- Submissions

Full Text

Polymer Science: Peer Review Journal

Rheological Properties of Low-Density Polyethylene/Random Copolymer- Polypropylene

Fan Zepeng, Wang Kejian*, Li Sihan, Lou Zihao and Wang Zhiwei

College of Mechanical and Electrical Engineering, Beijing University of Chemical Technology, China

*Corresponding author:Wang Kejian, College of Mechanical and Electrical Engineering, Beijing University of Chemical Technology, China

Submission: March 14, 2023;Published: April 05, 2023

ISSN: 2770-6613 Volume4 Issue5

Abstract

Low-Density Polyethylene (LDPE) was blended into random copolymer Polypropylene (PPR) to alter the rheological capacity studied in extrusion. The blending was conducted with a single-screw extruder before pelletizing. Shown are the influences of blends ratio and shear rate on the rheological behaviors by capillary at 200 ℃. As the content of LDPE in PPR/LDPE rises, the apparent viscosity of the blends gradually decreases while the Non-Newtonian index of also decreases. LDPE, PPR and their blends appear in obvious shear-thinning behavior.

Keywords:Random copolymer polypropylene (PPR); Low density polyethylene (LDPE); Viscosity; Non-Newtonian index

Introduction

Polypropylene-Random (PPR), also called type III of polypropylene, is widely used to prepare pipes with outstanding creep resistance and cracking resistance to environmental stress [1]. However, PPR exhibits low processibility for blowing films and not-sufficient rigidity for extruding profiles due to its narrow molecular weight distribution and larger molecular weight. PPR is a kind of random copolymer, whose comonomer molecular chain is composed of ca. 1-4% of viny and high percentage of propenyl in random distribution. It is noted that Low-Density Polyethylene (LDPE) is easy in processing and molding due to its direct chain structure with vinyl [2]. It is possible to improve the processing properties of PPR by being blended with LDPE because of partial compatibility of coexistence of vinyl [3]. The convenience in present renders the modification to produce a material with low specific gravity, chemical stability, low cost and wider applications. However, the flowability of PPR/ LDPE should be explored in variation of the blend ratio and shear function for choosing the composition and the appropriate processing window. It is to be done in this paper to measure extrusion behavior.

Experimental

Materials

PPR pellet of melt mass flow rate of MFR=0.45g/10min and density of ρ=0.9g/cm3 with brand number of 4220 is produced by Yanshan Petrochemical Co. Ltd. LDPE (2426K) of ρ=0.9g/cm3 and MRF=4g/10min is from Yanshan Petrochemical Co. Ltd.

Sample preparation

PPR and LDPE were weighed in mass ratios of 90:10, 80:20, 70:30, 60:40, 50:50, 40:60, 30:70, 20:80 and 10:90 with a balance. After they are manually premixed uniformly, they are extruded, blended and pelletized with a single-screw extruder at a melting temperature of 200 °C. For improving their homogeneity, the extrusion-pelletizing were repeated twice. For comparison, pure PPR and pure LDPE are processed in the same way.

Test method

One capillary rheometer was used to test the viscosity in the step shear rate viscosity measurement mode, where the shear rate is set as 10, 50, 100, 300, 500 and 1000 (1/s) at 200 °C. The ratio of length to diameter of the used die was 10:1.5.

Results and Analysis

The apparent viscosity of PPR/LDPE blends

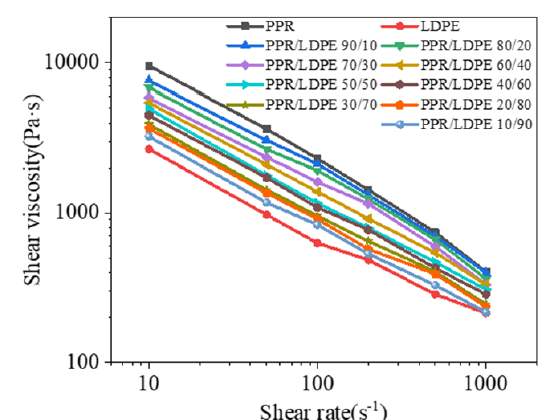

The flow properties of materials are related to the processing properties of materials. The melt viscosity of pure PPR, and pure LDPE and their blends PPR/LDPE of different blend ratio at 200 ℃ are shown in Figure 1. The viscosity of PPR is far higher than that of LDPE due to the propenyl being larger than vinyl while those of their blends lie between them at the same shear rate. On the other hand, the greater the content of PPR in PPR/LDPE, the higher the viscosity is. The greater percentage of the propenyl in blends is reflected by the viscosity curves for blend with more PPR being closer to that of PPR. Thus, LDPE really improves the fluidity of PPR. The addition of more LDPE is convenient to reduce the viscosity of the blends.

