- Submissions

Full Text

Research & Development in Material Science

Selection of High Temperature Phase Change Materials for Energy Storage

Chiranjib Bhowmik1, Sumit Bhowmik1* and Amitava Ray2

1Department of Mechanical Engineering, National Institute of Technology Silchar, India

2Jalpaiguri Government Engineering College, India

*Corresponding author: Sumit Bhowmik, Assistant Professor, Department of Mechanical Engineering, National Institute of Technology Silchar, Assam 788010, India

Submission: March 01, 2018;Published: April 25, 2018

ISSN: 2576-8840

Volume5 Issue4

Abstract

In this study two way multi-criteria decision-making approaches are used to select and rank the best phase change material for energy storage from a given set of alternatives. Firstly, multi-objective optimization on the basis of ratio analysis (MOORA) plus full multiplicative form (MULTIMOORA) is applied to select the best candidate material. Result shows that 88Al:12Si is the best material considering the selection strategy. Again, multi-objective optimization on the basis of simple ratio analysis (MOOSRA) is used to measure the performance of the candidate material. Study also reveals that Aluminium, commercial purity, 1-0 wrought is the optimum material for energy storage described by MOOSRA method.

Keywords: Energy storage; Phase change materials; Multi-criteria decision making; Selection

Introduction

As rapidly developed living standards around the globe forces the community to find the optimal materials for energy storage. Extensive utilization of fossil energy has caused serious ecological damage, which attract the governments and researchers around the globe. Enthusiastically endorsing green energy has undoubtedly become a significant means of the ecological damage. Concentrated solar power (CSP) technology is one of the most auspicious forms of green energy [1]. This technology possesses huge energy reserves without emission of any harmful gases. Past researchers also believe that vigorously evolving CSP technology is one of the furthermost operative traditions to reveal the energy supply glitches in near future [1]. For continuity in energy supply, phase change materials (PCMs) are playing a crucial role on energy storage followed by sensible heat storage (SHS) and latent heat storage (LHS) [2]. SHS comprises storing the energy in the form of heat by varying the internal energy of a material without phase change whereas, a material endures a phase change mode when LHS energy is stored [2]. Phase change materials fascinate or release heat at persistent temperature which is a vital reflection of efficient power generation [2]. With the copiousness and emergent numeral of novel materials being testified in the current researches, phase change materials selection is becoming more shared. Through this is a fundamental issue that must be solved by exploiting the optimal PCMs for energy storage. Therefore, this work has attempted to screen and rank various PCMs for energy storage application using hybrid multicriteria decision-making (MCDM) approach [1-3].

Materials and Methods

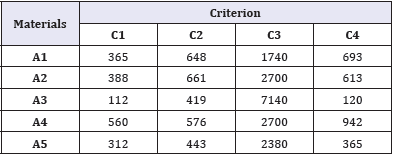

The selection of phase change materials for energy storage be subject to various factors, such as material possessions, stowing volume, performance, functioning temperature etc. [1]. Traditional material selection from side to side documented strategies, such as collected works have limitation in terms of information and right to use of germane data [2]. Therefore, this study considers the technologically important PCMs for energy storage applications, such as Magnesium, commercial purity (A1); Aluminium, commercial purity, 1-0 wrought (A2); Zinc, commercial purity, high grade, min 99.9% (A3); 88Al:12Si (A4) and 60Al:34Mg:6Zn (A5). The significant properties of the aforementioned materials are latent heat (KJ/Kg) (C1); melting point (°C) (C2); density (Kg/m3) (C3) and total energy stored (KJ/Kg) (C4) documented in Table 1.

Table 1: Properties of materials [2].

Many different methods are available to screen and rank the phase change materials, including experimental methods [1,4,5], theoretical calculations and numerical simulations [1,6,7]. In this study authors have attempted to screen and rank various PCMs for energy storage applications using hybrid MCDM techniques. Two MCDM techniques have been used namely multiobjective optimization on the basis of ratio analysis (MOORA) plus full multiplicative form (MULTIMOORA) and multi-objective optimization on the basis of simple ratio analysis (MOOSRA) to measure the performance of the candidate materials [8-11]. All these techniques together have been used as an efficient tool for initial ranking and screening the materials for various phase change materials based storage applications. Shannon’s entropy method is used to calculate the relative importance of the properties on the decision making process [3,12-14].

Results and Discussion

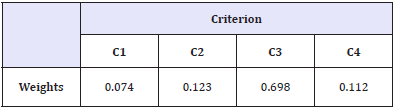

To demonstrate the applicability of the MOORA plus multiplicative form MULTIMOORA and MOOSRA methods in the selection dilemma, this work considers four criteria, viz. latent heat, melting point, density and total energy stored and five alternatives Magnesium, commercial purity; Aluminium, commercial purity, 1-0 wrought; Zinc, commercial purity, high grade, min 99.9%; 88Al:12Si and 60Al:34Mg: 6Zn from a published literature [2]. The decision matrix of the selected problem is shown in Table 1. Before applying MOORA plus multiplicative form MULTIMOORA and MOOSRA methods, weight of each criteria is calculated using Shannon’s entropy method and shown in Table 2.

Table 2: Weights of each criteria.

