- Submissions

Full Text

Research & Development in Material Science

Review of Liquid Metal-Based Strain and Tactile Sensors

Yuxin Wang1,2, Zhe Yu1,2,3, Jie Shang1,2*, Yiwei Liu1,2 and Run-Wei Li1,2*

1CAS Key Laboratory of Magnetic Materials and Devices, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, China

2Zhejiang Province Key Laboratory of Magnetic Materials and Application Technology, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, China

3College of Materials Science and Opto-Electronic Technology, University of Chinese Academy of Sciences, China

*Corresponding author: Jie Shang, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, Zhejiang, P. R. China, 315201

Submission: March 12, 2018;Published: April 18, 2018

ISSN: 2576-8840

Volume5 Issue4

Abstract

With the popularity and multi-function of intelligent electronic equipment, the wearable electronic devices present a huge market prospect. Stretchable sensor, as an important wearable electronic device, is not only required to have high sensitivity, but also to have good stretchability, robustness, and other mechanical properties. Because the room temperature liquid metal has remarkable deformation ability and good electrical conductivity, it is applied to develop several new high-powered stretchable sensors. In this paper, the current researches of liquid metal-based strain and tactile sensors are reviewed, and future directions of those sensors are proposed according to the present challenges.

Keywords: Liquid metal; Strain sensor; Tactile sensor; Stretchable sensor

Introduction

As an important wearable electronic device, stretchable sensor has played a vital role in many fields, such as healthcare, motion detection, electronic skin, and etc [1-4]. Stretchable strain sensor and tactile sensor are two widely used stretchable sensors [3,5], which can transform external stretching or pressing stimulus signals into detectable electrical signals. The common signal transformations are force-resistance transformation and forcecapacitance transformation [4,5]. Presently, the materials of reported stretchable strain and tactile sensors are mainly composite conductive polymer based on solid conductive fillers [3,5-7], including graphene, carbon nanotube, metal nanoparticle, and etc. Those strain and tactile sensors exhibit a remarkable electrical signal response to stretching and pressing, which means it, has an excellent sensitivity. However, the mechanical properties of those sensors are not ideal, such as stretchability and robustness [8,9], which makes it difficult to use for long time under a lager strain. The reason of this is the elastic modulus of conventional solid fillers are 5-6 orders of magnitude higher than that of elastic polymer matrix [8,10]. It severely limits the application and development of stretchable strain and tactile sensors. The room temperature liquid conductive materials have remarkable deformation ability. If they are applied to replace conventional solid conductive fillers, it is expected to prepare the high performance stretchable strain and tactile sensors by eliminating the elastic modulus mismatch. Gallium-based room temperature liquid metal (LM) is one of the ideal liquid conductive materials for their high conductivity, low melting point, and non-toxic. For examples, the conductivity and melting point of eutectic gallium-indium alloy (EGaIn) respectively are 3.4×106S/cm and 15.5 °C, and the conductivity and melting point of gallium-indium-tin alloy (Galinstan) respectively are 3.46×106S/cm and -19 °C [11]. In this review, we highlight several recent significant results related to liquid metal-based strain and tactile sensors, including preparation methods, sensor types, and application fields. Finally, some major challenges and perspectives are also discussed

Recent Development

Right now, a variety of technologies are available to prepare the LM-based strain and tactile sensors. The key point of preparation is how to pattern the LM on or into the elastic matrix [12]. Presently, there are five main methods to pattern the LM, including fluidic injection, stamp lithography, selective wetting, soft imprinting and direct-write printing.

1. Fluidic injection is injecting the LM into microchannel of elastic matrix or elastic fiber tube [13]

2. Stamp lithography is spreading the LM across a stiff stencil placed atop a elastic substrate, and then encapsulating the patterned LM by elastic material [14,15]

3. Selective wetting is utilizing the unique wettability of the LM with several metal (e.g. Sn, Au, and Cu) [16-18], spreading the LM on the substrate with pre-patterned wetting and nonwetting regions, and then encapsulating.