Quantitative analysis of the viscosity

All the above materials exhibit shear thinning, i.e., the viscosity drops due to the disentanglement and re-orientation at stronger shear. However, there is a dynamic competence between the reconstruction of entanglement network and the destruction of the structure. The destruction overcomes reconstruction for a decrease in entanglement points being embodied with lower [4]. The viscosity versus shear rate can be fitted into the power-law model [5] as Eq.1.

where τ is shear stress in MPa. ηa is apparent viscosity in Pa·s. K is consistency coefficient. γ is shear rate in s-1. n is Non-Newtonian exponent, whose value indicates the degree of deviation from 1 of Newtonian fluid flow behavior. Take the logarithm of both sides of the above formula to be Eq.2.

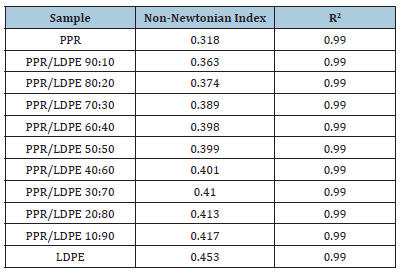

Lgηa versus Lgγ can be drawn in double logarithmic coordinates as Figure 1. The non-Newtonian exponent n is obtained by fitting the slope of the straight line. The value of n is listed in Table 1. The fitting correlation is well.

Figure 1:The viscosity versus shear rate for PPR, LDPE and their blends 200 ℃.

Table 1:The values of n for PPR/LDPE.

The smaller the value of n, the stronger the non-Newtonian nature of the polymer, and the more sensitive the blend is to shear [6].The greater the deviation of n from 1, the stronger the pseudoplasticity (Non-Newtonian) of the material. The n value of all blend materials is less than 1 behavioring as pseudoplastic fluid. n for PPR is lower than that for LDPE while those of their blends lie between them. It is almost inversely proportional to that of blend ratio of PPR/LDPE confirming the partial compatibility between PPR and LDPE due to the coexistence of vinyl in two kinds of molecules. LDPE improves the processability of PPR.

Conclusion

The conclusion of this article is as follows:

a. In PPR/LDPE blends, as the content of LDPE increases,

the apparent viscosity decreases.

b. LDPE improves the processability of PPR.

c. The greater the content of LDPE, the smaller the non-

Newtonian index of the PPR/LDPE blends, and the stronger the

Non-Newtonian property.

References

- Hisham M (2016) Polypropylene as a promising plastic: A review. American Journal of Polymer Science 6(1): 1-11.

- Cao J, Zheng Y, Lin T (2016) Synergistic toughening effect of β-nucleating agent and long chain branching on polypropylene random copolymer. Polymer Testing 55: 318-327.

- Mehrabli B, Mojtahedi MRM, Shoushtari AM (2014) Investigation on physical properties of textured yarns produced from PP/LDPE blends. Journal of Engineered Fibers and Fabrics 9(4): 135-139.

- Tarashi S, Nazockdast H, Javidi Z, Mehranpour M (2019) Long-chain branch-induced interfacial interaction and its effect on morphology development in polypropylene/ethylene octene copolymer blend. Journal of Materials Science 54(8): 6742-6751.

- Yang W, Liu Z, Shan G, Li ZM, Xie BH, et al. (2005) Study on the melt flow behavior of glass bead filled polypropylene. Polymer Testing 24(4): 490-497.

- Shao H, Wang S, Dong X, He A (2018) Rheological behaviors of polypropylene/poly(1-butene) blends. Journal of Macromolecular Science, Part B 57(9): 608-662.

© 2023 Wang Kejian. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)