- Submissions

Full Text

Polymer Science: Peer Review Journal

Study on Effect of Fillers in Stress Relaxation Characteristics

Ajay C*, Gupta SD, Barun Kumar S and Rabindra M

Hari Shankar Singhania Elastomer and Tyre Research Institute (Hasetri), India

*Corresponding author: C Ajay, Hari Shankar Singhania Elastomer and Tyre Research Institute (Hasetri), Mysuru-570016, India

Submission: July 28, 2022;Published: August 11, 2022

ISSN: 2770-6613 Volume4 Issue1

Abstract

The increasing demand for rubber products in different applications necessitates the study of the deformation of the rubber material under long-term service. Stress relaxation tester can be used to study this rubber deformation. The effect of fillers on the stress relaxation characteristics of a Natural Rubber based compound by varying the applied strain at an elevated temperature has been considered in this work.

Keywords:Rubber; Carbon; Organic chemicals; Deformation; Particle size

Introduction

Lower stress relaxation rate directs to high elastic properties and higher relaxation rate towards high viscous nature of the rubber compound [1]. Based on the literature review, several research works have been published in studying the stress relaxation behavior of rubber compounds and in related areas. In this present research, a focused approach has been applied to see the cumulative effect of strain and the temperature on Stress relaxation characteristics.

Experimental

Materials

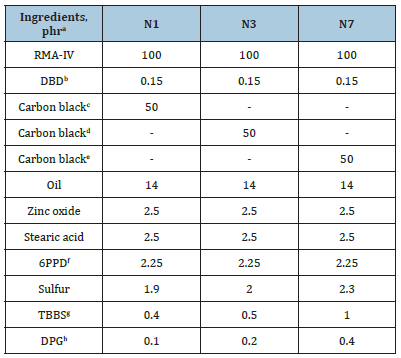

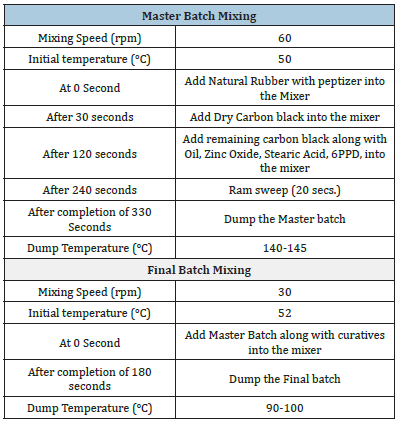

Natural Rubber (RMA IV) was supplied by JK Industries Pvt. Ltd., India. The other ingredients were 2,2’-Dithiobisbenzanilide (DBD; Acmechem Pvt. Ltd., India) N134, N339 and N774 carbon black (Birla Carbon Black India Pvt. Ltd., India), Oil of aromatic grade (Raj Petro, Chennai, India), zinc oxide (rubber grade; Zinc-o-India, India), stearic acid (Godrej Industries Ltd., India), N-phenyl-N’-(1,3-dimethylbutyl) p-phenylene-diamine (6PPD; National Organic Chemicals Industries Ltd., India), N- tert-butyl-benzothiazole sulfonamide (TBBS; National Organic Chemicals, India Ltd., India), soluble sulfur (Jain Chemicals Ltd., India), and diphenyl guanidine (DPG; National Organic Chemicals, India Ltd., India) used for the compound preparation. All the ingredients used in these studies presented here were used as obtained. In this study, Natural rubber base with high structure carbon black by varying the particle size such as N134 (N1), N339 (N3) and N774 (N7) series fillers were utilized. The formulations of all the compounds are given in Table 1. Hardness of all the compounds are made similar by adjusting the curative package. The mixing of rubber compounds was carried out in a 1.5L volume Lab. Banbury mixer (Stewart Bowling, USA). The mixing sequence of Master and Final Batch is given in Table 2.

Table 1: Formulation of compounds. aphr, parts per hundred rubber by weight. b2,2’-Dithiobisbenzanilide, cCarbon black grade N134, dCarbon black grade N339, eCarbon black grade N774, fN,N’-diphenyl-p-phenylenediamine, gN-tertbutyl- benzothiazole sulfonamide, hDiphenyl guanidine.

Table 2:Mixing sequence.

Characterization

Stress relaxation study was performed by using Automatic Creep and Stress relaxation Tester (ACSR, Elastocon, Sweden). Photographic view of the Creep and Stress Relaxation Tester is shown in Figure 1. The test sample button is moulded at 141 °C for 60 minutes. The dimension of the cylindrical button sample specimen used for testing is with a Diameter of 13±0.2mm, and with a thickness of 6±0.2mm. Stress relaxation test was carried out in compression mode on three different strains such as 10%, 20% and 30%. Test Temperature was set at 70 °C and relaxation was captured in continuous mode for the study purpose. At Room temperature, the rubber cured products are well above the glass transition and well below the degradation temperature, in such cases the stresses under constant deformation, changes very minute as the time progress [2]. The duration of the test was 24 Hours and was carried out in accordance with ISO 3384.

Figure 1:Creep and stress relaxation tester.

Results and Discussion

Table 3 illustrates the Stress relaxation data of the studied rubber compounds. It is observed that Stress relaxation property increases upon increasing the particle size. The effect of strain is not significant and did not show any remarkable difference in stress relaxation data in the experimental range. This was observed in earlier studies while stress relaxation carried out in different machines [3]. Normalized force against time is plotted in Figure 2.

Table 3:Stress relaxation (%).

Figure 2:Normalized force vs time.

Conclusion

The results show that the Rubber matrix with the lowest particle size carbon black (N1) has the highest stress relaxation and the compound with highest particle size carbon black (N7) shows the lowest stress relaxation. The effect of strain has not made any impact on this study.

Acknowledgement

The authors would like to thank the Management of Hari Shankar Singhania Elastomer and Tyre Research Institute for granting the permission to publish this work.

References

- Askarbekov R, Herak D, Jelgava CM (2016) Mechanical behavior of rubber samples under relaxation. Engineering For Rural Development pp. 745-749.

- Gent AN (1963) Relaxation processes in vulcanized rubber. III. relaxation at large strains and the effect of fillers. Rubber Chem and Technol 36(3): 697-708.

- Armah JC, Birley AW, Fernando KP, Hepburn C, Tahir M (1986) Stress-relaxation measurements on rubbers in compression. Equipment and methodology. Rubber Chem and Technol 59(5): 765-778.

© 2022 Ajay C. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)