4. Soft imprinting is dipping a structured elastic stamp into LM and transferring it to another surface, embossing a LM film and producing separate structures by squeezing out metal, or by transferring from a single LM film into recesses on a structured surface [19,20]

5. Direct-write printing is utilizing the stickiness of thin oxide skin at the surface of LM to pattern by direct-write printing LM ink [21].

Depending on the different signal transformation mechanisms, the reported LM-based strain and tactile sensors can be divided into resistance type and capacitance type. For resistive-type LMbased strain and tactile sensors, the resistance of the sensors will change when external strain/pressure is applied to the LM-based active materials. Compared with traditional resistive-type sensors, the LM-based sensors not only exhibit excellent stretchability, but also have good robustness and small hysteresis coefficient. For examples, the resistive-type LM-based strain sensor reported by Wu et al. [22] can still be stable after 3500 cycles under 70% strain, and the hysteresis coefficient of sensor is only 0.11%; The resistivetype LM-based tactile sensor reported by Voget et al. [23] can measure the magnitude and direction of pressure; The resistivetype LM-based multi-functional sensor reported by Park et al. [24] can detect the strain from 0% to 250% and the pressure from 0kPa to 40kPa. For capacitance-type LM-based strain and tactile sensors, the mechanical deformation induced by the external strain/ pressure leads to the change of overlap area or space between the two electrodes, and then results in variation of the capacitance. The function of capacitance-type LM-based sensors is determined by the structure of two LM conductors. In addition to the traditional parallel plate structure, the common structure of two LM conductors is cross array structure, flat comb structure, and double helix fibers structure. The capacitance-type sensor with cross array structure can be used to detect the tactile pressure distribution. For example, Li et al. [25] adopted fluidic injection method to successfully prepare a capacitance-type LM-based sensor with cross array structure, which realized the millimeter-level detection of pressure distribution. The capacitance-type sensor with flat comb structure usually is used to detect strain. For example, Tabatabai et al. [14] adopted stamp lithography method to prepare a capacitance-type LM-based sensor with flat comb structure, which has a good linear response during stretched from 0% to 250%. The capacitancetype sensor with double helix fibers structure, such as prepared by Cooper et al. [26] using fluidic injection method, can be used for strain sensor, tactile sensor, and torsion sensor. Furthermore, the LM microdroplets can be embedded into the elastic matrix to prepare a stretchable composite material with high dielectric constant [27], which can be used for dielectric layer of capacitancetype sensor.

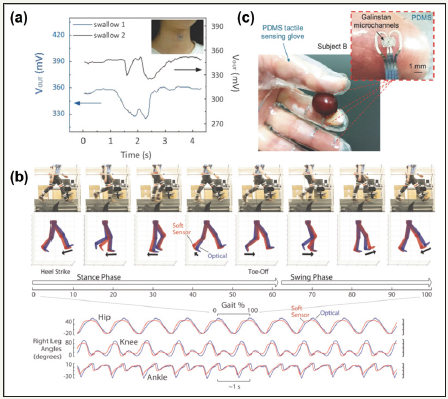

Figure 1: The application of LM-based strain and tactile sensors.

1a: The real-time wireless monitoring of muscle motion upon swallowing [29]

1b: The real-time monitoring of human gait during walking and running [30]

1c: Photograph of the PDMS glove electronic skin embedding multiple LM-based tactile sensors worn while grasping a grape [33].

