- Submissions

Full Text

Research & Development in Material Science

On the Energy Harvesting Potential of Lead- Free Piezoelectric Composites from Air-Flow and Temperature Change

Zhenjin Wang, Shoki Abe and Fumio Narita*

Department of Materials Processing, Tohoku University, Japan

*Corresponding author: Fumio Narita, Department of Materials Processing, Graduate School of Engineering, Tohoku University, Aoba-yama, 6-6-02, Sendai 980-8579, Japan

Submission: March 03, 2018;Published: April 03, 2018

ISSN: 2576-8840

Volume5 Issue2

Abstract

This communication gives a short overview of our recent findings of output voltage in lead-free piezoelectric particle/polymer composites due to air-flow and temperature change. Barium titanate (BTO)/epoxy composite and potassium sodium niobate (KNN)/epoxy composite sheets were fabricated. The composite samples were polarized using either a parallel plate contact or contactless (corona) poling technique. The distribution of the phases in the matrix was studied by a scanning electron microscopy (SEM). The output voltage was then measured for the composite sheets due to airflow. The output voltage was also examined for the composites due to temperature change, and the effect of the poling conditions on the performance was examined. This short communication opens the door for development of flexible multi-energy harvesting devices.

Keywords: Piezoelectric composites; Vibration energy harvesting; Temperature energy harvesting; Sensors

Introduction

With the appearance of the wearable devices and Internet of Things (IoT), energy harvesting nodes are becoming more and more important. Recently, Narita & Fox [1] have published a review of recent development of the energy harvesting materials. The article was focused on three types of materials utilized in energy harvesters: piezoelectric ceramics and polymers, magnetostrictive alloys, and magnetoelectric (ME) composite materials. Piezoelectric ceramics have been widely recognized for their potential utility in energy harvesting applications [2,3]. However, several drawbacks such as their brittleness have limited the adoption of the piezoelectric ceramics, and the flexibility to tailor the properties of composite materials is an indispensable advantage compared with piezoelectric ceramics. Shahab & Erturk [4] investigated the resonant dynamic actuation and power generation with resistive shunt damping for various piezoelectric macro-fiber composite bimorph cantilevers. Zeng et al. [5] designed and fabricated a sandwich structure flexible energy harvester using a high performance bulk form PIN-PMN-PT/epoxy 2-2 composite flake (epoxy volume ratio of 20%), and studied systematically the electrical properties of the device under different frequency, strains, strain rates and load resistances.

Energy harvesters have a wide range of applications, for instance, they can generate heat in various machines during operations where temperature changes. The pyroelectric effect is exhibited by some dielectric materials with polar point symmetry that show spontaneous polarization as a function of temperature. Karim et al. [6] studied a lead free alternative for lead zirconate titanate (PZT) thermal energy harvesting and storage systems using LiNbO3 as the pyroelectric material. Narita et al. [7] studied the energy harvesting characteristics of piezoelectric laminates consisting of BTO and copper undergoing temperature changes from room temperature to cryogenic (77K) and high (333K) temperatures. The effect of pyroelectricity was probably too small to be the single major contributor to the obtained output voltage and, as experimental results and linking phase field and finite element simulations suggested, electricity in the BTO layer was generated not only through the piezoelectric effect caused by a thermally-induced bending stress, but also by the temperature dependence of the piezoelectric coefficient and permittivity.

The purpose of this communication is to report the potential of flexible lead-free piezoelectric particle/polymer composites for vibration and temperature energy harvesting. BTO/epoxy composite and KNN/epoxy composite sheets were prepared and polarized. The output voltage was then measured for the composite sheets due to air-flow and temperature change.

Experimental Procedure

The lead-free piezoelectric composites were comprised of BTO particles (KCM Corporation Co., Ltd., Japan) or KNN particles (Nippon Chemical Industrial Co., Ltd., Japan) and a commercially available epoxy resin (EP-106NL, Cemedine Co., Ltd., Japan) with a polyamine curing agent. The weight fraction of BTO and KNN was held constant at 70wt% and 66.7wt%, respectively. These composites were stirred for 30 minutes, and then painted on a cupper electrode. The length, width and thickness of the composite were 25mm, 13mm and 0.5mm, respectively. The thickness of the electrode was 0.2mm. These composite sheets with electrode were cured under a condition of 130 °C for 35 minutes in an oven.

