- Submissions

Full Text

Polymer Science: Peer Review Journal

Capillary Rheological Behavior of HDPE/ EUG Blends

Chen Yabo, Wang Kejian*, Li Sihan,Lou Zihao and Wang Zhiwei

College of Mechanical and Electrical Engineering, Beijing University of Chemical Technology, Beijing,100029, China

*Corresponding author:Wang Kejian, College of Mechanical and Electrical Engineering, Beijing University of Chemical Technology, Beijing,100029, China

Submission: March 14, 2023;Published: April 14, 2023

ISSN: 2770-6613 Volume4 Issue5

Abstract

HDPE/EUG blends prepared by melt blending are extruded through capillary rheometer at different shear rates and temperatures. The results show that the viscosity of HDPE is increased when mixed with gutta-percha (EUG) while it reduces when increasing shear rate. Increasing the extrusion temperature will reduce the shear viscosity. With the increase of the EUG content, the extrusion swell ratio of HDPE/ EUG blends will increase, where the melt resilience will increase, and the melt strength will increase. Increasing the extrusion temperature will reduce the extrusion swell ratio.

Keywords:HDPE; EUG; Blending; Viscosity

Introduction

High Density Polyethylene (HDPE) is a common polymer with good mechanical properties, chemical stability and electrical insulation [1]. However, HDPE performs poorly in thermal molding, blow molding and foaming for its low melt strength in the processing process resulted by linear molecular chain structure. The blending is simply and directly applied to improve the melt strength based on its good thermoplasticity and compatibility with guttapercha (EUG) [2], the effects of temperature and blending ratio on the shear viscosity and extrusion swell ratio of HDPE/EUG blends were investigated.

Experiment

Experimental materials

HDPE: high-density polyethylene, DMDA8007, density 0.963g/cm3, Shenhua Baotou Coal Chemical Co., Ltd. EUG: gutta-percha F21061301-1, Qingdao Dipai New Material Co., Ltd.

Sample preparation

HDPE and EUG were weighed at mass ratio of 9:1, 8:2, 7:3, 8:4, 5;5 with a balance. They are extruded, blended through a single-screw extruder at a melting temperature of 170 °C after they are manually premixed uniformly, and then pelletized.

Test

A capillary rheometer (LW-400, Changchun intelligent instrument equipment) is used to conduct extrusion tests on HDPE/EUG blends. The step shear rate viscosity measurement mode is used. The length-diameter ratio of the die is 20:2, the shear rate is 20, 50, 100, 200 and 500s-1, and the extrusion temperature is 150 °C or 170 °C. The extrudate at 50s-1 and 500s-1 is used to measure the extrusion swell ratio.

Results and Discussion

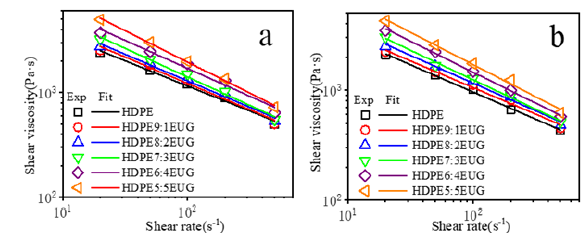

The shear viscosity curve of HDPE/EUG blends are shown in Figure 1. When other conditions are the same, the shear viscosity of HDPE/EUG blends decreases with the increase of shear rate, which is the phenomenon of shear thining [3]. There is a certain velocity gradient in the vertical flow direction of the polymer in flowing. When the slender macromolecules pass in parallel distribution flow layers with different flow rates at the same time, the interaction between the molecular chains will always make the long-chain molecules tend to enter the flow layer with the same flow rate. This leads to the orientation of the molecular chain in the flow direction, and the molecular chain can slip, causing the viscosity of the polymer to decrease as the shear rate increases during the flow process. The addition of EUG increases the viscosity of HDPE, which is beneficial to improve the melt strength. This is due to the higher molecular weight of EUG and the difficulty of molecular chain orientation. The shear thinning flow indicates that the viscosity can be fitted by the power law. Double logarithmic coordinate form is easy to get the values of parameters as Eq.1.