Now, LM-based strain and tactile sensors have been widely used in medical healthcare, motion detection, electronic skin, and etc. In medical healthcare, Xi et al. [28] utilized a microtubular LM-based tactile sensor (Φ=250μm) to achieve continuous realtime monitoring of arterial pulse waves; Jeong et al. [29] used a multifunctional LM-based integrated system of sensors to achieve real-time wireless monitoring of muscle motion upon swallowing or during speech, as shown in Figure 1a. In motion detection, Mengüc et al. [30] developed a detection system using several LMbased strain sensors for human gait measurement during walking and running, and the root mean square errors are less than 5° and 15°, respectively, for walking speed of 0.89m/s and running speed of 2.7m/s, as shown in Figure 1b; Matsuzaki et al. [31] identified slight differences of the folding states of finger by a data glove, which is composed of LM-based strain sensors. In electronic skin, Kim et al. [32] prepared a fingertip electronic skin based on LM by soft imprinting method, which can perceive the bending, touching, and pressing motion of finger; Gao et al. [33] prepared a PDMS glove electronic skin embedding multiple LM-based tactile sensors (Figure 1c) to provide comprehensive tactile feedback of a human hand when touching or holding objects.

Conclusion

In the field of flexible electronics, the LM-base strain and tactile sensors have gradually displayed their unique advantages. However, the existing room temperature liquid metal will solidify and turn into solid at low temperature, which leads to existing LM-based sensors cannot work properly. Therefore, the low temperature LM is needed. Moreover, the performances of sensor are closely related to the structure and pattern of sensor. For the LM-based strain and tactile sensors, the research of structure and pattern has just begun and needs to be further developed. In general, the development of LM-based strain and tactile sensors is in its infancy, which means it not only has more important research value and broad application prospect, but also faces many challenges.

References

- Hammock ML, Chortos A, Tee BCK, Tok JBH, Bao Z (2013) 25th anniversary article: the evolution of electronic skin (e-skin): a brief history, design considerations, and recent progress. Advanced Material 25(42): 5997-6038.

- Wang XW, Liu Z, Zhang T (2017) Flexible sensing electronics for wearable/attachable health monitoring. Small 13(25): 1602790.

- Amjadi M, Kyung KU, Park I, Sitti M (2016) Stretchable, Skin-mountable, and wearable strain sensors and their potential applications: a review. Advanced Functional Material 26(11): 1678-1698.

- Wan YB, Wang Y, Guo CF (2017) Recent progresses on fexible tactile sensors. Materials Today Physics 1: 61-73.

- Yao SS, Swetha P, Zhu Y (2018) Nanomaterial-enabled wearable sensors for healthcare. Advanced Healthcare Material 7(1): 1700889.

- McCoul D, Hu WL, Gao MM, Mehta V, Pei QB (2016) Recent advances in stretchable and transparent electronic materials. Advanced Electronic Material 2(5): 1500407.

- Park M, Park J, Jeong U (2014) Design of conductive composite elastomers for stretchable electronics. Nano today 9(2): 244-260.

- Guan LY, Nilghaz A, Su B, Jiang L, Cheng Wl, et al. (2016) Stretchablefiber- confined wetting conductive liquids as wearable human health monitors. Advanced Functional Material 26(25): 4511-4517.

- Varga M, Mehmann A, Marjanovic J, Reber J, Vogt C, et al. (2017) Adsorbed eutectic GaIn structures on a neoprene foam for stretchable MRI coils. Advanced Material 29(44): 1703744.

- Bartlett MD, Kazem N, Powell-Palm MJ, Huang XN, Sun WH, et al. (2017) High thermal conductivity in soft elastomers with elongated liquid metal inclusions. Proceedings of the National Academy of Science of the United States of America 114(9): 2143-2148.

- Dickey MD (2017) Stretchable and soft electronics using liquid metals. Advanced Material 29(27): 1606425.

- Khondoker MAH, Sameoto D (2016) Fabrication methods and applications of microstructured gallium based liquid metal alloys. Smart Materials and Structures 25(9): 093001.

- Zhu S, So JH, Mays R, Desai S, Barnes WR, et al. (2013) Ultrastretchable fibers with metallic conductivity using a liquid metal alloy core. Advanced Functional Material 23(18): 2308-2314.

- Tabatabai A, Fassler A, Usiak C, Majidi C (2013) Liquid-phase gallium− indium alloy electronics with microcontact printing. Langmuir 29(20): 6194-6200.