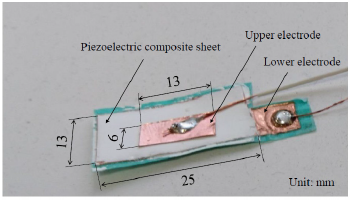

The composite sheet samples were either contact or corona polarized. The detail can be found in [8]. For the contact poling, a cupper electrode of length 13mm and width 6mm was put on the upper surface of the piezoelectric composite. The composite sheet samples were then polarized for 30min at an electric field of 2MV/m. The parallel plate contact polarization method was achieved by placing the composite sheet with the upper and lower electrodes into silicone oil. The beaker containing the composite sheet and silicone oil was heated to 100 °C. The Corona discharge polarization method was also carried out by applying 16 and 5MV/m to a needle suspended above the BTO and KNN composite sheets, while the composite temperature was held at 100 °C for 3min and 50 °C for 30min in atmosphere, respectively. Figure 1 shows the BTO composite sample.

Figure 1: BTO composite sample.

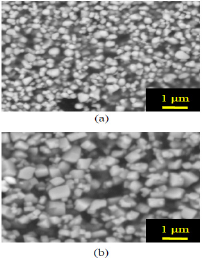

Figure 2: SEM images of the cross section of the BTO and KNN composite sheets.

SEM micrograph was analyzed for the BTO and KNN composite sheet samples. Figure 2 shows the SEM images of the cross section of the BTO and KNN composite sheets.

The composite sheet sample was first fixed to a jig, and connected to an oscilloscope (GDS-1062A, Good Will Instrument Co., Ltd., Japan). Then, open-circuit output voltage was measured for the samples under the wind of speed 2.5m/s. Next, the composite sheet sample was connected to a digital multimeter (ADCMT 7461A, ADC Corporation, Japan) and was inserted into a constant temperature oven. The sample was not clamped. The open-circuit output voltage was recorded until the sample reached a settled-down state where voltage readings decreased consistently at which point the sample was taken out.

Results and Discussion

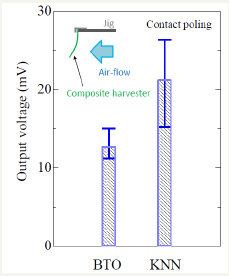

Figure 3: Open-circuit output voltage of the contact polarized BTO/epoxy and KNN/epoxy composites due to air-flow of 2.5m/s.

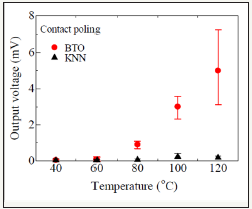

Figure 4: Open-circuit output voltage of the contact polarized BTO/epoxy and KNN/epoxy composites due to temperature change from room temperature to high temperature.