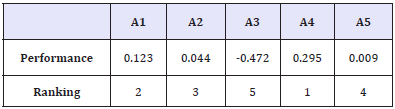

MOORA and MULTIMOORA methods are easy to calculate, does not require huge mathematics fully depends on ratio system. Firstly, the decision matrix shown in Table 1 is normalized and then depending on the beneficial and non-beneficial criteria overall performance of the candidate materials is computed. Table 3 shows the overall performance and the ranking of the candidate materials. 88Al:12Si is the best PCM according to the ratio system part of MOORA and full multiplicative form MULTIMOORA [2].

Table 3: Overall performance and ranking by MOORA & MULTIMOORA method.

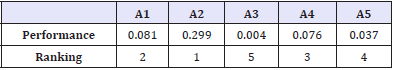

The initial steps of MOOSRA method are similar to MOORA method. But in this case weighted normalized decision matrix is computed. Shannon’s entropy method is used to calculate the weights of each criteria. Thereafter, the sum of the beneficial criteria is divided by the sum of non-beneficial criteria, to find the overall performance score and ranking of each alternative shown in Table 4 [2].

Table 4: Overall performance and ranking by MOOSRA.

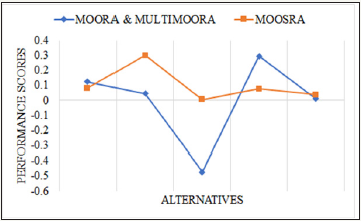

According to the MOOSRA method, Aluminium, commercial purity, 1-0 wrought is the best PCM for energy storage material selection problem. The MOORA and full multiplicative form MULTIMOORA methods produce same rankings, whereas MOOSRA method gives different ranking shown in Figure 1.

Figure 1: Performance rankings.

Conclusion

Energy storage materials selection is very significant for the expansion of high-temperature CSP technologies. Based on the collection and scrutiny of pertinent data associated with this work following conclusions are drawn.

A. In this work multi-objective decision making dilemma for energy storage material is fingered and explained by MOORA and its full multiplicative form MULTIMOORA and MOOSRA methods.

B. Results suggest that 88Al:12Si is the best storage material by MOORA and MULTIMOORA methods and Aluminium, commercial purity, 1-0 wrought is the best alternative by MOOSRA method.

Finally, these approaches are visualized as a suitable tool for selecting the best alternative from a set of candidate materials. In future, studies like high-temperature phase change materials for energy storage problem can be solved by other multi-objective decision making methods with any other number of criterions and alternatives.

References

- Wei G, Wang G, Xu C, Ju X, Xing L, et al. (2017) Selection principles and thermophysical properties of high temperature phase change materials for thermal energy storage: a review. Renewable and Sustainable Energy Reviews 81: 1771-1786.

- Khare S, Knight CD, McGarry S (2012) Selection of materials for high temperature latent heat energy storage. Solar Energy Materials and Solar Cells 107: 20-27.

- Rastogi M, Chauhan A, Vaish R, Kishan A (2015) Selection and performance assessment of phase change materials for heating, ventilation and air-conditioning applications. Energy Conversion and Management 89: 260-269.

- Yang M, Yang X, Yang X, Ding J (2010) Heat transfer enhancement and performance of the molten salt receiver of a solar power tower. Applied Energy 87(9): 2808-2811.

- Zhang Y, Yi J, Yi J (1999) A simple method, the-history method, of determining the heat of fusion, specific heat and thermal conductivity of phase-change materials. Measurement Science and Technology 10(3): 201-205.

- Lu J, Jing D (2009) Dynamical and thermal performance of molten salt pipe during filling process. International Journal of Heat and Mass Transfer 52 (15-16): 3576-3584.

- Lu J, Jing D, Yang J (2010) Solidification and melting behaviors and characteristics of molten salt in cold filling pipe. International Journal of Heat and Mass Transfer 53(9-10): 1628-1635.

- Adalı EA, Işık AT (2017) The multi-objective decision making methods based on MULTIMOORA and MOOSRA for the laptop selection problem. Journal of Industrial Engineering International 13(2): 229-237.

- Karande P, Chakraborty S (2012) Application of multi-objective optimization on the basis of ratio analysis (MOORA) method for materials selection. Materials & Design 37: 317-324.

- Bhowmik C (2014) Optimization of process parameter using theory of constraints. International Journal of Basic and Applied Science Research 1(1): 7-10.

- Kumar R, Ray A (2015) Selection of material under conflicting situation using simple ratio optimization technique. In: Das K, Deep K, Pant M, Bansal J, Nagar A (Eds.), Proceedings of fourth international conference on soft computing for problem solving. Advances in Intelligent Systems and Computing. Springer, New Delhi, India, Vol. 335.

- Lotfi FH, Fallahnejad R (2010) Imprecise shannon’s entropy and multi attribute decision making. Entropy 12(1): 53-62.

- Bhowmik C, Gangwar S, Bhowmik S, Ray A (2018) Selection of energyefficient material: an entropy-topsis approach. In: Pant M, Ray K, Sharma T, Rawat S, Bandyopadhyay A (Eds.), Soft Computing: Theories and Applications. Advances in Intelligent Systems and Computing, Springer, Singapore, Vol. 584.

- Yeh CH (2002) A problem‐based selection of multi‐attribute decisionmaking methods. International Transactions in Operational Research 9(2): 169-181.

© 2018 Sumit Bhowmik. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)