- Jeong SH, Hagman A, Hjort K, Jobs M, Sundqvist J, et al. (2012) Liquid alloy printing of microfluidic stretchable electronics. Lab on a Chip 12(22): 4657-4664.

- Kramer RK, Majidi C, Wood RJ (2013) Masked deposition of galliumindium alloys for liquid embedded elastomer conductors. Advanced Functional Material 23(42): 5292-5296.

- Kim HJ, Son C, Ziaie B (2008) A multiaxial stretchable interconnect using liquid-alloy-filled elastomeric microchannels. Applied Physics Letters 92: 011904.

- Li GY, Lee DW (2017) An advanced selective liquid-metal plating technique for stretchable biosensor applications. Lab on a Chip 17: 3415-3421.

- Gozen A, Tabatabai A, Ozdoganlar OB, Majidi C (2014) High-density soft-matter electronics with micron-scale line width. Advanced Material 26(30): 5211-5216.

- Kim MG, Alrowais H, Pavlidis S, Brand O (2016) Size-scalable and highdensity liquid-metal-based soft electronic passive components and circuits using soft lithography. Advanced Functional Material 27(3): 1604464.

- Sheng L, Teo SH, Liu J (2016) Liquid-metal-painted stretchable capacitor sensors for wearable healthcare electronics. Journal of Medical and Biological Engineering 36(2): 265-272.

- Wu YH, Zhen RM, Liu HZ, Liu SQ, Deng ZF, et al. (2017) Liquid metal fiber composed of a tubular channel as a high-performance strain sensor. Journal of Materials Chemistry C 5(47): 12483-12491.

- Vogt DM, Park YL, Wood RJ (2013) Design and characterization of a soft multi-axis force sensor using embedded microfluidic channels. IEEE Sensors Journal 13(10): 4056-4064.

- Park YL, Chen BR, Wood RJ (2012) Design and fabrication of soft artificial skin using embedded microchannels and liquid conductors. IEEE Sensors Journal 12(8): 2711-2718.

- Li B, Gao Y, Fontecchio A, Visell Y (2016) Soft capacitive tactile sensing arrays fabricated via direct filament casting. Smart Materials and Structures 25(7): 075009.

- Cooper CB, Arutselvan K, Liu Y, Armstrong D, Lin YL, et al. (2017) Stretchable capacitive sensors of torsion, strain, and touch using double helix liquid metal fibers. Advanced Functional Material 27(20): 1605630.

- Bartlett MD, Fassler A, Kazem N, Markvicka EJ, Mandal P, et al. (2016) Stretchable, high-k dielectric elastomers through liquid-metal inclusions. Advanced Material 28(19): 3726-3731.

- Xi W, Yeo JC, Yu LT, Zhang S, Lim CT (2017) Ultrathin and wearable microtubular epidermal sensor for real-time physiological pulse monitoring. Advanced Material Technologies 2(5): 1700016.

- Jeong YR, Kim J, Xie ZQ, Xue YG, Won SM, et al. (2017) A skin-attachable, stretchable integrated system based on liquid GaInSn for wireless human motion monitoring with multi-site sensing capabilities. NPG Asia Materials 9: e443.

- Menguc Y, Park YL, Pei H, Vogt D, Aubin PM, et al. (2014) Wearable soft sensing suit for human gait measurement. The International Journal of Robotics Research 33(14): 1748-1764.

- Matsuzaki R, Tabayashi K (2015) Highly stretchable, global, and distributed local strain sensing line using GaInSn electrodes for wearable electronics. Advanced Functional Material 25(25): 3806-3813.

- Kim MG, Alrowais H, Brand O (2018) 3D-integrated and multifunctional all-soft physical microsystems based on liquid metal for electronic skin applications. Advanced Electronic Material 4(2): 1700434.

- Gao YJ, Ota H, Schaler EW, Chen K, Zhao A, et al. (2017) Wearable microfluidic diaphragm pressure sensor for health and tactile touch monitoring. Advanced Material 29(39): 1701985.

© 2018 Jie Shang. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)