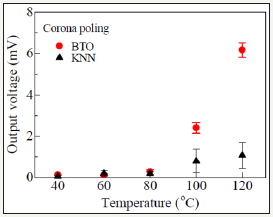

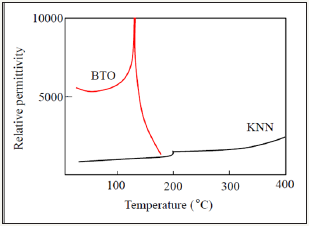

Figure 3 shows the open-circuit output voltage of the contact polarized BTO/epoxy and KNN/epoxy composites due to air-flow of 2.5m/s. The output voltage of KNN/epoxy composite is larger than that of BTO/epoxy composite. This is due to the fact that the piezoelectric constant of KNN is larger than that of BTO. Figure 4 shows the open-circuit output voltage of the contact polarized BTO/epoxy and KNN/epoxy composites due to temperature change from room temperature to high temperature. BTO/epoxy composite generated approximately 5.0mV by changing from room temperature to 120 °C. As the temperature increases, the value of voltage of BTO/epoxy composite increases. On the other hand, KNN/epoxy composite generated approximately 0.24mV at 100 °C. It is interesting to note that the output voltage of BTO/epoxy composite due to temperature change is larger than that of KNN / epoxy composite in contrast to the case under the air-flow. Figure 5 shows the similar results of the Corona polarized BTO/epoxy and KNN/epoxy composites. BTO/epoxy composite generated approximately 6.2mV by changing from room temperature to 120 °C, whereas KNN/epoxy composite generated approximately 1.1mV. In temperature energy harvesting, BTO/epoxy composite has better performance than KNN/epoxy composite. The temperature dependence of permittivity of BTO is considered to be one of the causes for the better performance than the KNN. Figure 6 illustrates the images of the temperature dependent permittivity of BTO [9] and KNN [10]. The temperature dependence of piezoelectric coefficient may also be considered. Moreover, from the comparison between Figure 4 & 5 it is clear that the output voltage of Corona polarized composites is larger than that of contact polarized composites. Hence, the other contributor of output voltage of BTO/epoxy and KNN/epoxy composites may be contemplated deformation of the composites due to temperature change. This is due to the fact that the piezoelectric constant of Corona polarized composites is larger than that of the contact polarized composites [8].

Figure 5: Similar results of the Corona polarized BTO/epoxy and KNN/epoxy composites.

Figure 6: Open-circuit output voltage of the contact polarized BTO/epoxy and KNN/epoxy composites due to temperature change from room temperature to high temperature.

Conclusion

The unique discovery of our experiments lies in the observation that the BTO/epoxy and KNN/epoxy composites are able to display both vibration and temperature energy harvesting properties. It seems that the voltage in the piezoelectric composites is generated due to temperature change not only through the piezoelectric effect caused by a thermally-induced bending stress but also by the temperature dependence of permittivity and piezoelectric coefficient for the BTO and KNN particles. On the other hand, although not shown here, we found that the voltage variation of the composites decreases as time passes. Further research is needed to understand these findings and to develop high-performance flexible multi-energy harvesting devices.

Acknowledgement

This work was supported by JSPS KAKENHI Grant Number 16H04227.

References

- Narita F, Fox M (2018) A Review on piezoelectric, magnetostrictive, and magnetoelectric materials and device technologies for energy harvesting applications. Adv Eng Mater 20(5).

- Shindo Y, Narita F (2014) Dynamic bending/torsion and output power of S-shaped piezoelectric energy harvesters. Int J Mech Mater Des 10(3): 305-311.

- Narita F, Zhu X, Shindo Y (2017) Piezoelectric energy harvesting characteristics of barium titanate based composite laminates under cyclic concentrated loads. J Compo Biodegradable Polym 5: 43-47.

- Shahab S, Erturk A (2016) Coupling of experimentally validated electroelastic dynamics and mixing rules formulation for macro-fiber composite piezoelectric structures. J Intell Mater Sys Struct 28(12): 1575-1588.

- Zeng Z, Gai L, Petitpas A, Li Y, Luo H, et al. (2017) A flexible, sandwich structure piezoelectric energy harvester using PIN-PMN-PT/epoxy 2-2 composite flake for wearable application. Sens Actuators A 265: 62-69.

- Karim H, Sarker MRH, Shahriar S, Shuvo MAI, Delfin D, et al. (2016) Feasibility study of thermal energy harvesting using lead free pyroelectrics. Smart Mater Struct 25(5): 055022.

- Narita F, Fox M, Mori K, Takeuchi H, Kobayashi T, et al. (2017) Potential of energy harvesting in barium titanate based laminates from room temperature to cryogenic/high temperatures: Measurements and linking phase field and finite element simulations. Smart Mater Struct 26(11): 115027.

- Banerjee S, Cook-Chennault KA, Du W, Sundar U, Halim H, et al. (2016) Piezoelectric and dielectric characterization of corona and contact polarized PZT-epoxy-MWCNT bulk composites. Smart Mater Struct 25(1): 115018.

- Kinoshita K, Yamaji A (1976) Grain-size effects on dielectric properties in barium titanate ceramics. J Appl Phys 47: 371-373.

- Birol H, Damjanovic D, Setter N (2006) Preparation and characterization of (K0.5Na0.5) NbO3 ceramics. J Eur Caram Soc 26: 861-866.

© 2018 Fumio Narita. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)