Figure 1:Shear viscosity curve of HDPE/EUG blend at 140 °C (a) or 150 °C (b).

Where η is viscosity in Pa·s. γ is shear rate in s-1. k is consistency coefficient while n is Non-Newtonian index.

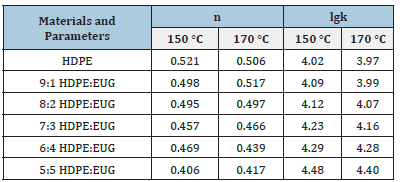

As shown in Table 1, the fitting data of non-Newtonian index n and the consistency coefficient k of HDPE/EUG blend are found to be less than 1 indicating the blend is a pseudoplastic fluid [4]. With increase of EUG content, the n value of HDPE/EUG tends to decrease in general, which shows that the increase of EUG content makes the viscosity of blends more affected by shear rate. In addition, with the increase of EUG content, lgk increases, indicating that the viscosity increases. lgk decreases after increasing the temperature, which indicates that the temperature will reduce the viscosity of the blend and improve the fluidity.

Table 1:The values of n and lgk are fitted from experimental data.

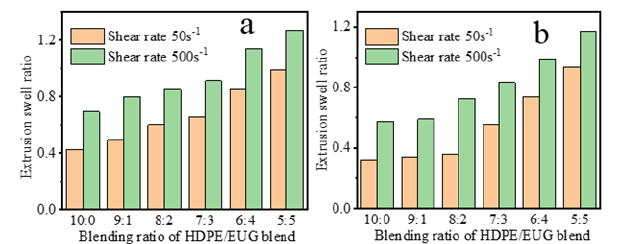

Figure 2:Extrusion swell ratio of HDPE/EUG blends and HDPE at 150 °C (a) and 170 °C (b).

Extrusion swell is caused by the residual high elastic deformation of the melt in the entrance effect. As shown in Figure 2, the extrusion swell ratio of HDPE/EUG blends increases with the increase of EUG content, the extrusion swell ratio of HDPE/EUG blends gradually increases, and the elasticity of the melt increases, while the extrusion swell ratio at high shear rate (500s-1) is higher than that at low shear rate (50s-1), which is because the melt flow rate in the capillary is faster, and the relaxation time of the oriented< and deformed molecular chain is shorter. When the temperature rises, the extrusion swell ratio of the blends decreases, because the movement ability of the polymer molecular chain increases with the temperature, and the viscosity dissipation of the deformation energy stored in the melt in the flow increases, resulting in the weakening of its elastic properties, so the extrusion swell ratio decreases.

Conclusion

The extrusion process of HDPE/EUG blends exhibits shear thinning, which is caused by the orientation of polymer chain. The addition of EUG with large molecular weight will increase the viscosity of HDPE/EUG and increase the effect of shear rate on the viscosity of the blend. Increasing the extrusion temperature will reduce the shear viscosity. With the increase of EUG content, the extrusion swell ratio of HDPE/EUG blends increases, the melt resilience increases, and the melt strength increases. Increasing the extrusion temperature will reduce the extrusion swell ratio.

References

- Li Y, Li D, Cheng H, Yu Y, Zhang Y, et al. (2022) Morphology, rheological, thermal, and mechanical properties of high-density polyethylene toughened by propylene-ethylene random copolymers. Colloid and Polymer Science 301(2): 117-126.

- Chang JH, Baek SH, Lee IB (2011) Rheological characterization of thermoplasticized injectable gutta percha and resilon. Methods in Enzymology 36(5): 166-178.

- Xu Z, Sun R, Lu W, Patil S, Mays J, et al. (2022) Nature of steady-state fast flow in entangled polymer melts: chain stretching, shear thinning, and viscosity scaling. Macromolecules 55(23): 10737-10750.

- Yektapour M, Ashrafi N (2019) Rotational and axial flow of pseudoplastic fluids. Mechanics of Time-Dependent Materials 23(2): 173-192.

© 2023 Wang Kejian. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)