiological hip joint simulator. Biomed Mater Eng 11(2): 143-157.

- Ishida T, Clarke IC, Donaldson TK, Shirasu H, Shishido T, et al. (2009) Comparing ceramic-metal to metal-metal total hip replacements-A simulator study of metal wear and ion release in 32- and 38-mm bearings. Journal of Biomedical Materials Research Part B: Applied Biomaterials 91B: 887-896.

- Jin ZM, Stone M, Ingham E, Fisher J (2006) (v)Biotribology. Current Orthopaedics 20: 32-40.

- Yao JQ, Blanchet TA, Murphy DJ, Laurent MP (2003) Effect of fluid absorption on the wear resistance of UHMWPE orthopedic bearing surfaces. Wear 255: 1113-1120.

© 2018 DML Meyer. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)